Patents

Literature

43results about How to "Not easy to infiltrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conductive silver paste for ceramic filter and preparation method thereof

PendingCN111489848ASolve conductivity problemsSolve solder performanceNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteThermal dilatation

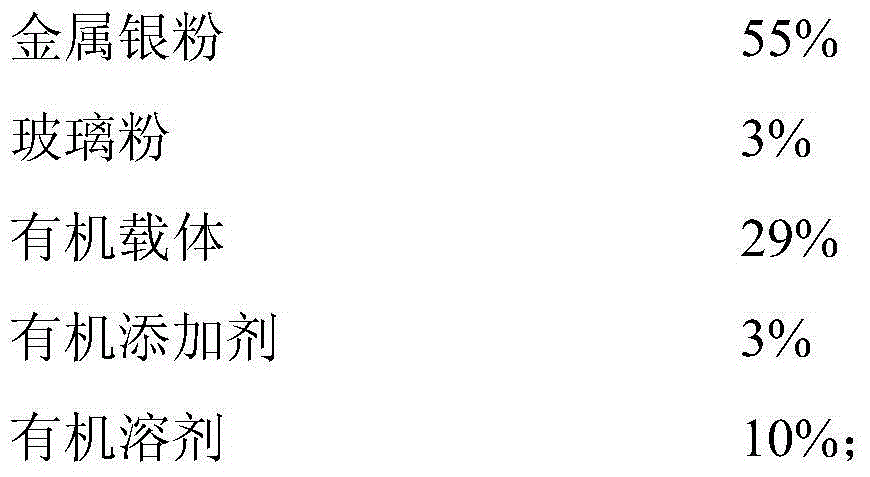

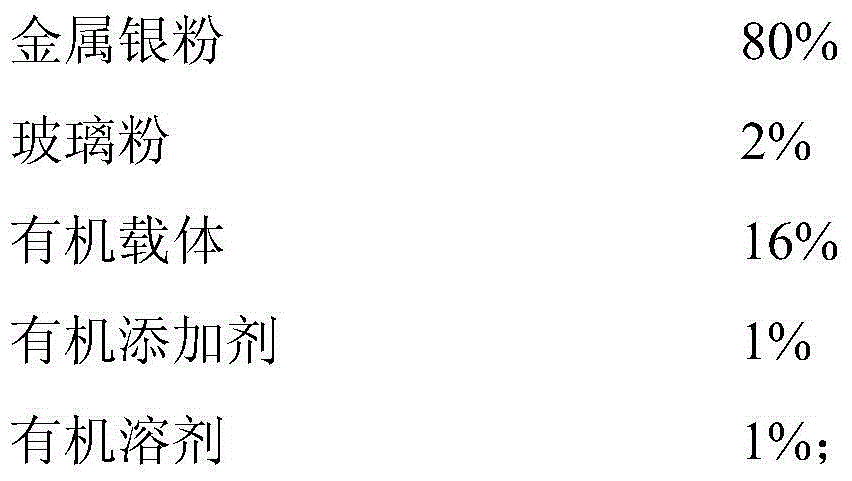

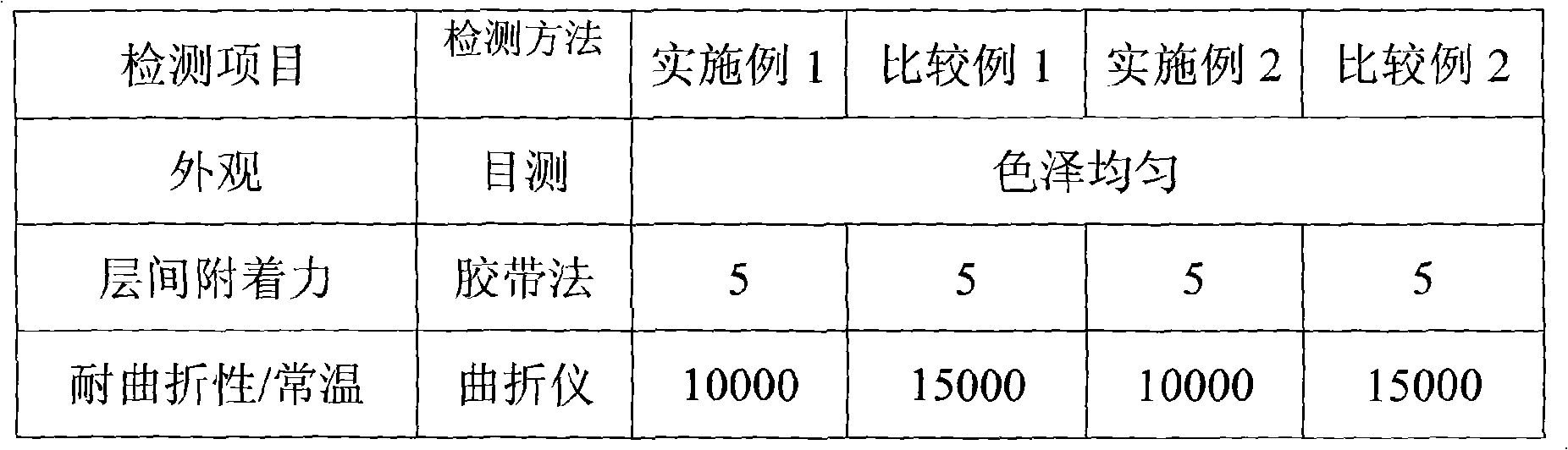

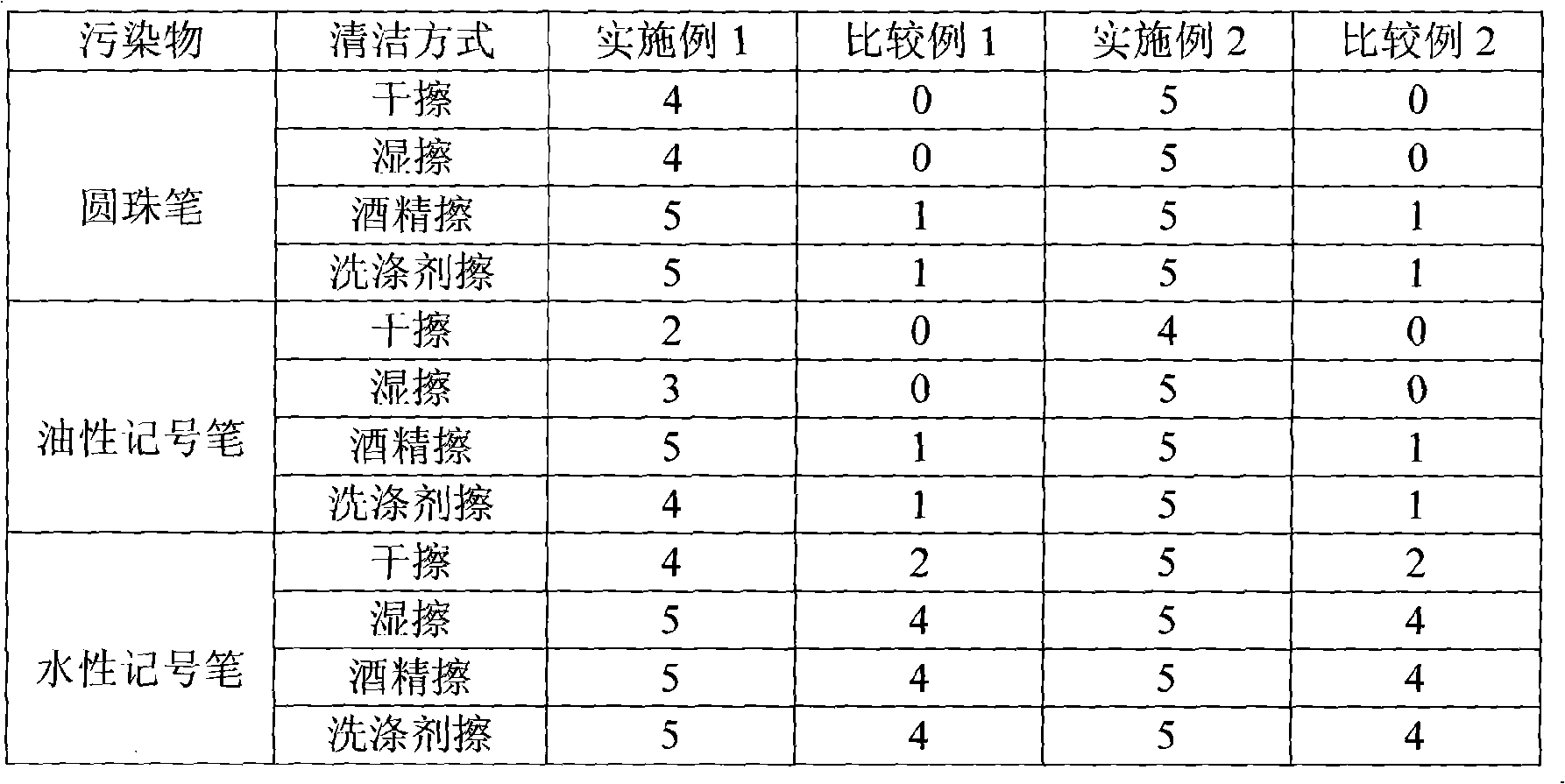

The invention relates to conductive silver paste for a ceramic filter and a preparation method of the conductive silver paste. The conductive silver paste comprises the following components in parts by weight: 50-80 parts of metal silver powder, 2-5 parts of glass powder, 10-30 parts of an organic carrier, 1-3 parts of an organic additive and 1-10 parts of an organic solvent, wherein the glass powder is lead-free glass powder, the coefficient of thermal expansion is 110-120*10<-7> / DEG C, and the sintering temperature is 550-750 DEG C. The preparation method comprises the following steps: adding the organic carrier and the organic solvent into a mixer, adding the metal silver powder, the glass powder and the organic additive, fully mixing, transferring a mixture into a high-speed dispersionmachine, and uniformly dispersing at a high speed to obtain a conductive silver paste; and grinding the prepared conductive silver paste in a three-roller mill, and finely adjusting a roller to enable the fineness of the conductive silver paste to be less than 10mu m and the viscosity to be 30-50Pa.S, thereby obtaining the conductive silver paste for the ceramic filter. The conductive silver paste for the filter can form a conductive silver layer which is high in compactness, high in adhesive force, high in conductivity, good in weldability and stable in performance.

