A combined house plate wall structure and a digital printing production method thereof

A combined, slab wall technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of large waste, long construction period, complicated construction procedures, etc., to ensure the overall strength and rigidity, save time and cost, The effect of reducing installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

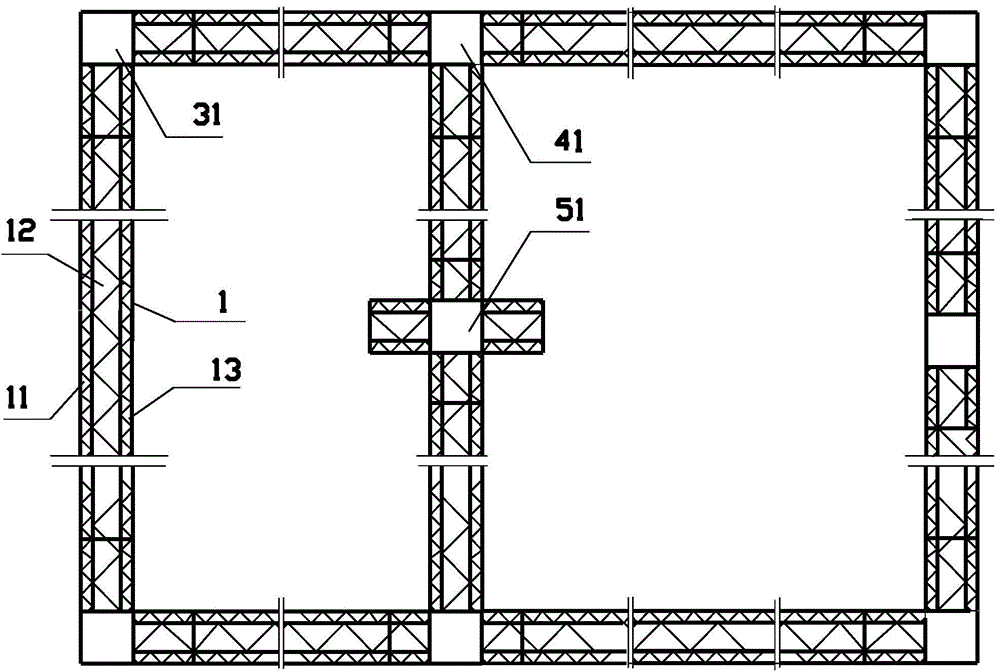

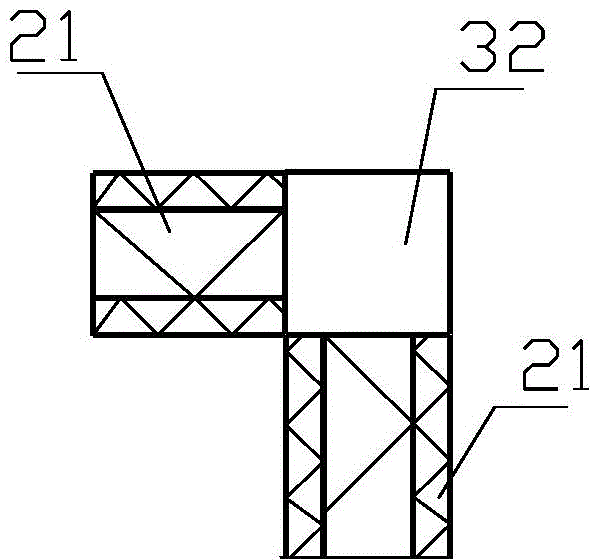

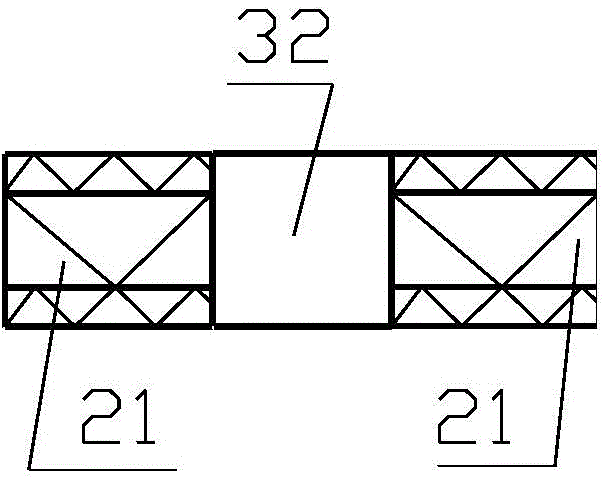

[0024] Below in conjunction with embodiment the present invention will be further described: figure 1 It is a structural schematic diagram of an embodiment of the present invention. In the figure, a structure of a combined house slab wall includes: a long straight part 1, a short straight part 21, and connecting nodes; the long straight part 1 and the short straight part 21 have the same cross-sectional structure , only the length dimension of the section is different. Here, the cross-sectional structure of the long straight member 1 is used to illustrate: it includes: an outer thermal insulation layer 11, a wall layer 12, and the wall layer 12 is composed of outer and inner cement boards separated by a certain distance and the " Zigzag ribs, the space between the zigzag ribs and the outer and inner cement boards can be filled with polystyrene and cement slurry, and can also be used as reserved holes to connect with adjacent walls When placing reinforcement cages. The outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com