Patents

Literature

138results about How to "Strong thermal shock resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

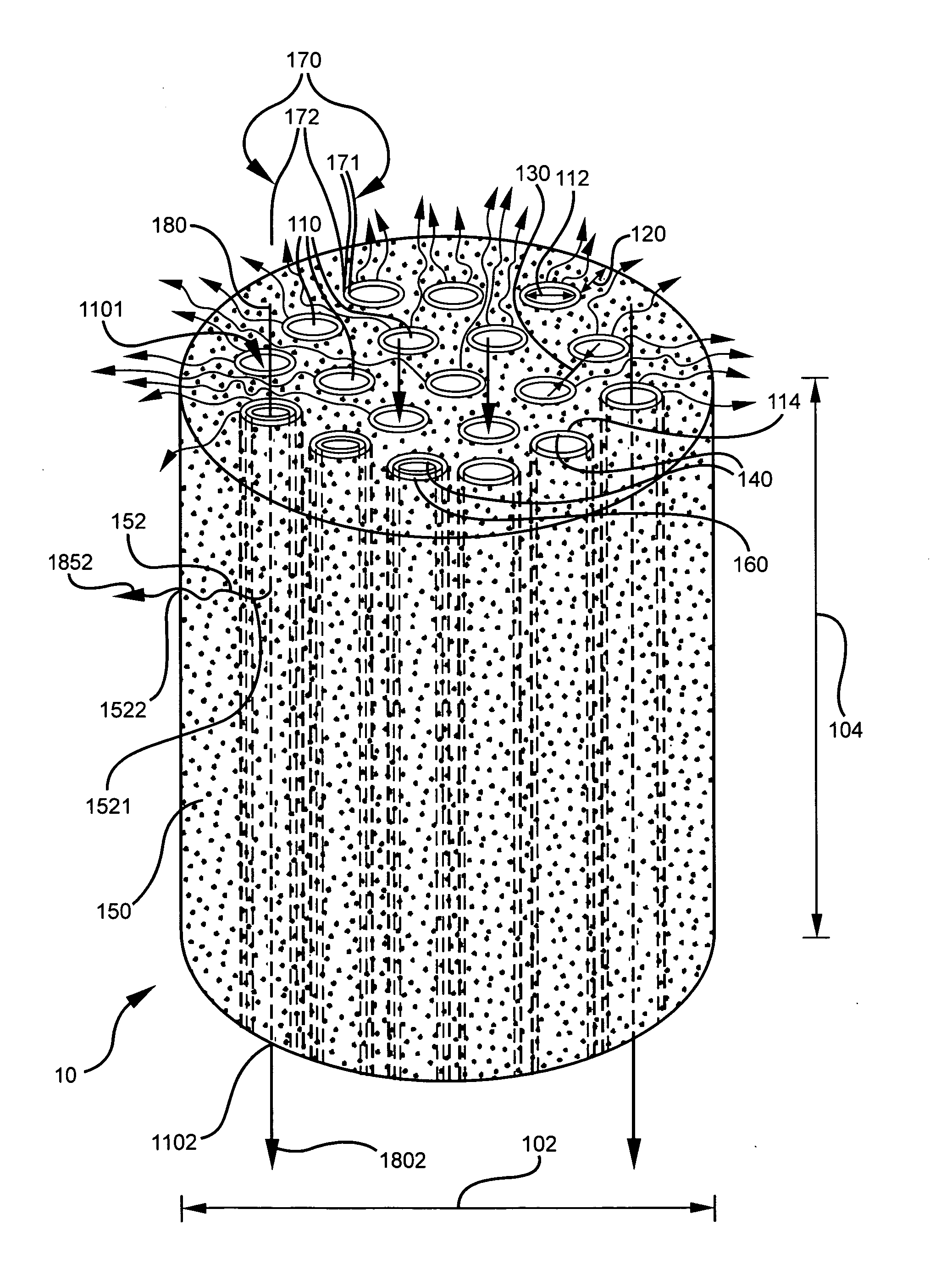

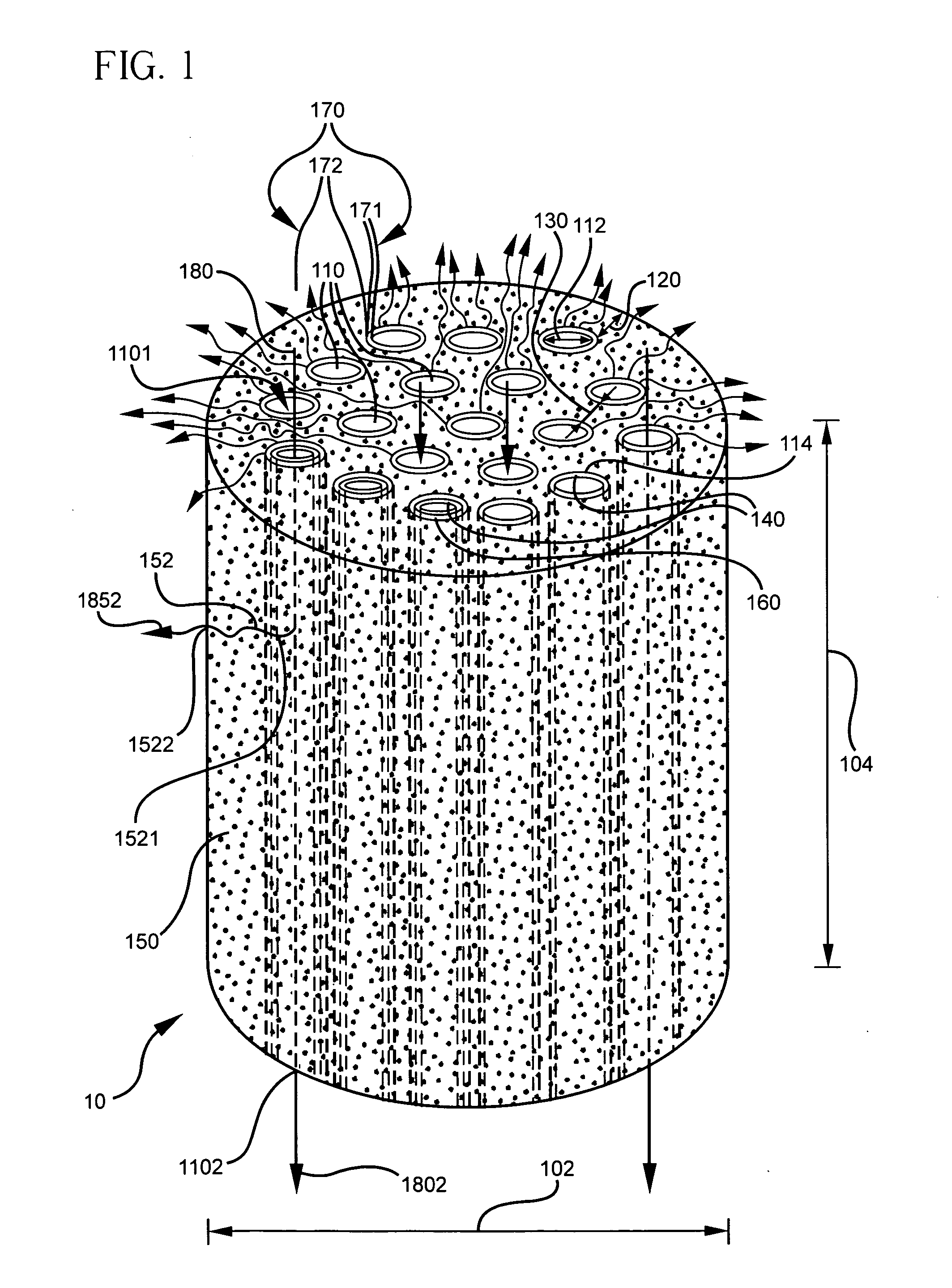

High separation area membrane module

InactiveUS20060090649A1Easy to separateReduce in quantityMembranesSemi-permeable membranesChannel densityEngineering

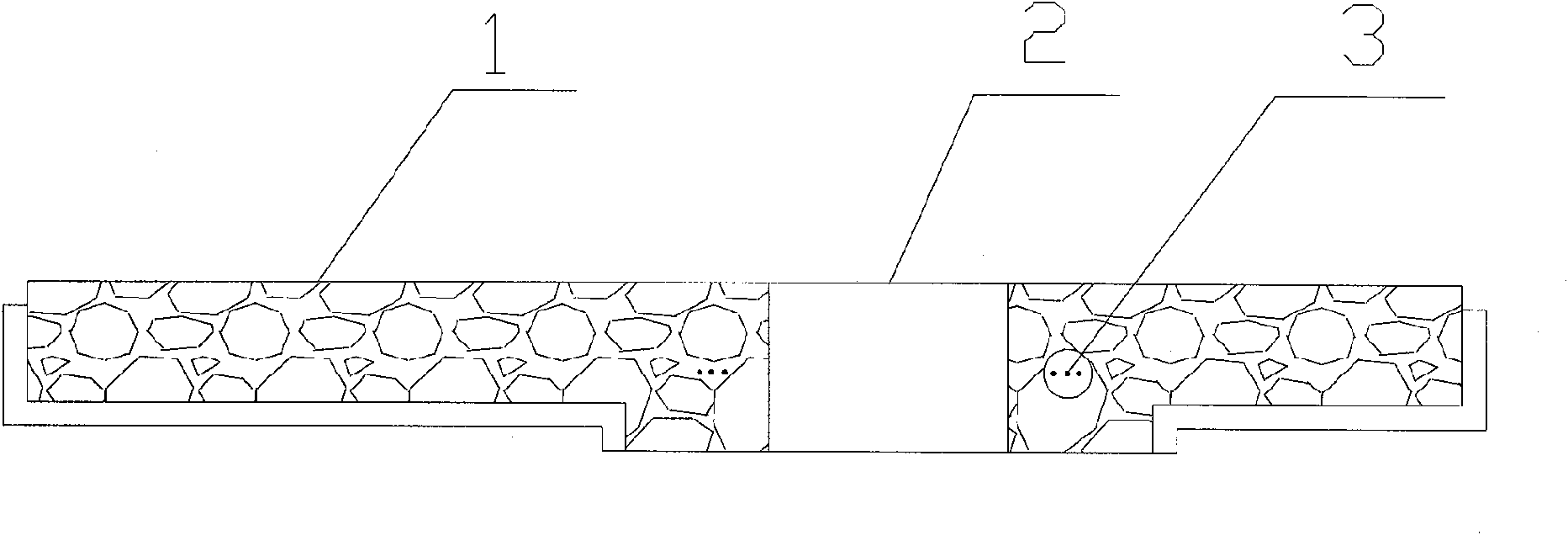

A ceramic monolithic multi-channel module support (10) has a module hydraulic diameter (102) in a range about 9 to 100 mm, an aspect ratio of the module hydraulic diameter (102) to a module length (104) greater than 1, a plurality of feed flow channels (110) distributed substantially in parallel over a module cross-section, the plurality of feed flow channels (110) having a size and shape defining a channel density in the range of about 50-800 channels / in2 (7.8-124 channels / cm2) in a module frontal area, a channel hydraulic diameter (112) in the range of about 0.5-3 mm, a rim distance (120) having a thickness greater than 1.0 mm (0.04 in), and a percent open frontal area (OFA) in the range of about 20-80%.

Owner:CORNING INC

Alumina titanate ceramica lift tube preparation method

The invention relates to a preparation method of ceramic materials; the raw materials used in the method comprises alumina powder, titanium oxide powder, synthetic material of aluminium titanate and stabilizing agents, wherein, the stabilizing agents comprise magnesium oxide, silica dioxide, ferric oxide, chromium dioxide and zirconium oxide. The conditions of the preparation process are as follows: firstly, the raw material and water carry out ball milling and pulping by a wet method; secondly, the slurry is granulated and dried into powder with the water content to be less than 2 percent; thirdly, isostatic pressing molding is carried out; fourthly, the powder is sintered into a lift tube of aluminium titanate ceramics under the conditions that the sintering temperature is 1,480 to 1,550 DEG C, the sintering time is 20 to 30 hours and the sintering atmosphere is oxidizing atmosphere; wherein, alumina powder, titanium oxide powder, stabilizing agents and water carry out ball milling and pulping by the wet method and granulation to prepare particle size, then the synthetic material of aluminium titanate is prepared by sintering. The product prepared by the method is characterized by low price, non-infiltration of alumina melt, no reaction, high intensity, strong thermal shock resistant capability, no slag during the using process, long service life, etc.

Owner:DONGYING XINKEXINTETAO

Composite combining corundum based refractory materials

ActiveCN101423401AImprove high temperature resistanceStrong thermal shock resistanceSuperplasticizerMaterials science

The invention relates to a composite sialon-corundum fire-resisting material, which is characterized in that the formulation of the fire-resisting material comprises the following: 30 to 54 percent of corundum or aluminum oxide hollow sphere the diameter of which is between 3 and 1 millimeter, 7 to 30 percent of the corundum or the aluminum oxide hollow sphere the diameter of which is between 1 and 0.0088 milliliter, 16 to 30 percent of corundum powder the diameter d90 of which is less than 0.088 millimeter, 3 to 10 percent of alpha aluminum oxide micro powder, 2 to 8 percent of hydrated aluminum oxide, 0.2 to 2 percent of siliceous dust, 0 to 2 percent of barium aluminate cement, 0.05 to 0.4 percent of efficient water reducing agent (which is prepared from polycarboxylic acid, sulfonated naphthaldehyde polymer and sulfonated melamine polymer), 1 to 6 percent of polyacrylic acid emulsion, and 1 to 6 percent of water. The composite sialon-corundum fire-resisting material obviously has the advantages of coagulation, hardening, demolding, drying and heating performances remarkably similar to a low cement casting material, and good high-temperature resistant performance, and can be made into various products or be used as an unshaped material.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

Preparation method of filtering membrane used for industrial air filter

InactiveCN107511077AHigh affinityPrevent flocculationSemi-permeable membranesDispersed particle filtrationFiberFiltration membrane

The invention discloses a preparation method of a filtering membrane used for an industrial air filter. The preparation method of the filtering membrane includes the following steps that 1, ceramic adhesive is prepared; 2, a sodium carboxymethylcellulose solution is prepared; 3, a composite supporting body is prepared; 4, a ceramic fiber transition layer is prepared; 5, the filtering membrane is prepared. The preparation method is simple and easy to implement, the preparation technology has high anti-fake performance, the prepared filtering membrane is uniform in structure, and has good high temperature resistance, high pressure resistance and chemical stability, filtering pressure is reduced, and the service life is prolonged.

