Environment-friendly outer wall and construction method thereof

An environmentally friendly, wall technology, applied in building structures, walls, buildings, etc., can solve the problems of reduced indoor activity area, inconvenient construction, low work efficiency, etc., to achieve effective use of waste, reduce stacking labor, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

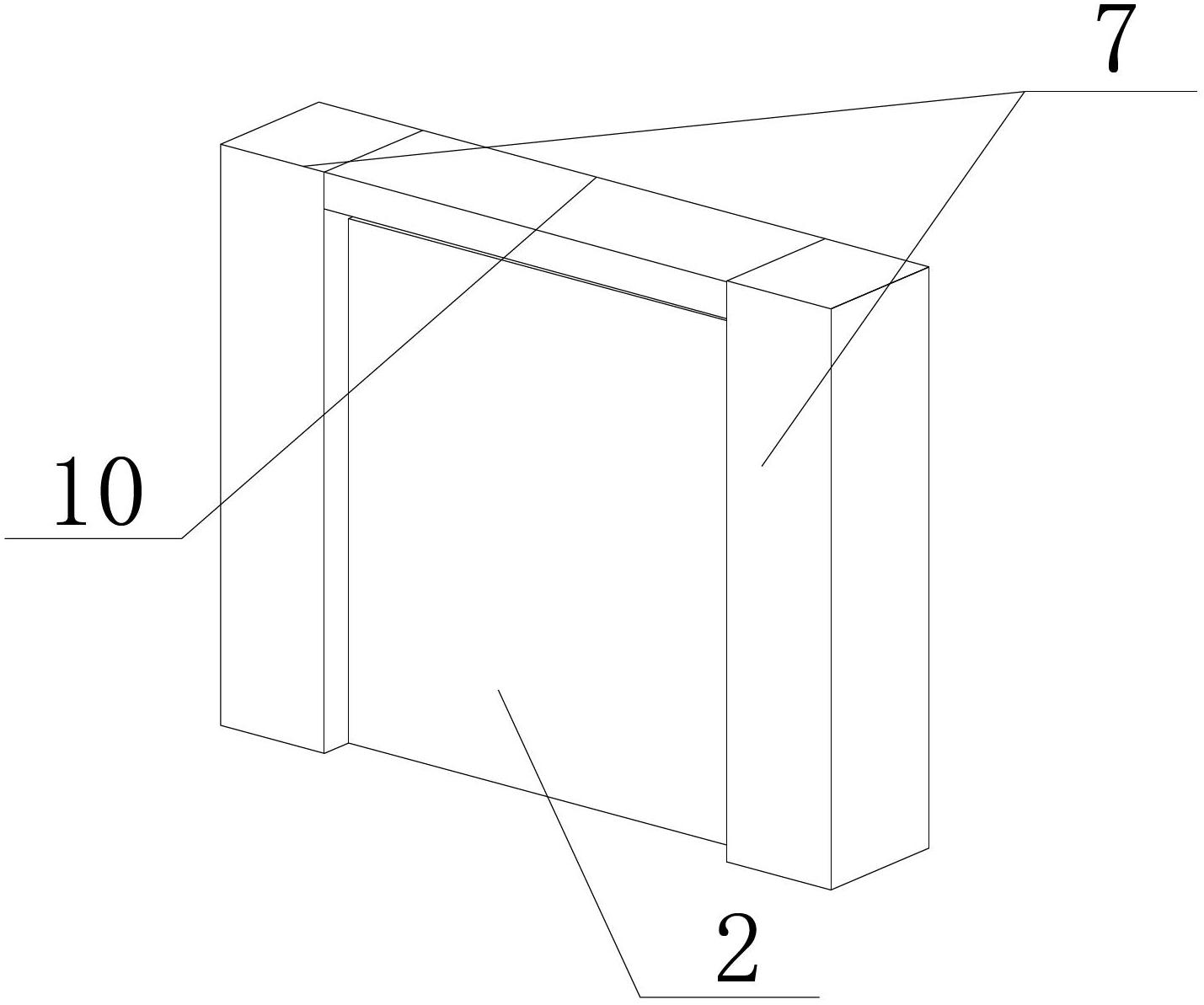

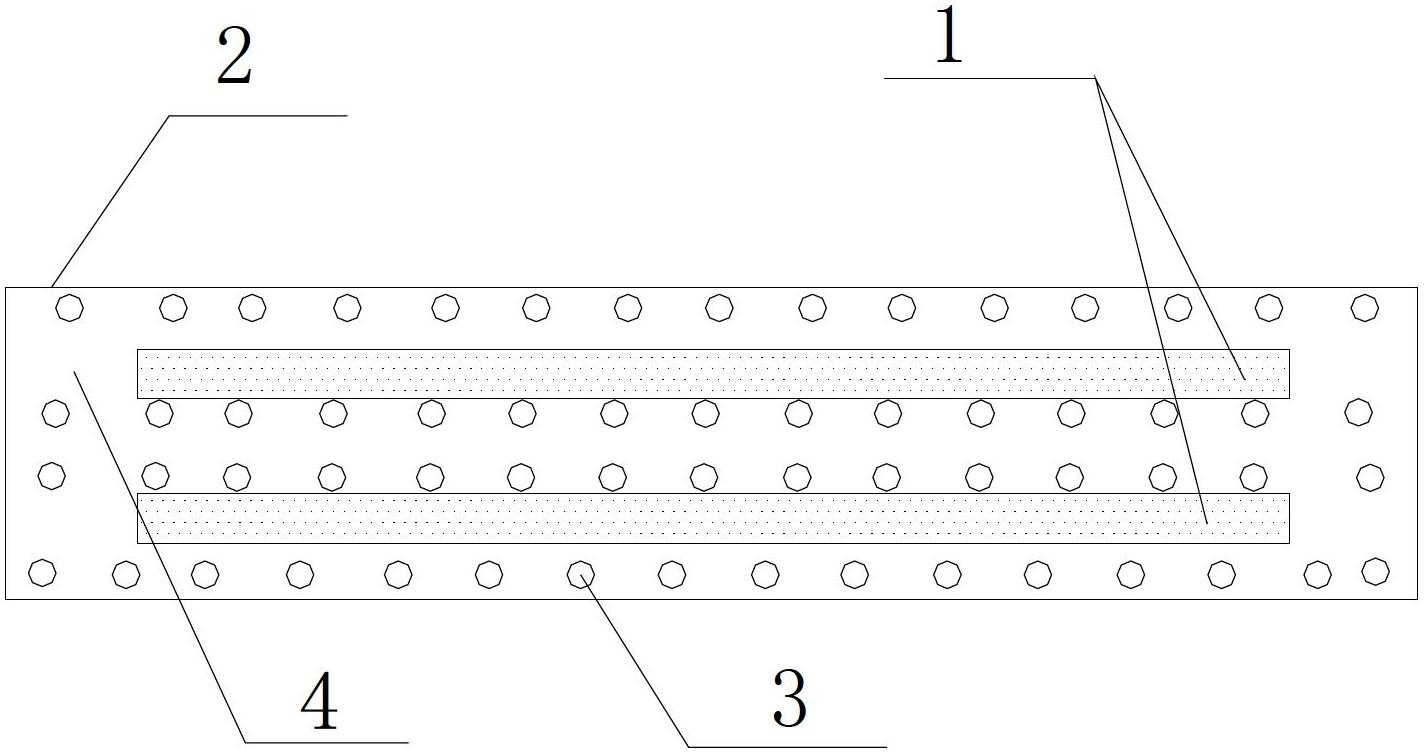

[0038] Such as figure 1 , 2 As shown, an environment-friendly exterior wall, the environment-friendly exterior wall includes an inner module 1, an outer module 2 arranged on the outside of the inner module 1, fixed columns 7 located at both ends of the outer module 2, and a cover arranged on the top of the outer module 2 The beam 10; the inner module 1 is one or a plurality of evenly spaced distributions. By setting the inner module inside the outer module, the purpose of earthquake resistance, heat preservation, heat insulation and sound insulation can be effectively achieved, and the inner module is made of straw die-casting, which reduces the amount of raw materials used, realizes the effective utilization of waste, energy saving and environmental protection. Moreover, the toughness and strength of the inner module are increased by adopting straw die-casting to form the inner module, and problems such as wall cracks are avoided.

[0039] In addition, in addition to straw ...