Owner:SHANGHAI BAOYIN ELECTRONICS MATERIALS CO LTD

High-temperature and high-humidity resistant electrode silver paste for ZnO piezoresistor and preparation method for electrode silver paste

ActiveCN105788699AReduce contact resistanceImprove conductivityNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteOrganic solvent

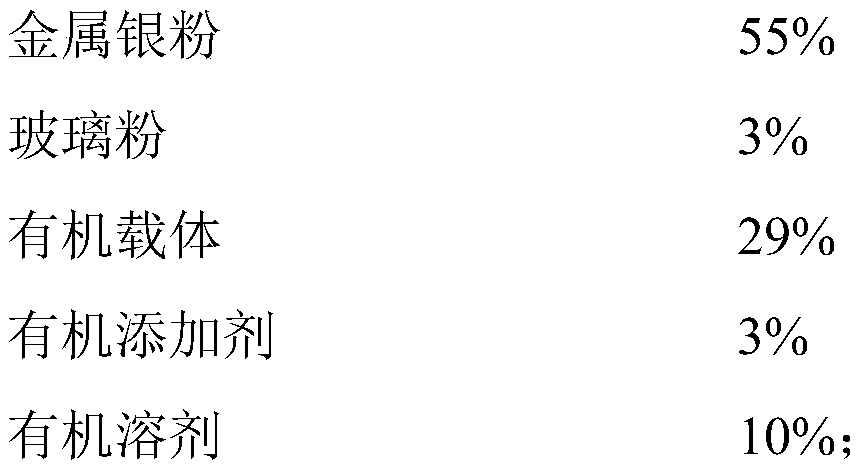

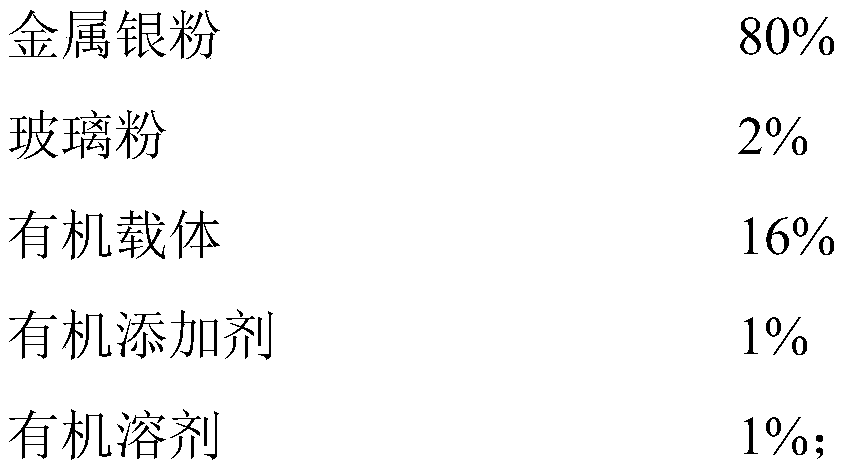

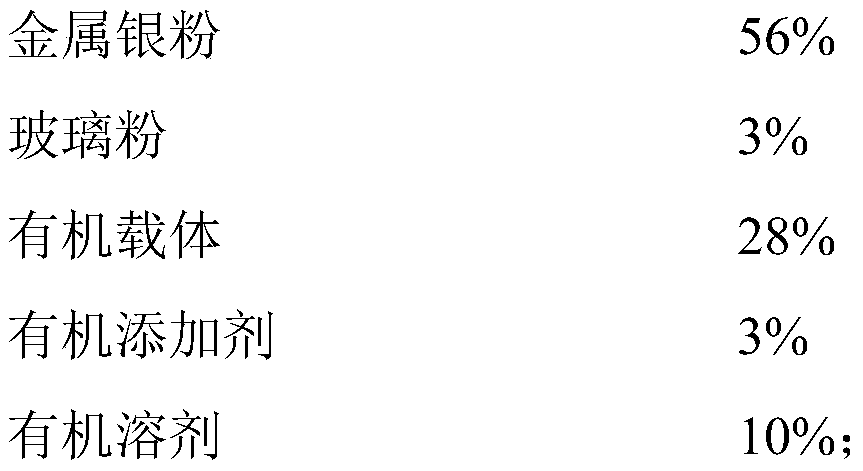

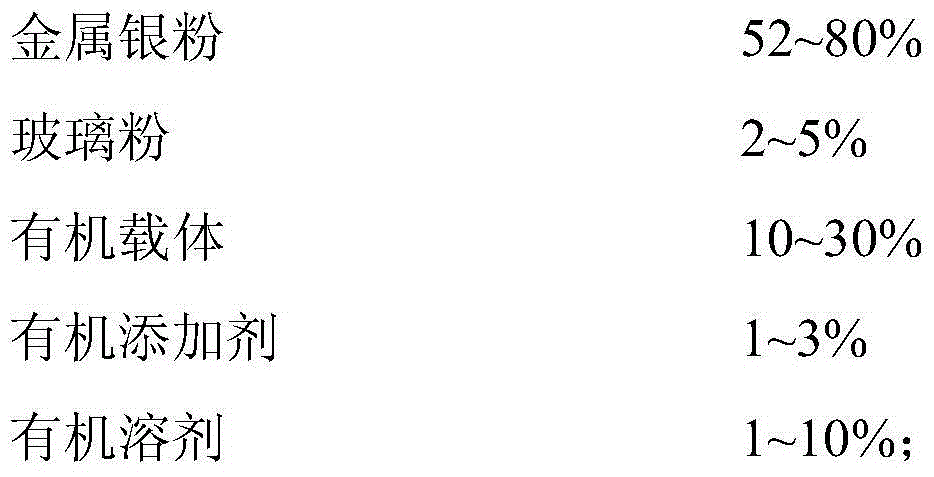

The invention discloses high-temperature and high-humidity resistant electrode silver paste for a ZnO piezoresistor. The conductive silver paste comprises the following components in percentage by weight: 52-80% of metal silver powder, 2-5% of glass powder, 10-30% of organic carrier, 1-3% of organic additives and 1-10% of organic solvent; the preparation method for the electrode silver paste comprises the steps of uniformly mixing the organic carrier and the organic solvent to prepare a uniform colloidal solution; then adding the other components in sequence; and enabling the mixture to be mixed through a mixer, grinded through a three-roll mill, and the like to obtain the high-temperature and high-humidity resistant electrode silver paste for the ZnO piezoresistor. Compared with the prior art, the electrode silver paste for the ZnO piezoresistor prepared by the invention is high in adhesive force, high in circulation volume, high in voltage resistance, low in ohmic contact resistance, high in flatness, excellent in structural compactness, and excellent in high-temperature and high-humidity resistance.

Owner:SHANGHAI BAOYIN ELECTRONICS MATERIALS CO LTD

Organic silicon-fluorine modified resin and coating preparation method

InactiveCN101638512AImprove adhesionGood adhesionFibre treatmentLeather surface finishingSlurryDip-coating

The invention provides silicon-fluorine modified resin and a method for preparing antifouling and easy-clean surface modified coating by utilizing the silicon-fluorine modified resin, wherein the silicon-fluorine modified resin is a modified surface processing agent which has uniform structure, extremely low surface tension, extremely good drainage and antifouling effect and excellent physical andmechanical properties and solvent resistance. The silicon-fluorine modified resin comprises the following raw materials in percentage by weight: 0.1-20 percent of silicon resin, 0-10 percent of fluororesin, 0.1-20 percent of hydroxyl acrylate resin, 20-50 percent of hydroxyl polyurethane resin and 20-70 percent of solvent. Coating slurry comprises the following components by weight part: 100 parts of silicon-fluorine modified resin, 10-40 parts of curing agent, 10-40 parts of accelerating agent and 10-200 parts of solvent, and the coating is constructed through printing, roller painting, spraying, brushing, dip-coating, and the like. The silicon-fluorine modified resin and the coating thereof have excellent antifouling and easy-clean functions and better comprehensive physicochemical property, and can be widely applied to the fields of furniture, automotive trims and seats, clothes, shoe leather, bags, and the like.

