Method for diffusing and plating aluminum on surface of titanium-aluminium intermetallic compound

An intermetallic compound and aluminum-based technology, applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of easy peeling off of hard coating, hydrogen embrittlement, and decline in oxidation resistance, and achieve anti-oxidation Strong thermal shock resistance, ensuring effectiveness and durability, and outstanding engineering value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Aluminum infiltration on the surface of γ-TiAl alloy sample

[0026] (1) Sample pretreatment . Clean and dry the surface of the sample, if necessary, polish and then clean.

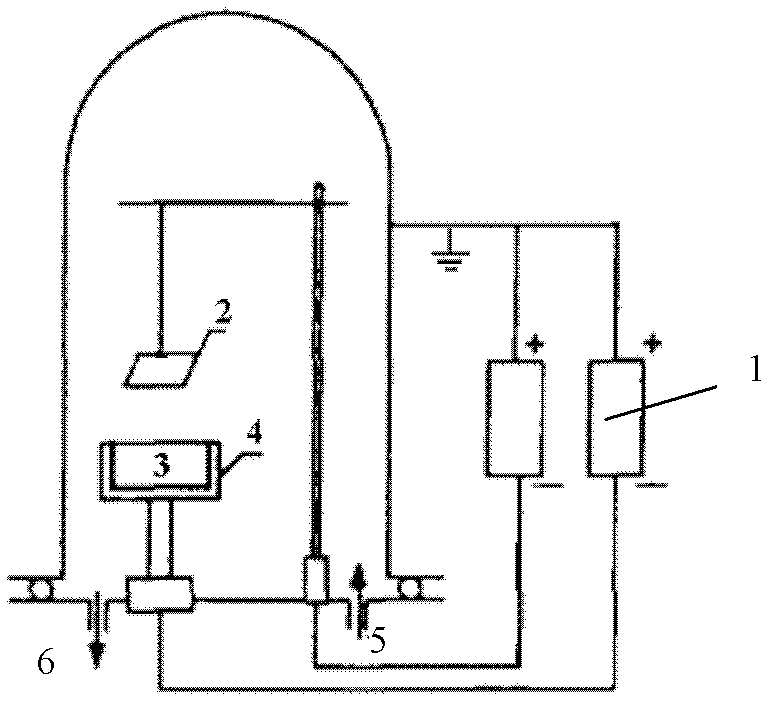

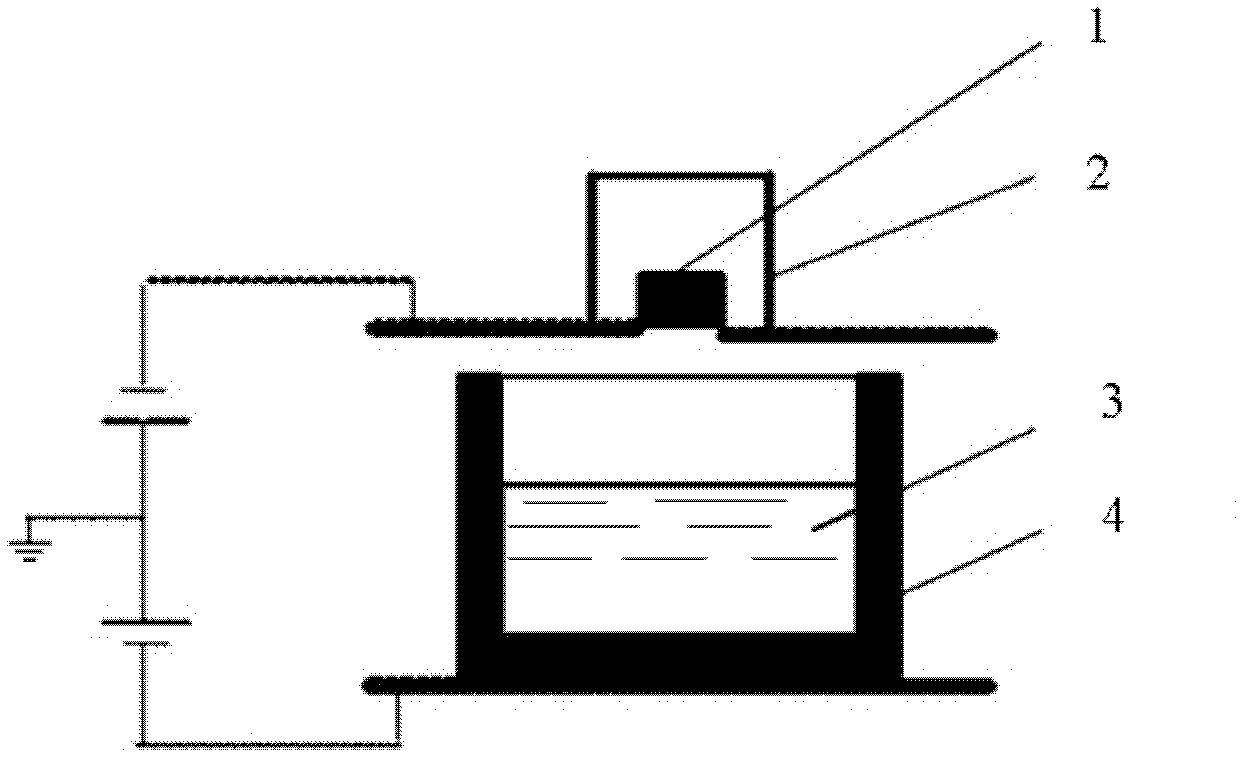

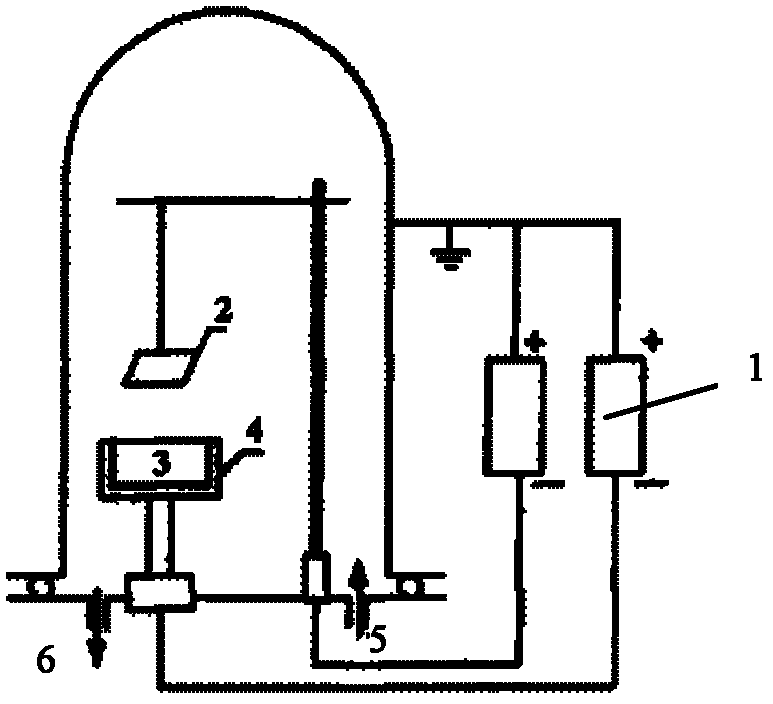

[0027] (2) Furnace . according to figure 2 Place the seepage source and the workpiece in the layout method shown, and adjust the electrode spacing within the range of 10~50mm.

[0028] (3) Vacuum . Close the air inlet, turn on the vacuum pump, and pump the air pressure in the furnace to 10 -1 Below Pa, then pass argon to the working pressure of 30Pa.

