Environment-friendly autoclaved aerated concrete block

A concrete block, autoclaved and aerated technology, which is applied in the direction of building components, buildings, building structures, etc., can solve the problems of block production workers and installation workers, germs endangering indoor human health, and affecting the health of residents, etc. Achieve the effect of making the method and easy to master, protecting the health and preventing the problem of bacteria breeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

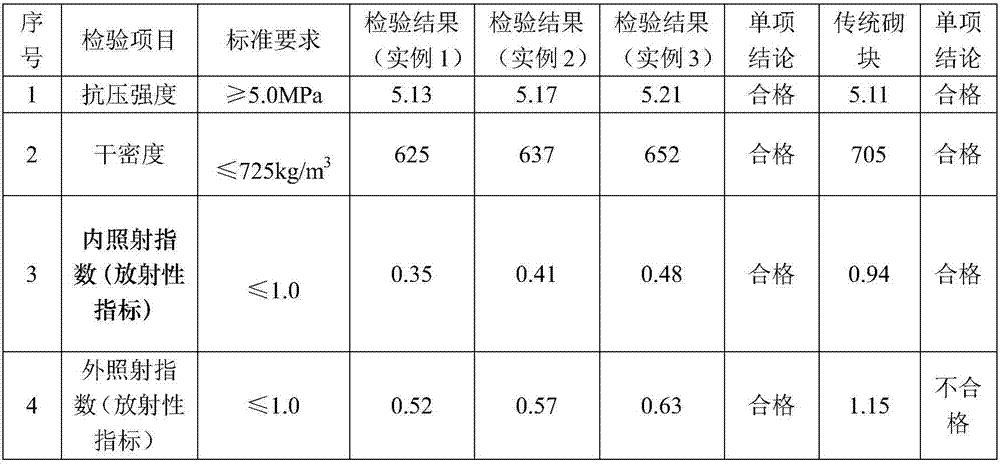

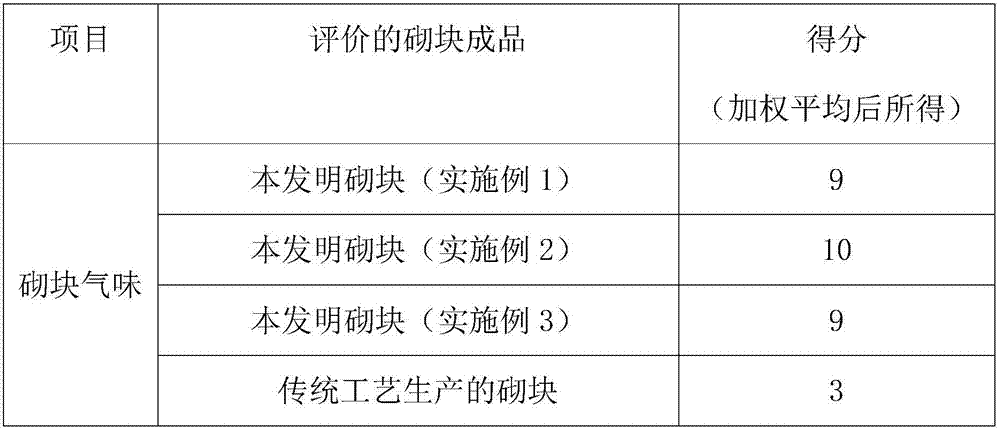

[0038] An environment-friendly autoclaved aerated concrete block is made by the following steps:

[0039] (1) choose 5Kg fresh aloe, 5Kg fresh thyme and put it into the crusher for crushing for 4 minutes to obtain product A;

[0040] (2) Put 20Kg of oil shale ash and 32Kg of water into a high-speed mixer and stir for 10 minutes, then add 15Kg of cement and 10Kg of diatomaceous earth and stir for 15 minutes, finally add product A and stir for 10 minutes, and leave the mixture to stand for 3 minutes to obtain product B;

[0041] (3) Put B product and 0.04Kg gas-generating agent into a high-speed mixer and stir for 5 minutes, mix well to make a slurry, and obtain C product;

[0042] (4) Pour product C into a mold and cast it into a mold. After static stopping for 1.5 hours, turning and cutting, and autoclaving for 8 hours, the finished product is obtained.

Embodiment 2

[0044] An environment-friendly autoclaved aerated concrete block is made by the following steps:

[0045] (1) choose 8Kg fresh aloe, 8Kg fresh thyme and put it into a crusher for crushing for 5 minutes to obtain product A;

[0046] (2) Put 25Kg of oil shale ash and 36Kg of water into a high-speed mixer and stir for 12 minutes, then add 20Kg of cement and 15Kg of diatomaceous earth and stir for 18 minutes, finally add product A and stir for 12 minutes, and leave the mixture to stand for 3 minutes to obtain product B;

[0047] (3) Put B product and 0.08Kg gas-generating agent into a high-speed mixer and stir for 8 minutes, mix well to make a slurry, and obtain C product;

[0048] (4) Pour product C into a mold and cast it into a mold. After static stopping for 1.8 hours, turning and cutting, and autoclaving for 9 hours, the finished product is obtained.

Embodiment 3

[0050] An environment-friendly autoclaved aerated concrete block is made by the following steps:

[0051] (1) Choose 10Kg fresh aloe and 10Kg fresh thyme and put them into a crusher for crushing for 6 minutes to obtain product A;

[0052] (2) Put 30Kg of oil shale ash and 40Kg of water into a high-speed mixer and stir for 15 minutes, then add 25Kg of cement and 20Kg of diatomaceous earth and stir for 20 minutes, finally add product A and stir for 15 minutes, and leave the mixture to stand for 3 minutes to obtain product B;

[0053] (3) Put B product and 0.12Kg gas-generating agent into a high-speed mixer and stir for 10 minutes, mix well to make a slurry, and obtain C product;

[0054] (4) Pour product C into a mold and cast it into a mold, and then stop and pre-cure for 2 hours, turn over and cut, and autoclave for 10 hours to obtain a finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com