A kind of high-strength polyester fiberglass honeycomb composite board and its production process

A polyester fiberglass honeycomb and polyester fiberglass board technology, applied in the field of building materials, can solve the problems of low impact resistance, poor load-bearing capacity, troublesome installation, etc., and achieve excellent impact resistance, long service life and convenient installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

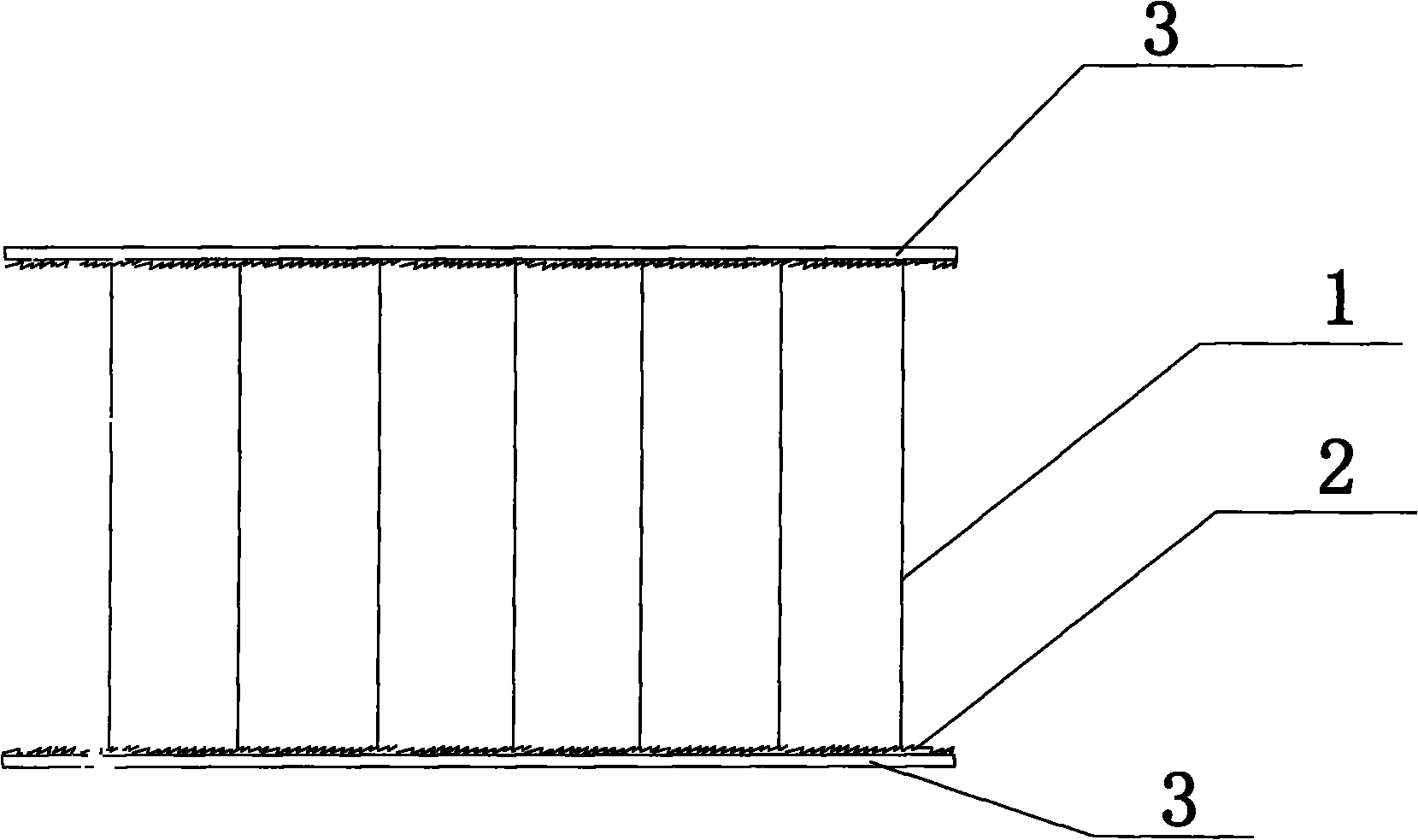

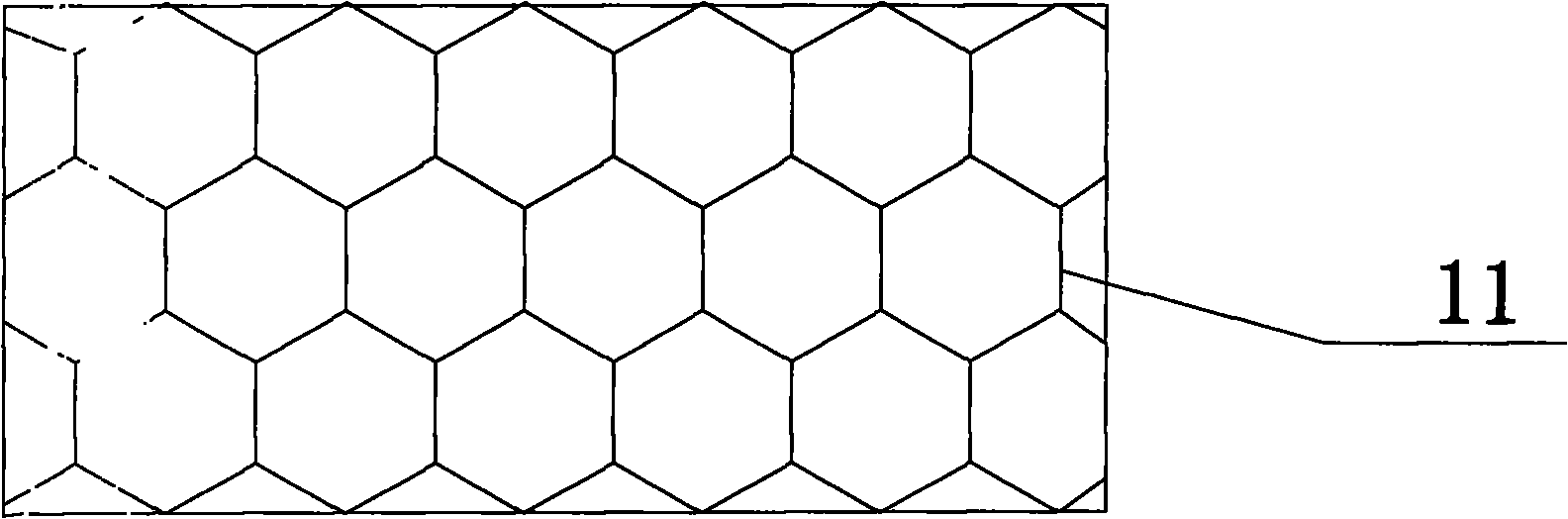

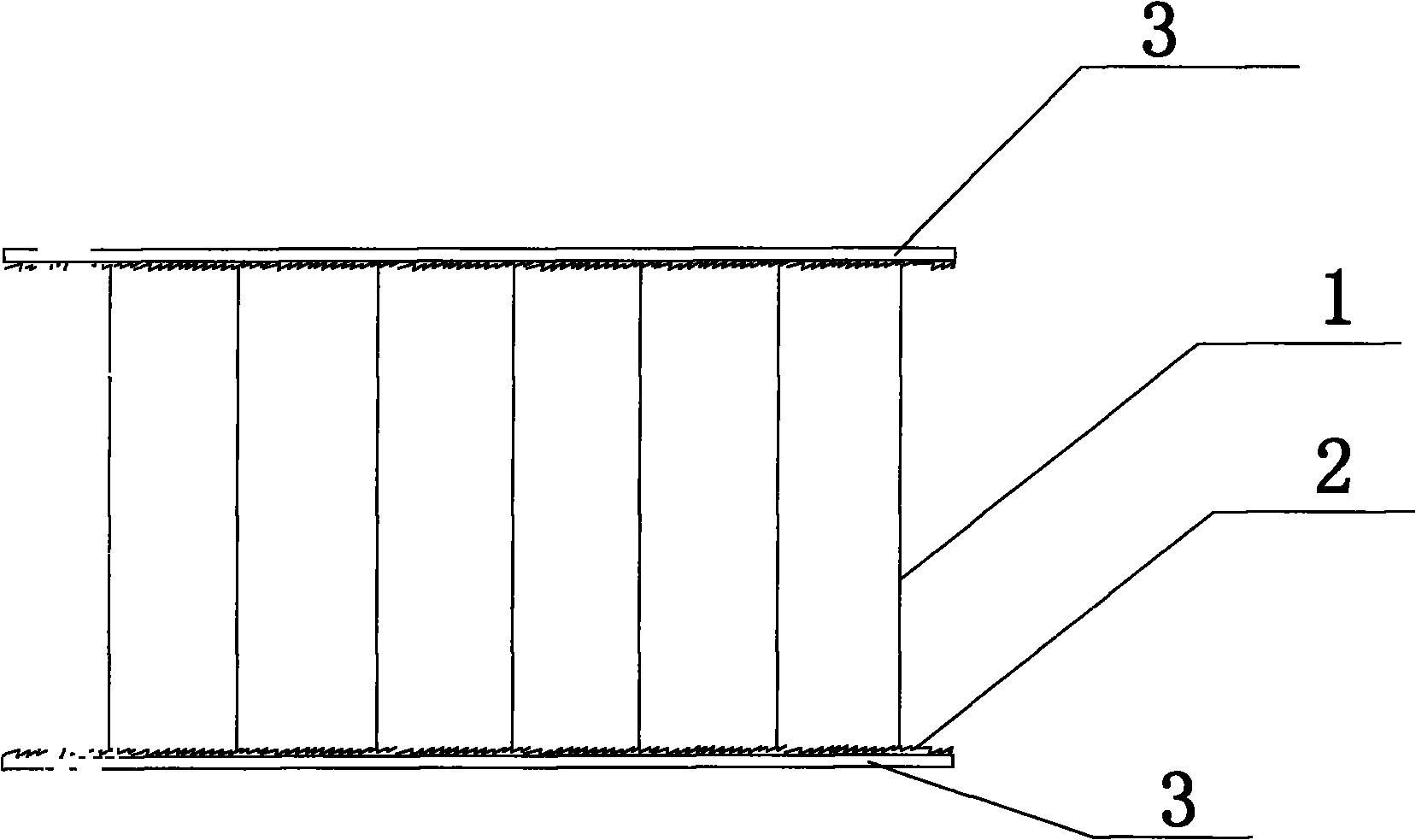

[0019] Such as figure 1 and figure 2 Shown, the present invention is a kind of high-strength polyester fiberglass honeycomb composite board, and it comprises three-layer structure, and middle layer is hexagonal honeycomb core 1; The upper and lower sides of described hexagonal honeycomb core 1 are all provided with thin steel wire mesh 2; The upper and lower sides of the thin wire mesh 2 are