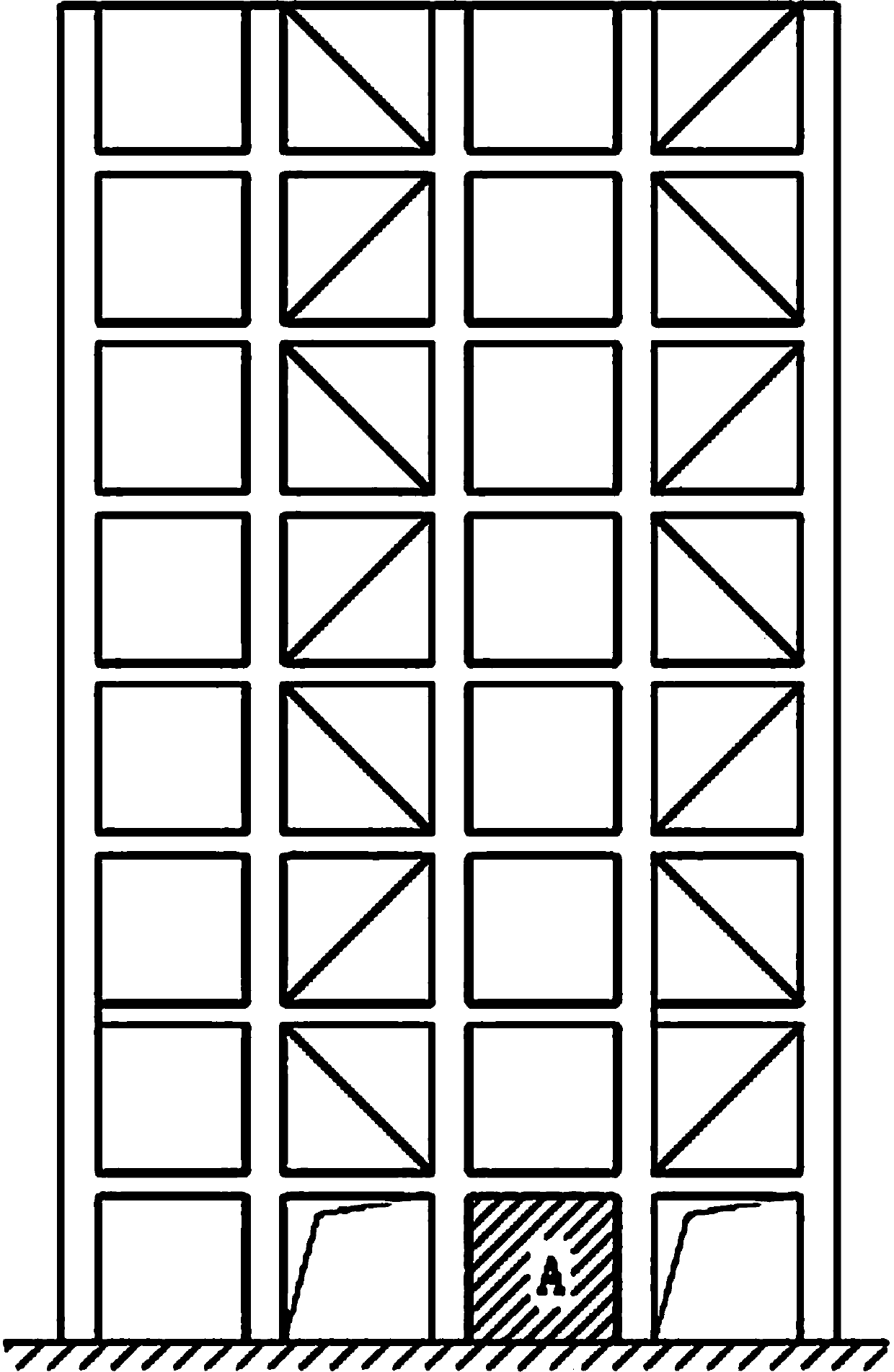

Anti-buckling energy consumption steel plate shear wall with concealed brace

A steel plate shear wall, anti-buckling energy consumption technology, applied to walls, earthquake resistance, building components, etc., can solve problems such as performance degradation, buckling of inner filling steel plates, and limited building space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

