Polyacrylates interpenetrating network polymer emulsion and high damping material thereof

A technology of polyacrylates and polymer emulsions, which is applied in the field of water-based wide-temperature high-damping damping materials and interpenetrating network polymer emulsions, can solve problems such as difficult control, and achieve the goal of improving mechanical properties, enhancing toughness and elasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of methacrylic acid prepolymer: Add 150ml of water and 0.5g of ammonium persulfate initiator to a 250ml three-necked bottle equipped with a stirrer, reflux condenser and water bath heating, raise the temperature to 80°C, add methyl 20.0 g of acrylic acid monomers were reacted for about 1 hour until the system became viscous to obtain a methacrylic acid prepolymer.

Embodiment 2

[0031] The methacrylic acid prepolymer (1.09%) prepared with embodiment 1 is as protective glue, and MS-1 is emulsifier (1.91%), and ammonium persulfate is initiator (0.38%), and sodium bicarbonate is buffering agent (0.26%) %), ethylene glycol dimethacrylate as crosslinking agent (0.3%), butyl acrylate (15.7%), methyl methacrylate (1.01%), methacrylic acid (2.15%), glycidyl acrylate Ester (0.22%) and styrene (8.3%) were used as monomers to prepare polyacrylate interpenetrating network polymer emulsion, and the balance in the system was water.

[0032] The process of preparing polyacrylate interpenetrating network polymer emulsion is that the methacrylic acid prepolymer obtained by an appropriate amount of water and initiator and embodiment 1 is added into a container with agitator, condenser and water bath heating (such as 500 Milliliter three-necked flask), heat up to 75°C, react for 10 minutes, heat up to 85°C, slowly add butyl acrylate, methyl methacrylate, methacrylic aci...

Embodiment 3

[0039] The methacrylic acid prepolymer (1.09%) prepared with embodiment 1 is as protective glue, and MS-1 is emulsifier (1.91%), and ammonium persulfate is initiator (0.38%), and sodium bicarbonate is buffering agent (0.26%) %), ethylene glycol dimethacrylate as crosslinking agent (0.3%), butyl acrylate (15.7%), methyl methacrylate (1.01%), methacrylic acid (2.15%), glycidyl acrylate Ester (0.22%) and styrene (8.3%) are monomers to prepare polyacrylate interpenetrating network polymer emulsion, and the balance in the system is water (the composition of polyacrylate interpenetrating network polymer emulsion is completely consistent with the embodiment 2 same).

[0040] The preparation process is the same as in Example 2.

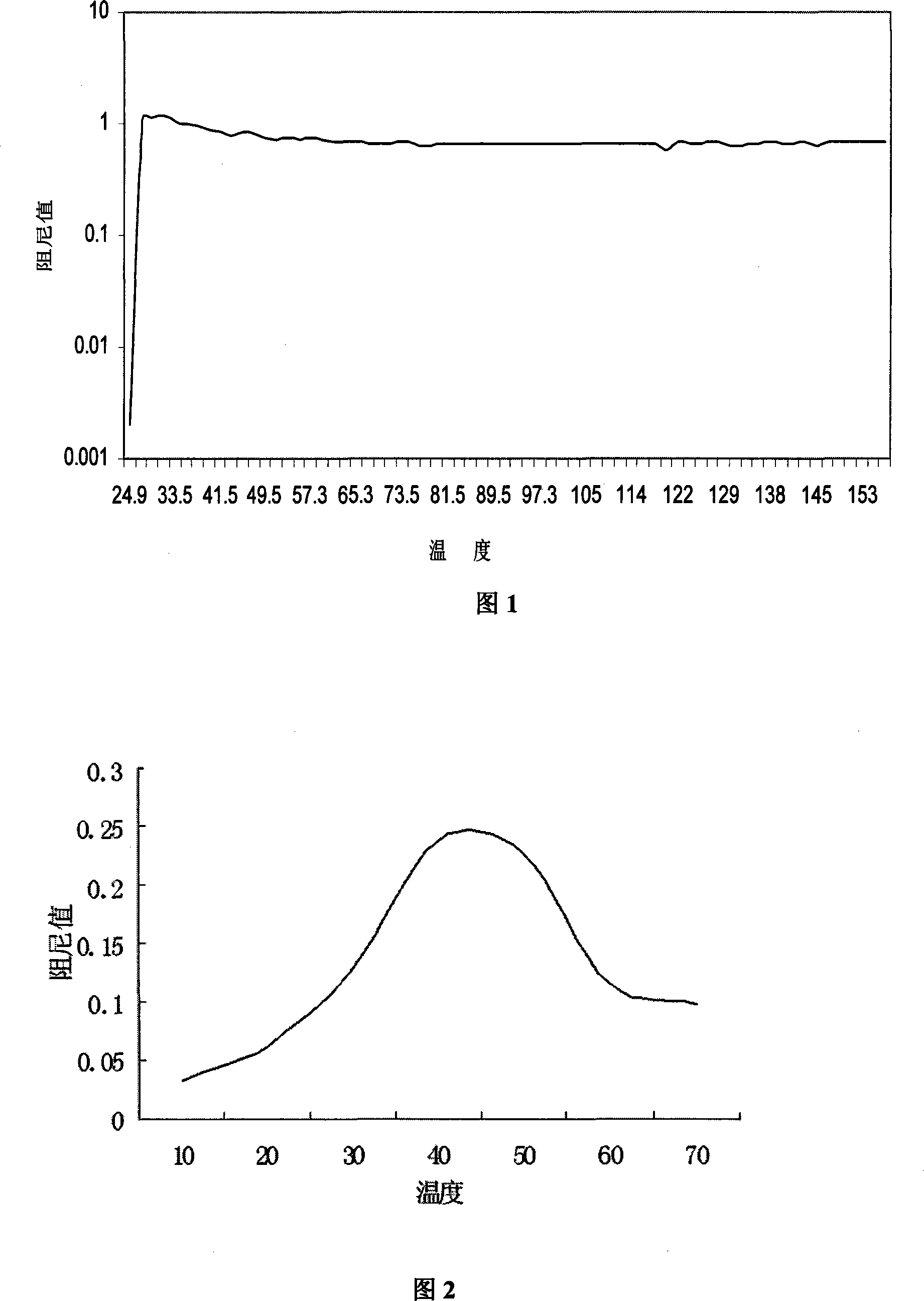

[0041] The dynamic mechanical spectrum of the emulsion was measured with a twister, and the measurement frequency was 10 Hz; the test temperature range: 25°C-170°C; the heating rate: 2°C / min. The specific spectrum is the same as Figure 1.

[0042] After th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com