Sound insulation cotton, air-conditioning outdoor unit and sound insulation structure mounting method

A technology for air-conditioning outdoor units and sound-proof cotton, applied in air-conditioning systems, chemical instruments and methods, heating methods, etc., can solve problems such as low production efficiency, complicated operation, and poor noise reduction effect, so as to improve satisfaction and reduce noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

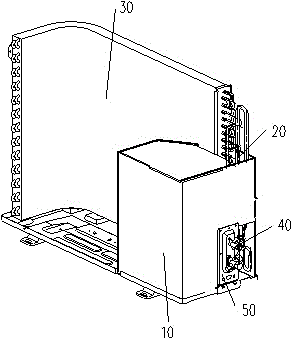

[0039] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0040] First, a brief description of the orientations involved in this specific embodiment: when referring to the front, back, left, and right of a structural component, it is defined by the position of the structural component relative to the user in normal use.

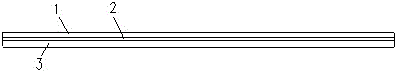

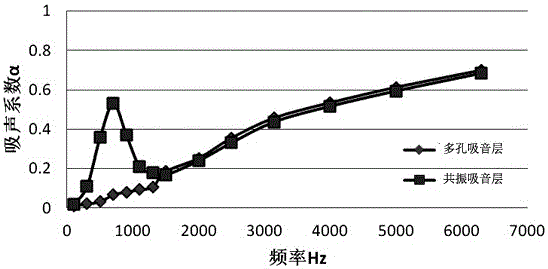

[0041] refer to Figure 1-Figure 6 , is an embodiment of the sound-insulating cotton proposed by the present invention. The sound-insulating cotton is a three-layer structure, which sequentially includes a porous sound-absorbing layer 1, a sound-insulating shock-absorbing layer 2, and a resonant sound-absorbing layer 3 from the inside to the outside, wherein the porous sound-absorbing layer 1 adopts The open-cell fiber material is used to absorb high-frequency noise; the resonant sound-absorbing layer 3 is made of closed-cell foam material, which is used to absorb the resonant sound...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com