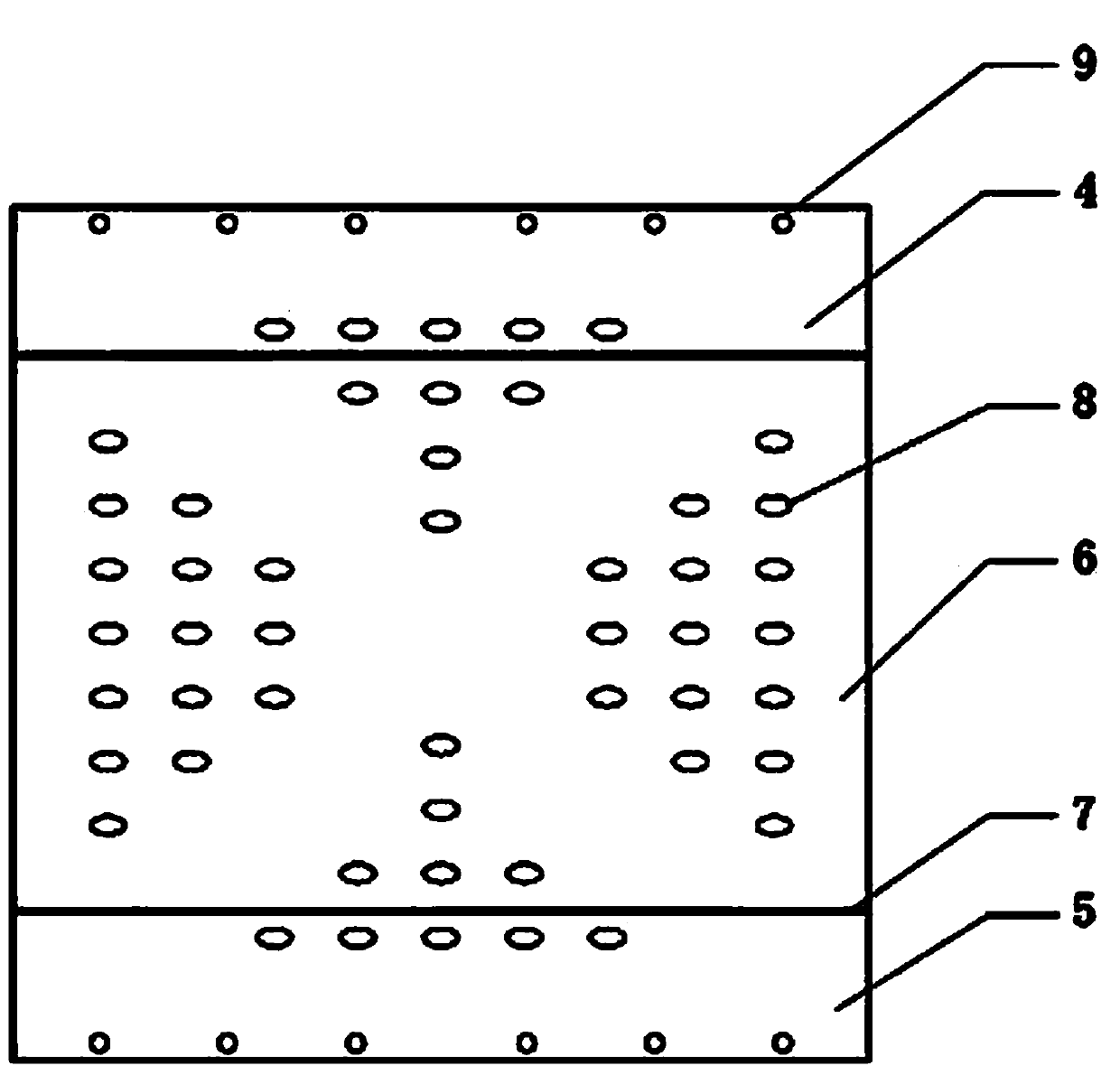

[0028] Such as figure 2 As shown, the inner filling energy-dissipating steel plate 1 is composed of three parts:

[0029] The upper strip 4 and the lower strip 5 are used for connection, and the upper and lower strips can be made of high-strength steel such as Q345 or Q420;

[0030] Low yield point steel plate 6 for side resistance and energy consumption, steel plate 6 can use low yield point steel such as Q235;

[0031] The above three steel plates are connected by welds 7; the inner filling energy-dissipating steel plate 1 is provided with ordinary bolt holes 9 connected with steel beams and oblong bolt holes 8 connected with concrete slabs 3.