all provided with polyester fiberglass boards 3 . Its hexagonal honeycomb core is composed of several closed hexagonal honeycomb cavities 11 . Its hexagonal honeycomb core 1 adopts PVC to make. The thickness of its polyester fiberglass board 3 is 1mm.

[0020] Production Process:

[0021] (1) Material preparation: hexagonal honeycomb core made of PVC, steel wire mesh and polyester fiberglass board with a thickness of 1-3mm;

[0022] (2) The fine steel wire mesh is melted on the upper and lower sides of the hexagonal honeycomb core by hot rollers to make it a body with good grip and w...

Embodiment 2

[0026] Such as figure 1 and figure 2 Shown, the present invention is a kind of high-strength polyester fiberglass honeycomb composite board, and it comprises three-layer structure, and middle layer is hexagonal honeycomb core 1; The upper and lower sides of described hexagonal honeycomb core 1 are all provided with thin steel wire mesh 2; The upper and lower sides of the thin wire mesh 2 are all provided with polyester fiberglass boards 3 . Its hexagonal honeycomb core is composed of several closed hexagonal honeycomb cavities 11 . Its hexagonal honeycomb core 1 adopts PVC to make. The thickness of its polyester fiberglass board 3 is 3mm.

Embodiment 3

[0028] Such as figure 1 and figure 2 Shown, the present invention is a kind of high-strength polyester fiberglass honeycomb composite board, and it comprises three-layer structure, and middle layer is hexagonal honeycomb core 1; The upper and lower sides of described hexagonal honeycomb core 1 are all provided with thin steel wire mesh 2; The upper and lower sides of the thin wire mesh 2 are all provided with polyester fiberglass boards 3 . Its hexagonal honeycomb core is composed of several closed hexagonal honeycomb cavities 11 . Its hexagonal honeycomb core 1 adopts PVC to make. The thickness of its polyester fiberglass plate 3 is 2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com