Environment-friendly thermal insulation outer wall and manufacturing method thereof

An environment-friendly, wall-based technology, applied in thermal insulation, walls, building structures, etc., can solve problems such as poor thermal insulation effect of external walls, unsatisfactory fire performance, complicated manufacturing and construction, etc., and reduce stacking labor Quantity, simple manufacturing process, and the effect of reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific examples.

[0033] All features disclosed in this specification, or steps in all disclosed methods or processes, except for mutually exclusive characteristics and / or steps, can be combined in any way, unless otherwise stated, they can be used by other equivalent or similar Instead, each feature is intended to be replaced by alternative features, that is, each feature is only one embodiment of a series of equivalent or similar features unless stated otherwise.

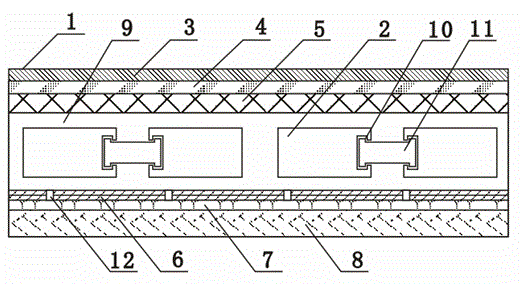

[0034] Such as figure 1 As shown, an environment-friendly thermal insulation outer wall includes an outer module 1 and several straw inner modules 2, the outer module 1 includes a base wall 3, a thermal insulation layer 4, an adhesive mortar layer 5, an inner protective layer 6, Alkali-resistant grid cloth layer 7, outer protective layer 8 and mortar layer 9, the base wall 3 is arranged on the outer side of the outer module 1, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com