Owner:江苏华强新能源科技有限公司

Preparation method of specific high-performance wear-resistant castable for coal burner

InactiveCN101805195AImprove thermal shock resistanceStrong thermal shock resistanceWear resistantTemperature resistance

The invention discloses a preparation method of specific high-performance wear-resistant castable for a coal burner, which comprises the following steps that: (1) raw material which comprises corundum, carborundum, corundum powder, alumina powder, silica micro powder, pure calcium aluminate cement, stainless steel fiber, anti-explosion fiber and water reducing agent is homogenized; (2) the homogenized raw material is poured into a forced mixer to be mixed, dry material is put in at one step according to the capacity of the mixer to be dry mixed for 2 to 6min and added with water to be wet mixed for 4 to 8min, the input of the water is strictly controlled, so that the water is stably 4 to 5 percent of the total weight of the raw material; and (3) the product is naturally cured for more than 50h at 25DEG C of ambient temperature and stripped after being fully hardened. The product prepared by the preparation method is characterized by high temperature resistance, anti-erosion, wear resistance and other performance, and has long service life.

Owner:蒋美芳

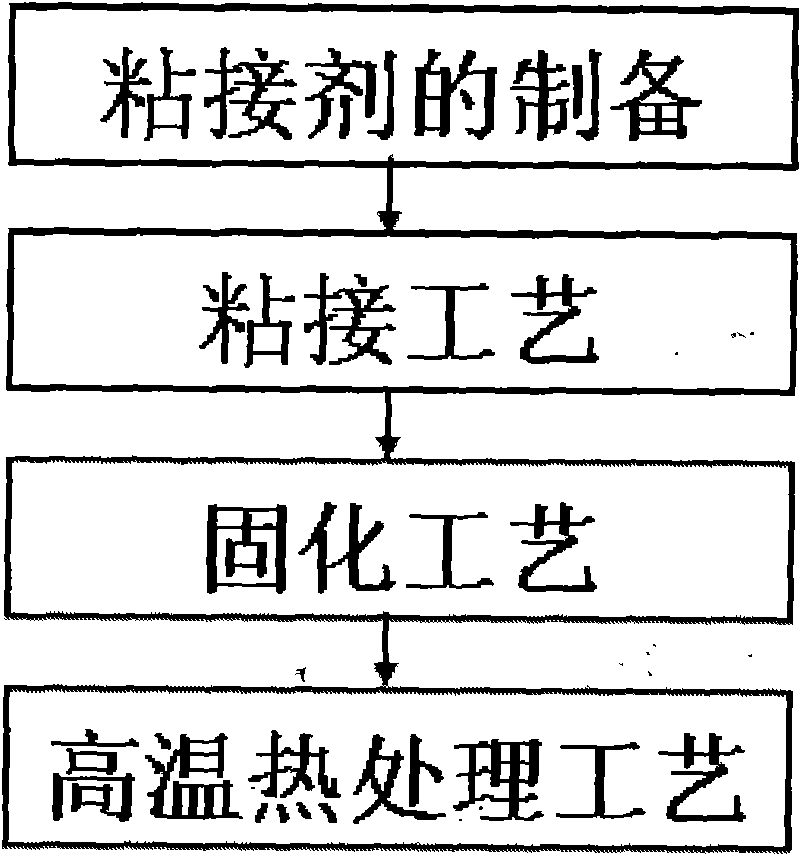

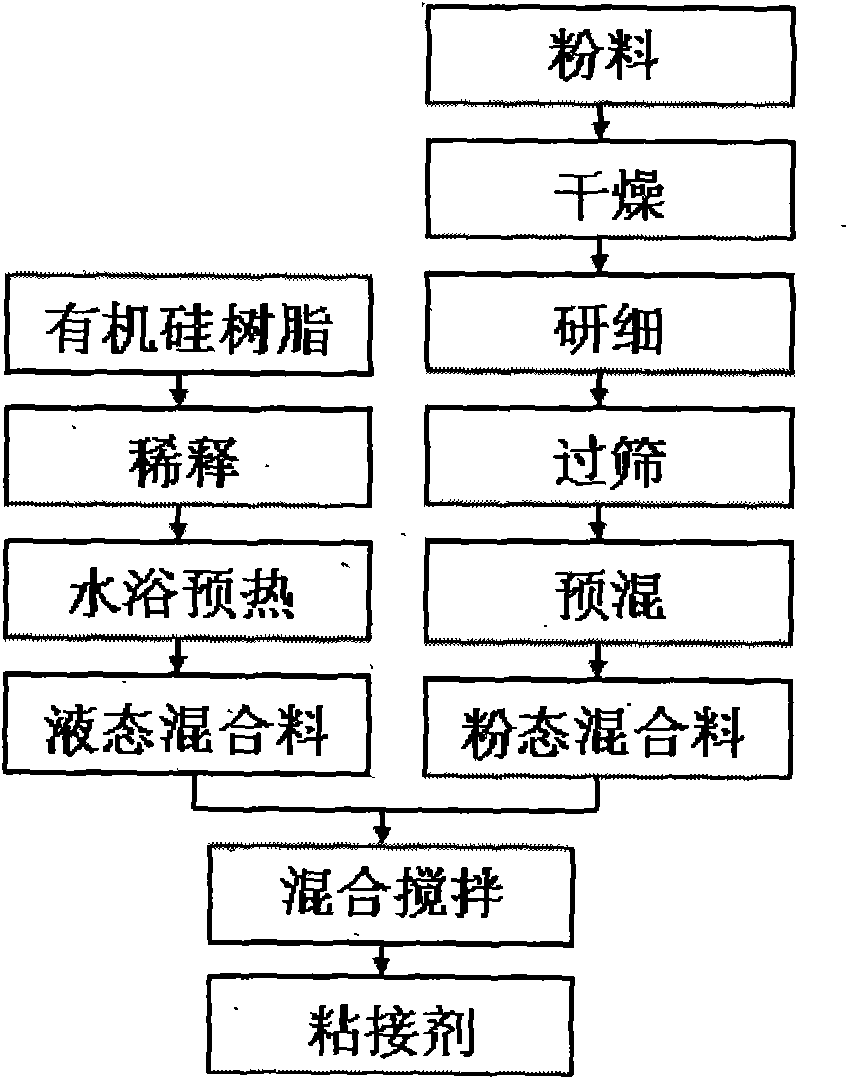

Preparation method of high temperature adhesive used for carbon-based composite material

A preparation method of a high temperature adhesive used for a carbon-based composite material includes the following steps: step 1. preparation process of high temperature adhesive: mixing 35-40wt.% of organic silicon resin, 25-30wt.% of low melting point filler, 15-20wt.% of boron powder, 15-25wt.% of silicon powder and 0.1-0.5wt.% of carbon fiber to form the adhesive; and step 2. adhesive solidification and high-temperature heat treatment process: during adhering process, uniformly coating the adhesive on an adhesion surface of the carbon-based composite material with the surface carved with a regular fine groove, then putting the carbon-based composite material in a high vacuum carbon tube furnace to be solidified at the temperature of 300 DEG C for 3h in a vacuum environment with 0.1MPa of vacuum degree, during the solidification, applying 2.5Mpa pressure on the material, then heating the material at the heating rate of 50 DEG C / h, and finally, conducting heat treatment for 1h atthe high temperature of 1, 700 DEG C. The preparation cost is low, the bonding strength is high, and the adhesive has resistance to high temperature as well as thermal shock. Besides, after 50 times of thermal circulation at the temperature of 1, 500 DEG C, the material can still maintain certain strength. The high temperature adhesive has broad practical value and application prospect in the field of the carbon-based composite materials.

Owner:BEIHANG UNIV

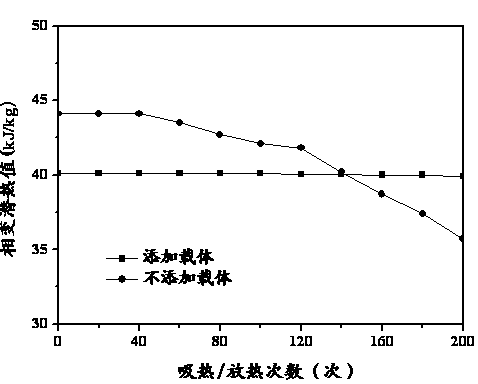

Phase-change energy storage floor tile and manufacturing method thereof

The invention discloses a phase-change energy storage floor tile and a manufacturing method thereof. According to a formula, the floor tile comprises: 50-100 parts of a phase change material, 100 parts of an inorganic flame retardant and 40-100 parts of a high polymer elastomer, wherein the phase change material consists of: 30-70 parts of cement, 30-50 parts of fly ash, 5-20 parts of gamma-alumina, and 50-100 parts of a phase change substance. The floor tile is manufactured by: first adsorbing the phase change substance into a porous substance composed of cement, fly ash and gamma-alumina in a proper portion, and then subjecting the adsorbed porous substance, the flame retardant and the high polymer elastomer to mixing. The obtained floor tile has the characteristics of high strength, good thermal shock resistance and wear resistance, difficult breackage, stable chemical properties, and strong thermal storage / refrigeration capability, and can prevent the phase change substance from seeping from the energy storage floor tile. And the phase change material has the advantages of long service life, good flame retardance and environmental performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Refractory castable for tundish cover

The invention discloses a refractory castable for a tundish cover. The refractory castable is prepared from the following components in parts by weight: 50-80 parts of magnesia, 5-20 parts of dolomite, 5-10 parts of zircon, 1-20 parts of carbon, 2-5 parts of water-free binder and 0.2-1 part of urotropine. The magnesia, the dolomite and the zircon are mixed to prepare particles and fine powder, wherein the part number of the particles is 35-55, the part number of the fine powder is 45-65, the particle size of the particles ranges from 3.0 to 2.0mm, the particle size of the fine powder is 2.0-0.5mm. The refractory castable has excellent thermal shock resistance and breakage and peel resistance.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

Sialon complex phase ceramic lift tube and production method thereof

The invention relates to a sialon composite ceramic lift tube and a preparation method thereof. The weight percents of the raw materials forming the composite ceramic lift tube are: 25-50 percent of silicon nitride, 15-30 percent of quartz, 5-20 percent of aluminum dioxide, 0.01-0.1 percent of yttria, 20-40 percent of carborundum, 1-10 percent of zirconia, 0.01-0.06 percent of acrylamide, 0.001-0.005 percent of N, N'-methylenebisacrylamide, 0.1-0.7 percent of polymethacrylic acid amine and 0.05-0.2 percent of ammonium persulfate. The preparation method comprises: adding pre-mix liquid to a ball mill in advance, adding the silicon nitride, the quartz, the yttria, the aluminum dioxide, the carborundum and zirconia in sequence and ball-milling for 15-30 hours; adding the ammonium persulfate to the sizing agent, vacuumizing by a vacuum agitator and injecting into a mold to be solidified; demolding, drying and sintering at the temperature of 1300-1600 DEG C to obtain the finished product. The sialon composite ceramic lift tube is characterized by long service life, high strength, strong thermal shock resistance and low cost, which is not infiltrated or reacted with aluminum melt.

Owner:DONGYING XINKEXINTETAO

Method for preparing porous ceramic by polycrystalline Al#-[2]O#-[3] fiber preforming method

InactiveCN1629101ASuitable for industrial productionStrong thermal shock resistanceCeramicwareFiberSlurry

The invention provides a method for preparing porous ceramic by polycrystalline Al#-[2]O#-[3] fiber preforming method which comprises, (1) mixing aluminium oxide powder, clay, high temperature bonding agent, slurry additive by the mass ratio of 70-80, 10-15, 4-19, 1-2 with water, ball grinding to prepare slurry, then mixing slurry, dispergator and pore forming agent to prepare filled slurry, (2) short cutting the polycrystalline Al2O3 ceramic fiber, mixing and dispersing in water, charging binding agent to prepare fabric paste, (3) injecting the fabric paste into die to obtain pre-shaped body and drying, (4) placing the dried pre-shaped body into gypsum die, then injecting into filling slurry and evacuating, (5) subjecting the pre-shaped body filled with slurry to drying and high temperature sintering.

