Upright post structure for operation of fully slewing drilling machine

A full-rotary drilling rig and working technology, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc., can solve the problems of inconvenient disassembly, poor alignment, complex diameter changing mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

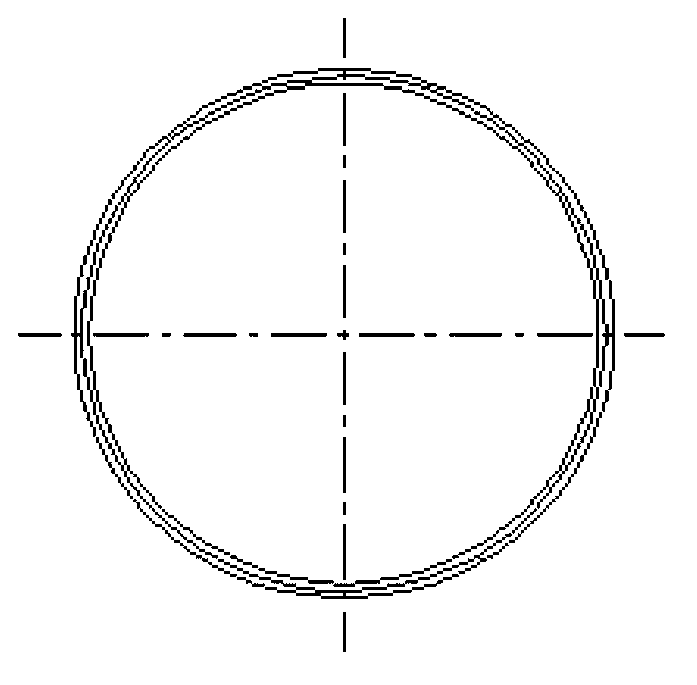

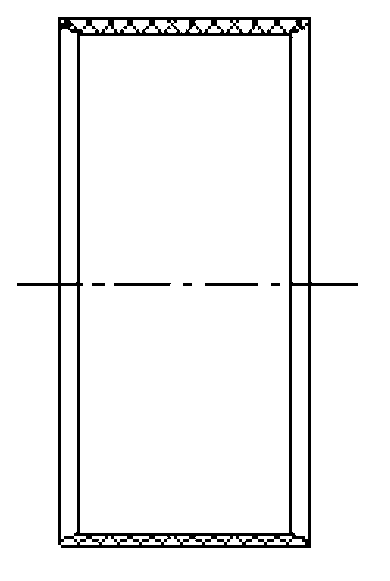

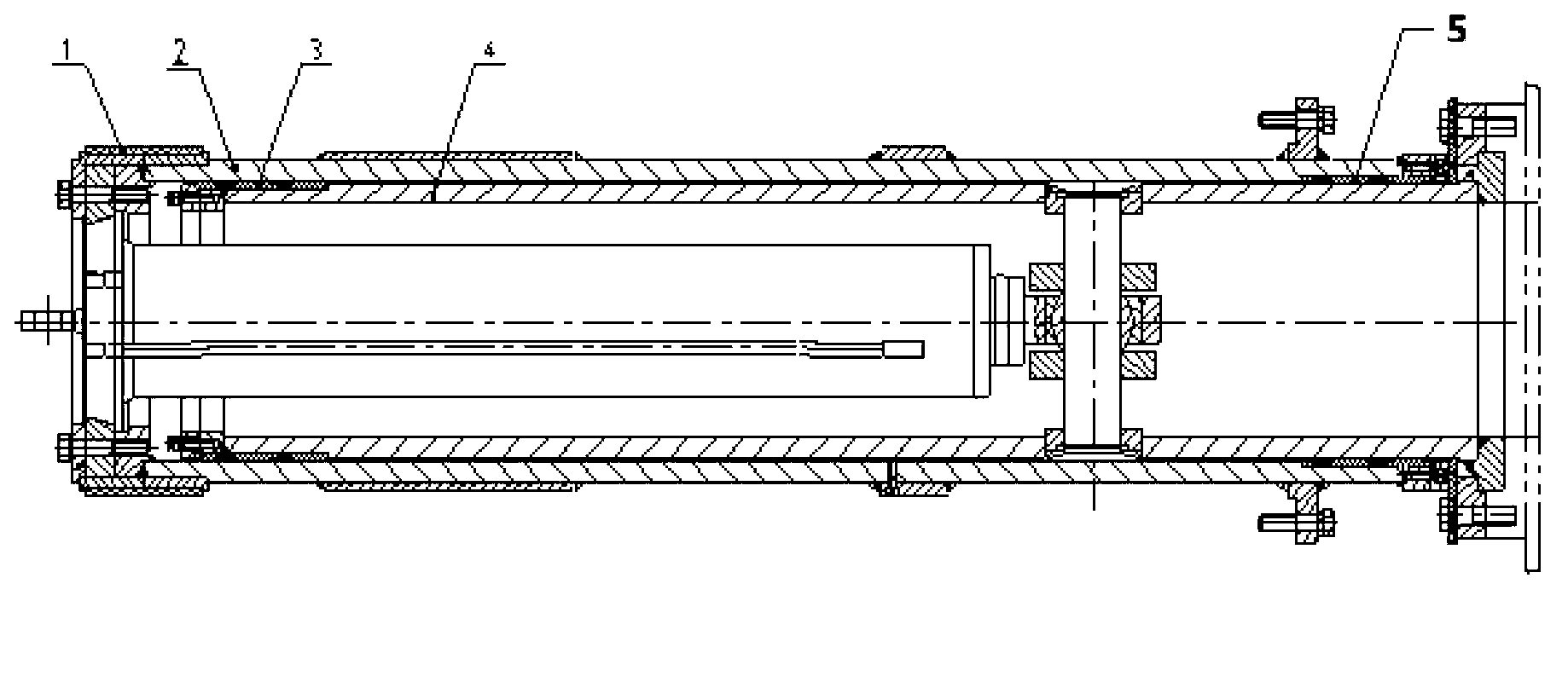

[0009] Such as figure 1 , 2 As shown, the working column structure of the full-turn drilling rig includes a guide column 4 and a sliding column 2 arranged outside the guide column 4 . One end of the sliding column 2 is provided with a first nylon sleeve 3 , and the other end is provided with another first nylon sleeve 5 for buffering between the guide column 4 and the sliding column 2 to reduce friction and vibration. The outer end of the sliding column 4 close to the first nylon sleeve 3 is also covered with a second nylon sleeve 1, which is used to reduce the friction and collision vibration between the column structure of the full-turn drilling rig and the surrounding components or the box after installation. Both the first nylon sheath (3, 5) and the second nylon sheath 1 are made of nylon, the cost is relatively low, and the processing and manufacturing are relatively convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com