Plastic cement floorboard installing structure and installing method thereof

A technology of plastic floor and installation structure, applied in the field of plastic floor, can solve problems such as affecting the use effect, high ground flatness, damage to the ground, etc., to achieve the effect of easy replacement of the floor, reduced experience and technical requirements, and convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

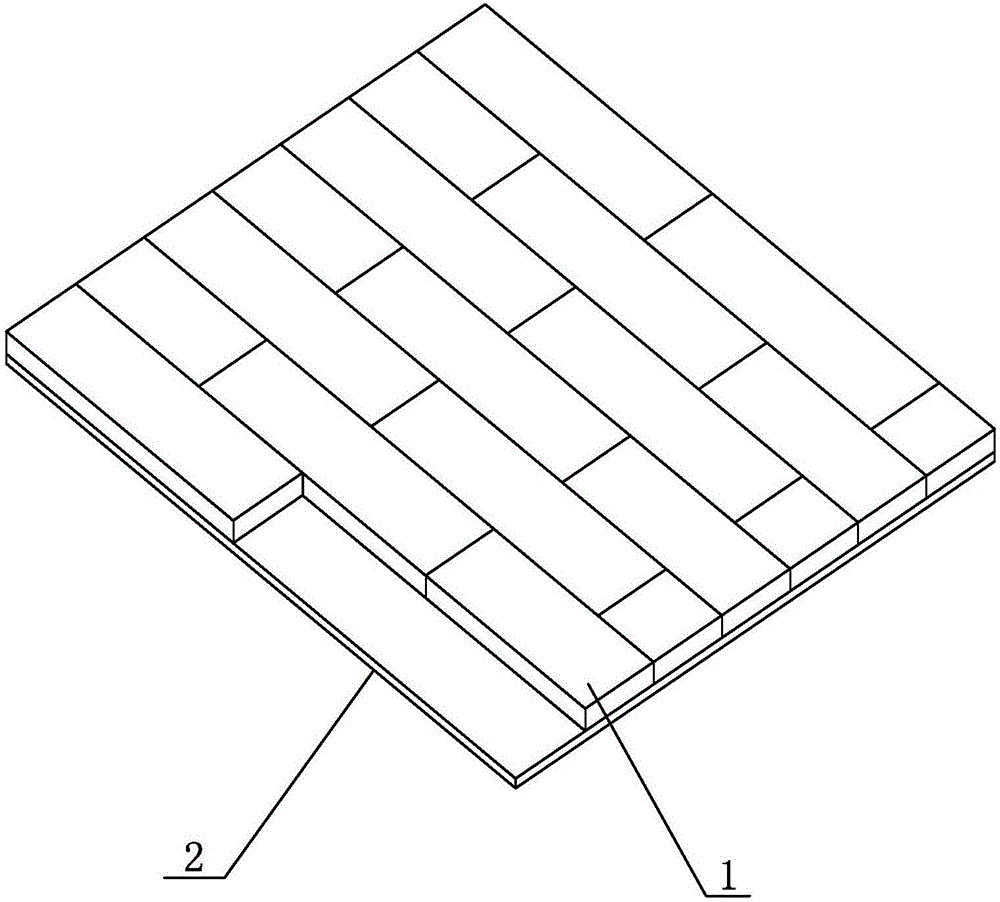

[0019] refer to figure 1 , the present invention provides a plastic floor installation structure, including a two-layer structure: a soft rubber pad 2 laid on the ground and a plastic floor 1 fixed on the upper surface of the soft rubber pad 2 . The back of the plastic floor 1 is provided with a glue layer, and the plastic floor 1 is pasted on the soft rubber pad 2 through glue. Specifically, the soft rubber pad 2 is a soft pad made of PVC material with a thickness of 0.3-2.5mm. Either side or both sides of the upper and lower surfaces of the rubber pad 2 are preferably provided with regular or irregular embossing. Lay and fix the plastic floor 1 on the soft rubber pad 2, the soft rubber pad 2 has the function of connecting the plastic floor 1, and also plays the role of sound insulation, shock absorption, anti-slip, moisture-proof, anti-fouling and sand-proof, and can also reduce the plastic Floor 1 requires no ground surface treatment before laying, which reduces the experi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com