Owner:SHANDONG UNIV OF TECH

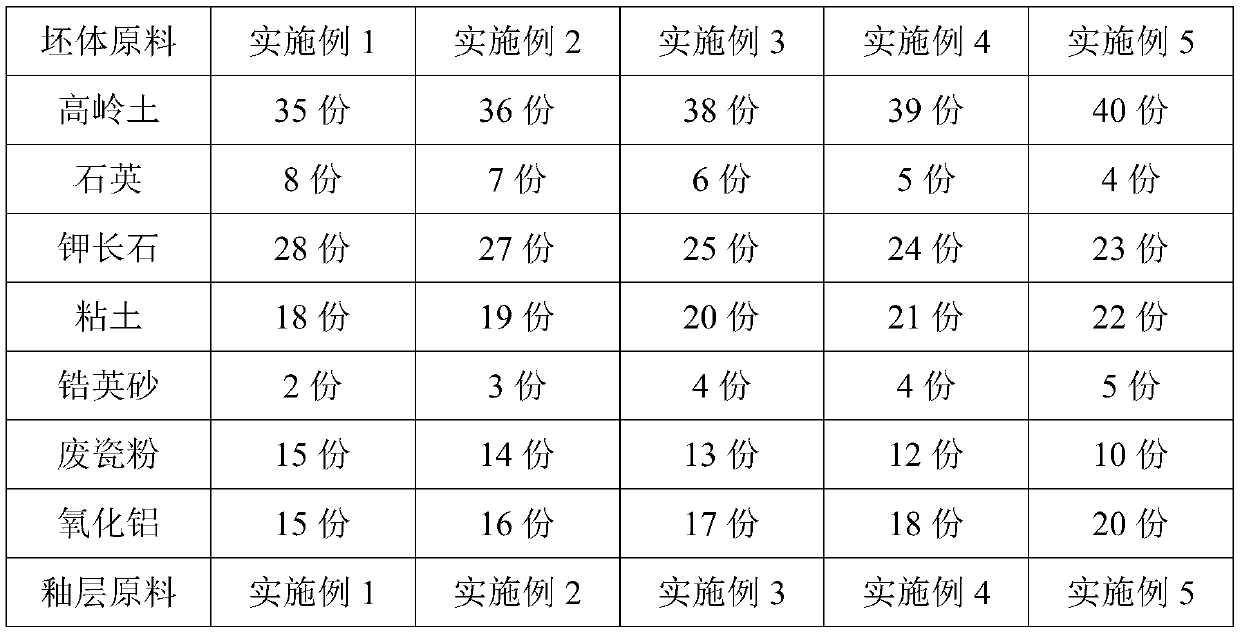

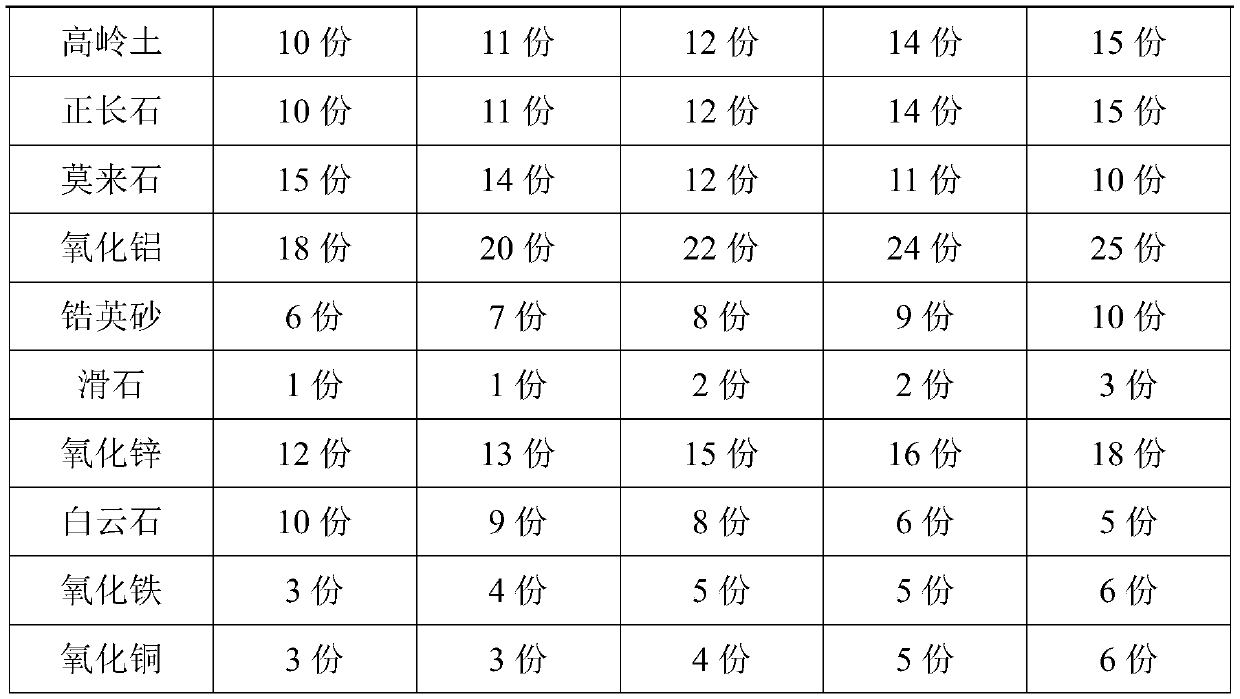

Wear-resistant domestic ceramic product and preparation method thereof

InactiveCN110117184AHigh strengthHigh hardnessCeramic materials productionClaywaresWear resistantMullite

The invention provides a wear-resistant domestic ceramic product and belongs to the technical field of ceramics. The ceramic product comprises a matrix and glaze. The matrix is prepared from, by weight, 35-40 parts of kaolin, 4-8 parts of quartz, 23-28 parts of potash feldspar, 18-22 parts of clay, 2-5 parts of zircon sand, 10-15 parts of waste ceramic powder and 15-20 parts of alumina. The glazeis prepared from, by weight, 10-15 parts of kaolin, 10-15 parts of orthoclase, 10-15 parts of mullite, 18-25 parts of alumina, 12-18 parts of zinc oxide, 1-3 parts of talc, 6-10 parts of zircon sand,5-10 parts of dolomite, 3-6 parts of ferric oxide and 3-6 parts of copper oxide. A preparation method of the wear-resistant domestic ceramic product includes the following steps that matrix slurry isprepared, glaze slip is prepared, and green bodies are immersed in the glaze slip, then subjected to bisque firing and finally sintered at 1280-1380 DEG C. The domestic ceramic product obtained by theprovided raw materials and the process through sintering has the advantages of good wear resistance and high shock resistance.

Owner:福建省德化县合和陶瓷技术开发有限公司

Preparation method of high-temperature smoke filter ceramic material with high thermal shock resistance

InactiveCN102442831AGood effectSuitable for high-volume industrial productionCeramicwarePorositySlag

The invention discloses a preparation method of a high-temperature smoke filter ceramic material with high thermal shock resistance, wherein the method takes beta-cordierite, potash feldspar, spodumene and kaolin as raw materials, takes mullite as additive and takes carbon powder, starch, silicon carbide powder, limestone, sawdust, coal slag and ceramic waste as hole-forming agent; the high-temperature smoke filter ceramic material with high porosity, high thermal shock resistance, high compression strength, excellent filter performance and controllable aperture can be prepared by ball grinding, molding and sintering processes. The source of the pore-forming agent is wide; the die pressing, cold isostatic pressing and casting molding can be adopted, so that the operation is convenient andthe production cost is low; the filter ceramic material has controllable aperture and porosity, and excellent high temperature resistance and thermal shock resistance. The technology provided by the invention solves dust filter problem of high-temperature and wet gas well and also is applied in kinds of fields such as separation and purification, sound absorption, catalyst carrier and the like.

Owner:SOUTH CHINA UNIV OF TECH

Sintered NdFeB magnet surface high anti-corrosion coating and preparation method thereof

ActiveCN109468576AHigh temperature resistantCorrosion resistantMolten spray coatingNanoparticlePliability

The invention provides a sintered NdFeB magnet surface high anti-corrosion coating and a preparation method thereof. The preparation method includes the following steps: nanoparticles are subjected togranulation treatment to obtain coating particles, wherein the nanoparticles are a mixture of nanometer zirconia, nanometer aluminum powder and nanometer zinc powder; the pretreated sintered NdFeB magnet surface is preheated; and a nanometer-structured coating is prepared on the preheated sintered NdFeB magnet surface by adopting a plasma spraying mode. The nanometer-structured coating composed of the nanometer-zirconia, the nanometer-aluminum powder and the nanometer-zinc powder is prepared on the preheated sintered NdFeB magnet surface by adopting the plasma spraying mode, the problems of poor anti-corrosion and environmental pollution during production, preparation and usage process of a conventional coating on the sintered NdFeB magnet surface are solved. The high anti-corrosion coating prepared according to the preparation method has good flexibility, adhesion, impact resistance, wear resistance, high-temperature resistance and anti-corrosion, and the sintered NdFeB magnet can beprevented from corrosion persistently by the anti-corrosion coating.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

High-temperature fireproof kiln material and preparing method thereof

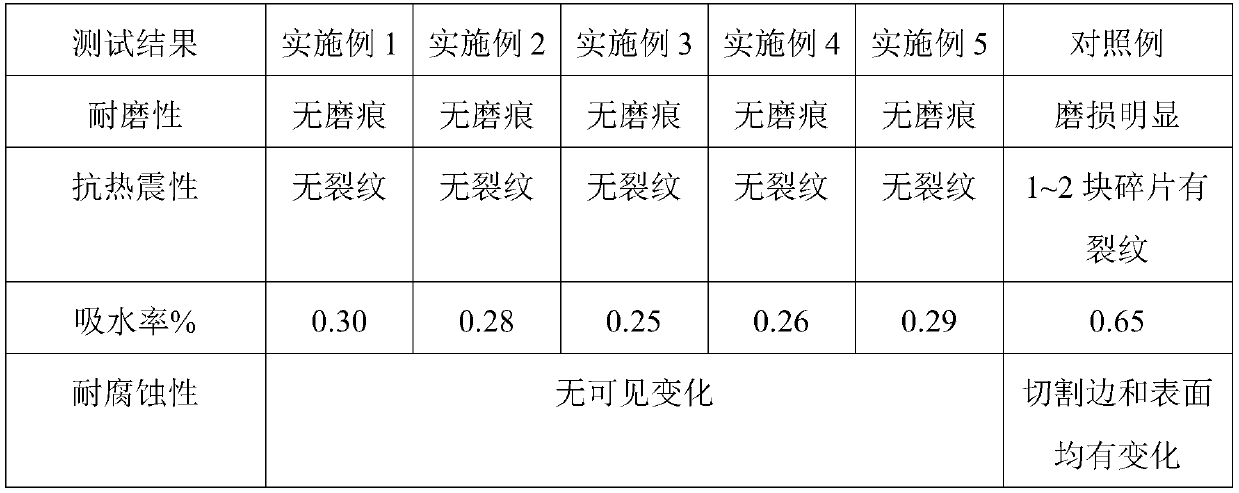

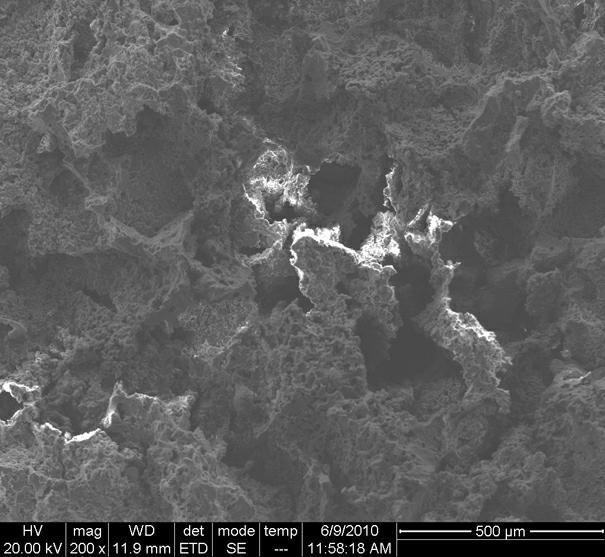

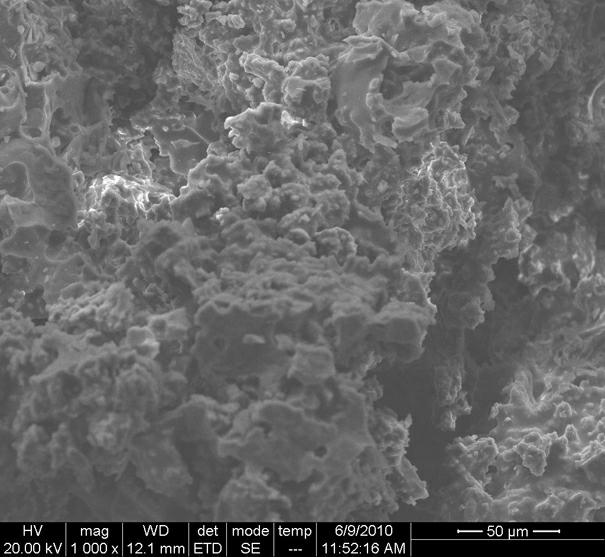

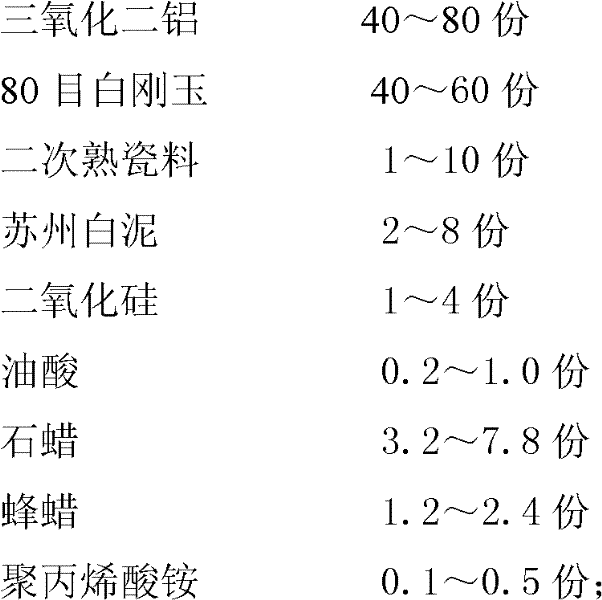

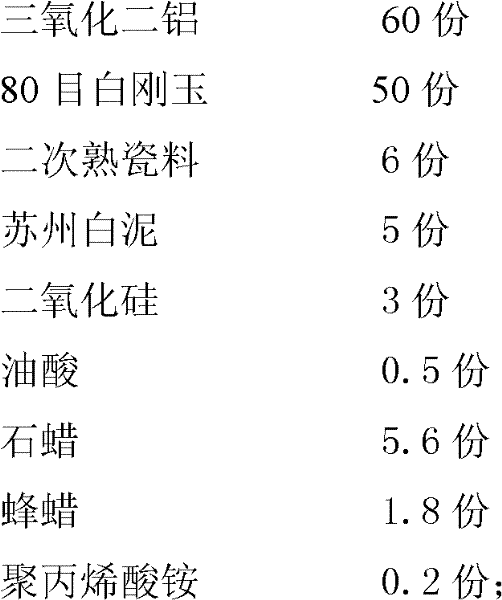

The invention discloses a high-temperature fireproof kiln material, which comprises the following components, by weight, 40 to 80 parts of aluminum oxide, 40 to 60 parts of 80-mesh white corundum, 1 to 10 parts of secondary ripe porcelain, 2 to 8 parts of Suzhou lime sludge, 1 to 4 parts of silicon dioxide, 0.2 to 1.0 part of oleic acid, 3.2 to 7.8 parts of paraffin wax, 1.2 to 2.4 parts of wax and 0.1 to 0.5 part of ammonium polyacrylate. Air holes of the kiln material utilizing the secondary ripe porcelain as raw materials are more compact and higher in density, and the kiln material is much lower in contractibility rate and high in heat and shock resistance stability, is not easy to burst when used at a high temperature, capable of bearing high temperature ranging from 1800 DEG C to 2000 DEG C, long in service life and has excellent performances of high strength, high fire resistance, high wear resistance and the like by the aid of the secondary ripe porcelain which is resistant tohigh temperature and high in wear resistance. Further, the secondary ripe porcelain as waste can be recycled, so that cost is saved, waste can be changed into treasure, and pollution to the environment is reduced. The high-temperature fireproof kiln material is simple in preparing process, easy to control in conditions and can be produced in large scale industrially.

Owner:CHANGSHU INNOVATION CERAMICS

Refractory material used for glass kilns

InactiveCN107162615AAvoid crackingPrevents the effects of sinteringGlass furnace apparatusGlass productionBoron carbideSilicon dioxide

The invention relates to the technical field of refractory materials, and discloses a refractory material used for glass kilns. The refractory material used for glass kilns comprises, by weight, 10-15 parts of silica, 1-3 parts of ferriferrous oxide, 1-8 parts of alumina, 1-2 parts of propylene glycol, 3-7 parts of acrylamide, 1-2 parts of aluminum nitride powder, 1-2 parts of yttrium oxide powder, 2-7 parts of barium sulfate, 1-1.5 parts of boron carbide, 0.5-1.5 parts of cerium oxide powder, 10-12 parts of phenolic resin, 6-8 parts of muscovite powder, 1-2 parts of sericite powder, 10-15 parts of polycarbosilane, 2-6 parts of zirconium oxide and 5-6 parts of magnesium oxide. The invention also provides a preparation method of the refractory material for glass kilns. The preparation method comprises the following steps: fully mixing the raw materials of all above components, ageing the raw materials, placing the aged raw materials in an electric furnace, heating the aged raw materials, cooling the heated raw materials, pouring the cooled raw materials into a precast mold, and cooling and annealing the raw materials. The refractory material used for glass kilns has the advantages of high thermal shock resistance, high strength, high toughness, good corrosion resistance and high wear resistance.

