Phase-change energy storage floor tile and manufacturing method thereof

A phase change energy storage and phase change energy storage material technology, applied in the field of floor tiles and their manufacturing, can solve the problems of poor strength, thermal shock resistance and wear resistance, short service life of phase change materials, unsuitable floor tiles, etc. , to achieve the effects of good thermal shock resistance and wear resistance, strong heat storage/cooling capacity, and excellent fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

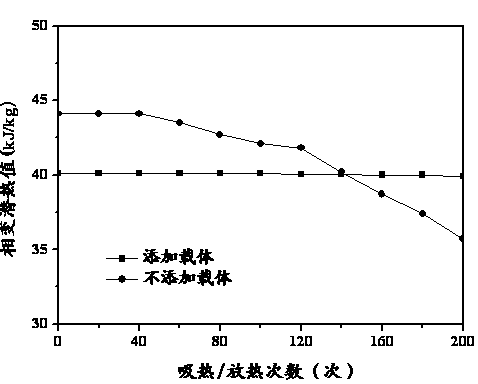

[0037] The 25 # Add 50 parts of paraffin to a magnetic constant temperature stirrer, heat to 35°C, and adjust the speed to 500 rpm after the paraffin is completely melted; add 50 parts of cement, 40 parts of fly ash, and 10 parts of γ-alumina to the stirrer, and stir at a constant speed for 60 minutes , to prepare a phase change energy storage material, and take it out for later use. The latent heat value of the phase change energy storage material measured by differential scanning calorimeter (DSC) is 65.5 kJ / kg.

[0038] Then heat the double-roller closed rubber mixing machine to 90°C, put 100 parts of PEBA elastomer and 100 parts of nano-scale calcium carbonate with surface organic treatment into the double-roller closed rubber mixing machine for blending, the speed is 50rpm, and knead 30min into a premix. Take 50 parts of a phase change energy storage material with a phase change latent heat of 65.5kJ / kg, mix it into the premix in a double-roller closed rubber mixer, adj...

Embodiment 2

[0049] In Example 1, the surface-treated nano-scale calcium carbonate was replaced by surface-organized nano-scale magnesium hydroxide, and the remaining materials and operating conditions were unchanged to obtain shaped floor tiles. The flame retardant performance is measured by the oxygen index method / GB / T2406-93 (the same below), and the oxygen index of the floor tile is only 24; moreover, there is a certain amount of smoke generated during the combustion test. Compared with it, the flame retardancy and smoke generation of the floor tiles prepared in Example 1 are obviously much better.

Embodiment 3

[0051] In Example 1, after step (1) is reconciled, the latent heat of phase change is 150.2kJ / kg of 25 # Replace 50 parts of paraffin with 80 parts, and keep other conditions unchanged, the latent heat value of the prepared phase change energy storage material is 83.2kJ / kg. Then follow step (2) to replace 50 parts of the phase change energy storage material with a phase change latent heat of 83.2kJ / kg into 80 parts, and keep the rest of the conditions unchanged. 59.8kJ / kg, oxygen index 26.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com