Owner:浙江康成新材料科技有限公司

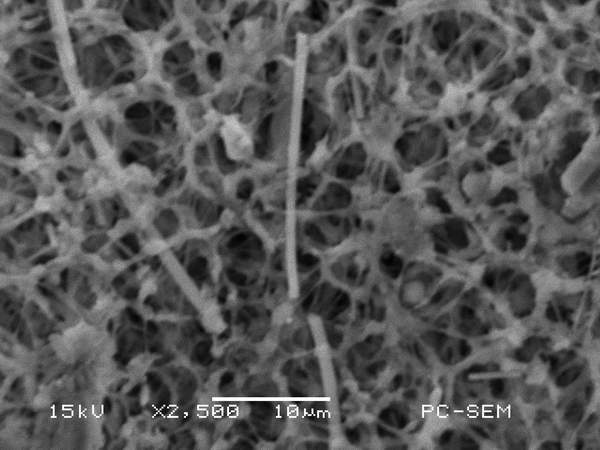

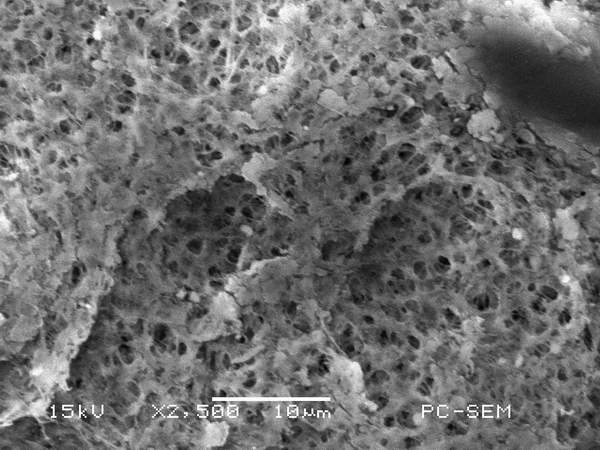

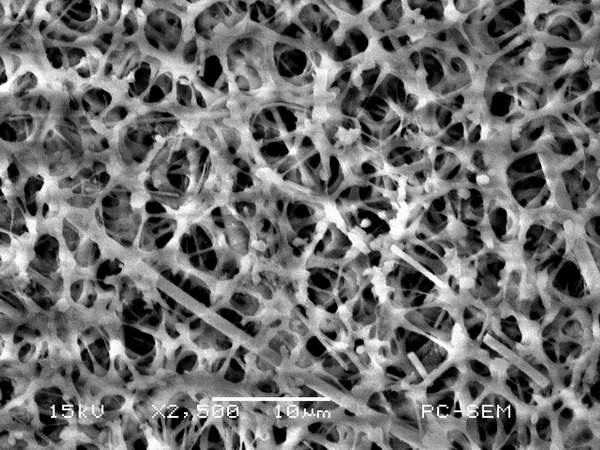

Composite enhanced baffle containing glass fibers and preparation method thereof

The invention relates to a baffle for an accumulator and particularly discloses a composite enhanced baffle containing glass fibers and a preparation method thereof. The preparation method disclosed by the invention comprises the following steps: (1) weighing each raw material in proportion, adding the raw materials to a reaction kettle, adding a solvent while stirring so as to enable the system to be uniformly mixed, and controlling the viscosity of the system to be 10.0-200.0Pa.s so as to obtain s mixture 1; and (2) molding the mixture 1 through normal-temperature extrusion and calendaring processes, and digesting through warm water and drying to obtain the composite enhanced baffle containing glass fibers. Because the glass fibers exist, the mechanical strength of the baffle is effectively improved, the pore structure is optimized, and the wettability is improved. The baffle disclosed by the invention is used for assembling a battery, thereby optimizing the oxygen circulation in the battery, preventing the generation of lead dendritic crystals, improving the capacity of the battery, reducing the internal resistance of the battery, avoiding the premature failure of the battery, effectively improving the performance of the battery and obviously prolonging the service life of the battery.

Owner:LUOYANG GEBAO DIAPHRAGM CO LTD

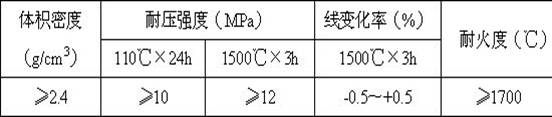

Refractory castable for tundish cover

The invention discloses a refractory castable for a tundish cover. The refractory castable is prepared from the following components in parts by weight: 50-80 parts of magnesia, 5-20 parts of dolomite, 5-10 parts of zircon, 1-20 parts of carbon, 2-5 parts of water-free binder and 0.2-1 part of urotropine. The magnesia, the dolomite and the zircon are mixed to prepare particles and fine powder, wherein the part number of the particles is 35-55, the part number of the fine powder is 45-65, the particle size of the particles ranges from 3.0 to 2.0mm, the particle size of the fine powder is 2.0-0.5mm. The refractory castable has excellent thermal shock resistance and breakage and peel resistance.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

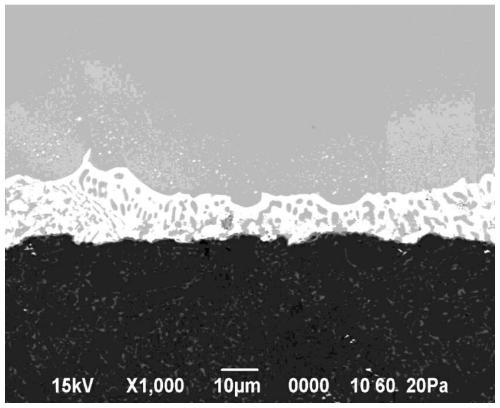

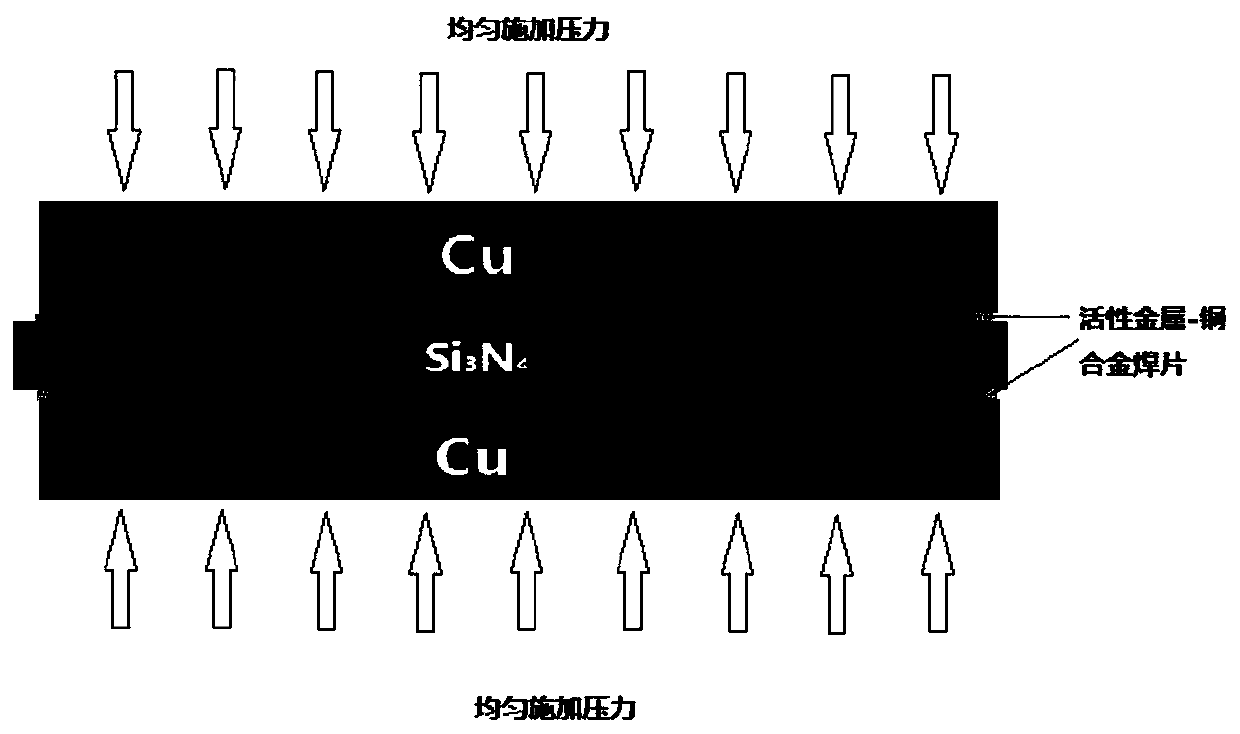

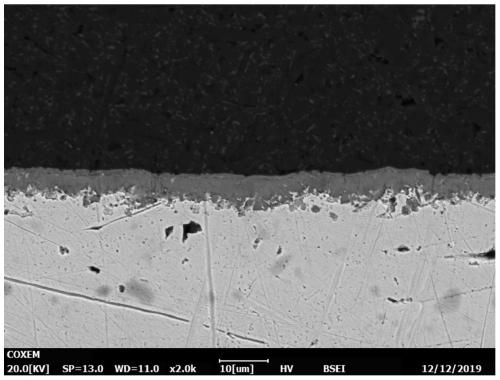

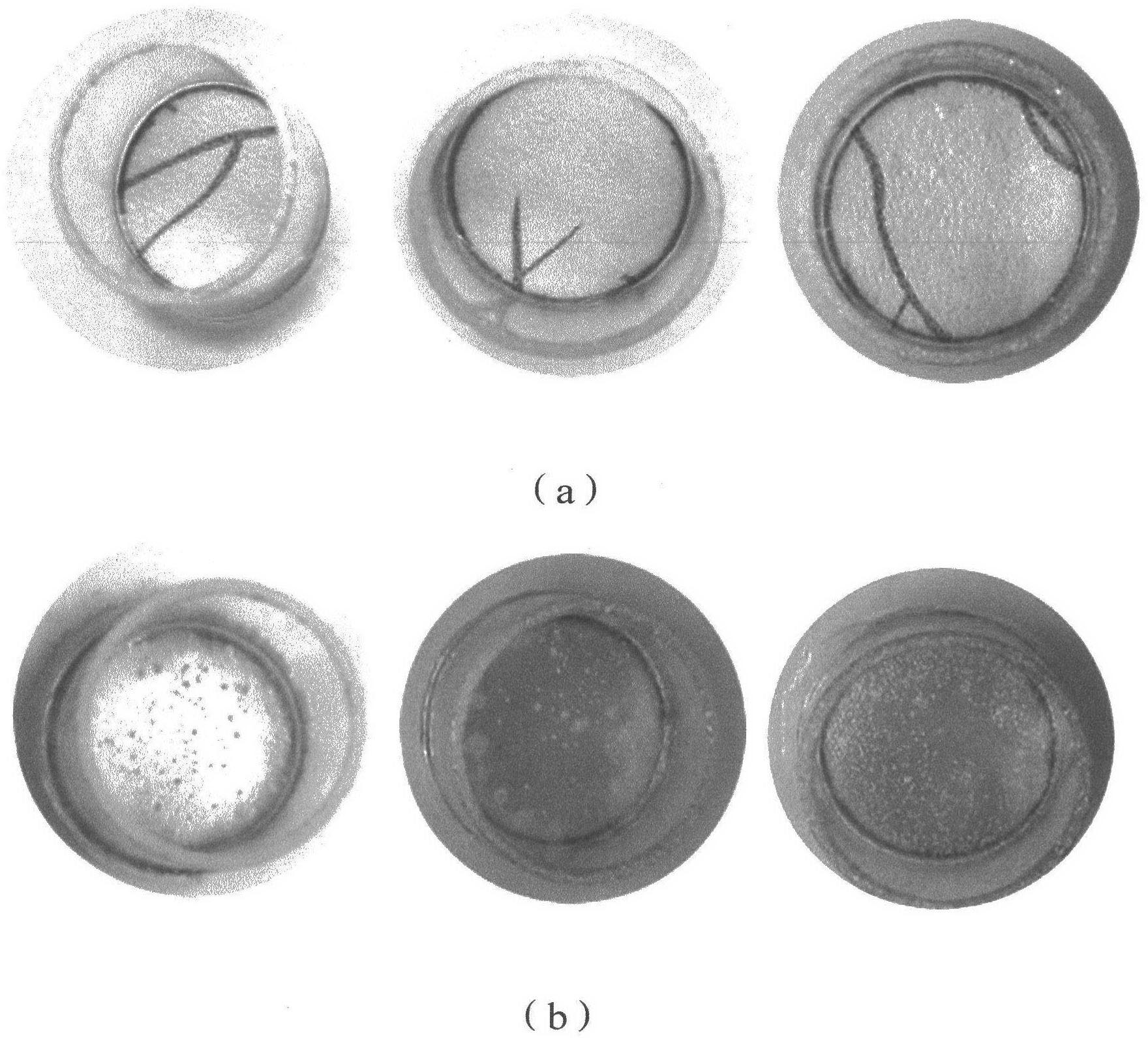

Copper-ceramic interface structure of high-reliability silicon nitride copper-coated ceramic substrate and preparation method of copper-ceramic interface structure

