Lightweight, high-strength and high-toughness foamed ceramic decorative integrated board and production method thereof

A technology of foamed ceramics, high strength and high toughness, applied in the field of decorative materials, can solve problems such as easy cracks, and achieve the effects of improved adhesion, good toughness, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

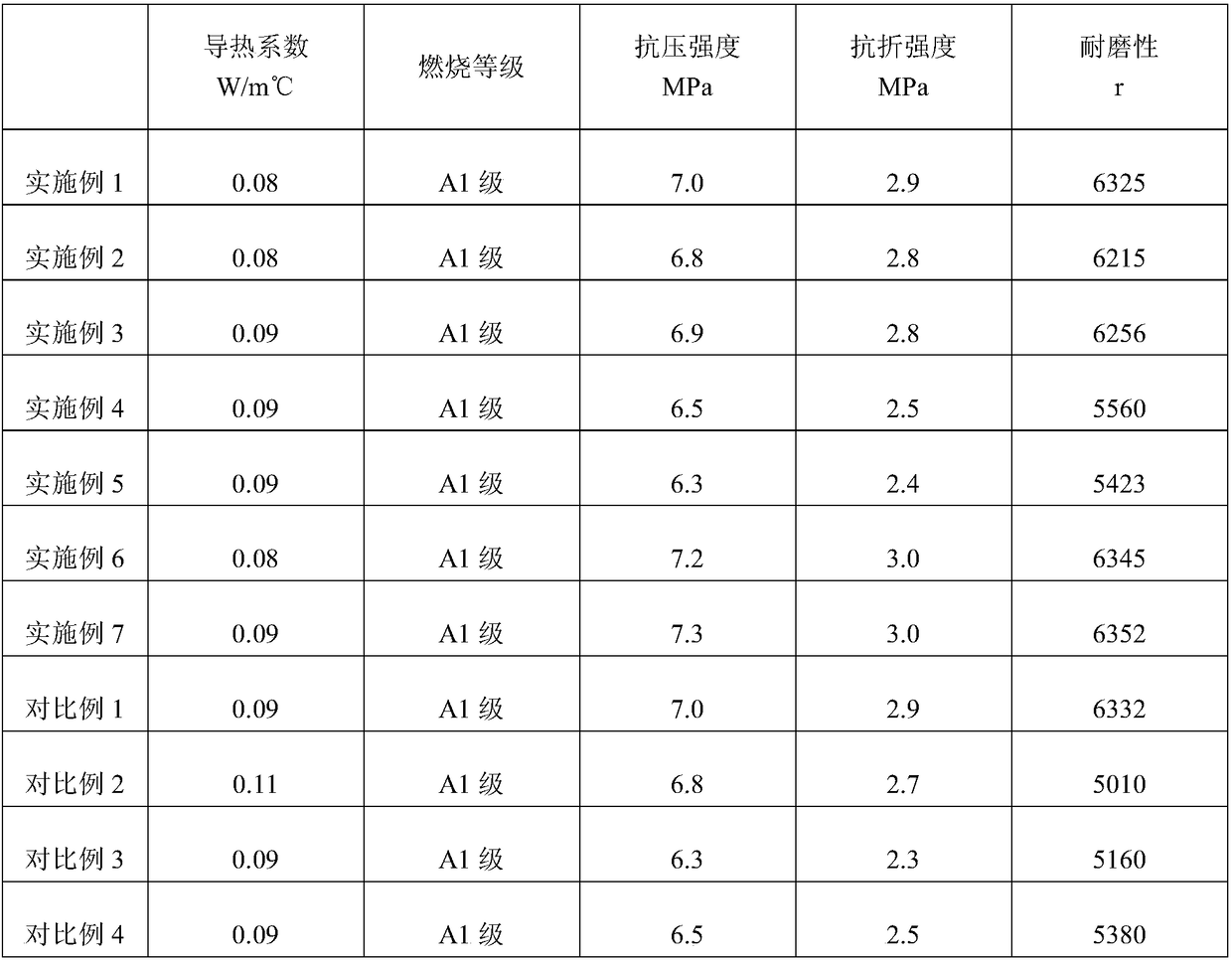

Examples

Embodiment 1

[0037] A lightweight, high-strength and high-toughness foamed ceramic decorative integrated board

[0038] It includes a foamed lightweight material layer, a high-tough decorative surface layer and a wear-resistant coating; the high-tough decorative surface layer is made of soft porcelain, and is bonded together with the foamed lightweight material layer through compression molding , the wear-resistant coating is coated on the surface of the high-toughness decorative surface layer.

[0039] The foamed lightweight material layer includes the following raw materials by weight percentage: 75% of stone tailings, 5% of graphene, 5% of zirconia, 5% of high-temperature flux, 5% of clay, 2% of stabilizer and debonding agent 3%.

[0040] The soft porcelain includes the following raw materials by weight percentage: 35% calcium carbonate, 5% graphene, 2% silicon carbide whiskers, 3% clay, 2% AC foaming agent, 3% stabilizer, processing aids 1%, lubricant 2%, high-strength resin 40%, mic...

Embodiment 2

[0052] A lightweight, high-strength and high-toughness foamed ceramic decorative integrated board

[0053] It includes a foamed lightweight material layer, a high-tough decorative surface layer and a wear-resistant coating; the high-tough decorative surface layer is made of soft porcelain, and is bonded together with the foamed lightweight material layer through compression molding , the wear-resistant coating is coated on the surface of the high-toughness decorative surface layer.

[0054] The foamed lightweight material layer includes the following raw materials by weight percentage: 85% of stone tailings, 5% of graphene, 3% of zirconia, 2% of high-temperature flux, 3% of clay, 1% of stabilizer and debonding agent 1%.

[0055] The soft porcelain includes the following raw materials by weight percentage: 40% calcium carbonate, 5% graphene, 2% silicon carbide whiskers, 3% clay, 2% AC foaming agent, 3% stabilizer, processing aids 2%, lubricant 5%, high-strength resin 30%, mic...

Embodiment 3

[0068] A lightweight, high-strength and high-toughness foamed ceramic decorative integrated board

[0069] It includes a foamed lightweight material layer, a high-tough decorative surface layer and a wear-resistant coating; the high-tough decorative surface layer is made of soft porcelain, and is bonded together with the foamed lightweight material layer through compression molding , the wear-resistant coating is coated on the surface of the high-toughness decorative surface layer.

[0070] The foamed lightweight material layer includes the following raw materials by weight percentage: 65% of stone tailings, 10% of graphene, 10% of zirconia, 4% of high-temperature flux, 8% of clay, 2% of stabilizer and debonding agent 1%.

[0071] The soft porcelain includes the following raw materials by weight percentage: 50% of calcium carbonate, 2% of graphene, 1% of silicon carbide whiskers, 1% of clay, 1.5% of AC foaming agent, 1% of stabilizer, and processing aids 0.5%, lubricant 0.5%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com