Elastic coupler

An elastic coupling and semi-coupling technology, applied in elastic couplings, couplings, mechanical equipment, etc., can solve the problems of easy wear and tear, large torque of nylon pins, large machine loss, etc. The effect of installation and removal, increased torque, and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

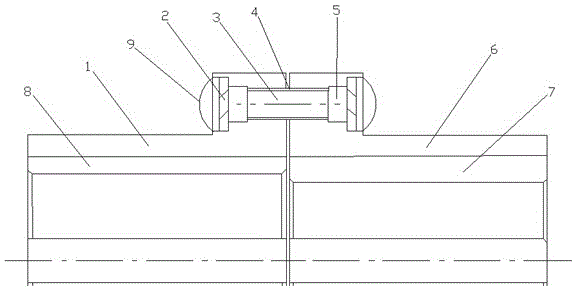

[0017] Example: such as figure 1 As shown, an elastic coupling of the present invention includes an output half coupling 1, an elastic washer 2, a nylon pin 3, a metal pin sleeve 4, a hexagon socket plug 5, an input half coupling 6, and the right part 7. The left part 8 and the screw plug 9; it is characterized in that the contact surface of the output half coupling 1 and the input half coupling 6 is provided with a pin hole, and the output half coupling 1 The lower part is provided with the left part 8, the lower part of the input half coupling 6 is provided with the right part 7, the nylon pin 3 is placed in the pin hole, and the outer part of the nylon pin 3 is provided with the Described metal pin sleeve 4.

[0018] Further, in order to axially fix the nylon pin 3 and the metal pin sleeve 4 , the inner hexagon plugs 5 are provided at both ends of the metal pin sleeve 4 and the nylon pin 3 .

[0019] Further, in order to provide pre-tightening force to realize the anti-lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com