Processing technology of air-permeable glass material structure and air-permeable glass material structure

A processing technology, glass material technology, applied in epoxy resin coatings, polyurea/polyurethane coatings, laminations, etc., can solve problems such as maladaptation, tightness and dry skin, skin deterioration, etc., and achieve good lighting effect , strong anti-scratch ability, good self-cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

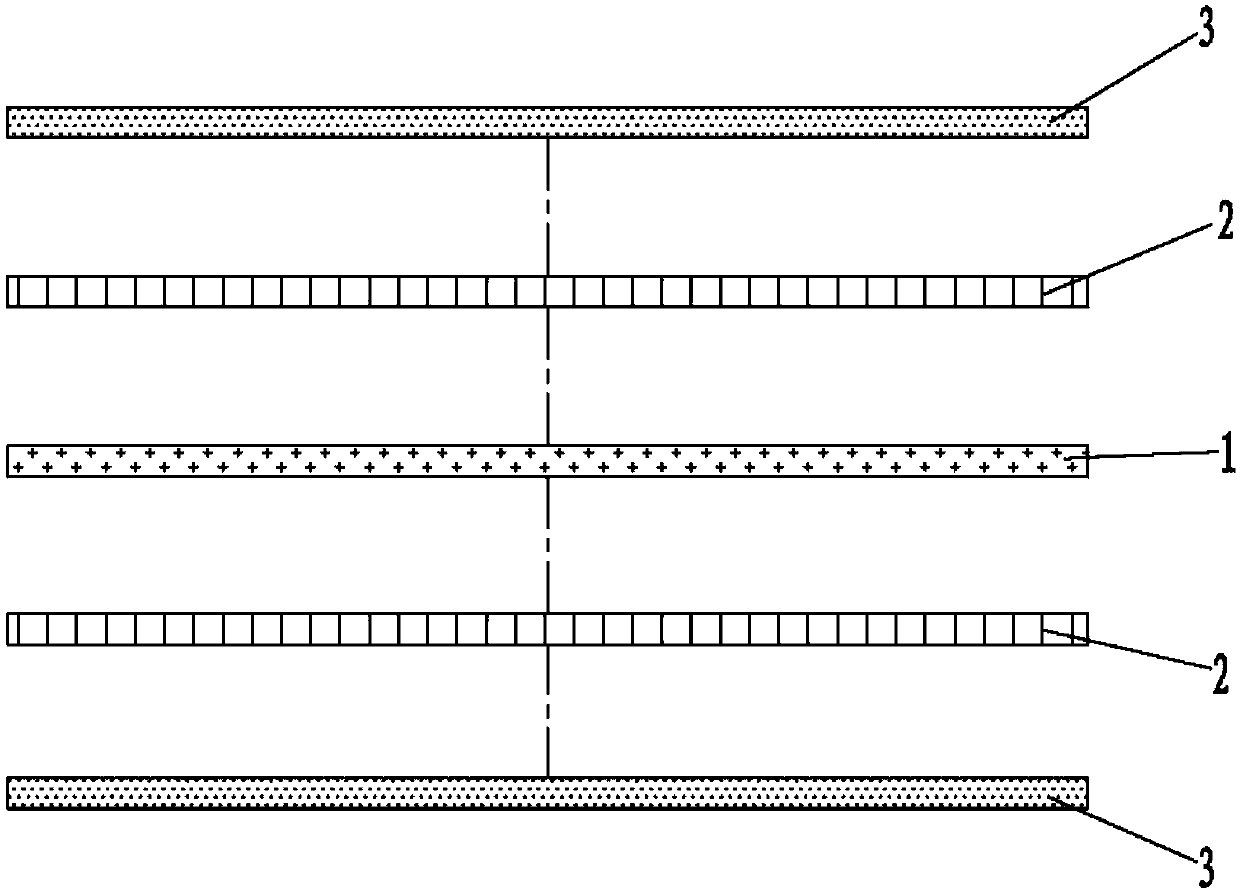

[0034] The flow chart of the gas-permeable glass material structure processing process of the present invention comprises the following steps:

[0035] (1) On the front and back of the substrate with a thickness of 0.05-3mm, use a dry weight of 2-30g / m 2 Graphene coatings or antistatic and anti-scratch functional coatings are coated respectively. This embodiment uses graphene coatings to form functional layers positioned on the front and back sides of the substrate. This functional layer can also be antistatic and scratch resistant. It is made of functional coatings such as scratches, wherein the substrate is one of PET, PETG, ABS, BOPP, PP, PC, PVC, TPU transparent resin materials, and the graphene coating is formulated by the following components in parts by weight: : 20-40 parts of water-based polyurethane emulsion, 3-8 parts of graphene dispersion, 0.1-0.4 parts of silicone surfactant, 5-20 parts of deionized water, wherein the solid content of graphene dispersion is 0.5-5...