ActiveCN111403347AUniform welding layerLess prone to stress concentrationSemiconductor/solid-state device detailsSolid-state devicesSilicon nitrideTa element

The invention discloses a copper-ceramic interface structure of a high-reliability silicon nitride copper-coated ceramic substrate. The copper-ceramic interface structure comprises copper, a connecting layer, a reaction layer, silicon nitride ceramic, a reaction layer, a connecting layer and copper from top to bottom, the reaction layer is nitride of active metal formed by reaction of active metalelements and silicon nitride, and is used for realizing infiltration and connection of solder, silicon nitride ceramic and copper; the connecting layer is a stress buffer layer for connecting copperand silicon nitride ceramic, and the stress buffer layer is a copper alloy layer of copper and active metal elements; through the optimal design of a welding interface and the use of Ag-free solderinglugs, the uniformity of a welding layer can be effectively improved, and the residual stress between copper-ceramic interfaces is reduced, so that the binding force of the copper-ceramic interfaces is improved, and meanwhile, the risk of environmental pollution is reduced.

Owner:江苏富乐华半导体科技股份有限公司

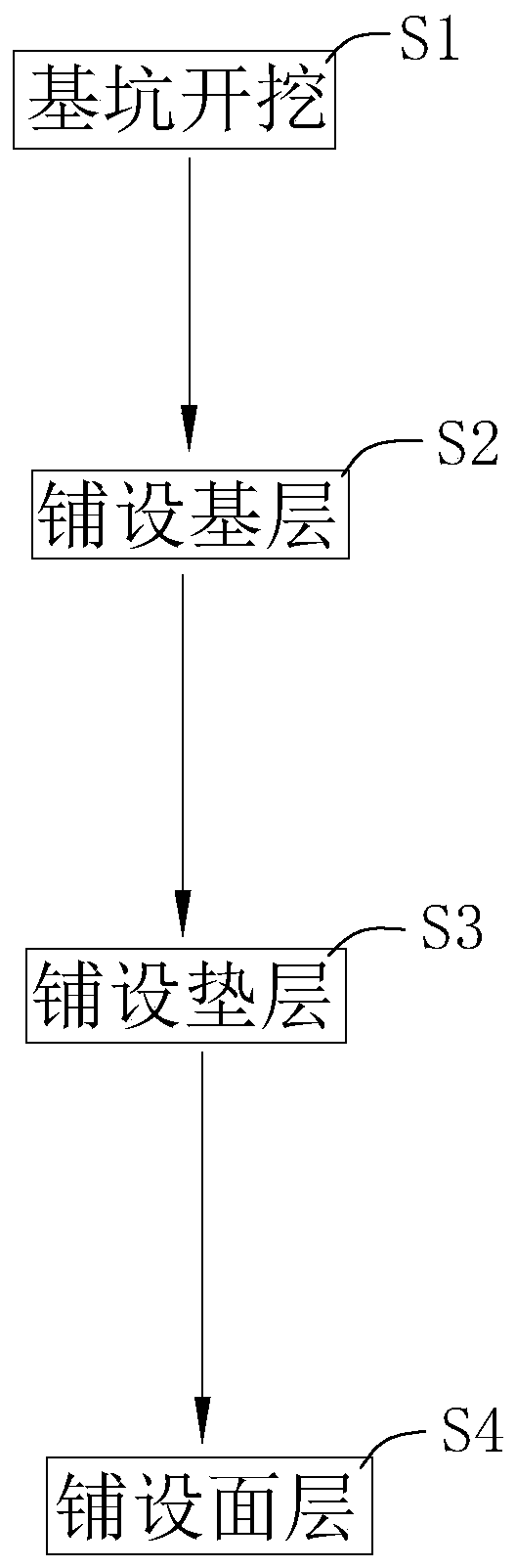

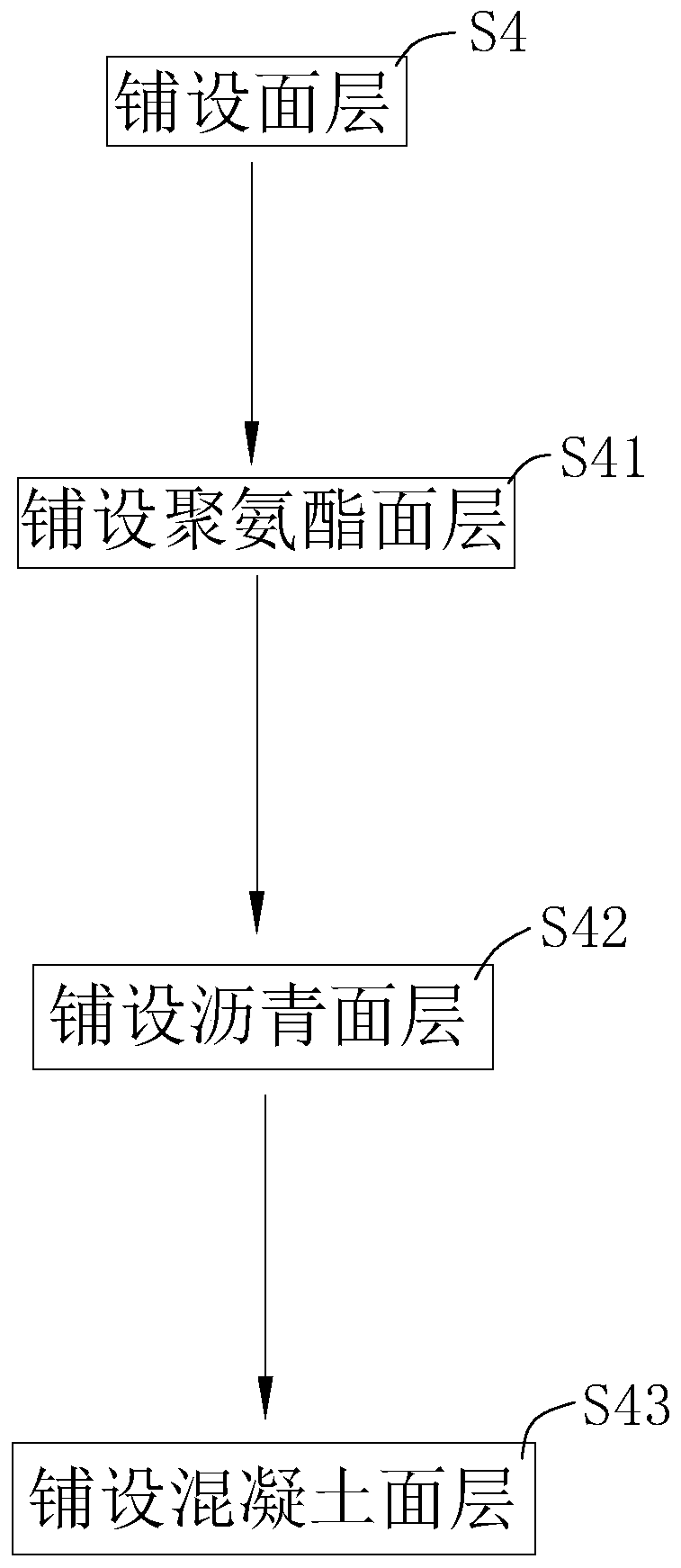

Municipal road construction method

The invention relates to the technical field of municipal roads, and provides a municipal road construction method which aims to solve the problem that road collapse is possibly caused as structural strength of soil is reduced if soil below a road is soaked excessively. According to the technical scheme, the municipal road construction method comprises the following steps: S1, excavating foundation pits; S2, laying a base layer; S3, laying a cushion layer; S4, laying a surface layer: S41, laying a polyurethane surface layer; S42, laying an asphalt surface layer; and S43, laying a concrete surface layer, wherein the concrete surface layer is formed by concrete slurry pouring, and the concrete slurry comprises the following components in parts by mass: 100 parts of silicate cement, 300-400 parts of coarse aggregates, 150-200 parts of fine aggregates, 100-150 parts of an polyurethane adhesive, 5-10 parts of a silane coupling agent and 90-110 parts of water. The surface layer comprises thepolyurethane surface layer, the asphalt surface layer and the concrete surface layer, and the polyurethane surface layer is utilized to provide relatively good water resistance, so that water on theroad is not liable to penetrate into the cushion layer, influences on a bottom soil base of the road are reduced, the bottom soil structure of the road is kept stable, and the road is relatively stable and is not liable to collapse.

Owner:广东金建建筑股份有限公司

Production process of ceramic tile capable of accurately positioning dry particles, and product thereof

InactiveCN112010677AGood effectBright color and textureAuxillary shaping apparatusBrickAdhesive glue

The invention discloses a production process of a ceramic tile capable of accurately positioning dry particles, and a product thereof. The production process comprises the following steps: A, applyingground coat to the surface of a ceramic tile blank through a glazing device; B, digitally printing surface glaze through a glaze printing device; and C, printing a glue and ink pattern in a first limited area on the surface of the ceramic tile blank through a gluing unit of a dry particle printing device, and then positioning and distributing the dry particles in the first limited area through adry particle positioning and distributing unit of the dry particle printing device. The production process of the ceramic tile capable of accurately positioning dry particles is simple; and firing canbe carried out after rapid drying, and the sintering effect is good, so the problems of long-time drying or cracking of the brick body and large dosage of the dry particles when the dry particles andthe protective glaze are purely applied are solved, the prepared ceramic tile has the advantages of high wear resistance, hardness and flatness, high texture pattern definition, strong permeability and strong three-dimensional contrast, and the problems of poor use performance and poor three-dimensional effect of the ceramic tile purely coated with dry particles and protective glaze are solved.

