Shock-resistance light-weight fireproof plate

A fire-proof board and impact-resistant technology, which is applied in the direction of fire prevention and building components, etc., can solve the problems of fragility, low safety performance, and easy cracking, etc., and achieve the effects of improving impact resistance, convenient use, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

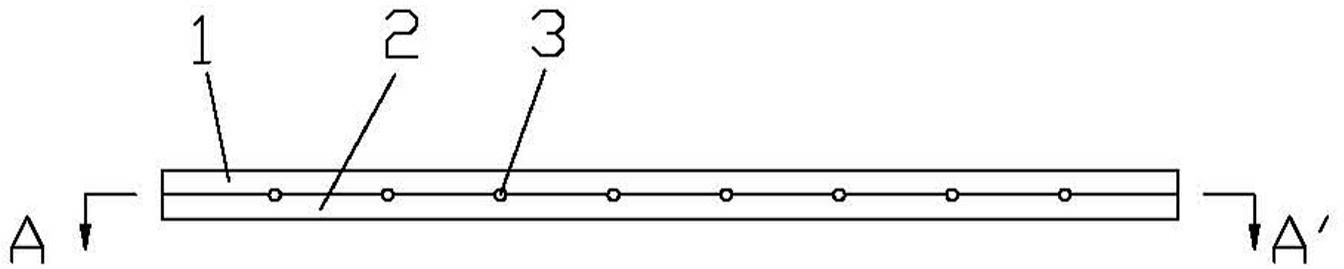

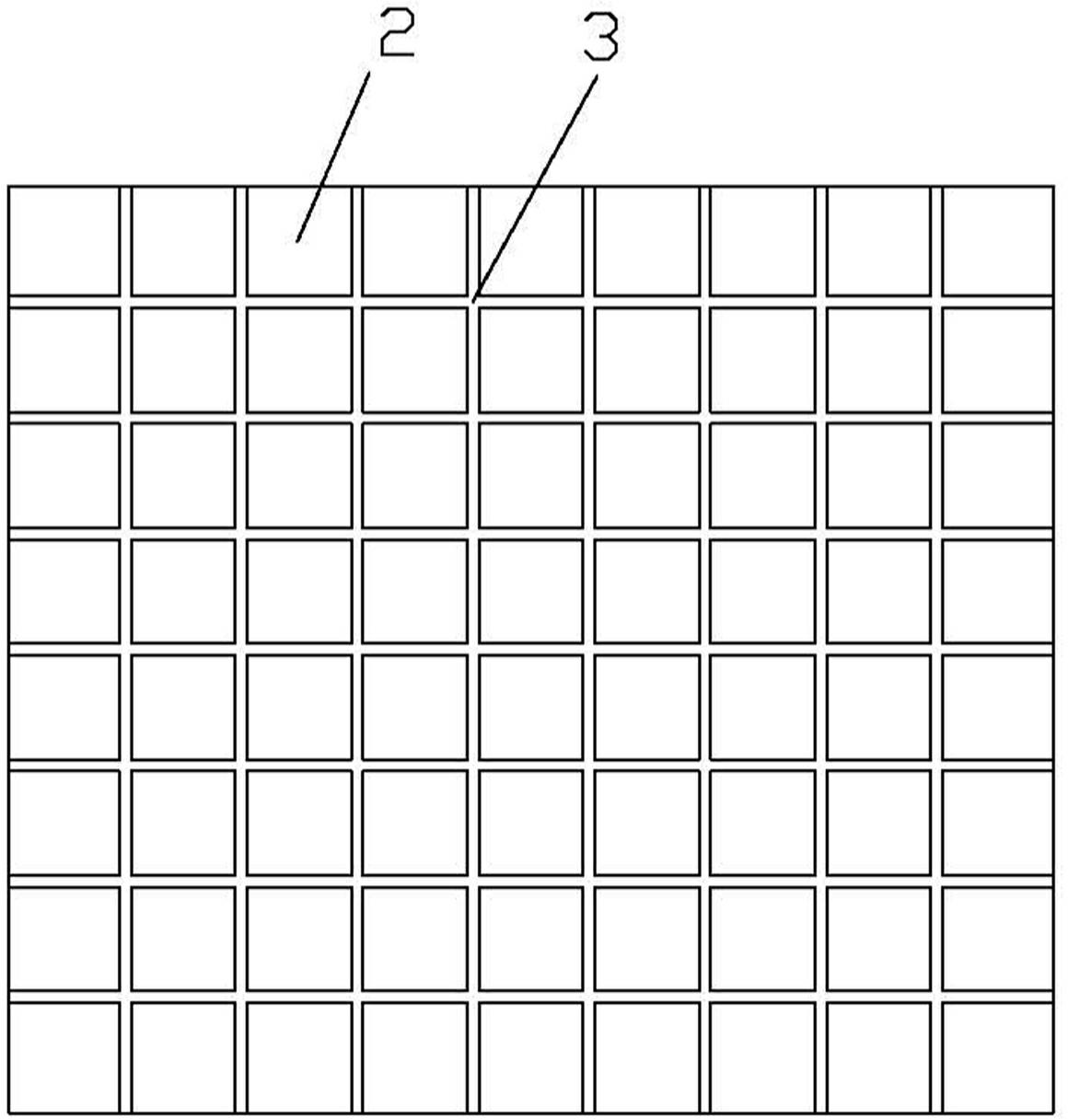

[0013] refer to figure 1 , figure 2 , a light-weight fireproof board with simple structure, convenient manufacture and strong impact resistance provided by the present invention has: upper and lower base materials 1, 2 made of fireproof materials; upper and lower base materials 1, 2 There is a layer of tough mesh layer 3 between them, the material of which is metal mesh, which makes the fireproof board have strong toughness, improves the strength and impact resistance of the fireproof board, and the tough mesh layer 3 is parallel to the outer surface of the base material. Of course, at this point, the tenacious net layer 3 can also be a fiber net, which has the same effect and is an equivalent technical solution. The upper and lower substrates 1, 2 and the tough mesh layer 3 are pressed together by a press.