Owner:长兴华悦耐火材料厂

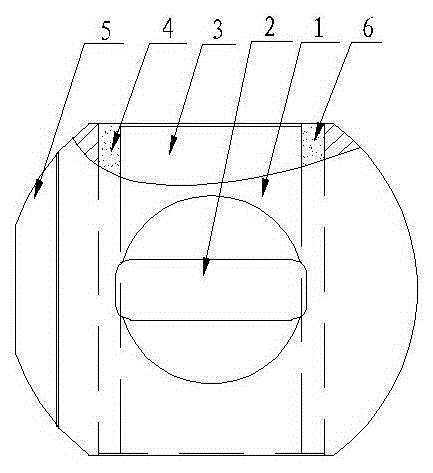

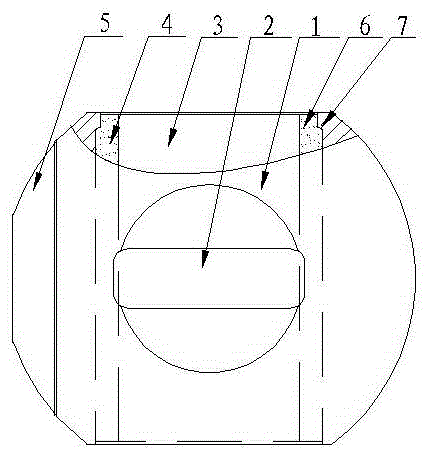

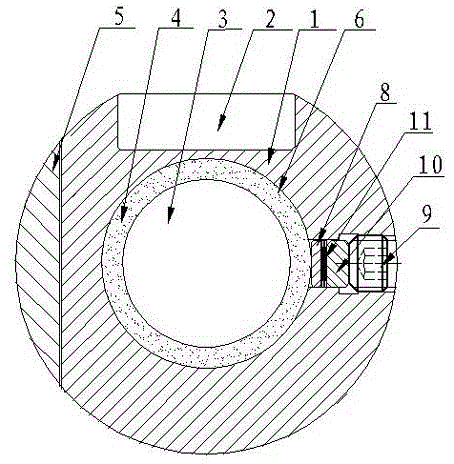

Composite ball core for ball valve

InactiveCN104806782AAvoid corrosionPrevent tamperingPlug valvesValve member-seat contactsCavity wallMaterials science

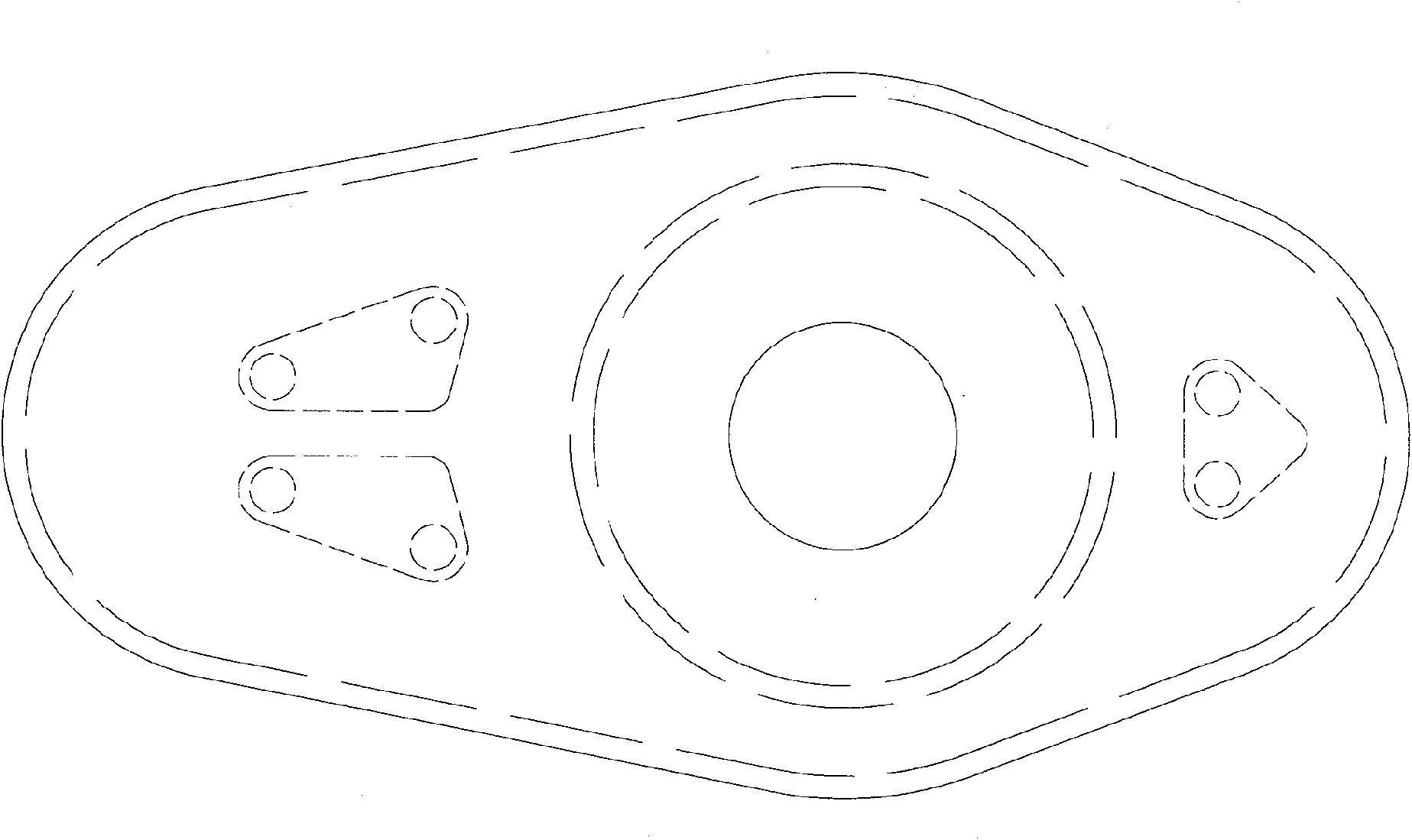

The invention discloses a composite ball core for a ball valve. The composite ball core is composed of a metal ball core substrate, a valve rod hole and a flow channel cavity and is characterized in that a ceramic flow channel is fixed in the flow channel cavity and close to the cavity wall, and a ceramic sealing surface is used as the sealing surface of the metal ball core. The composite ball core has erosion resistance and pressure resistance when being comparable with a full ceramic ball.

Owner:YANTAI KINGWAY SCI & TECH

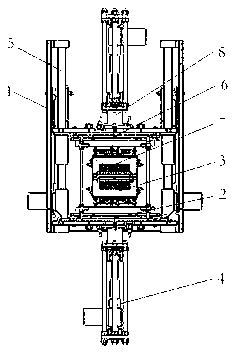

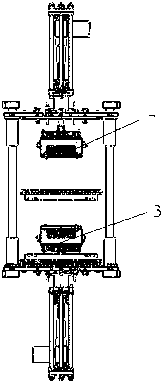

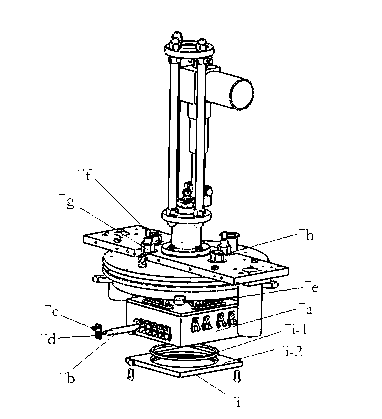

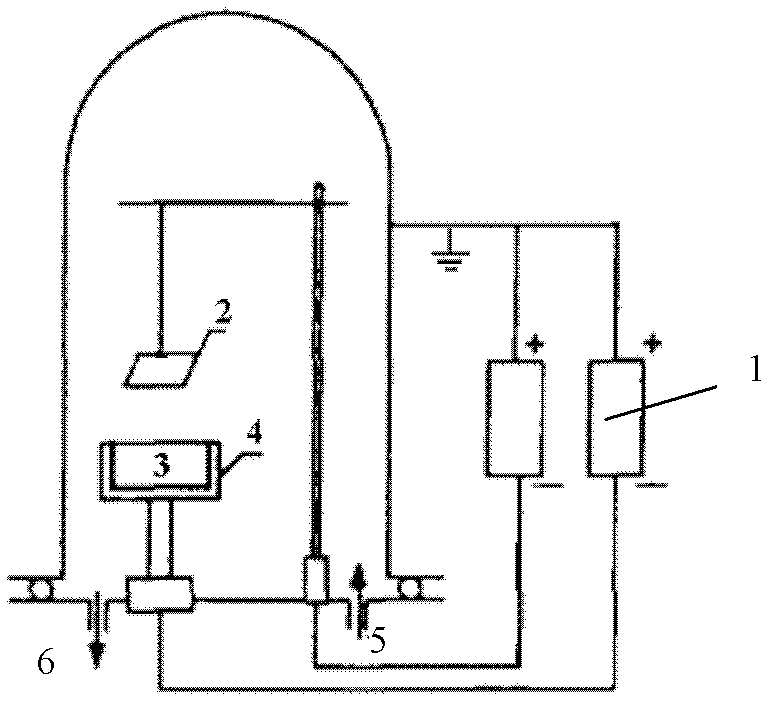

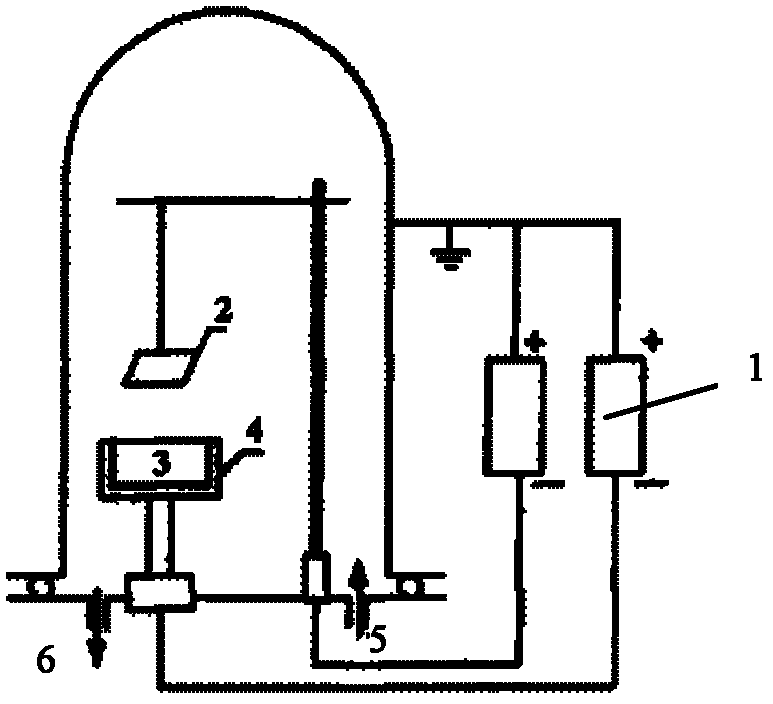

Evaporation furnace capable of shortening distance and rapidly increasing and reducing temperature, and manufacturing method thereof

InactiveCN103266301AGuaranteed uniformityGuaranteed experimental efficiencyVacuum evaporation coatingSputtering coatingEvaporationEngineering

The invention discloses an evaporation furnace capable of shortening distance and rapidly increasing and reducing temperature, and a manufacturing method thereof. The evaporation furnace comprises an upper heating table and a lower heating table, wherein the upper heating table and the lower heating table are oppositely arranged inside a slot groove up and down; the heating table has the freedom of moving up and down along the slot bracket; the lower heating table has the freedom of rotating along the bottom part of the slot bracket; a sample table capable of loading an evaporation substrate is arranged at the bottom part of the upper heating table; an evaporation source opposite to the sample table is arranged at the top part of the lower heating table; short-wave infrared lamp tubes are inserted into the upper heating table and the lower heating table; and an air inlet and outlet and a cooling water inlet and outlet communicated with the heating tables are arranged inside the upper heating table and the lower heating table. The upper and lower heating tables can achieve the temperature difference which is much greater than that of the traditional equipment within the shortest distance by utilizing up and down opposite mode of dual temperature fields and using a water-cooling cavity; and the evaporation distance and the temperature difference of the upper and lower temperature fields are increased and reduced by adjusting the distance between the upper and lower heating tables, so that adjustable solid-phase evaporation is achieved.

Owner:合肥科晶材料技术有限公司

Coating glaze and use method thereof

ActiveCN107601883AImprove performanceImprove heating efficiencyMelt-holding vesselsBall millSpray coating

The invention discloses a coating glaze, which comprises main materials and auxiliary materials, wherein the main materials comprise, by weight, 15-25% of quartz, 3-10% of boron carbide, 40-60% of boron glass, 3-10% of toner, 5-15% of glaze dissolving powder, and 5-15% of white corundum, and the auxiliary materials comprise a binder accounting for 20-35% of the total weight of the main materials,water glass accounting for 30-50% of the total weight of the main materials, a dispersant accounting for 0.5-1% of the total weight of the main materials, and a suspending agent accounting for 0.2-0.5% of the total weight of the main materials. The invention further discloses a use method of the coating glaze, wherein the use method comprises: 1, mixing the main materials and the auxiliary materials, and carrying out ball milling for 2-3 h to prepare a uniformly-mixed coating glaze composition; and 2, carrying out spray coating at a working area, and carrying out high temperature heating. According to the present invention, quartz, boron carbide, boron glass and white corundum are used as the main materials, have different melting temperatures, and can well react with each other during thehigh temperature firing to generate the dissolving phase, wherein the continuous casting member and the coating glaze can be closely combined through the dissolving phase so as to solve the technicalproblem of the unstable use performance of the physical coating.

