Sound insulation cabin of turbine engine

A turbine engine and sound insulation technology, applied in the field of noise reduction, can solve the problems that have not been effectively solved, such as the noise of the turbine engine, and achieve the effect of convenient daily maintenance and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

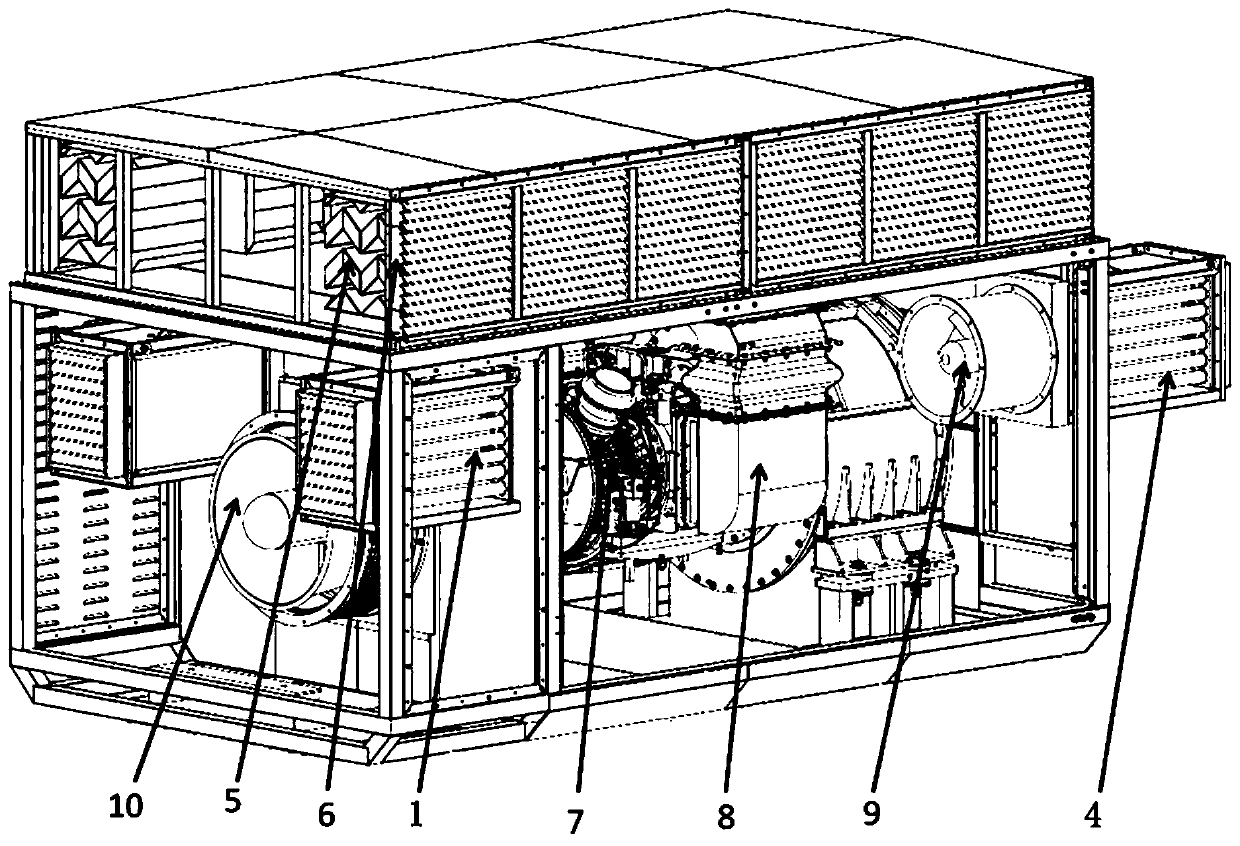

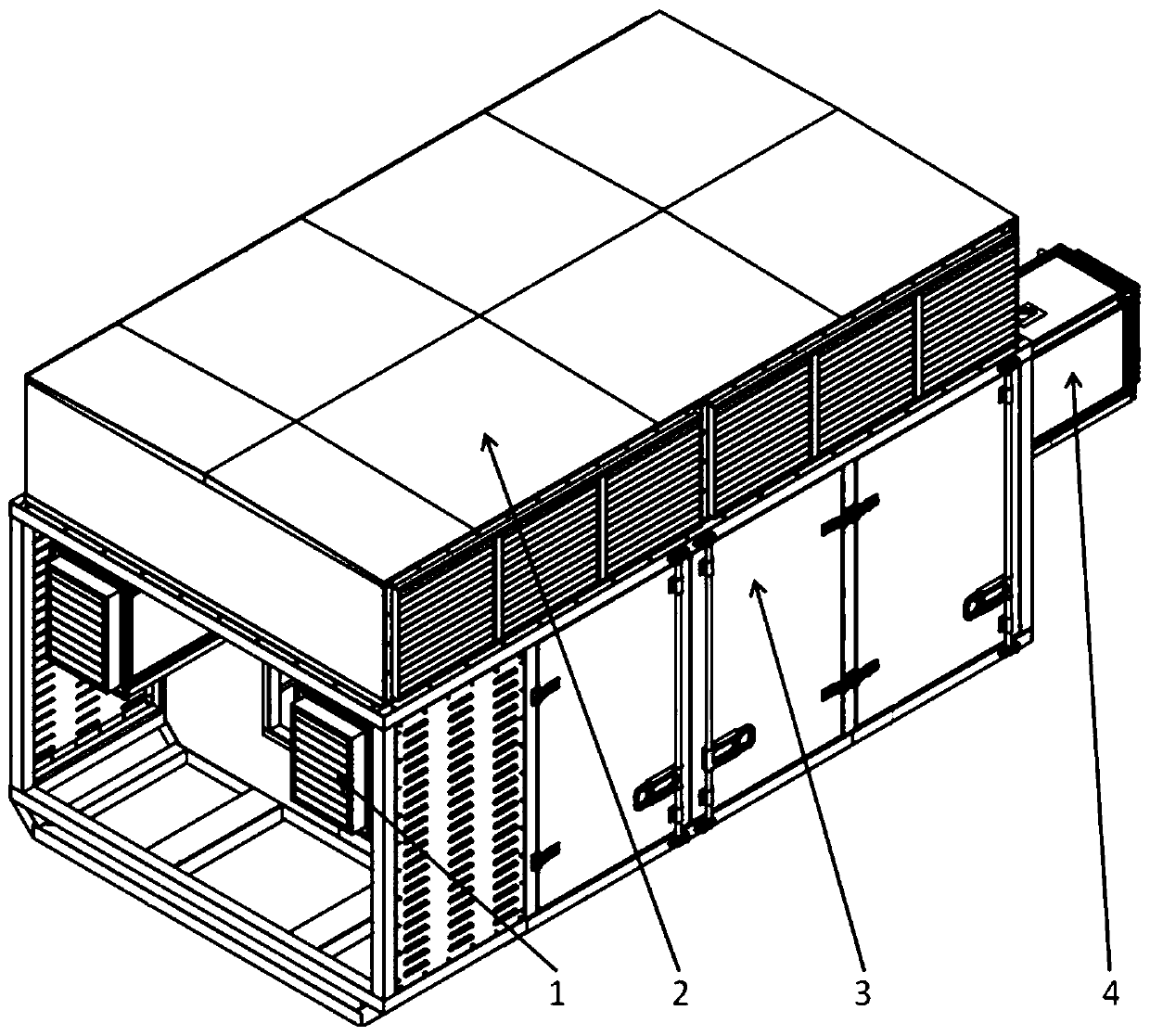

[0017] Such as Figures 1 to 2 As shown, a sound insulation cabin body of a turbine engine, the sound insulation cabin body is sleeved on the turbine engine 7, the sound insulation cabin body includes a cabin body, an intake noise reduction unit and a ventilation noise reduction unit, the The intake noise reduction unit and the ventilation noise reduction unit are arranged on the cabin body, and the frame of the cabin body is filled with soundproof materials, and the intake noise reduction unit is used for the intake noise reduction of the turbine engine 7, and the ventilation noise reduction The unit is used for noise reduction of the ventilation system of the turbine engine 7. The sound insulation material can be glass fiber wool, rock wool, polyurethane, aluminum honeycomb panel, peak type cotton, etc.

[0018] The air intake noise reduction unit includes an air intake filter 6, an air intake muffler 5, an air intake room 2 and an air intake duct. Air intake filter 6 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com