Method for paving and sticking stone materials or ceramic tiles

A stone and tile technology, applied in covering/lining, construction, building structure, etc., can solve the problems of thick panel board, long construction period and high technical requirements, achieve earthquake-resistant building weight, reduce building weight, and improve economical effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

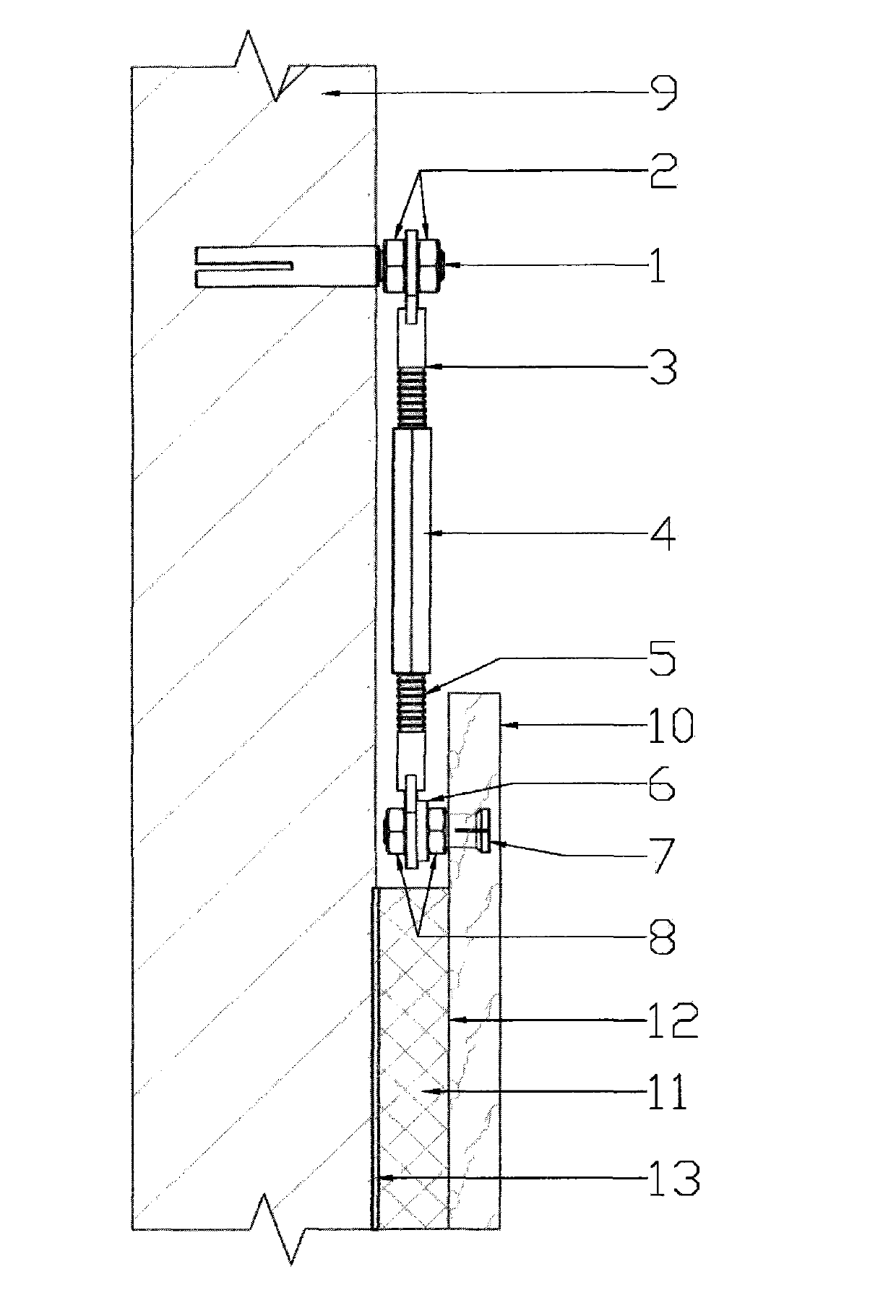

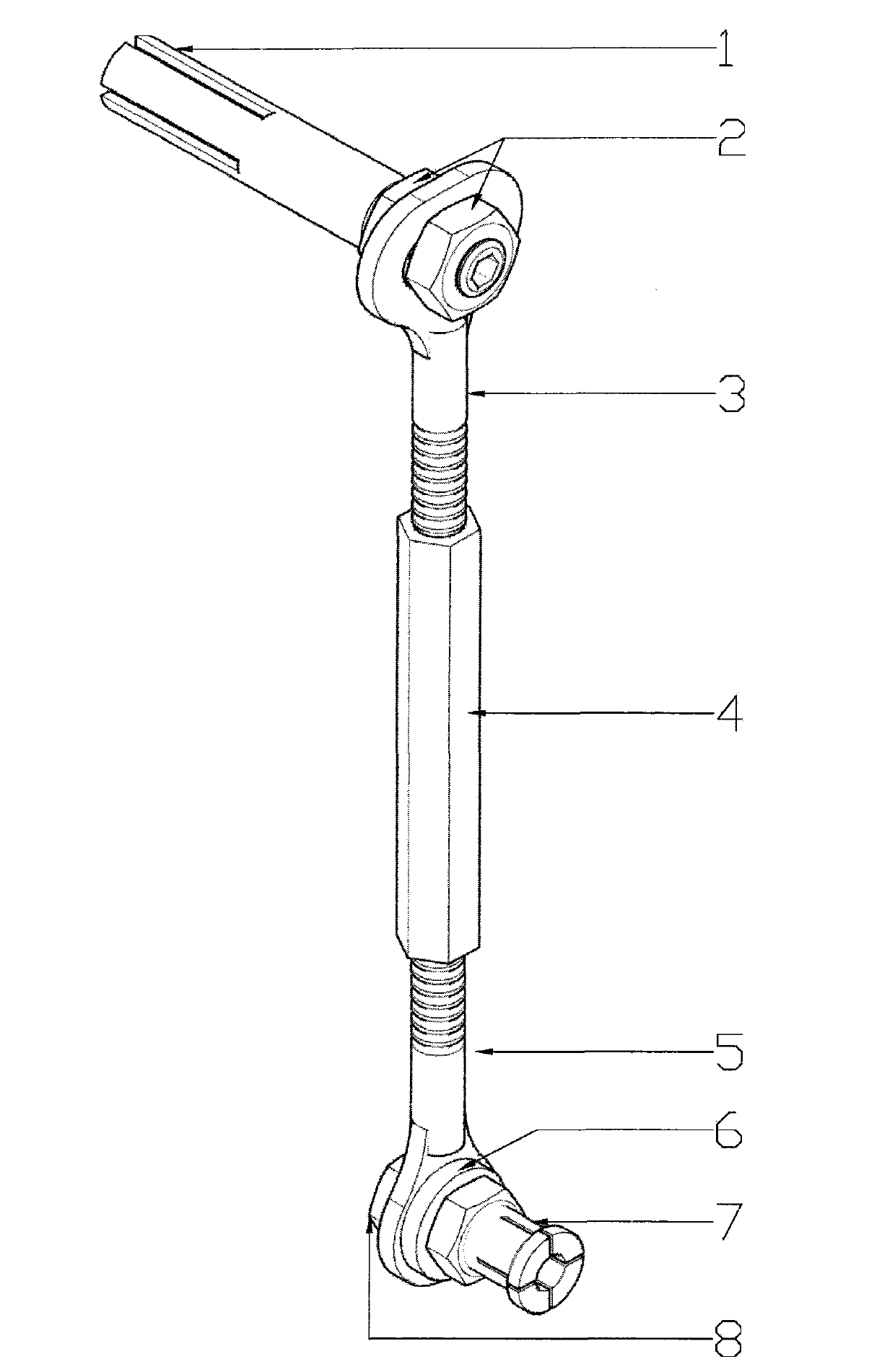

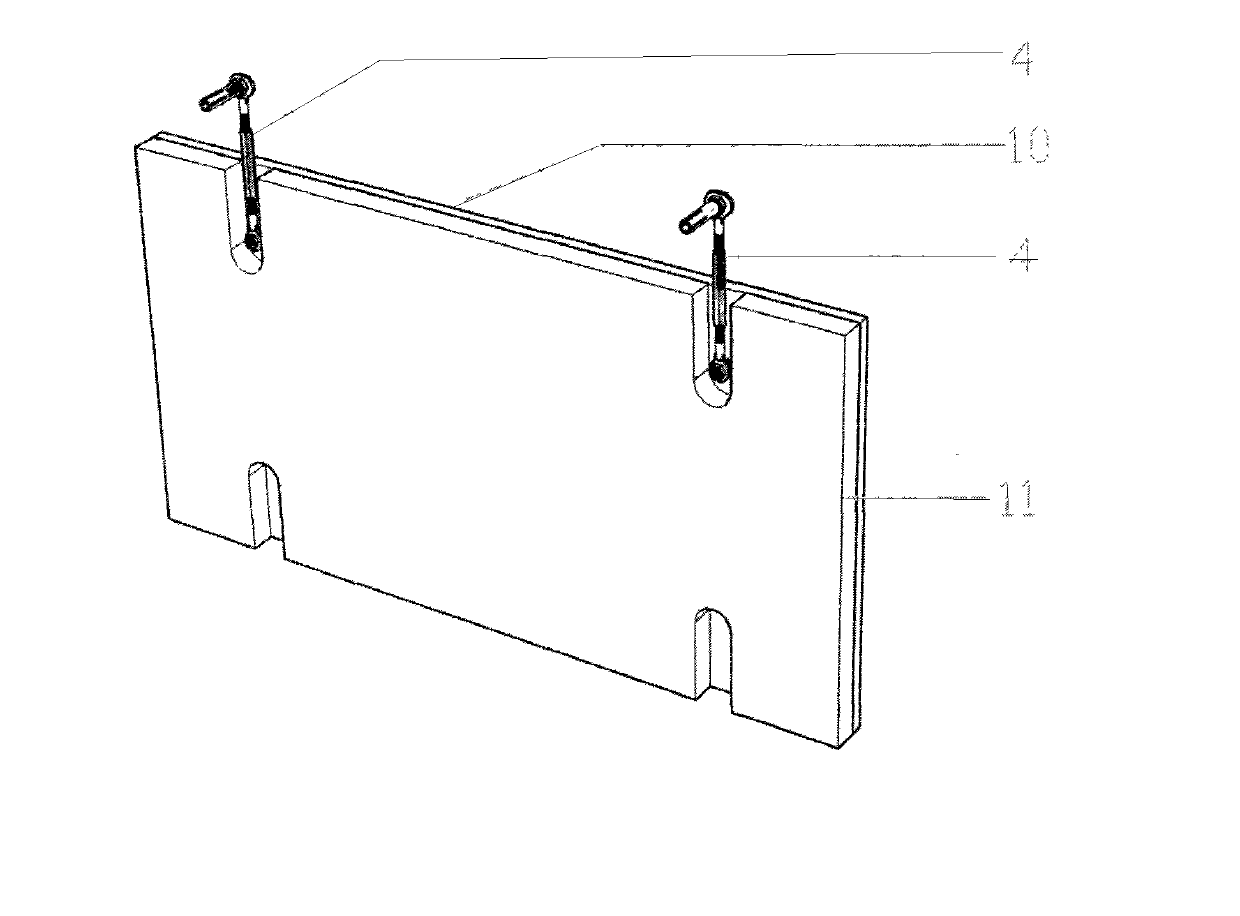

[0035] The present invention is a kind of method for paving stone or ceramic tile on the wall, such as figure 1 As shown, use the inner hexagonal wrench to fix the implosion expansion bolt 1 on the wall, rotate the self-locking nut 2 to change its position on the bolt, and adjust the distance between the normal thread screw 3 and the wall, and can reach For the effect of self-locking, the ferrule of the positive thread screw 3 is provided with a U-shaped groove to facilitate horizontal adjustment during installation. The positive thread screw 3 and the negative thread screw 5 are connected through the positive and negative thread screw connecting sleeve 4, Rotate the positive and negative screw connecting sleeve to adjust the length of the hanging piece, the ferrule of the negative screw 5 can be set on the bolt of the stainless steel back bolt, and the thickness washer 6 is used to ensure a certain adjustment between the hanging piece and the hanging plate Gap, tighten the se...

Embodiment 2

[0039] In this embodiment, stone or ceramic tiles are paved on the ground. The operation method is simpler. Extruded boards are used instead of cement mortar. The difference from the wall is that there is no need to install stainless steel back bolts and hanging parts, and it is directly brushed on the leveled ground. Adhesive, lay stone or tiles on it, if there are individual unevenness, you can use measures such as trimming the thickness of extruded board and leveling with adhesive to meet the requirements, as in the case of extruded board on the wall. The specific methods and implementation Example 1 is the same and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com