Owner:ZHEJIANG IRON LION HIGH TEMPERATURE MATERIALS CO LTD

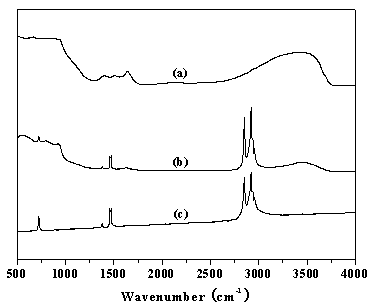

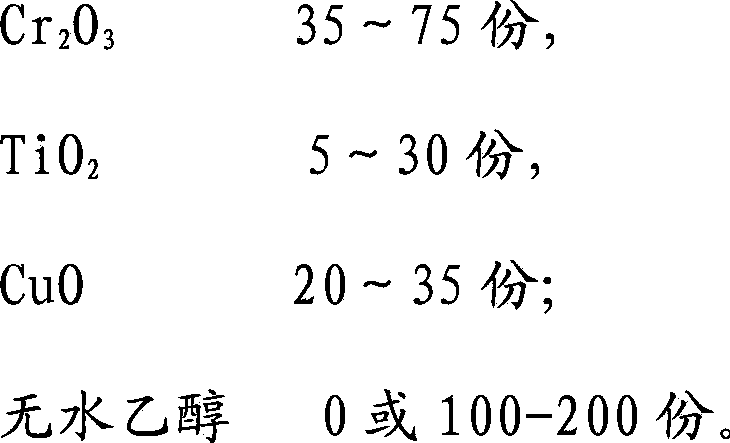

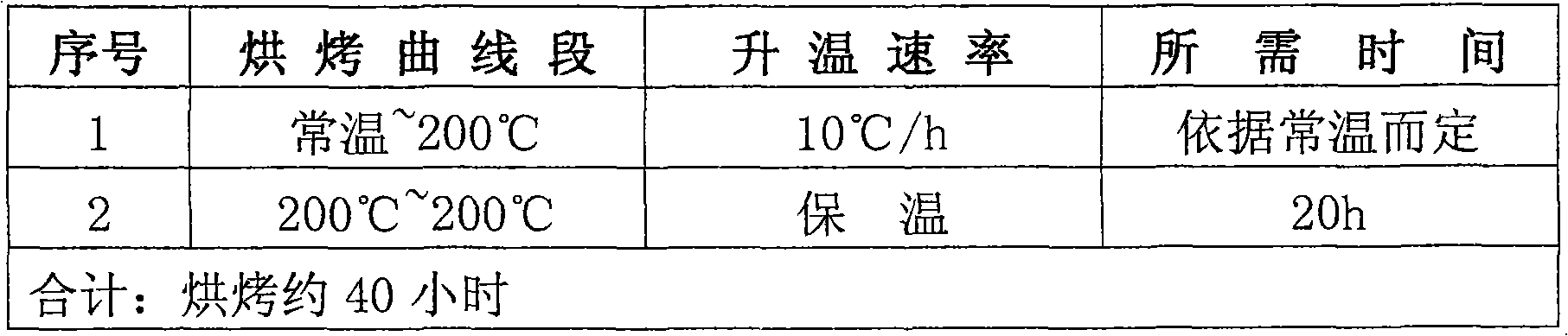

Preparation method of infrared coating used for household cooking utensils, and preparation method of infrared coat

The invention relates to a preparation method of an infrared coating used for household cooking utensils, and a preparation method of an infrared coat. The problems of low emissivity, large thermal efficiency loss and limited coating shape of coats existing in the prior art at a high temperature are mainly solved in the invention. The infrared coating is synthesized by using an infrared composite filler and a high temperature resistant adhesive, wherein the composite filler is synthesized by using the following raw materials, by weight, 35-75 parts of Cr2O3, 5-30 parts of TiO2, 20-35 parts of CuO, and 0 / 100-200 parts of anhydrous ethanol. The preparation method of the infrared coating comprises the following steps: mixing the raw materials according to above proportions, ball-milling, carrying out high temperature roasting to prepare the infrared composite filler, ball-milling the infrared composite filler and the high temperature resistant adhesive in proportion, and mixing to prepare the infrared coating. The preparation method of the infrared coat is characterized in that the infrared coat with high emissivity is prepared by coating the infrared coating on the household cooking utensils through a reverse dip-coating process. The coat prepared in the invention still has a high emissivity at a high temperature, has a total infrared emissivity of above 0.90, has a superior thermal shock resistance, and can obviously improve the heating efficiency in order to realize energy saving. The reverse dip-coating process adopted in the invention is suitable for coating the cooking utensils with complex shapes.

Owner:辽宁省乌科新材料产业研究有限公司

Preparation method of solar heat absorption composite material

InactiveCN110423131AHigh mechanical strengthStrong thermal shock resistanceSolar heating energyAbsorbing elementsSlagMullite

The invention relates to a preparation method of a solar heat absorption composite material, belonging to the technical field of solar energy. The preparation method prepares the solar energy heat absorption composite material by adding andalusite, silicon carbide and silicon nitride, wherein the andalusite is an aluminosilicate mineral; after the andalusite is heated to 1350 DEG C under normal pressure, the andalusite begins to be converted into acicular mullite parallel to original crystals; the mullized andalusite is resistant to quenching and shock heating, has large mechanical strength, strong thermal impact resistance, strong slag resistance, high load conversion point, extremely high chemical stability and extremely strong chemical corrosion resistance; silicon carbide bonded silicon nitride has good oxidation resistance. In addition to good wear resistance, the silicon carbide in the material has high thermal conductivity and low thermal expansion coefficient, so that the silicon nitride bonded silicon carbide has excellent thermal shock resistance and acts as an obstacle and delay role in the penetration of external erosion media, and the solar heat absorption composite material has good chemical stability.

Owner:宁波宏翌能源科技有限公司

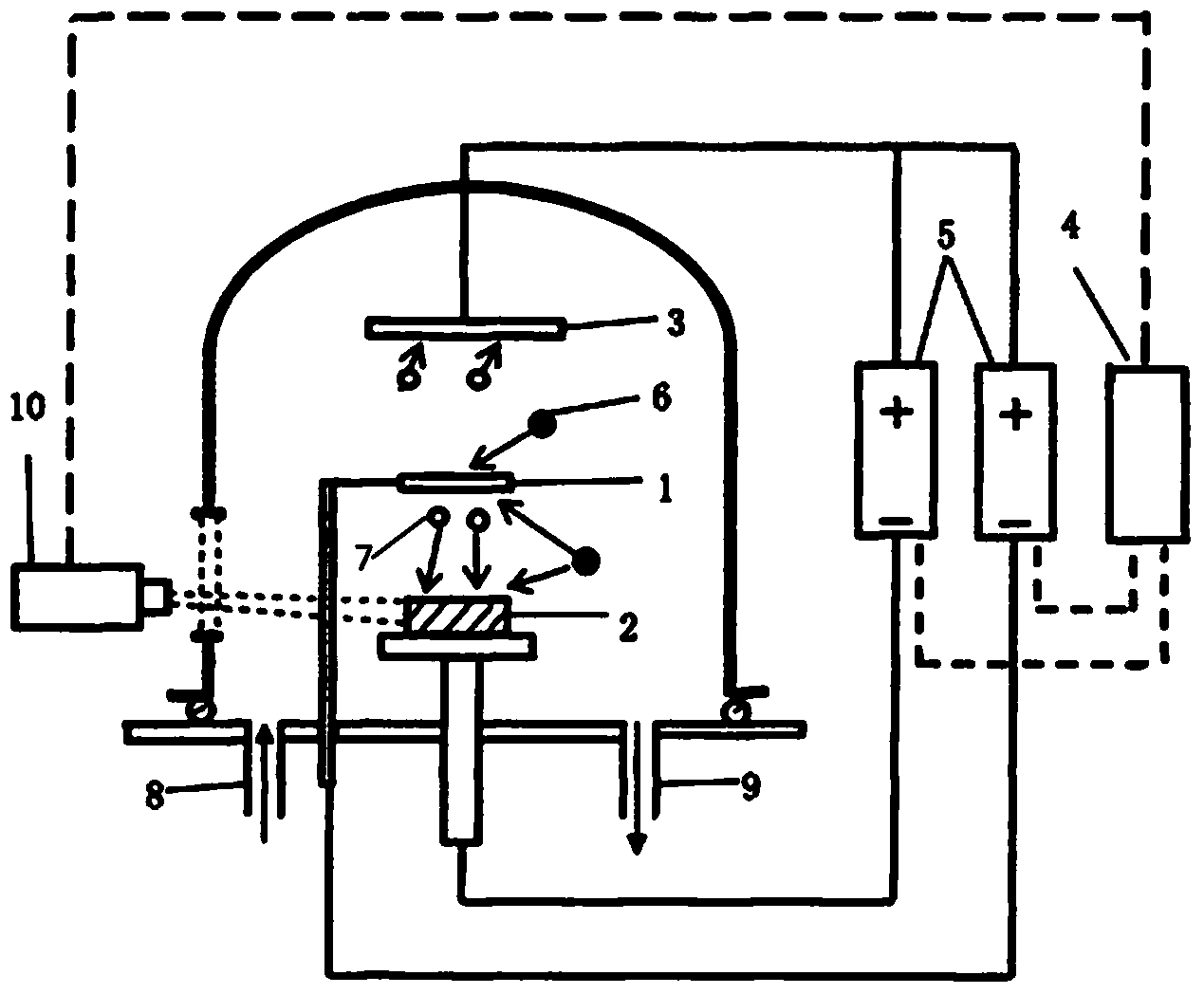

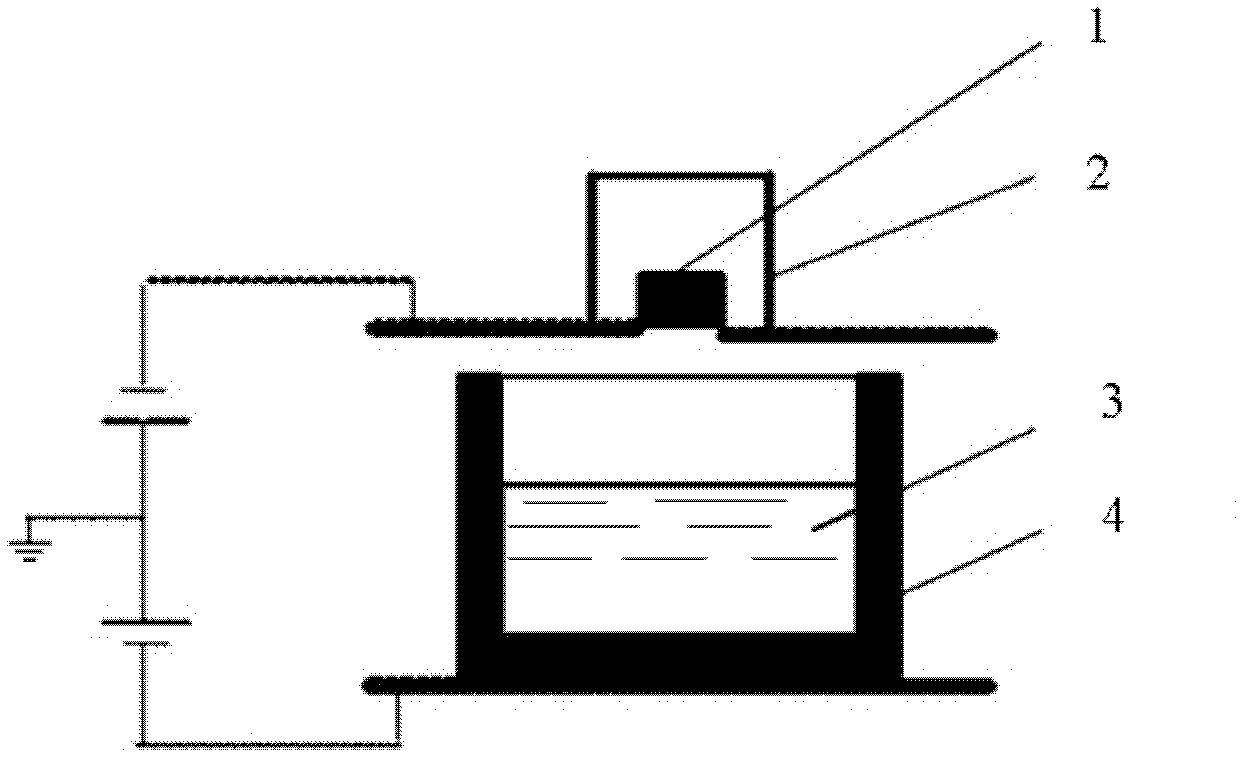

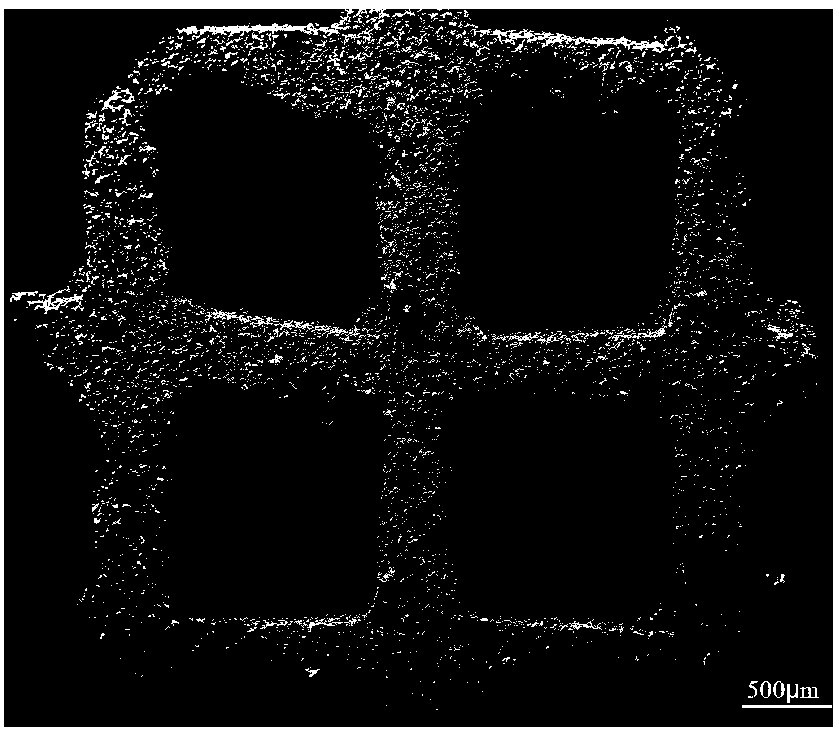

Method for diffusion coating of LaTaAlY alloy layer on surface of gamma-TiAl alloy

ActiveCN104388900AStrong thermal shock resistanceImprove the strengthening effectVacuum evaporation coatingSputtering coatingEvaporationOxidation resistant

The invention discloses a method for diffusion coating of a LaTaAlY alloy layer on the surface of gamma-TiAl alloy. The method comprises the following steps: heating a gamma-TiAl alloy workpiece and an LaTaAlY target material by utilizing glow discharge of two hollow cathodes; putting the LaTaAlY target material on a source electrode rack, heating to melt the LaTaAlY target material under bombardment of plasmas generated by glow discharge, so as to form evaporation and sputtering, depositing on the surface of the workpiece and diffusing inwards; and forming an LaTaAlY deposition layer which is 3-10 mu m and an LaTaAlY diffusion layer which is 5-10 mu m on the surface of the workpiece by regulating and controlling the working pressure, the source electrode voltage, the workpiece voltage and the source electrode-workpiece distance. By adopting the method, a diffusion coating treatment is carried out on the surface of the gamma-TiAl alloy workpiece, an excellent oxidation resistance can be given to the gamma-TiAl alloy workpiece under a high-temperature long-term service condition, and moreover the gamma-TiAl alloy workpiece has reliable bonding strength and excellent thermal shock resistance due to the existence of the diffusion layer with gradient compositions.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