Embodiment 2

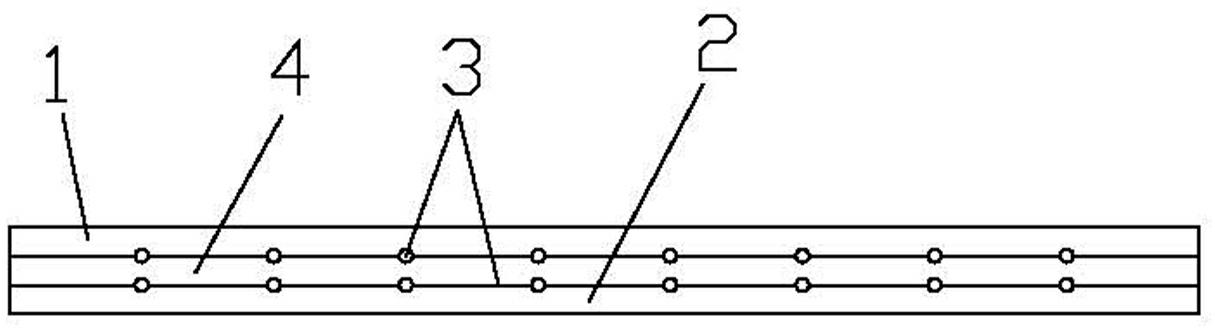

[0015] refer to image 3 , the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: two layers of tough mesh layers 3 are arranged between the upper and lower substrates 1 and 2, and two layers of tough mesh layers 3 are arranged between two layers of tough mesh layers 3. Intermediate substrate 4, the material of intermediate substrate 4 is the same as that of upper and lower substrates 1 and 2, and each layer of tough mesh layer 3 is evenly distributed between upper and lower substrates 1 and 2, that is, from the upper surface of the fireproof board to the second The distance between one layer of tough mesh layer 3, the distance between the first tough mesh layer 3 and the second tough mesh layer 3, and the distance from the second tough mesh layer 3 to the lower surface of the fireproof board are all equal, so that the fireproof board It has stronger toughness, which further improves the strength and impact resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com