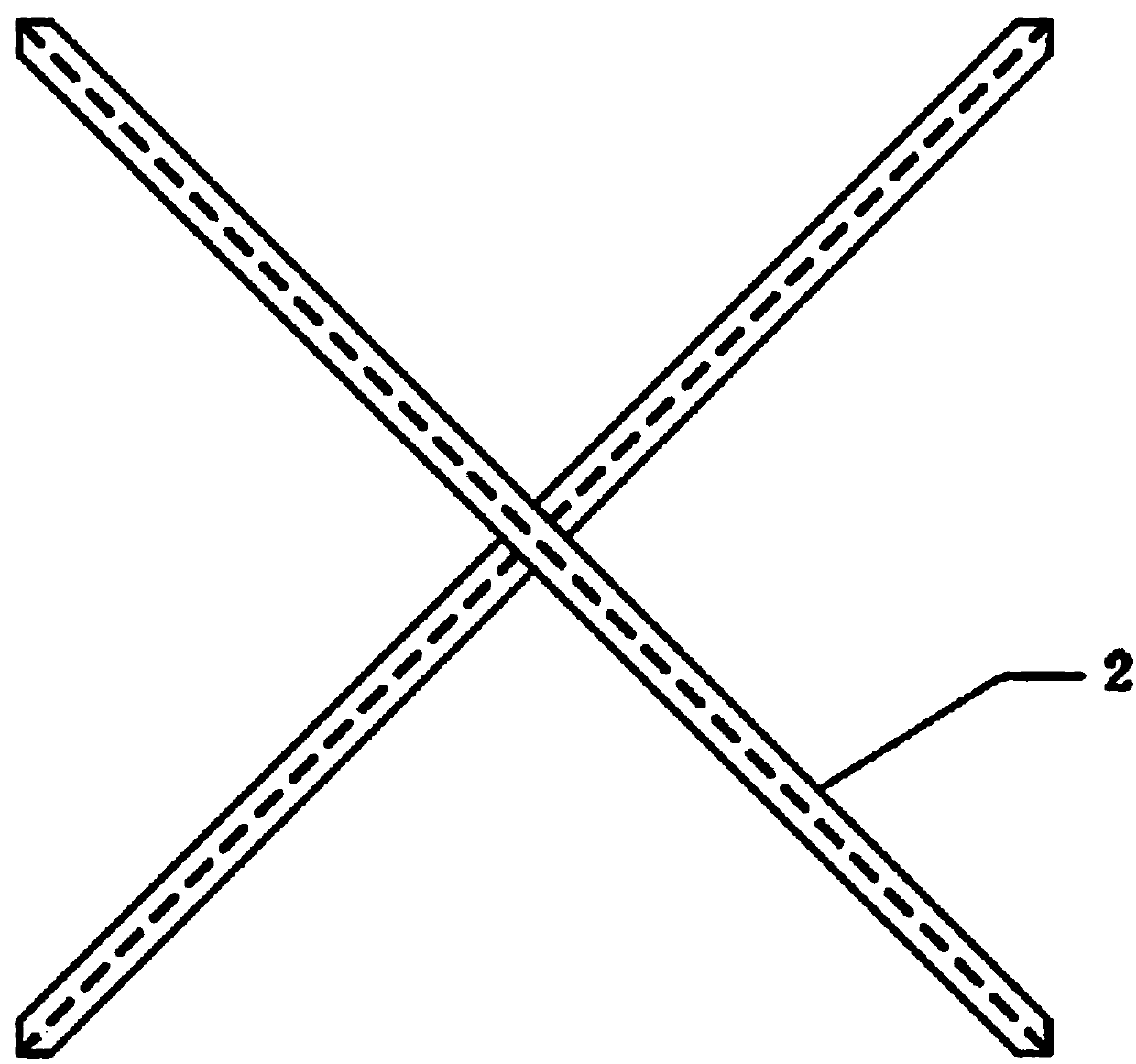

[0032] Such as image 3 As shown, the built-in support 2 can adopt angle steel, I-beam cut along the central axis, or thick and low yield point steel strips, etc. This embodiment is arranged diagonally, according to Figure 5 The way shown is connected with the inner filling energy-dissipating steel plate 1 . The built-in suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com