Wear-resistant domestic ceramic product and preparation method thereof

A wear-resistant, ceramic product technology, applied in the field of ceramics, can solve the problems of low impact strength, easy to wear, not resistant to falling, etc., to achieve the effect of improving wear resistance, reducing environmental pollution, and increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

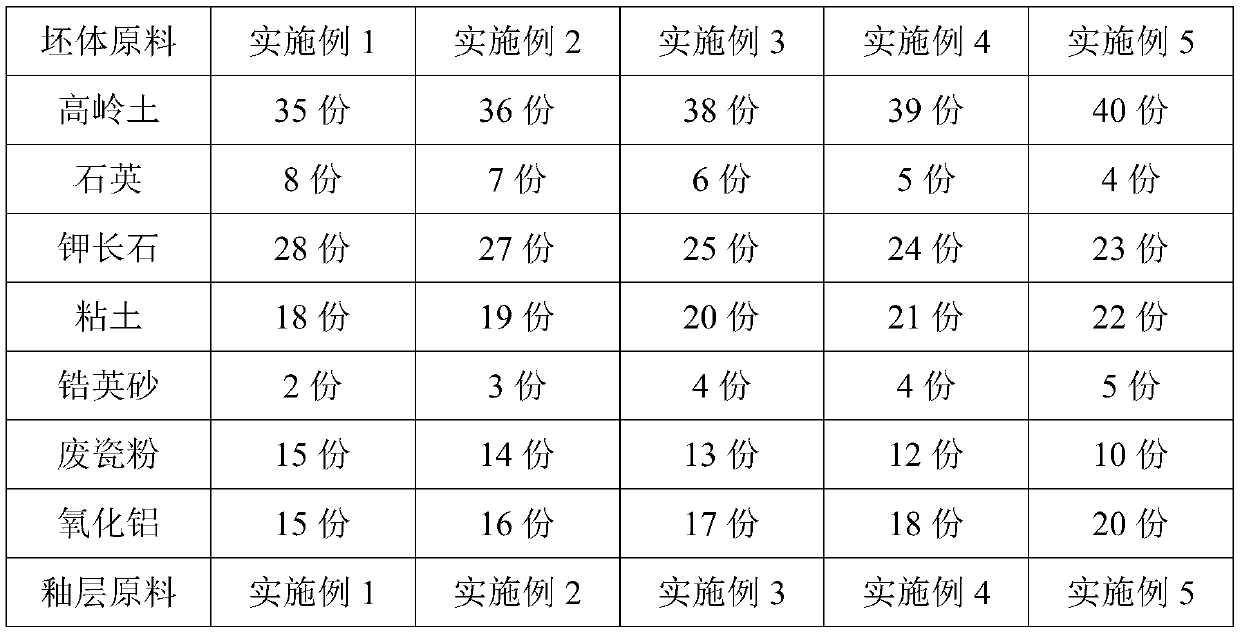

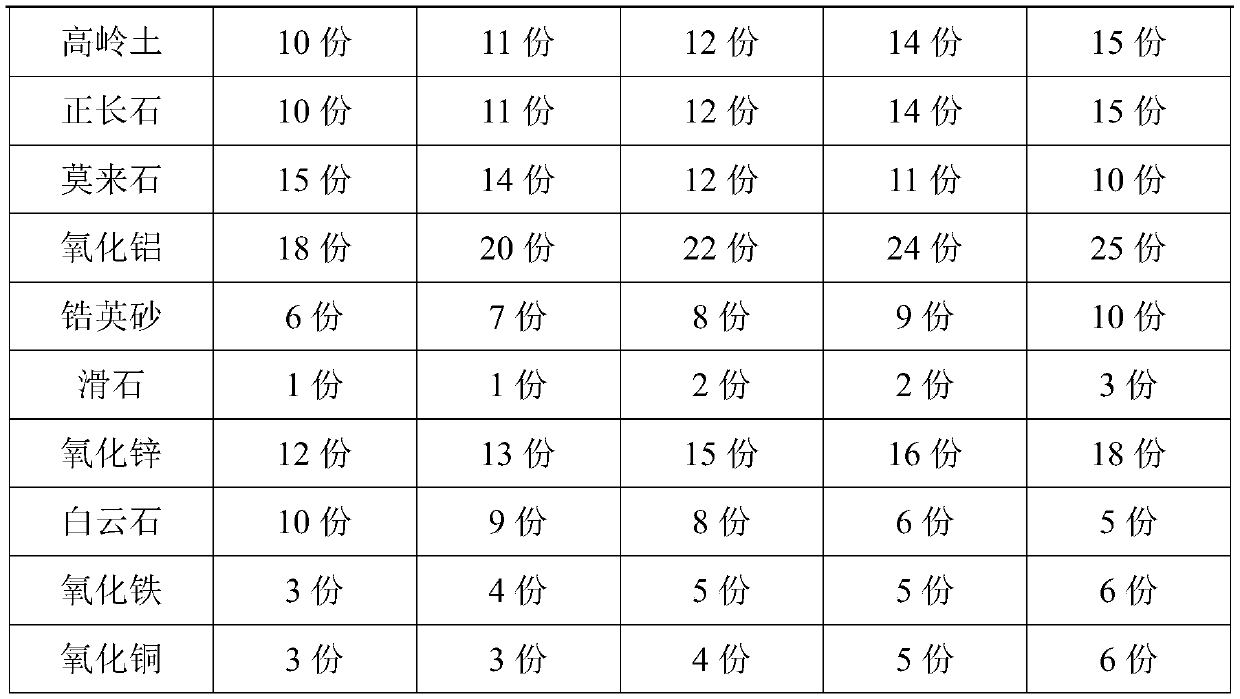

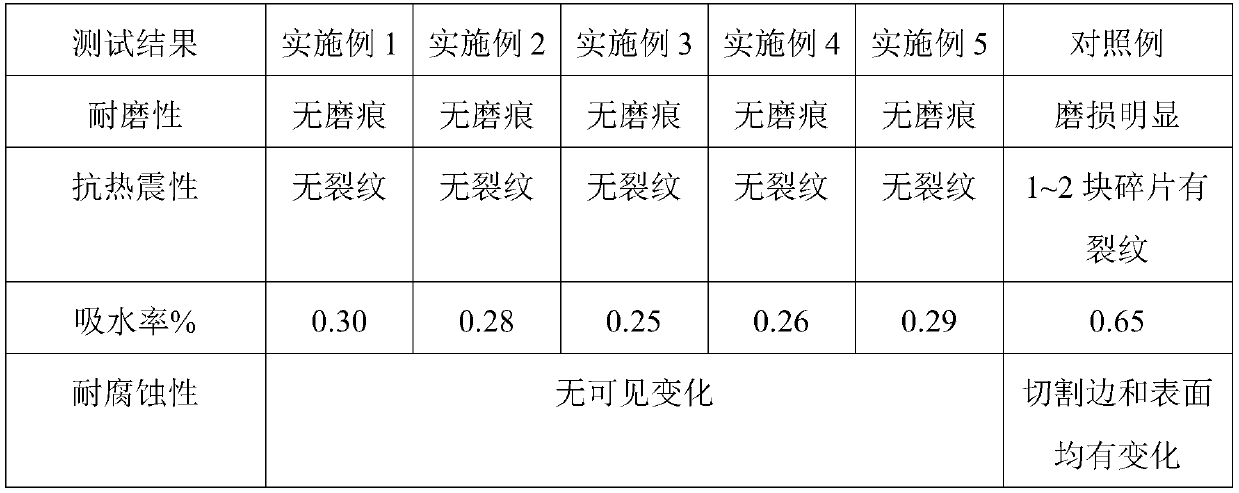

[0028] This embodiment provides a wear-resistant daily-use ceramic product, including tire material and glaze, and the tire material includes the following raw materials in parts by weight: 35 parts of kaolin, 8 parts of quartz, 28 parts of potassium feldspar, 18 parts of clay, zirconium 2 parts of British sand, 15 parts of waste porcelain powder, and 15 parts of alumina; the glaze includes the following raw materials in parts by weight: 10 parts of kaolin, 10 parts of orthoclase, 15 parts of mullite, 18 parts of aluminum oxide, and 12 parts of zinc oxide. 1 part of talc, 6 parts of zircon sand, 10 parts of dolomite, 3 parts of iron oxide, and 3 parts of copper oxide.

[0029] This embodiment also provides a preparation method of wear-resistant daily-use ceramic products, comprising the following steps:

[0030] Step 1. Weigh the tire material according to the weight ratio, put it into a ball mill and add water to carry out wet grinding. When the tire material is wet-milled, a...

Embodiment 2

