Fireproof expansion sealing strip and preparation method thereof

A technology of expanding sealing strips and raw materials, which is applied in the field of fireproof expanding sealing strips and its preparation, can solve the problems of increasing fire intensity, polluting the atmospheric environment, secondary disasters, etc., and achieve the effect of preventing early dense smoke and high ignition point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

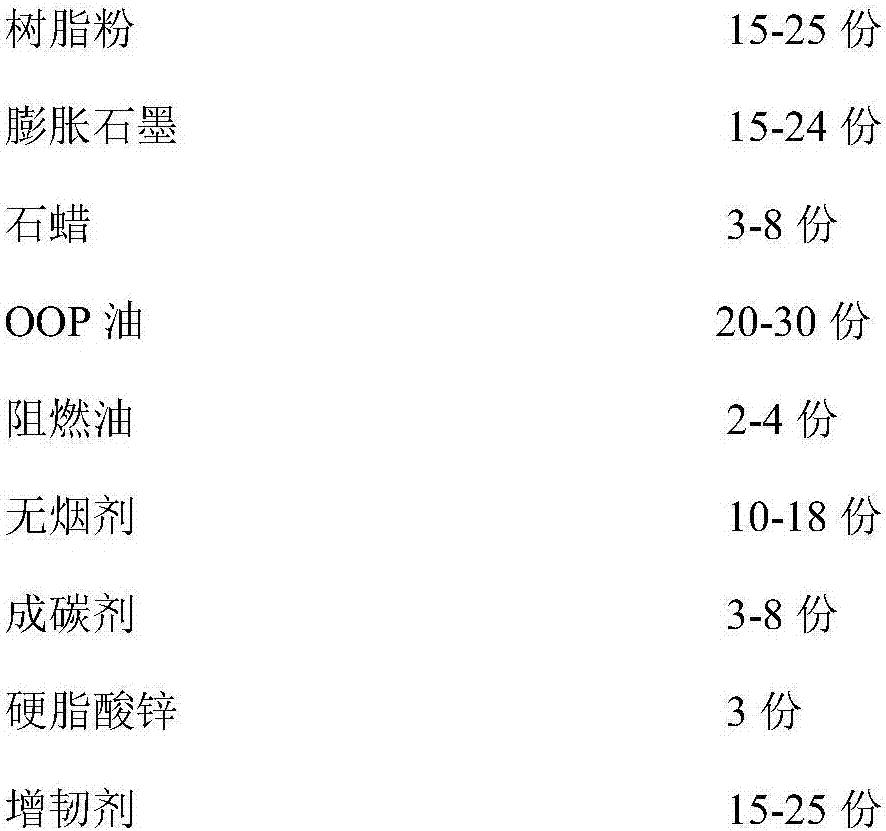

[0026] Weigh the raw materials of the following weight proportions:

[0027]

[0028] Selection of flame-retardant PVC mixed material→crushing treatment→heating and extrusion→vacuum suction and floatation→water cooling and shaping→air drying;

[0029] Making the core filling: After granulating each raw material, weigh the raw materials by weight and stir them in a high-speed mixer, and then they will become powdery substances after stirring. Put the stirred powder into the extrusion granulator, extrude and granulate at 100-120°C; introduce the prepared granules into the outer tube for extrusion molding, water cooling, air drying, and cut to get the finished sealing strip

Embodiment 2

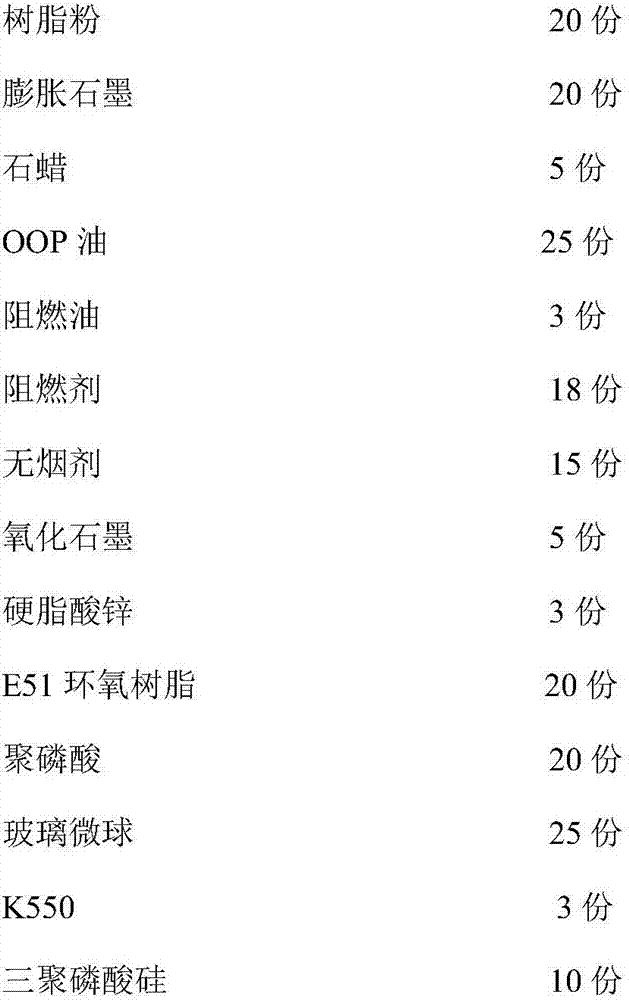

[0031] Weigh the raw materials of the following weight proportions:

[0032]

[0033]

[0034] Selection of flame-retardant PVC mixed material→crushing treatment→heating and extrusion→vacuum suction and floatation→water cooling and shaping→air drying;

[0035] Making the core filling: After granulating each raw material, weigh the raw materials by weight and stir them in a high-speed mixer, and then they will become powdery substances after stirring. Put the stirred powder into the extrusion granulator, extrude and granulate at 100-120°C; introduce the prepared granules into the outer tube for extrusion molding, water cooling, air drying, and cut to get the finished sealing strip

Embodiment 3

[0037] Weigh the raw materials of the following weight proportions:

[0038] Weigh the raw materials of the following weight proportions:

[0039]

[0040] Selection of flame-retardant PVC mixed material→crushing treatment→heating and extrusion→vacuum suction and floatation→water cooling and shaping→air drying;

[0041] Making the core filling: After granulating each raw material, weigh the raw materials by weight and stir them in a high-speed mixer, and then they will become powdery substances after stirring. Put the stirred powder into the extrusion granulator, extrude and granulate at 100-120°C; introduce the prepared granules into the outer tube for extrusion molding, water cooling, air drying, and cut to get the finished sealing strip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com