Owner:佛山市东鹏陶瓷发展有限公司

Refining ladle opening anti-sticking slag material and preparation method thereof

ActiveCN112010658AReduce manufacturing costComplementary and reasonableProcess efficiency improvementCarbide siliconSlag

The invention discloses a refining ladle opening anti-sticking slag material and a preparation method thereof. The material comprises the following raw materials in percentage by mass: 25-40% of forsterite aggregate, 5-10% of forsterite fine powder, 15-25% of waste magnesia carbon brick aggregate, 15-22% of magnesia fine powder, 3-7% of carbon material fine powder, 2-6% of silicon carbide fine powder, 1-3% of hardening accelerator and 10-14% of binding agent. The method comprises the steps that the raw materials are mixed in proportion and stirred to be uniform, then 10%-14% of a binding agentis added and stirred to be uniform, the amorphous anti-slag-sticking coating is formed, and the ladle opening and the slag feeding line are coated with the amorphous anti-slag-sticking coating. The material is a MgO-SiO2-C refined ladle opening anti-sticking slag material which is resistant to high temperature, good in slag wettability resistance, anhydrous and low in cost, ladle opening slag sticking can be effectively prevented, stuck steel slag is easy to clean, the service life of a ladle is prolonged, ladle repair is reduced, and the production efficiency of a steel mill is improved. Theraw materials adopted by the material can be recycled, and the preparation method and application of the material are simple and convenient.

