Blowout-proof tire

A technology of explosion-proof tires and tires, which is applied to tire parts, with independent inflatable cushions, transportation and packaging, etc. It can solve the problems of vehicle loss of control, rollover, traffic accidents, etc., and achieves increased pressure bearing capacity and easy installation , Convenience and popularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific embodiments.

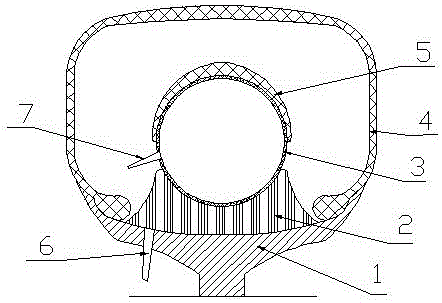

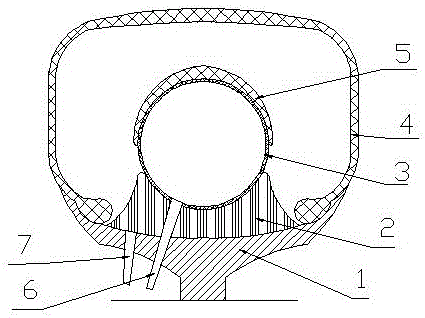

[0018] A kind of run-flat tire, comprises wheel hub and tire, and described tire is arranged on the wheel hub 1, and described tire comprises the tubeless radial tire 4 of outer layer and is arranged in this radial tire inner cavity and through the explosion-proof auxiliary tire that is fixed on the wheel hub through inflation , the auxiliary tire includes an annular pad 2 close to the inner wall of the wheel hub, an inflatable inner tube 3, and an annular reinforced arc belt 5 wrapped around the periphery of the inflatable inner tube; the auxiliary tire is in a non-contact state with the inner wall of the radial tire, and the distance between It can be enough to keep the inner and outer tires from contacting in the normal running state of the tire; the inflation nozzle of the inflatable inner tube passes through the hub and is fixed on the hub; connected or butted; the hub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com