Ultra-bright negative ion glazed brick and production process thereof

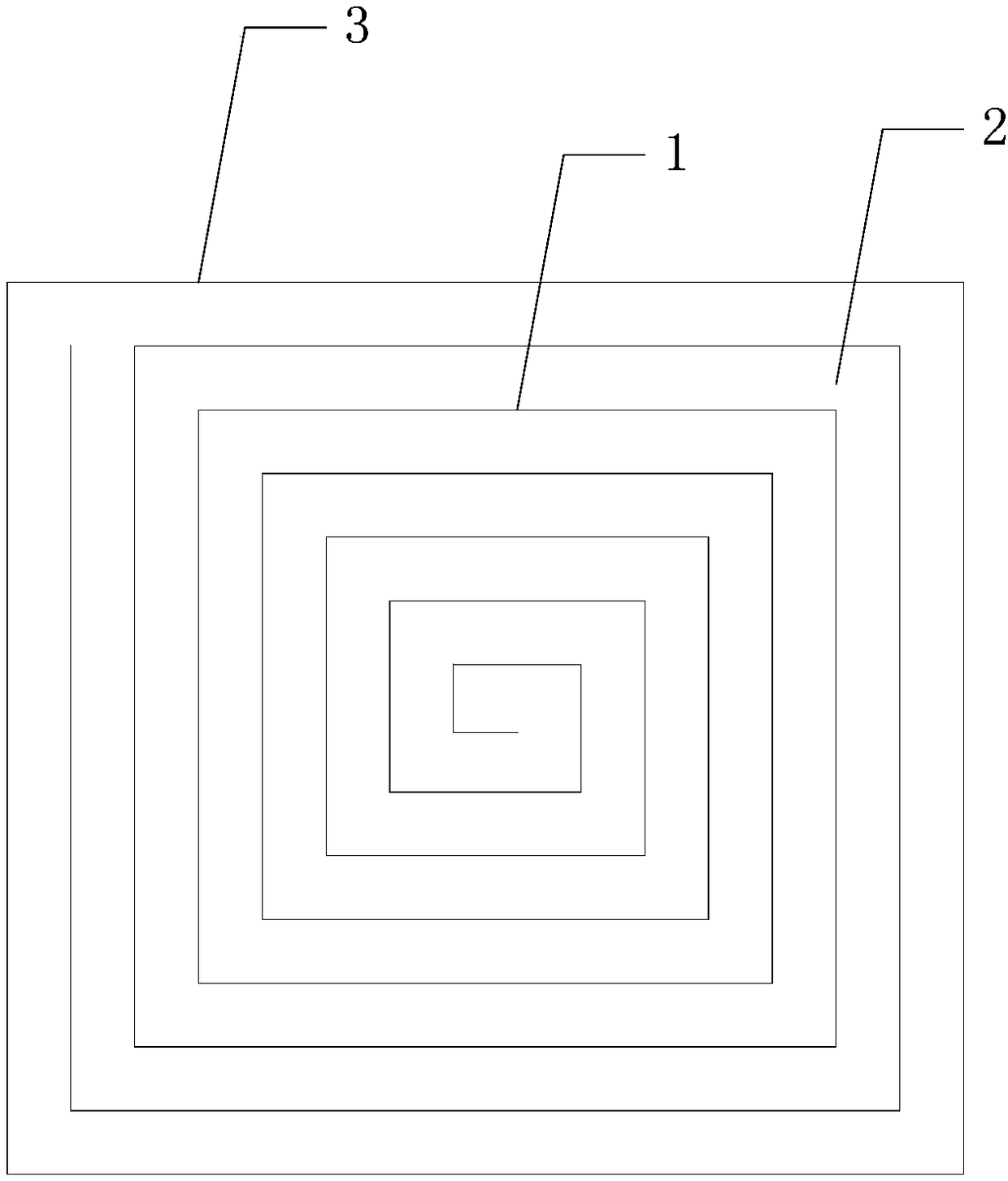

A negative ion, glazed tile technology, applied in construction, building structure, covering/lining, etc., can solve the problem of low effect, achieve the effect of balanced bonding area, novel structure, and strengthen the ability to stimulate negative ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Include the following steps:

[0086] A1, take the raw material SiO 2 、TiO 2 , CaO, K 2 O, LiO, Al 2 o 3 , B 2 o 3 , MgO, Na 2 O, Fe 2 o 3 , FeO, MnO, P 2 o 5 , crushed into 4000 mesh, take part of the powder for later use, and then take part of the powder and calcined at 1230 ° C, the calcining time is 90 minutes per 300 kg, to obtain ultra-fine anion crystals;

[0087] B1. Take 28 parts of stone powder, 24 parts of sand, 5 parts of superfine negative ion powder, 28 parts of diatom mud, 23 parts of mud, 20 parts of ceramic waste residue and crushed mud, water, mix and stir, and send the obtained embryo body material into the mold for drying Bake and form to obtain the bottom embryo body;

[0088] The ceramic waste slag is the waste slag in the ceramic production process;

[0089] C1. Sprinkle asbestos fiber and gypsum powder to the bottom embryo body placed in the mold, after laying polyamide net, continue to spread asbestos fiber and gypsum powder, add em...

Embodiment 2

[0094] Include the following steps:

[0095] A2, take the raw material SiO 2 、TiO 2 , CaO, K 2 O, LiO, Al 2 o 3 、B 2 o 3 , MgO, Na 2 O, Fe 2 o 3 , FeO, MnO, P 2 o 5 , crushed into 4000 mesh, take part of the powder for later use, and then take part of the powder and calcined at 1230 ° C, the calcining time is 90 minutes per 300 kg, to obtain ultra-fine anion crystals;

[0096] B2. Take 28 parts of stone powder, 24 parts of sand, 5 parts of superfine negative ion powder, 28 parts of diatom mud, 23 parts of mud, 20 parts of ceramic waste residue and crushed mud, water, mix and stir, and send the obtained embryo body material into the mold for drying Bake and form to obtain the bottom embryo body;

[0097] The ceramic waste slag is the waste slag in the ceramic production process;

[0098] C2. Spread asbestos fiber and gypsum powder to the bottom embryo body placed in the mold, after laying the polyamide net, continue to spread asbestos fiber and gypsum powder, add e...

Embodiment 3

[0103] Include the following steps:

[0104] A3, take the raw material SiO 2 、TiO 2 , CaO, K 2 O, LiO, Al 2 o 3 、B 2 o 3 , MgO, Na 2 O, Fe 2 o 3 , FeO, MnO, P 2 o 5 , crushed into 4000 mesh, take part of the powder for later use, and then take part of the powder and calcined at 1230 ° C, the calcining time is 90 minutes per 300 kg, to obtain ultra-fine anion crystals;

[0105] B3. Take 28 parts of stone powder, 24 parts of sand, 5 parts of superfine negative ion powder, 28 parts of diatom mud, 23 parts of mud, 20 parts of ceramic waste residue and crushed mud, water, mix and stir, and the obtained embryo body material is sent into a mold for drying Bake and form to obtain the bottom embryo body;

[0106] The ceramic waste slag is the waste slag in the ceramic production process;

[0107] C3. Spread asbestos fiber and gypsum powder to the bottom embryo body placed in the mold, after laying the polyamide net, continue to spread asbestos fiber and gypsum powder, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com