Owner:BAOSHAN IRON & STEEL CO LTD

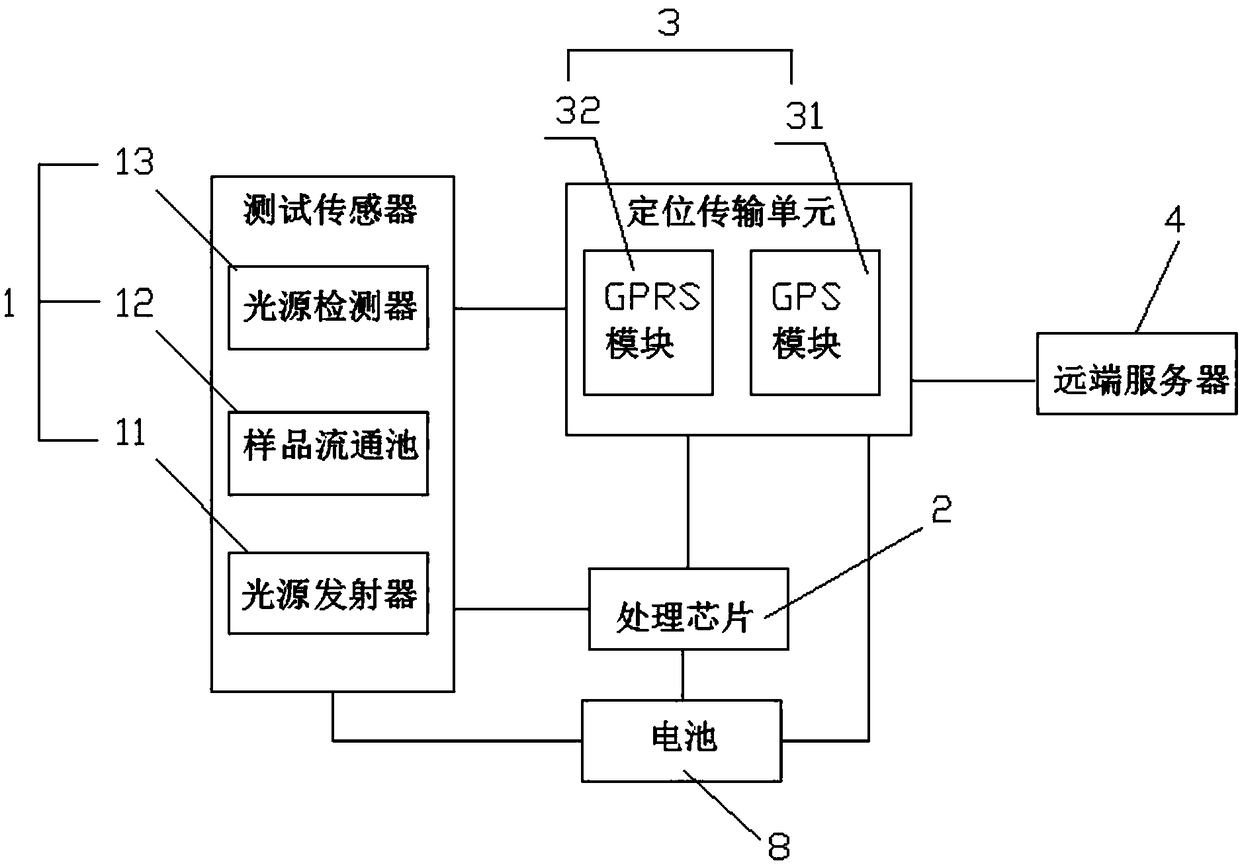

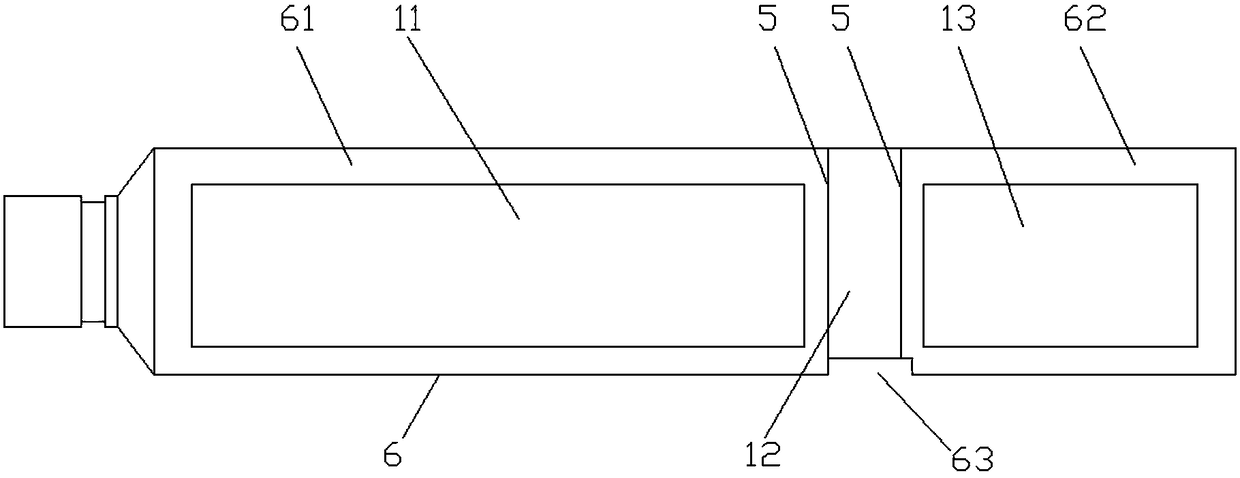

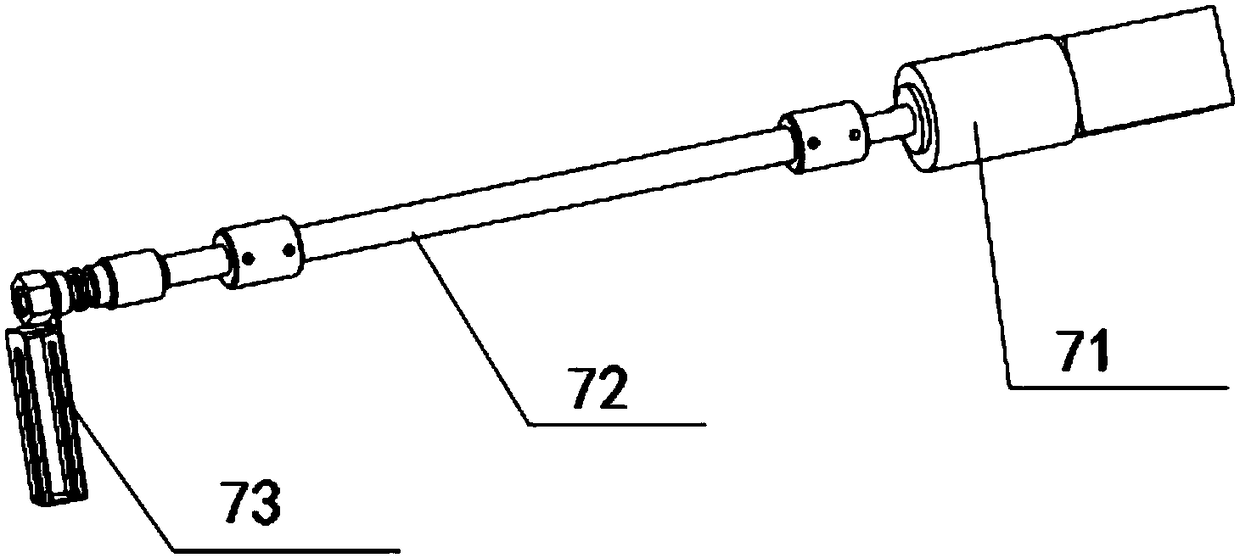

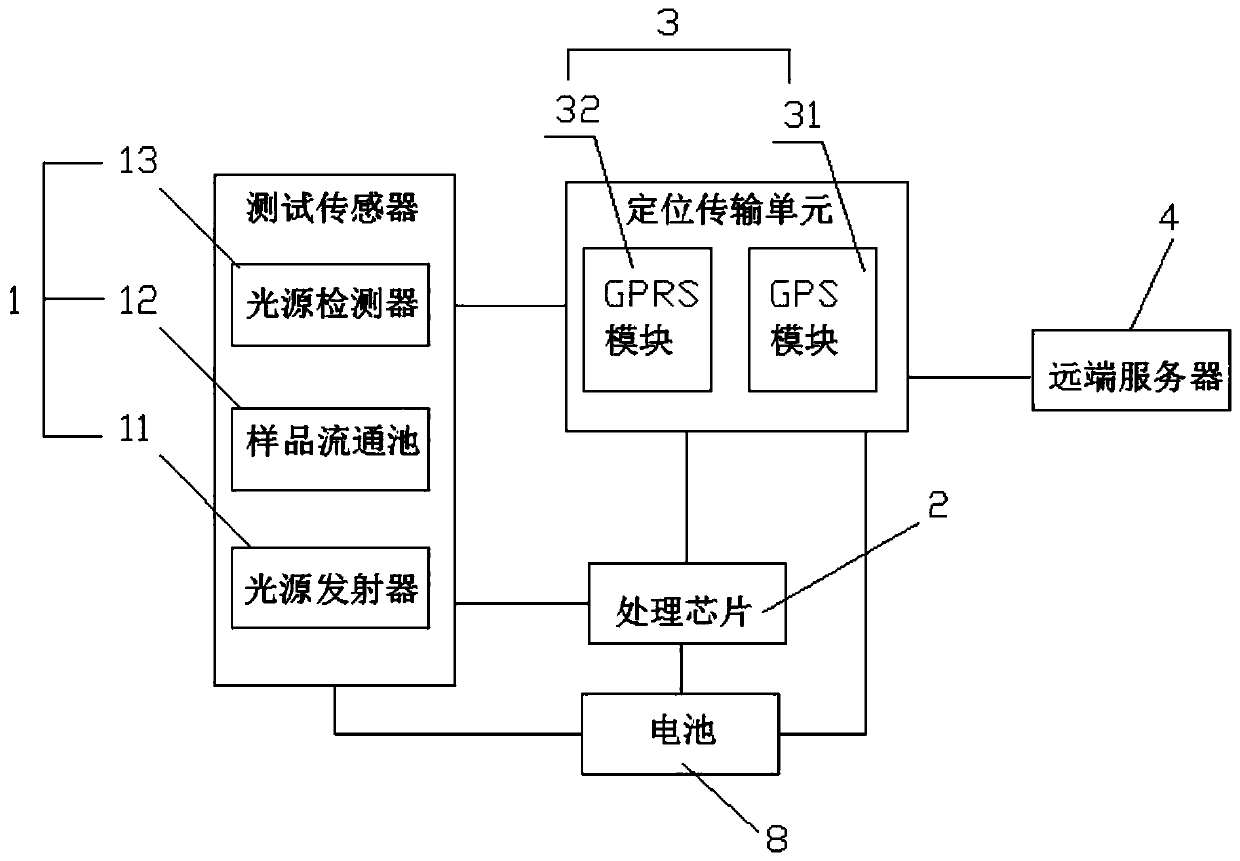

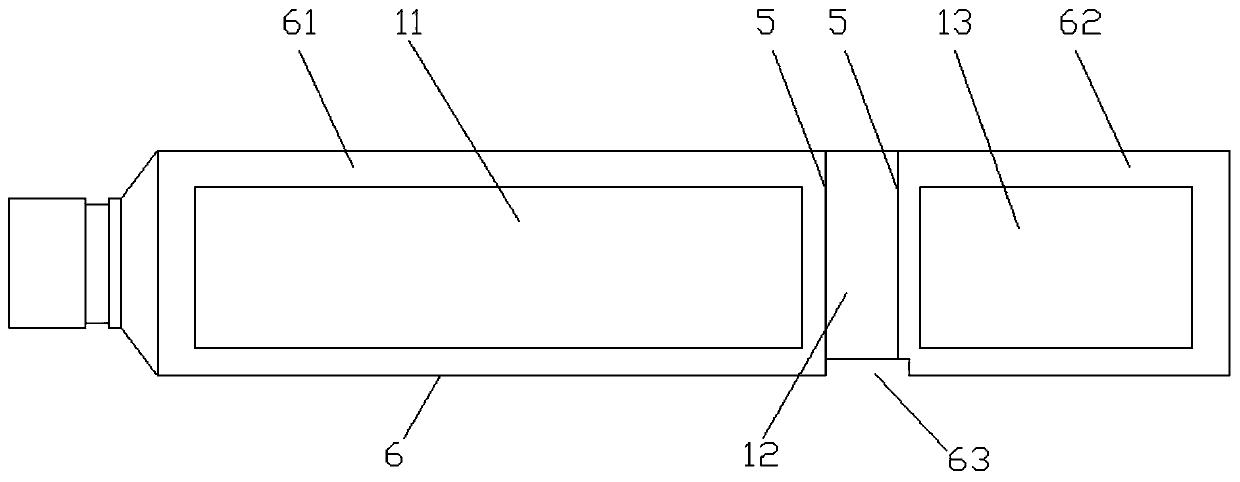

Water quality monitoring device

ActiveCN108426836AHydrophobicMinimize air bubblesTransmissivity measurementsTransmittanceWater quality

The invention relates to a water quality monitoring device. The device comprises a test sensor, a processing chip and a positioning and transmission unit, wherein the test sensor comprises a light source emitter, a sample flow cell and a light source detector; light transmitting pieces are arranged at a light path inlet end and a light path outlet end of the sample flow cell respectively; the surfaces of the light transmitting pieces are polished and plated with light transmitting hydrophobic films. The surfaces of the light transmitting pieces are polished and plated with light transmitting hydrophobic films, so that the light transmitting pieces can have the hydrophobic property, tiny bubbles attached to the surfaces of the light transmitting pieces can be reduced, light ray refraction,diffuse reflection and other phenomena can be reduced, and the transmittance at an ultraviolet-visible light waveband can be improved. Meanwhile, the surface contact angle between water and the lighttransmitting hydrophobic films is enlarged, thus, the surfaces of the light transmitting pieces cannot be soaked by water, the possibility of absorption of dust in water is reduced, and the light transmittance and the like are improved.

Owner:力德(中山)环境科技发展有限公司

Steel ladle fireproof casting material

The invention relates to a steel ladle fireproof casting material, which is prepared from the following components by weight: 50-70 parts of magnesite, 5-20 parts of dolomite, 5-10 parts of zircon, 1-20 parts of carbon, 2-5 parts of an anhydrous binder, and 1-8 parts of hercynite, wherein the magnesite, the dolomite, the zircon and the hercynite are mixed to prepare 40-50 parts by weight of particles and 50-60 parts by weight of fine powder, the particle size of the particles is 2.0-2.5 mm, and the particle size of the fine powder is 0.1-0.9 mm.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

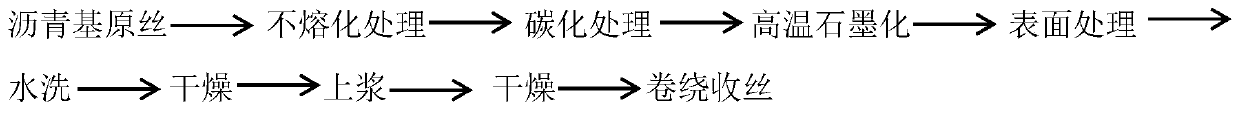

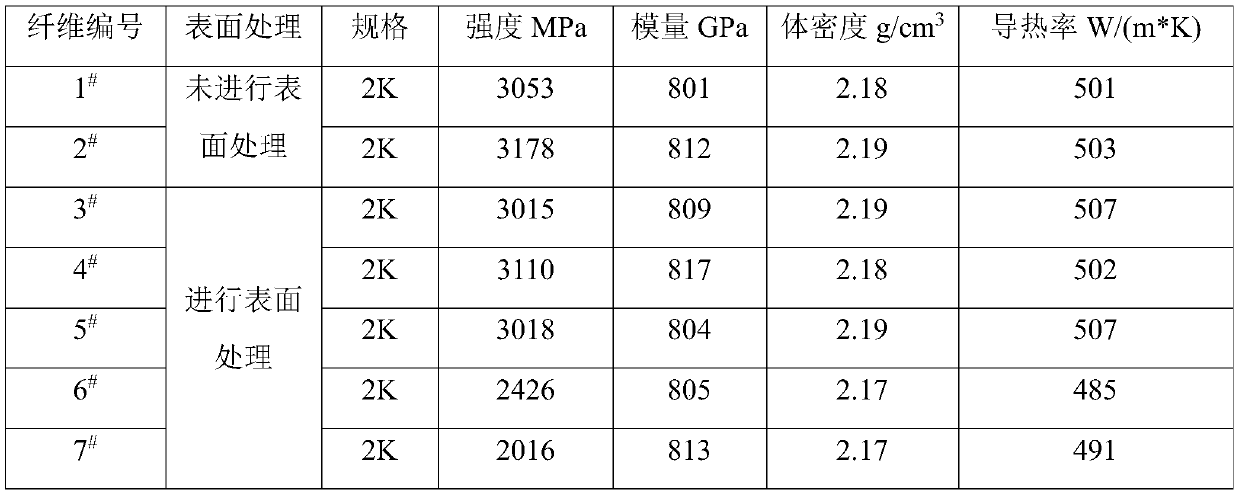

High surface activity pitch-based graphite fiber and preparation method thereof, and resin-based composite material prepared based on high surface activity pitch-based graphite fiber

InactiveCN110904674APromote infiltrationIncreased interlaminar shear strengthCarbon fibresInterlaminar shearResin-Based Composite

The invention discloses a high surface activity pitch-based graphite fiber and a preparation method thereof, and a resin-based composite material prepared based on the high surface activity pitch-based graphite fiber, and belongs to the technical field of preparation of carbon fibers. The preparation method comprises the steps of 1, using mesophase pitch as a raw material, and preparing pitch-based precursors with fiber diameters of 10 microns -30 microns via melt spinning; and 2, after winding the pitch-based precursors prepared in the step 1, sequentially performing active pay-off, non-melting treatment, low-temperature carbonizing treatment, high-temperature carbonizing treatment, graphitizing treatment, surface treatment (electrolysis), washing and drying, sizing and drying, and finalwinding, and thus acquiring pitch-based graphite fibers. According to the preparation method, via introduction of surface electrolysis and washing, under the condition that other performance of the pitch-based graphite fibers prepared according to the method are unvaried, the prepared resin-based composite material is greatly enhanced in interlaminar shear strength.

