Thermoplastic elastomer composition for crane cable sheath

A thermoplastic elastomer and cable protection technology, applied in the direction of insulated cables, plastic/resin/wax insulators, cables, etc., can solve problems such as elusiveness, and achieve the effect of simplifying the process and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

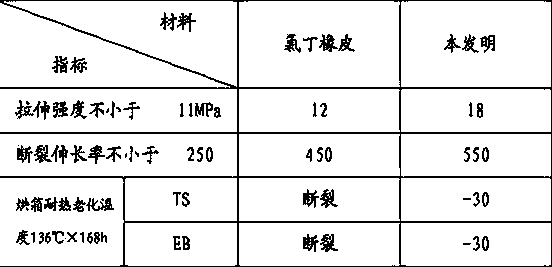

Examples

Embodiment Construction

[0033] A thermoplastic elastomer composition for a crane cable sheath, which comprises the following parts by weight:

[0034] PVC resin: 30~35,

[0035] Light calcium carbonate 1250 mesh: 8-10,

[0036] TOTM: 28~30,

[0037] DOS: 2~3,

[0038] Epoxidized soybean oil 1~1.5,

[0039] Environment-friendly calcium zinc stabilizer 2~2.5,

[0040] Low molecular weight polyethylene wax, molecular weight 2500-4000, 0.2-0.5;

[0041] Among them, the PVC resin is a mixture of PVC2500 type and PVC1300 type with a weight ratio of 4:1.

[0042] The thermoplastic elastomer composition for crane cable sheathing, preferably, it comprises the following parts by weight:

[0043] PVC resin: 32~34,

[0044] Light calcium carbonate 1250 mesh: 9~10,

[0045] TOTM: 29.5~30,

[0046] DOS: 2.5~3,

[0047] Epoxidized soybean oil 1~1.5,

[0048] Environment-friendly calcium zinc stabilizer 2~2.5,

[0049] Low molecular weight polyethylene wax, molecular weight 2500-4000, 0.2-0.5;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com