Embodiment 2

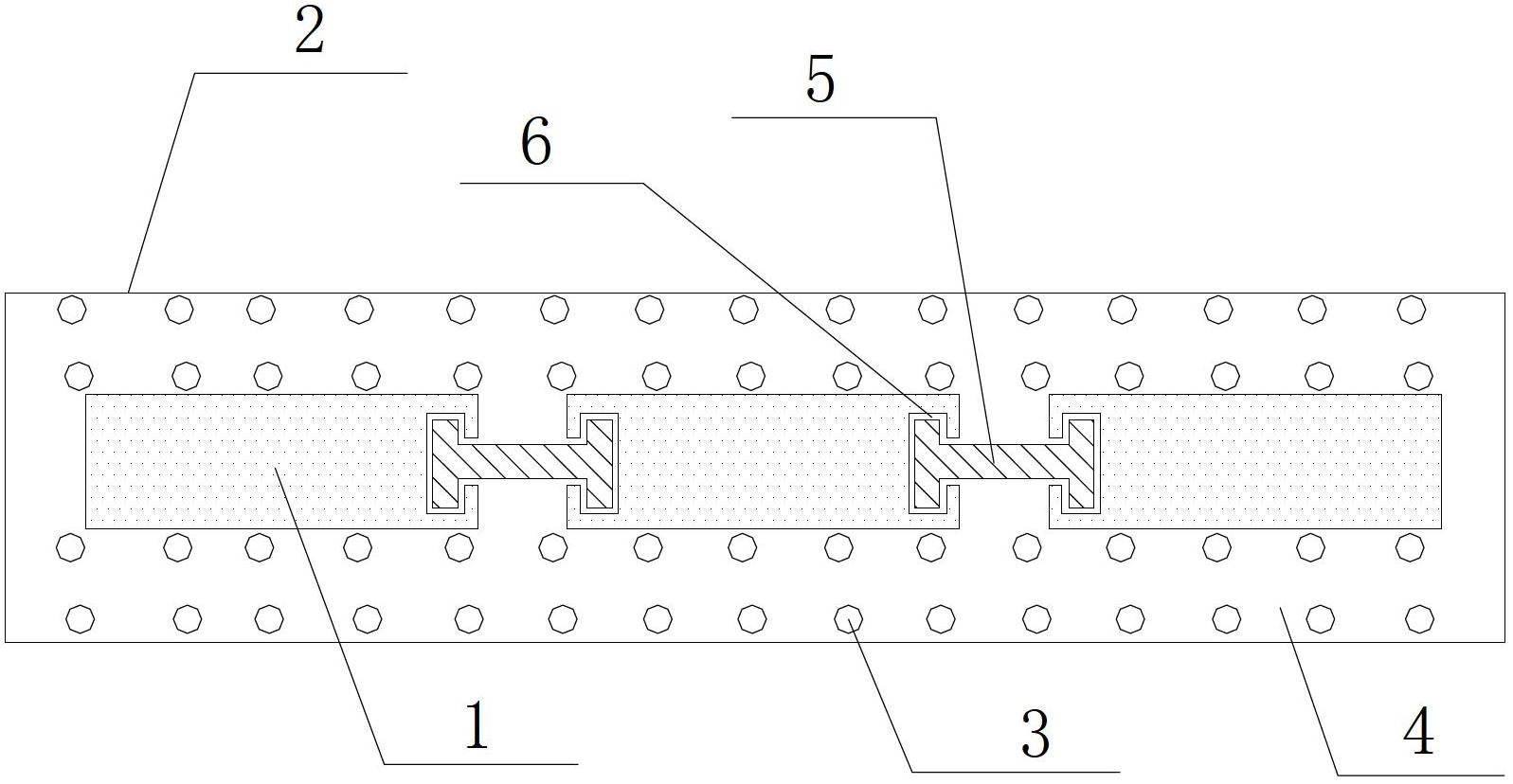

[0059] Such as image 3 As shown, the rest is the same as that of Embodiment 1, the difference is that the inner modules 1 are in a row at the center of the outer modules 2, and two adjacent inner modules 1 are provided with connectors to horizontally position them. The connecting piece is an I-shaped connecting rod 5 , and the corresponding ends of two adjacent inner modules 1 are provided with a slot 6 matching the connecting rod 5 . The cooperation between the connecting rod 5 and the slot 6 ensures the stability among multiple inner modules and improves the strength of the outer wall. In addition to clamping and fixing the inner modules with connecting rods, bolts can also be used, or pin rings are extended at the corresponding ends of two adjacent inner modules to effectively fix the inner modules through pins, etc. The specific fixing method is not limited.

[0060] The construction method of the environment-friendly exterior wall body in this embodiment, concrete steps...

Embodiment 3

[0069] Such as Figure 4 , 5 As shown, the rest are the same as in Embodiment 2, the difference is that at least one side of the inner module 1 that is in contact with the outer module 2 is provided with a fixing plate 8, and the fixing plate 8 is provided with a passage for the fixing steel bar 3 to pass through. Hole 9. The fixing plate 8 can be clamped and fixed with the inner module. By setting the fixing plate, it can effectively support and fix the inner module, ensuring the stability of the inner module and enhancing the strength of the outer wall.

[0070] The environment-friendly exterior wall body disclosed by the present invention includes an inner module, an outer module arranged outside the inner module, fixing columns located at both ends of the outer module, and a crossbeam covering the top of the outer module; through the outer module The interior is equipped with an inner module, which can effectively achieve the purpose of earthquake resistance, heat preser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com