Owner:SHAANXI TIANCE NEW MATERIAL TECH

Horizontal floor tile laying method for house construction

ActiveCN113530156AImprove insulation effectFully soakedBuilding constructionsComposite materialCeramic tiles

The invention relates to a horizontal ground tile laying method for house construction. The horizontal ground tile laying method specifically comprises the following steps: cleaning the ground, specifically, laying tiles in one area every day, removing foreign matters or dust on the ground when the tiles in one area are laid, and then spraying water mist on the ground for wetting; soaking ceramic tiles in water, specifically, soaking the ceramic tiles in water by using ceramic tile water soaking equipment while performing the step 1; laying a datum, specifically, firstly laying a row of ceramic tiles and a line of ceramic tiles, one ceramic tile at the end of the row of ceramic tiles and one ceramic tile at the end of the line of ceramic tiles are the same ceramic tile, reserving a gap between every two adjacent ceramic tiles, and knocking the ceramic tiles to be flat through a rubber hammer; laying the ceramic tiles, specifically, laying each ceramic tile in a flush mode corresponding to the adjacent ceramic tile; and conducting gap treatment, specifically, after cement on the ceramic surfaces of the ceramic tiles is dried and solidified, filling gaps between every two adjacent ceramic tiles with a gap beautifying agent. The effect that the possibility of the hollowing phenomenon after the ceramic tiles are laid can be reduced is achieved.

Owner:深圳市中弘建设工程有限公司

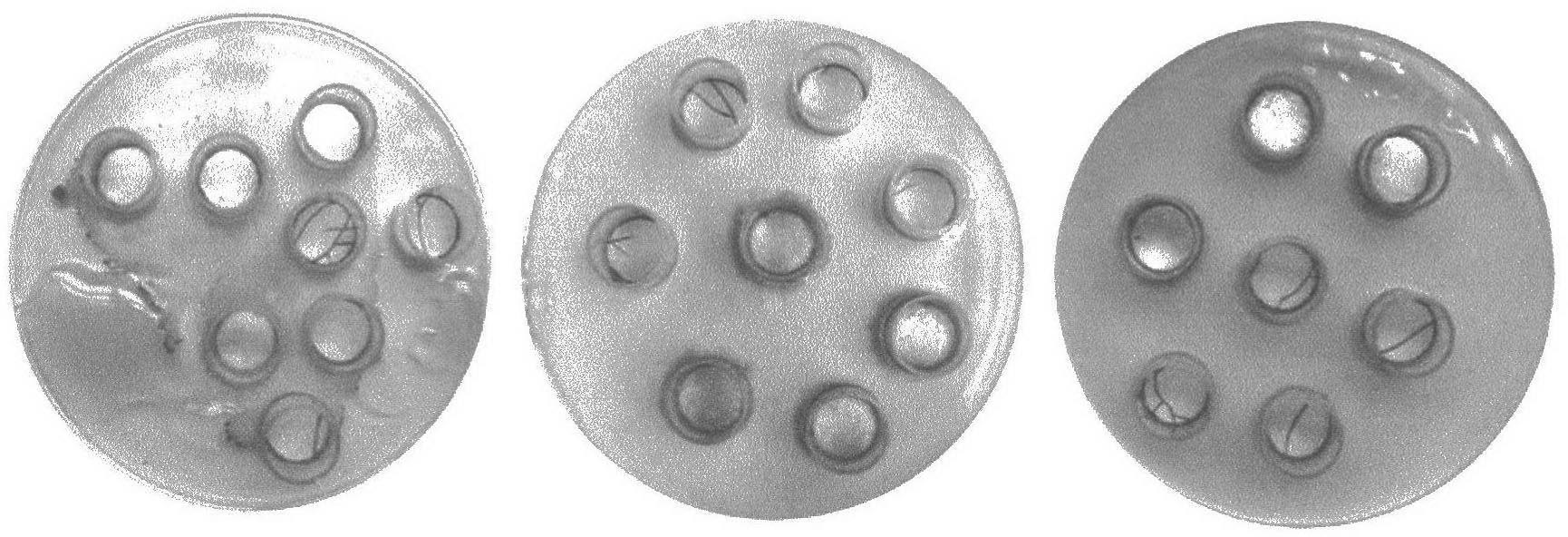

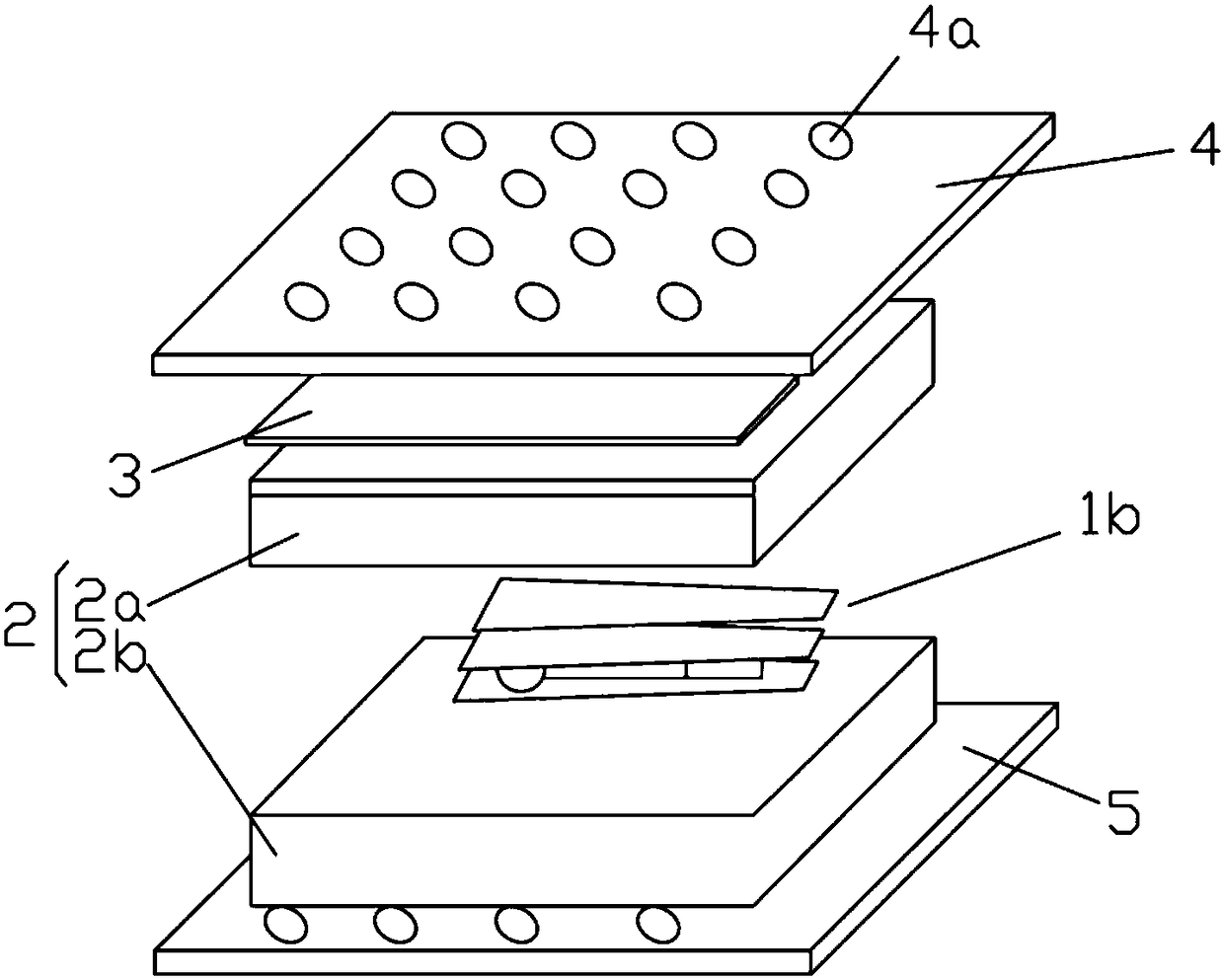

Sintering jig and manufacturing method for electronic components

The invention discloses a sintering jig and a manufacturing method for electronic components. The manufacturing method for the electronic components comprises the steps of producing blanks and producing outer electrodes on the blanks, wherein the step of producing the outer electrodes on the blanks is carried out in the sintering jig prepared from recrystallized silicon carbide, and the sintering jig is prepared through the following steps: (1) preparing a mixed material which comprises 46-63% of silicon carbide powder of 30-100mesh, 24-45% of silicon carbide powder of 1500-3000mesh, 3-10% of silicon powder of 250-500mesh, 3-8% of carbon powder of 250-500mesh and 2-4% of a binding agent; (2) processing the mixed material into a green; (3) sintering the green to obtain the sintering jig. With the adoption of the manufacturing method disclosed by the invention, the technical problem that the outer electrodes the electronic components are easy to fall off during sintering can be greatly solved, and the production yield and capacity of the electronic components can be improved.

Owner:SHENZHEN SUNLORD ELECTRONICS

Filling glue used at bottom of electronic device

InactiveCN109294499AAvoid breakingEnhanced interface bindingNon-macromolecular adhesive additivesMacromolecular adhesive additivesFiberEpoxy

The invention discloses a filling glue used at a bottom of an electronic device, which belongs to the technical field of electron packaging. According to the invention, glass fiber and hydrofluoric acid are mixed in a mass ratio of 1:10 to 1:20, a mixture is filtered, washed and dried to obtain the primarily processed glass fiber, in terms of parts by weight, 20 to 30 parts of primarily processedglass fiber 3 to 5 parts of biogas slurry, 1 to 2 parts of cane sugar, and 20 to 30 parts of water are mixed and fermented, filtered, and washed to obtain the secondary processed glass fiber, the secondary processed glass fiber and ethyl orthosilicate are stirred and mixed at the mass ratio of 1:10 to 1:20, the mixture is filtered, dried, charred, stepwise heated, high temperature treated, cooled,and ball milled to obtain a modified filler; the epoxy resin and a diluent are stirred and diluted, and then a curing agent, the modified filler, an antifoaming agent, and a curing accelerator and the nano humic acid are stirred and mixed, and the filling glue used at the bottom of the electronic device is obtained. The filling glue used at the bottom of the electronic device prepared by the technical scheme has the characteristics of excellent thermal conductivity.