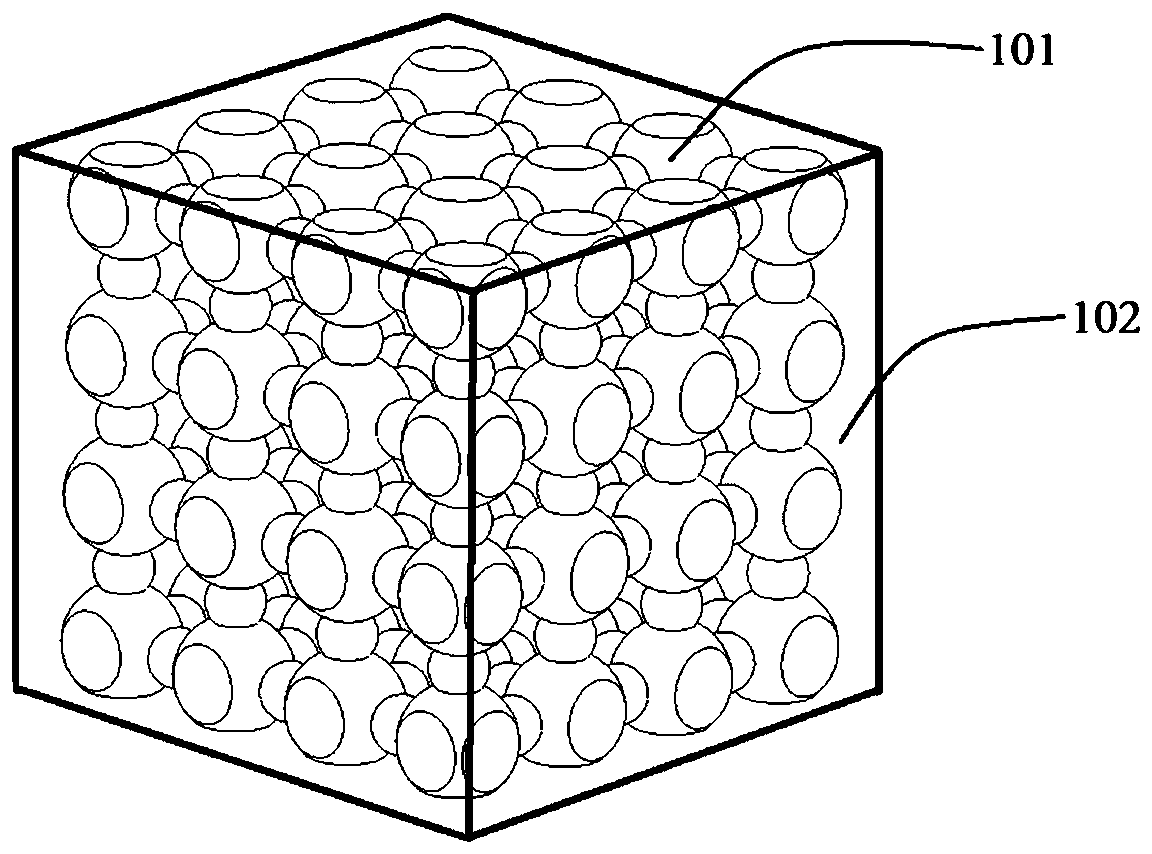

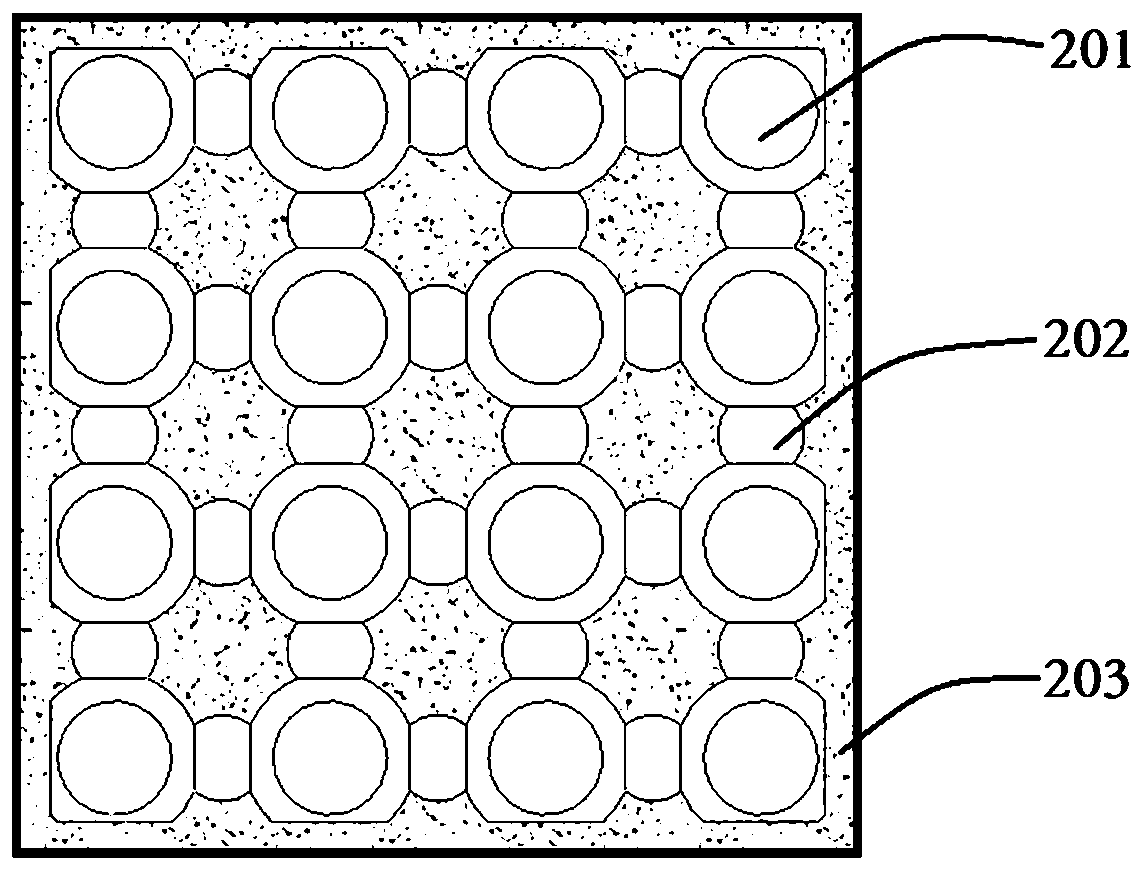

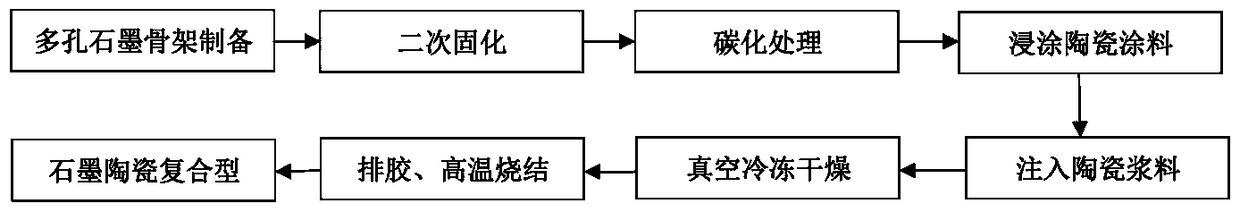

Graphite and ceramic composite material and preparation method thereof

ActiveCN108975936AGood chemical stabilitySmall coefficient of thermal expansionAdditive manufacturing apparatusCompound aSelective laser sintering

The invention provides a graphite and ceramic composite material and a preparation method thereof. The graphite and ceramic composite material is prepared by compounding a porous graphite framework and ceramic; the graphite and the ceramic are alternatively and uniformly distributed; the volume fraction of the porous graphite framework is 30 to 70%, and the balance amount is ceramic. The preparation method comprises the following steps of firstly, utilizing the porous graphite framework which is quickly prepared by a selective laser sintering forming technique, carbonizing, and coating the ceramic coating; utilizing a gel injection molding forming technique to fill the ceramic material, freeze-drying under the vacuum condition, discharging glue, and sintering at high temperature, so as toobtain the graphite and ceramic composite material. The graphite and ceramic composite material prepared by the preparation method has the characteristics that the heat conductivity is low, and the strength is high; the chemical stability is good, the heat expansion coefficient is low, the anti-thermal vibration ability is excellent, and the high-temperature metal liquid impact can be endured fora long time; after secondary mechanical cutting processing, the graphite and ceramic composite material can be repeatedly used for multiple times, and can replace the traditional water glass sand type; the graphite and ceramic composite material can be matched with the graphite casting in the production of steel castings.

Owner:CHINA THREE GORGES UNIV

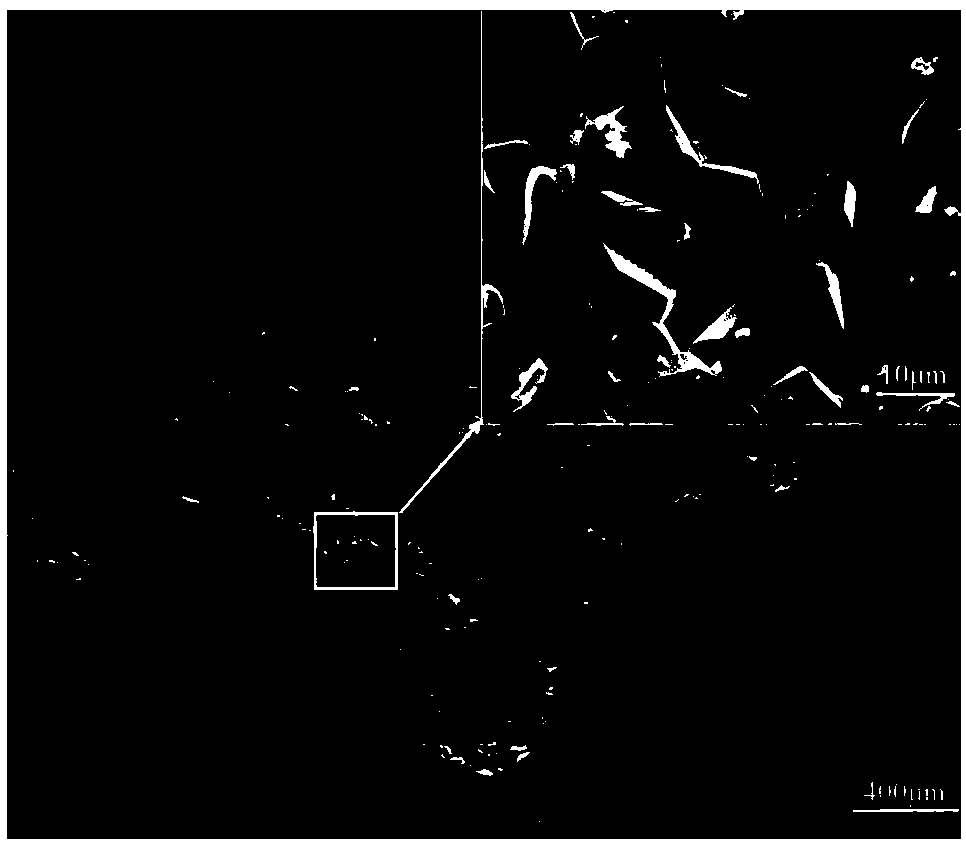

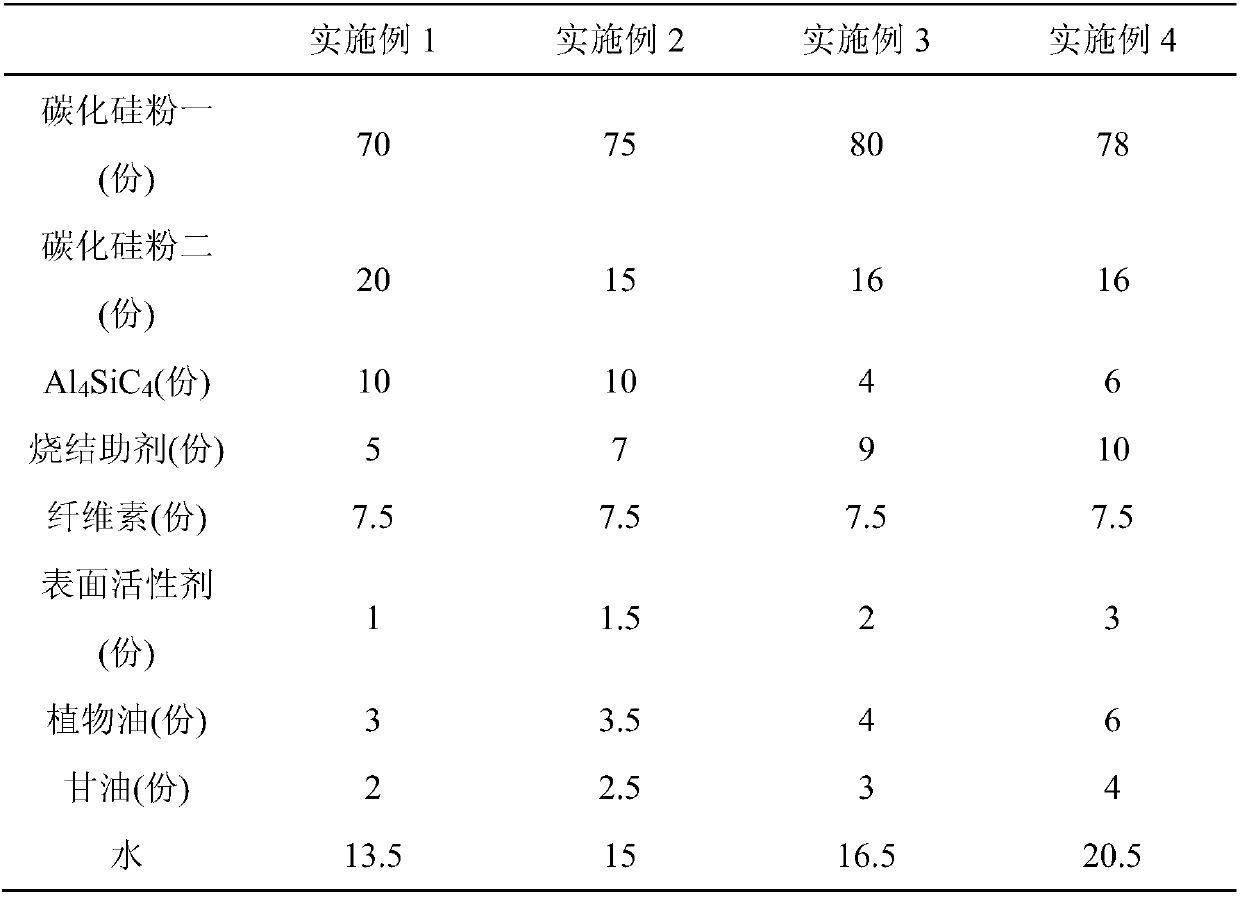

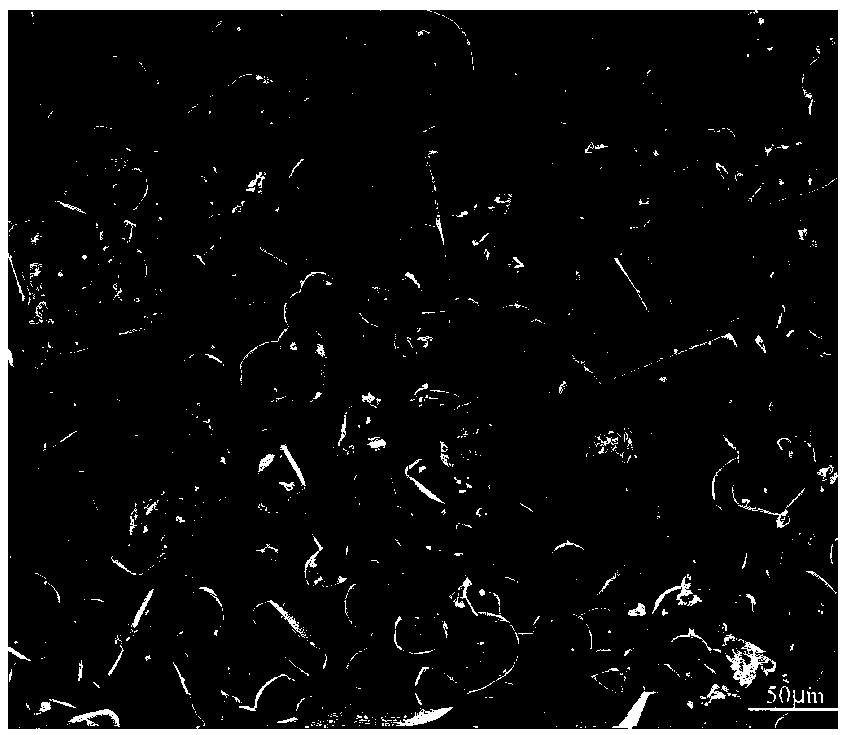

Al4SiC4 enhanced silicon carbide honeycomb ceramic and preparation method thereof