Embodiment 2

[0069] The flow chart of the gas-permeable glass material structure processing process of the present invention comprises the following steps:

[0070] (1) On the front and back of the base material with a thickness of 0.1-2mm, use a dry weight of 2-30g / m 2 Graphene coatings are coated separately to form functional layers located on the front and back of the substrate, wherein the substrate is one of PET, PETG, ABS, BOPP, PP, PC, PVC, TPU transparent resin materials, so The formula of the graphene coating is composed of the following components in parts by weight: 25 to 45 parts of water-based acrylic emulsion, 5 to 10 parts of graphene dispersion, 0.2 to 0.4 parts of organic silicon surfactant, and 5 to 15 parts of deionized water;

[0071] (2) coating or heating one layer of protective film again on the surface of described graphene paint functional layer;

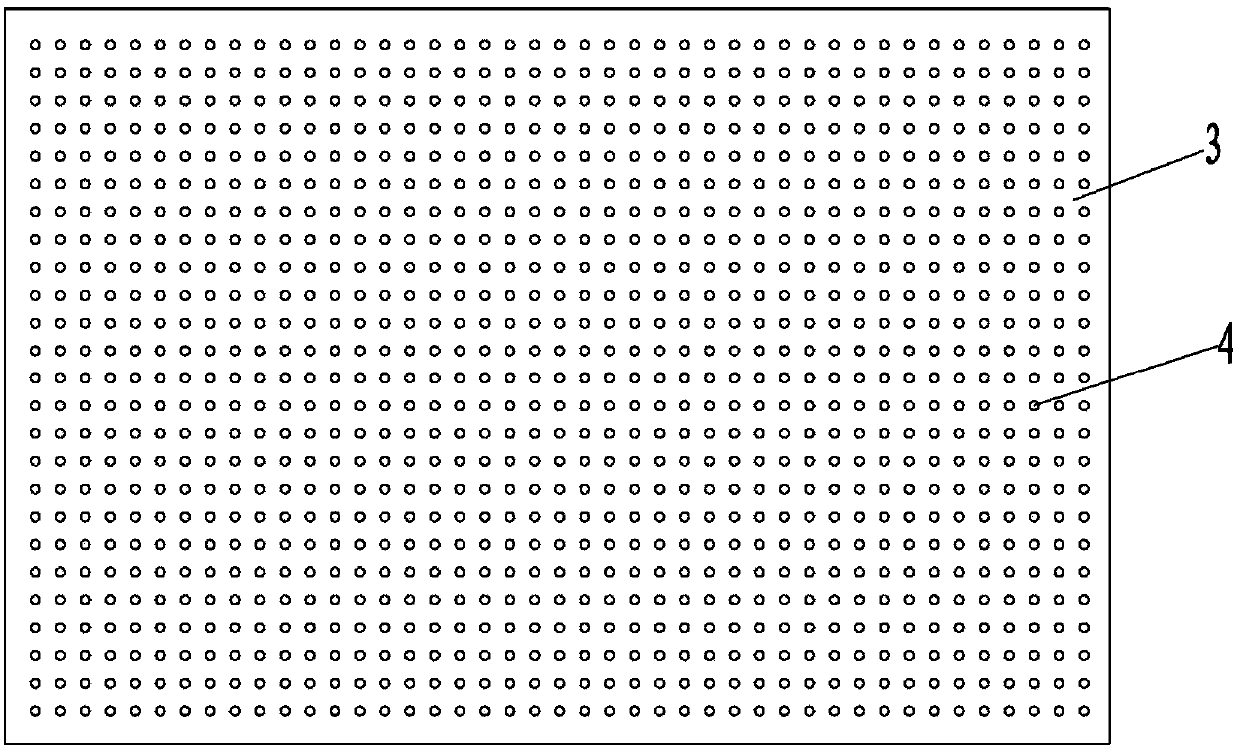

[0072] (3) The surface of the material prepared in step (2) is perforated by means of laser or plasma or needle rolle...

Embodiment 3

[0102] The flow chart of the gas-permeable glass material structure processing process of the present invention comprises the following steps:

[0103] (1) On the front and back of the substrate with a thickness of 0.1-0.15mm, the dry weight is 2-30g / m 2 Graphene paint is coated respectively in the amount of coating to form a functional layer positioned at the front and back of the substrate, wherein the substrate is one of PET, PETG, BOPP, PP, PC, PVC transparent resin materials, and the graphene paint The following ingredients are formulated in parts by weight: 30-40 parts of pure acrylic emulsion, 5-8 parts of graphene dispersion, 0.01-0.03 parts of fluorosurfactant, and 5-10 parts of deionized water;

[0104] (2) coating or heating one layer of protective film again on the surface of described graphene paint functional layer;

[0105] (3) The surface of the material prepared in step (2) is perforated by means of laser or plasma or needle roller or chemical corrosion or me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com