Vertical cotton breathable bra cup pad with silica gel net and preparation method thereof

A technology of standing cotton and silicone, applied in the field of bra coasters, can solve the problems of poor washing resistance and shaping effect of standing cotton, reducing the gathering and shaping effect of bras, poor washing resistance of standing cotton, etc., so as to improve the anti-deformation effect. , Improve the three-dimensional effect, the effect of good washing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

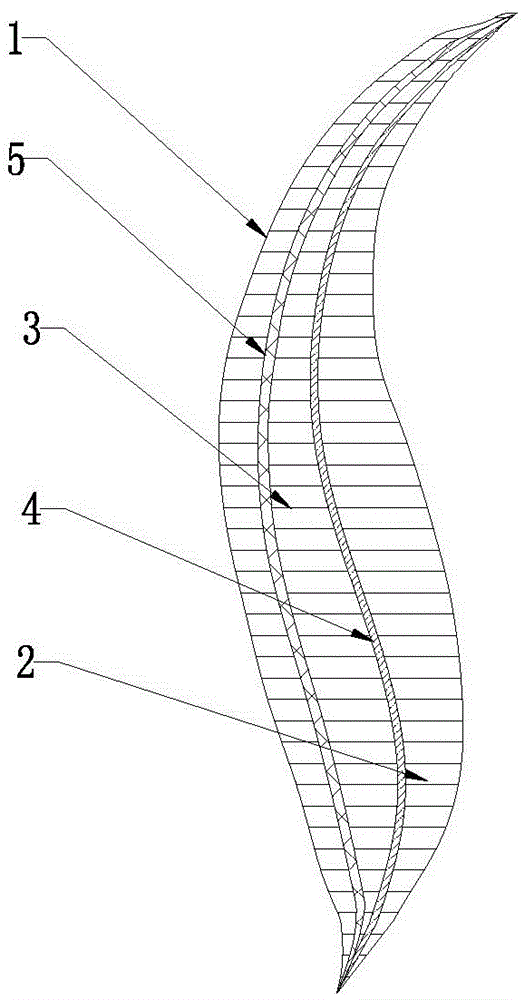

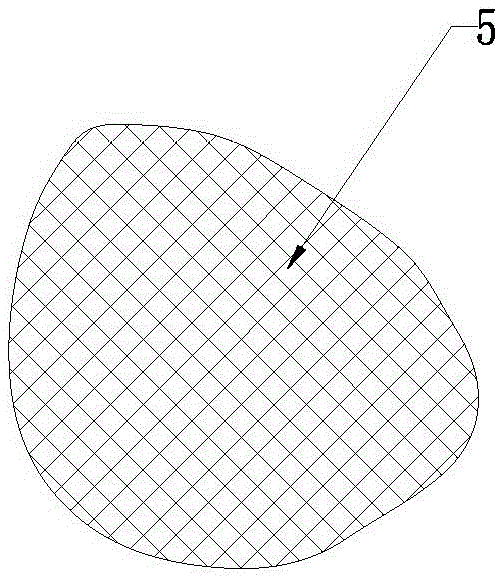

[0075] See figure 1 , an upright cotton breathable bra coaster with silica gel mesh, comprising an upright cotton outer layer 1 and an upright cotton inner layer 2, an upright cotton interlayer 3 is arranged between the upright cotton outer layer 1 and the upright cotton inner layer 2, A viscose layer 4 is arranged between the upright cotton interlayer 3 and the upright cotton inner layer 2 , and an adhesive mesh layer 5 is arranged between the upright cotton outer layer 1 and the upright cotton interlayer 3 .

[0076] The rubber mesh layer 5 of the present invention is connected with the upright cotton outer layer 1 and the upright cotton interlayer 3 by hot pressing.

[0077] This embodiment includes an upright cotton outer layer 1 and an upright cotton inner layer 2, an upright cotton interlayer 3 is arranged between the upright cotton outer layer 1 and the inner layer, and an upright cotton interlayer 3 and an upright cotton inner layer 2 are arranged. A viscose layer 4 i...

Embodiment 2

[0087] The difference between this implementation and Example 1 is that the glue in the adhesive layer 4 is mixed with the following raw materials in parts by weight:

[0088] Neoprene latex 20 parts

[0089] 20 parts deionized water

[0090] 1 part emulsifier

[0091] Acrylic emulsion 6 parts

[0092] Butyl acrylate 1 part

[0093] Ethylene-vinyl acetate copolymer emulsion 10 parts

[0094] Hide glue 3 parts

[0095] Polyurethane associative thickener 2 parts

[0096] 1 part magnesium stearate

[0097] Lauroyl peroxide 0.3 parts

[0098] Water-based defoamer K-510 1 part.

[0099] Other technical features of this embodiment adopt the explanation of Embodiment 1, and will not be repeated here.

Embodiment 3

[0101] The difference between this implementation and Example 1 is that the glue in the adhesive layer 4 is mixed with the following raw materials in parts by weight:

[0102] Neoprene latex 25 parts

[0103] 23 parts of deionized water

[0104] 2 parts emulsifier

[0105] Acrylic emulsion 8 parts

[0106] 3 parts butyl acrylate

[0107] Ethylene-vinyl acetate copolymer emulsion 10 parts

[0108] 5 parts hide glue

[0109] Polyurethane associative thickener 4 parts

[0110] Magnesium stearate 3 parts

[0111] Lauroyl peroxide 0.5 parts

[0112] Water-based defoamer K-510 1.5 parts.

[0113] Other technical features of this embodiment adopt the explanation of Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com