[0029] (4) Plasma cleaning samples . Start the power supply, first turn on the workpiece power supply, apply -400V voltage, and use the plasma beam generated by glow discharge to bombard the workpiece for about 30 minutes. On the one hand, the sample is further cleaned, and on the other hand, the surface is activated to facilitate the adsorption of active atoms. .

[0030] (5) Plating . After the pre-bombardment, the source voltag...

Embodiment 2

[0035] Ti 2 AlNb Alloy Sample Surface Plated with Aluminum

[0036] (1) Sample pretreatment . Clean and dry the surface of the sample, if necessary, polish and then clean.

[0037] (2) Furnace . according to figure 2 Place the seepage source and the workpiece in the layout method shown, and adjust the electrode spacing within the range of 10~50mm.

[0038] (3) vacuuming. Close the air inlet, turn on the vacuum pump, and pump the air pressure in the furnace to 10 -1 Below Pa, then pass argon to the working pressure of 30Pa.

[0039] (4) Plasma cleaning samples. Start the power supply, first turn on the workpiece power supply, apply -400V voltage, and use the plasma beam generated by glow discharge to bombard the workpiece for about 30 minutes. On the one hand, the sample is further cleaned, and on the other hand, the surface is activated to facilitate the adsorption of active atoms. .

[0040] (5) Plating . After the pre-bombardment, the source voltage -600V ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com