ActiveCN107814575AStrong thermal shock resistanceStrong thermal fatigue resistanceCeramicwareMicrostructureMaterials science

The invention discloses Al4SiC4 enhanced silicon carbide honeycomb ceramic and a preparation method thereof. The Al4SiC4 enhanced silicon carbide honeycomb ceramic is prepared from the raw material ingredients in parts by mass: 70 to 80 parts of first silicon carbide powder, 10 to 20 parts of second silicon carbide powder, 2 to 10 parts of Al4SiC4, 5 to 15 parts of sintering aid, 12.5 to 15.5 parts of binding agent and 12.5 to 15.5 parts of water, wherein the purity of the first silicon carbide powder is 85 to 99.9wt%, the granularity of the first silicon carbide is 5 to 50mu m, the purity ofthe second silicon carbide is 85 to 99.9wt%, and the granularity of the second silicon carbide is 0.05 to 0.5mu m. The Al4SiC4 enhanced silicon carbide honeycomb ceramic disclosed by the invention hasthe characteristics of high raw material utilization rate and high production efficiency; furthermore, a product structure is in a wall flow type, so that purifying capacity to waste gas is improved;the product is easy to form, and a process is easy to control; the Al4O4C enhanced silicon carbide honeycomb ceramic prepared by the method has the advantages of good microstructure, even micropore distribution, high mechanical strength and low thermal expansion coefficient.

Owner:JIANGSU GAOCHUN CERAMICS

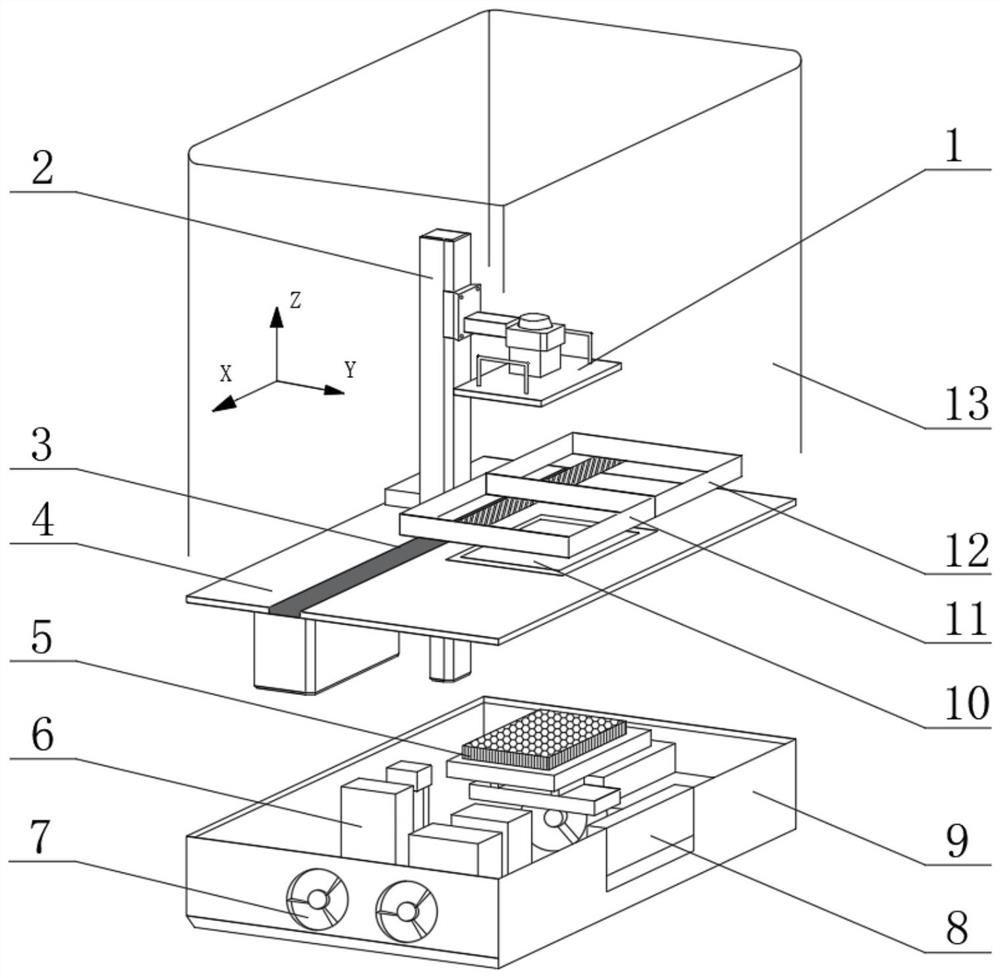

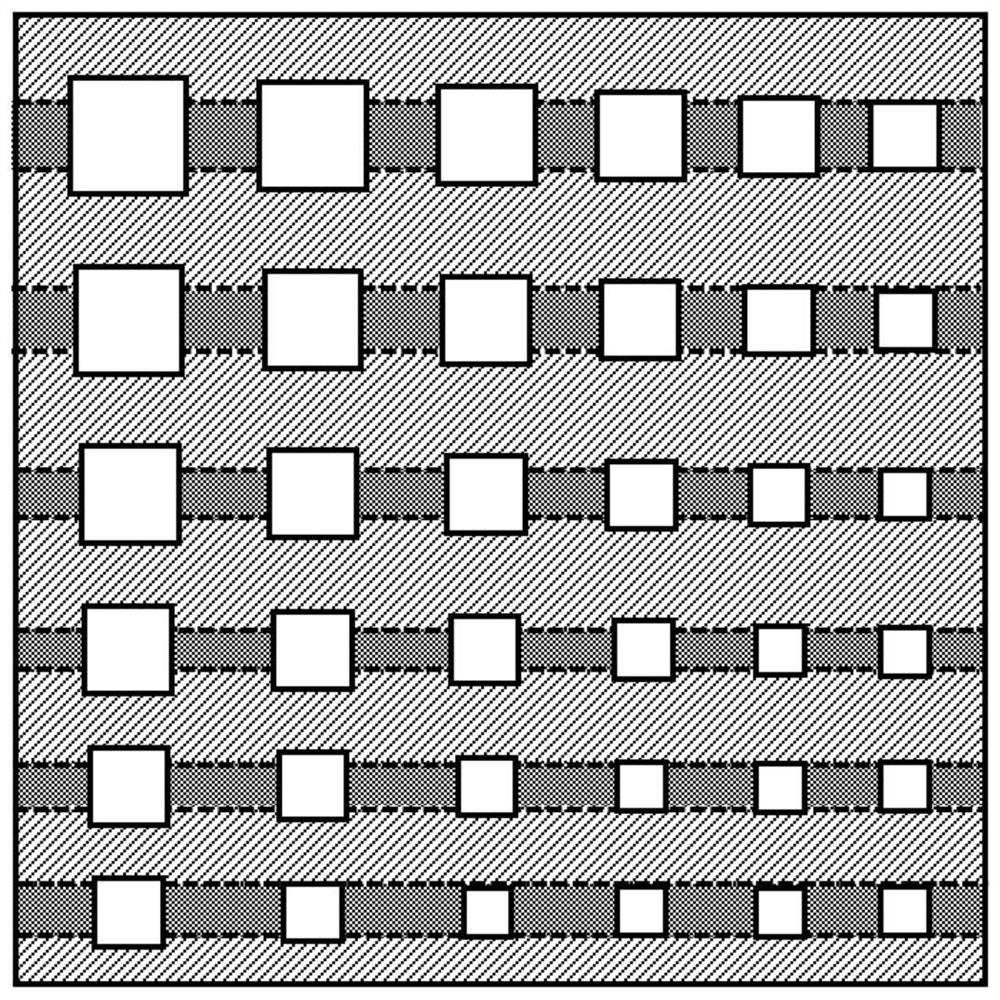

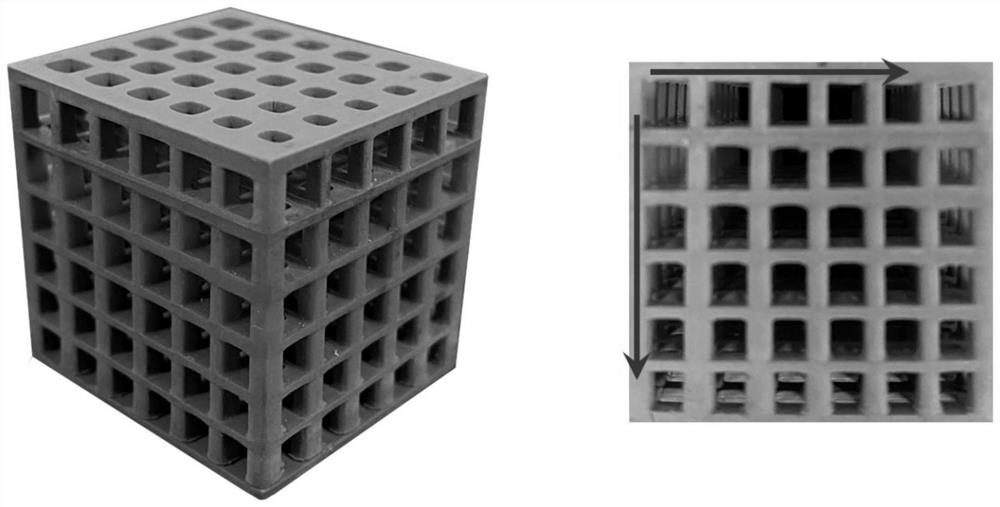

3D printing preparation method and device for heterogeneous bidirectional gradient aperture porous ceramic

ActiveCN114276145ARapid designFast preparationAdditive manufacturing apparatusCeramic shaping apparatusThermal dilatationManufacturing technology

The invention discloses a 3D printing preparation method and device for heterogeneous bidirectional gradient aperture porous ceramics, and belongs to the technical field of 3D printing of functional materials, gradient aperture functional materials are combined with an additive manufacturing technology, and alternate change of all layers of materials is achieved by controlling photocuring slurry, so that the 3D printing preparation method is suitable for 3D printing of the functional materials. Wherein the amorphous silicon powder content of the first precursor ceramic slurry is smaller than that of the second precursor ceramic slurry, so that the thermal expansion coefficient of the first precursor ceramic slurry is slightly higher than that of the second precursor ceramic slurry, pressure stress can be generated between pore layers after sintering, and the strength of the gradient aperture porous ceramic can be improved. In addition, the silicon powder can react with carbon residues generated by the photosensitive resin to be sintered, so that the green body is densified, and local microcracks between pore layers are effectively eliminated. In addition, the particle size of the silicon powder is changed, the macropores are controllable, meanwhile, the micropores are variable, and the functionality of the gradient aperture porous ceramic is further improved.