[0037] This embodiment provides a wear-resistant daily-use ceramic product, including tire material and glaze, and the tire material includes the following raw materials in parts by weight: 36 parts of kaolin, 7 parts of quartz, 27 parts of potassium feldspar, 19 parts of clay, zirconium 3 parts of British sand, 14 parts of waste porcelain powder, and 16 parts of alumina; the glaze includes the following raw materials in parts by weight: 11 parts of kaolin, 11 parts of orthoclase, 14 parts of mullite, 20 parts of alumina, 13 parts of zinc oxide 1 part of talc, 7 parts of zircon sand, 9 parts of dolomite, 4 parts of iron oxide, and 3 parts of copper oxide.

[0038]This embodiment also provides a preparation method of wear-resistant daily-use ceramic products, comprising the following steps:

[0039] Step 1. Weigh the tire material according to the weight ratio, put it into a ball mill and add water to carry out wet grinding. When the tire material is wet-milled, add water to th...

Embodiment 3

[0046] This embodiment provides a wear-resistant daily-use ceramic product, including tire material and glaze, and the tire material includes the following raw materials in parts by weight: 38 parts of kaolin, 6 parts of quartz, 25 parts of potassium feldspar, 20 parts of clay, 4 parts of zircon sand, 13 parts of waste porcelain powder, and 17 parts of alumina; the glaze includes the following raw materials in parts by weight: 12 parts of kaolin, 12 parts of orthoclase, 12 parts of mullite, 22 parts of alumina, zinc oxide 15 parts, talc 2 parts, zircon sand 8 parts, dolomite 8 parts, iron oxide 5 parts, copper oxide 4 parts.

[0047] This embodiment also provides a preparation method of wear-resistant daily-use ceramic products, comprising the following steps:

[0048] Step 1. Weigh the tire material according to the weight ratio, put it into a ball mill and add water to carry out wet grinding. When the tire material is wet-milled, add water to the weight ratio: ball: water = ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com