Owner:JILIN UNIV

Method for diffusing and plating aluminum on surface of titanium-aluminium intermetallic compound

InactiveCN102586724AEnsure effectivenessEnsure persistenceSolid state diffusion coatingAlcladOxidation resistant

The invention relates to a method for diffusing and plating aluminum on the surface of a titanium-aluminium intermetallic compound, comprising the following steps of: placing a pure aluminium product in a conductive crucible to form a diffusing-plating source electrode, and then placing the crucible into a vacuum chamber, placing a titanium-aluminium intermetallic compound workpiece above the crucible and filling argon into the vacuum chamber, applying direct current negative voltage to smelt an aluminium product in the source electrode and keeping a discharging and sputtering state, and then, applying negative voltage to the titanium-aluminium intermetallic compound workpiece to raise the temperature of the workpiece to 700-1200 DEG C, keeping the temperature for 0.5-8 hours to complete diffusing and plating operation. The surface of a diffused and plated workpiece is provided with a high-temperature antioxidant protective layer with a settled layer and a diffusion layer, and 3-10mu m compact Al on the outer layer can give alloy to have sufficient oxidation resistance, and a 50-200mu m of diffusion layer below the settled layer can preventing Al atoms of the settled layer from diffusing rapidly to a matrix when in long-time high-temperature service and enhance the bonding force of the functional settled layer and the matrix.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

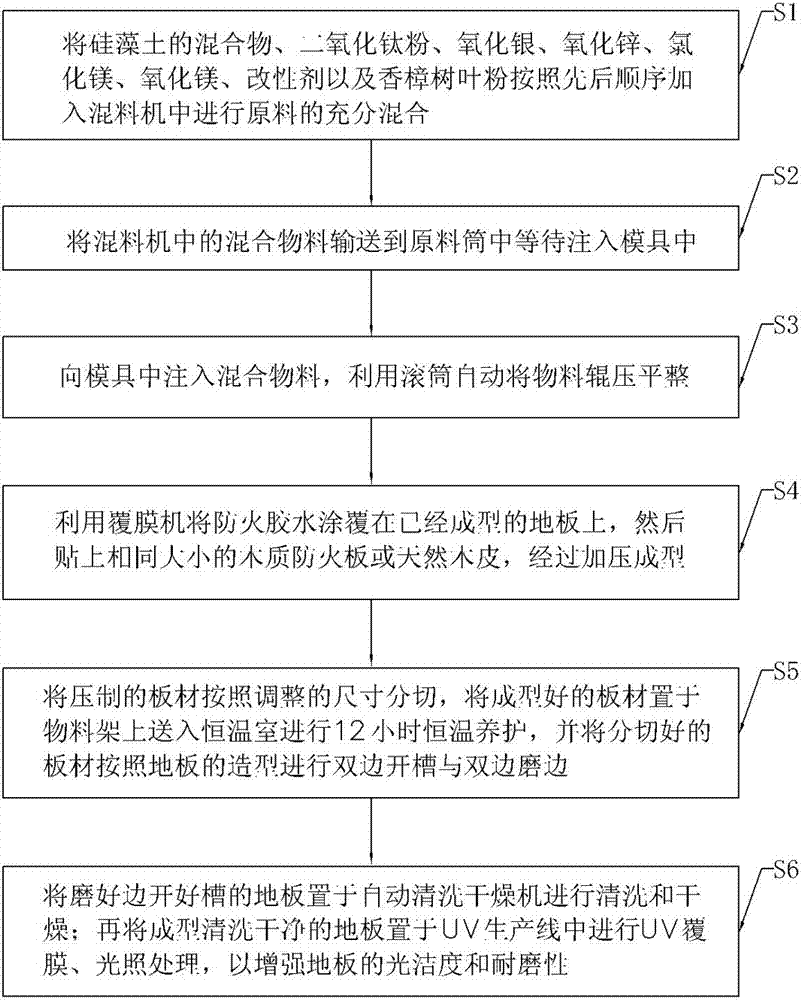

Nano wood-imitating floor and manufacturing method thereof

ActiveCN106894605AImprove adsorption capacityWith heat insulationFlooringEnvironmental resistanceOperability

The invention discloses a nano wood-imitating floor and a manufacturing method thereof. The floor comprises, by weight, 2-6 parts of diatomite, 1-3 parts of nano silicon dioxide, 0.1-1 part of zirconia, 0.1-1 part of zinc oxide, 5-15 parts of titanium dioxide powder, 0.1-1 part of silver oxide, 10-30 parts of magnesium chloride, 10-30 parts of magnesium oxide and 2-4 parts of modifiers. By combining the functional materials, the functions of environment friendliness, attractive appearance, sterilizing, mosquito repelling, cockroach repelling, ant repelling, fire preventing, damp preventing, weather resistance, no deformation, no formaldehyde, recovery-reuse and no pollution of the wood-imitating floor are achieved, the performance of an existing wood-imitating floor can be optimized greatly, and profound historical significance and market value are achieved. The manufacturing method of the wood-imitating floor is simple in technology process, low in equipment requirement and high in operability and can be applied and popularized widely.

Owner:何新桥 +1

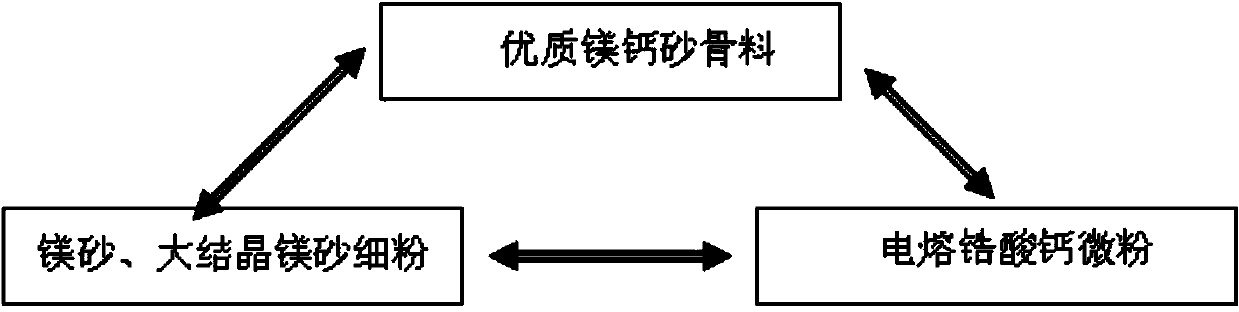

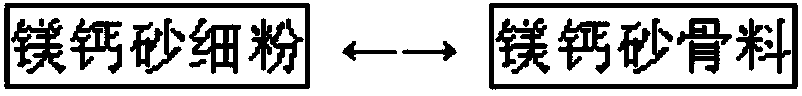

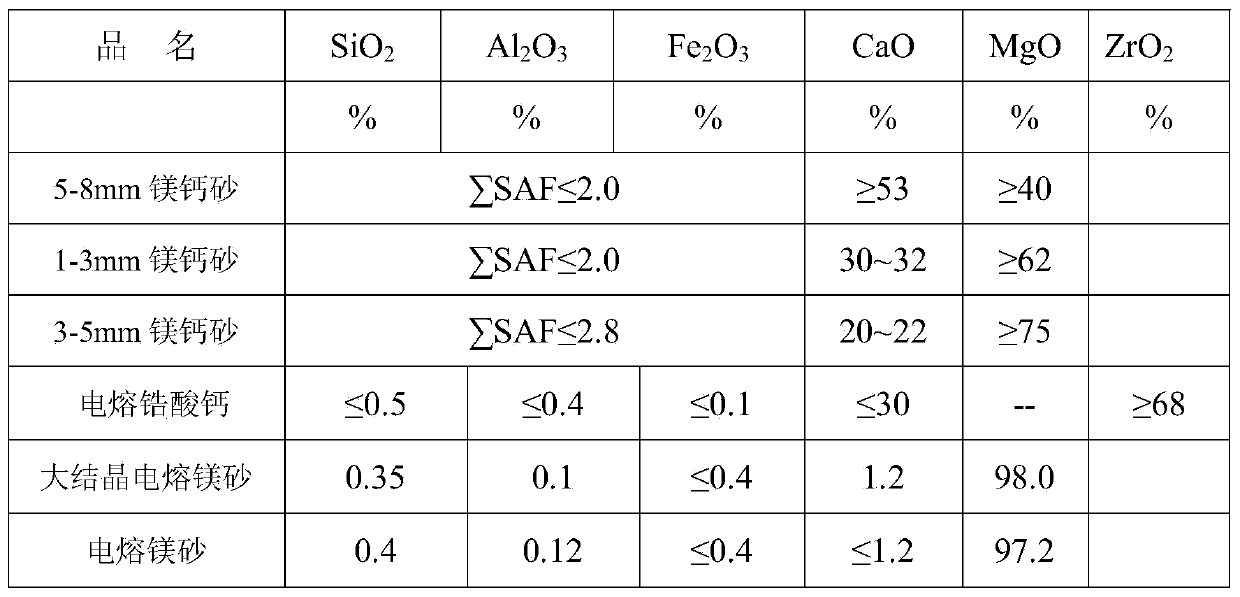

Dolomite-periclase-calcium zirconate composite fireproof material and preparation method thereof

The invention relates to a high-quality dolomite-periclase-calcium zirconate composite fireproof material suitable for smelting stainless steel, special steel AOD furnace and refining ladles. The adopted raw materials mainly comprise, by weight, 8-10% of magnesium calcium sand with a particle size of 5-8 mm, 9-18% of magnesium calcium sand with a particle size of 3-5 mm, 10-22% of magnesium calcium sand with a particle size of 1-3 mm, 5-10% of calcium zirconate with a particle size of 0.5-1 mm, 5-10% of magnesia with a particle size of 0.5-1 mm, 3-10% of 600 mesh electric melting calcium zirconate, 15-24% of magnesia with a particle size of less than or equal to 0.5 mm, 3-10% of 400 mesh 98 large crystal magnesia, 1-3% of a binding agent, and 1-2% of a sintering agent, wherein the raw materials are subjected to mixing, molding, sintering, finished product inspection, package and other steps to prepare the material.

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

Method for manufacturing thermal shock resistant movable nozzle brick

InactiveCN101623758AMore thermal shock resistanceStrong thermal shock resistanceMelt-holding vesselsThermal shockEngineering

The invention discloses a method for manufacturing thermal shock resistant movable nozzle bricks, which is characterized in that when the forming art is carried out, firstly 1-10 high-temperature coils or rings with different diameters are embedded in each movable nozzle brick mould, the high-temperature coils or rings with different diameters use a movable nozzle brick hole as a centre of a circle, and are put in movable nozzle brick materials parallel to the movable nozzle brick surface, the diameter of the high-temperature coils or rings is respectively 1.02-10 times of the hole diameter of the movable nozzle brick; pug is added into the formed movable nozzle brick mould, a brick machine is adopted for pressing, and the forming pressure is greater than 120 MPa. The movable nozzle brick has stronger thermal shock resistance, harder structure and more excellent mechanical property, thereby improving the thermal shock resistance of a slider and solving the problem of the short service life of the breakout caused by a crackle.

Owner:ANHUI XINHAI ENVIRONMENTAL PROTECTION NEW MATERIAL CO LTD

Carbon/ceramic heat-resistant composite material and preparation process thereof

InactiveCN1793037AObvious advantagesObvious positive effectCeramic shaping apparatusRoom temperatureFree cooling

The invention relates to a carbon / ceramic heat proof compounding material and the manufacturing method. The wt% of the material is C squama 25-65, ceramic powder SiC+B4C 30-60, of which SiC: SiC+B4C=5:1, TiO2 5-13, adopting acetone phenolic resin as binding agent. Mixing the constituents, molding at the pressure of 30-50MPa, keeping the temperature and cooling to room temperature, the material would be gained. The invention has the feature of light, high intensity, high toughness, antifriction, high temperature poof, and anti-oxidation.

Owner:NORTHEASTERN UNIV

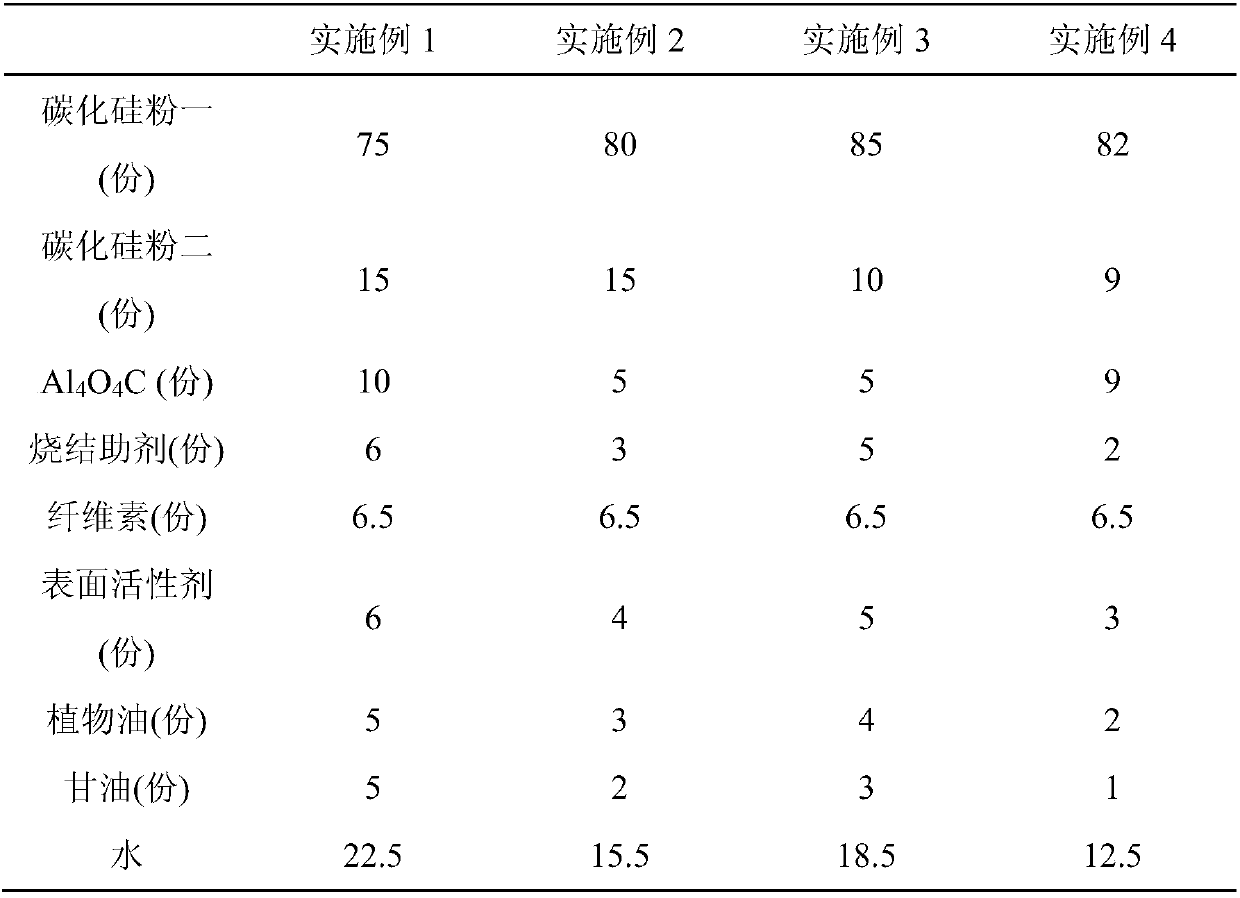

Al4O4C enhanced silicon carbide honeycomb ceramic and preparation method thereof

ActiveCN107814583AStrong thermal shock resistanceStrong thermal fatigue resistanceCeramicwareGranularityThermal expansion

The invention discloses Al4O4C enhanced silicon carbide honeycomb ceramic and a preparation method thereof. The Al4O4C enhanced silicon carbide honeycomb ceramic is prepared from raw material ingredients in parts by mass: 75 to 85 parts of first silicon carbide powder, 5 to 15 parts of second silicon carbide powder, 5 to 10 parts of Al4O4C, 2 to 6 parts of sintering aid, 12.5 to 22.5 parts of binding agent and 12.5 to 22.5 parts of water, wherein the purity of the first silicon carbide powder is 85 to 99.9wt%, the granularity of the first silicon carbide is 5 to 50mu m, the purity of the second silicon carbide is 85 to 99.9wt%, and the granularity of the second silicon carbide is 0.05 to 0.5mu m. The Al4O4C enhanced silicon carbide honeycomb ceramic disclosed by the invention has the characteristics of high raw material utilization rate and high production efficiency; furthermore, a product structure is in a wall flow type, so that purifying capacity to waste gas is improved; the product is easy to form, and a process is easy to control; the Al4O4C enhanced silicon carbide honeycomb ceramic prepared by the method has the advantages of good microstructure, even micropore distribution, high mechanical strength and low thermal expansion coefficient.

Owner:JIANGSU GAOCHUN CERAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com