Owner:王景硕

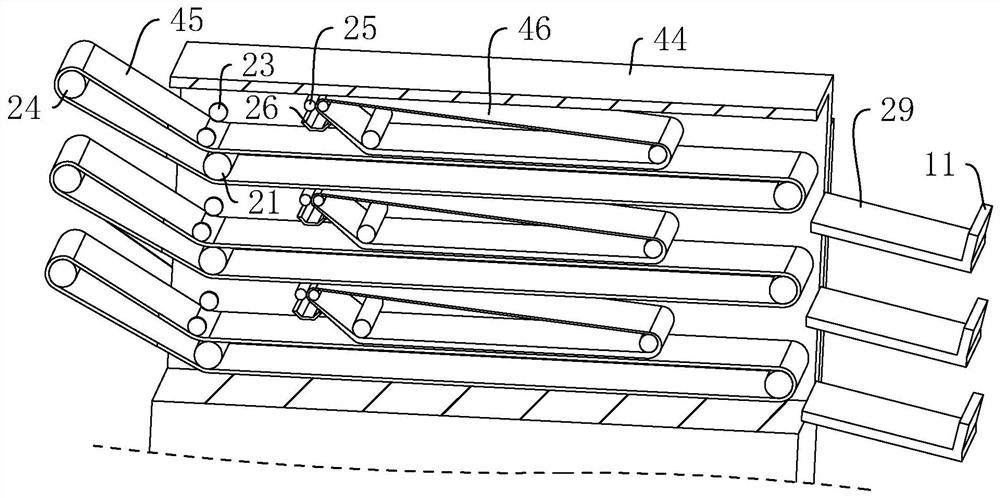

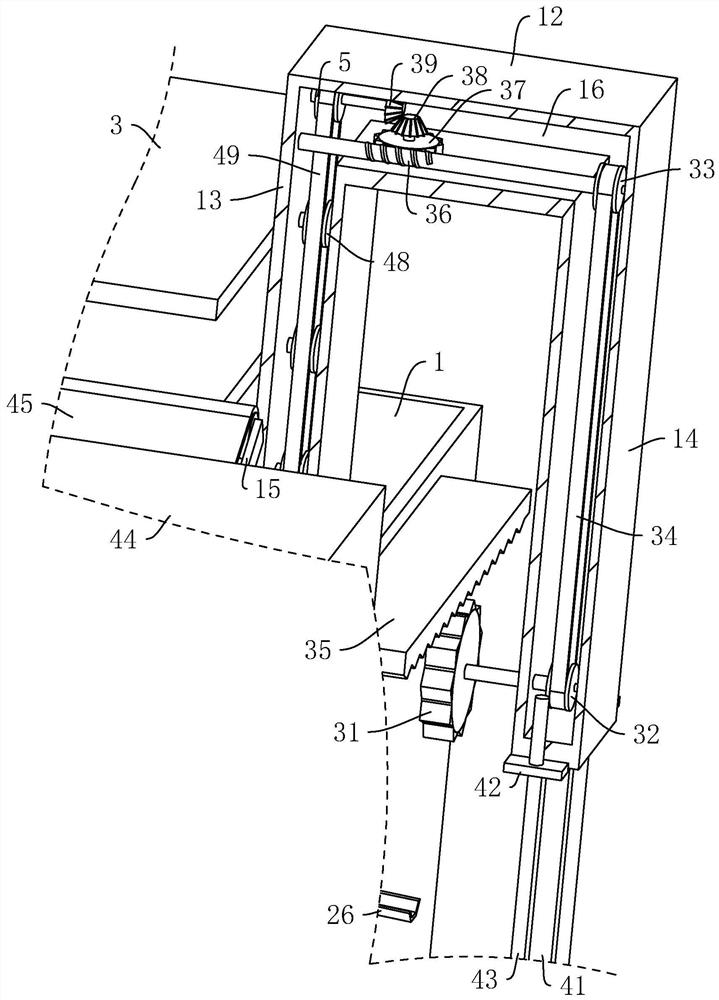

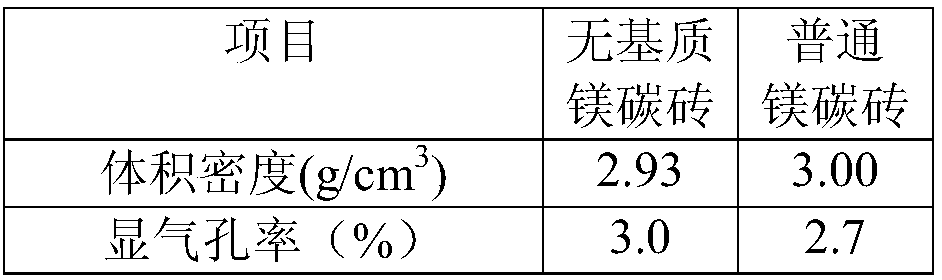

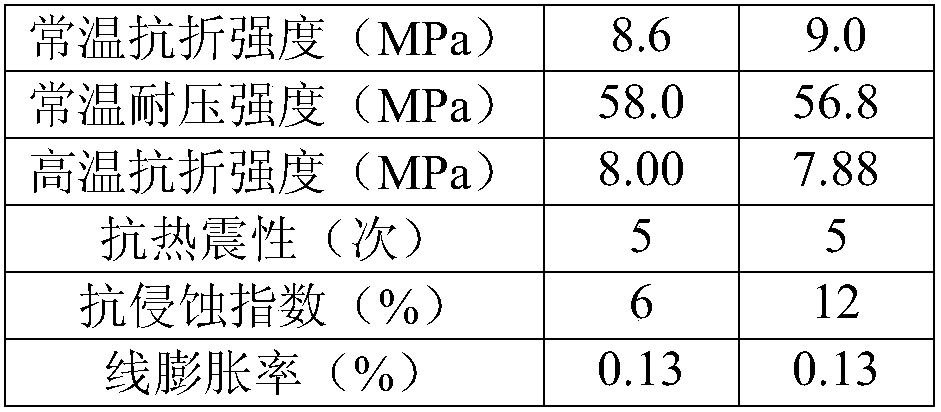

Magnesia carbon brick and preparation method thereof

The invention relates to a magnesia carbon brick and a preparation method thereof and belongs to the technical field of preparation of refractory materials. The magnesia carbon brick comprises the following components in parts by weight: 75-90 parts of electro-fused magnesite particles, 5-10 parts of carbon, 1-5 parts of an additive and 1-3 parts of a bonding agent. All the components are put in amuller for mulling and then are pressed, formed, baked and cured to obtain a final product, namely the magnesia carbon brick. The magnesia carbon brick and the preparation method thereof provided bythe invention have the benefits that the preparation method is simple, the steps are easy to operate, the thinking of a traditional magnesia carbon brick is changed, and a magnesite fine powder is notmixed; as a matrix is dominated by the carbon and a small quantity of additives, the better resistance of the magnesia carbon brick to high temperature, vacuum and acid slag is improved, so that theservice life of a refractory furnace lining is prolonged when advanced special steel is smelted, and the consumption of ton steel refractory materials is significantly reduced.

Owner:江苏苏嘉集团新材料有限公司

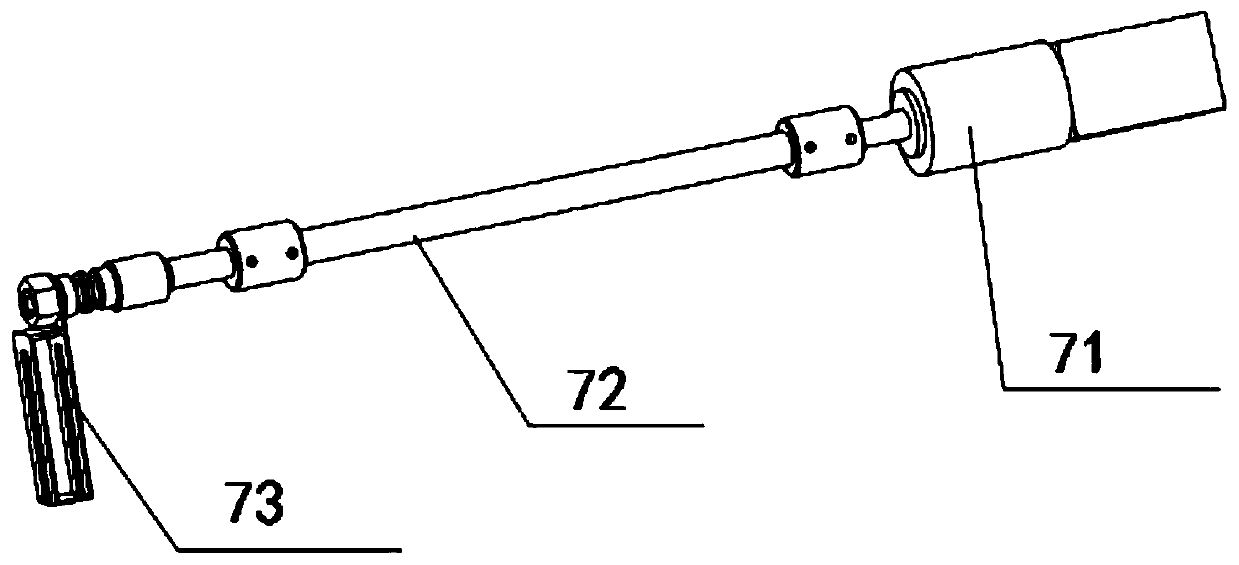

Cylinder plate method-based leather material bacteriostasis effect test method

InactiveCN102586396ANot easy to infiltrateNot easy to roll upMicrobiological testing/measurementEngineeringTriphenyltetrazolium chloride

The invention discloses a cylinder plate method-based leather material bacteriostasis effect test method. The test method includes the following steps: (1) sample preparation; (2) 2,3,5-triphenyltetrazolium chloride solid medium preparation; (3) 2,3,5-triphenyltetrazolium chloride semisolid medium preparation; (4) inoculant suspension preparation; (5) testing operation; (6) evaluation and reporting. The cylinder plate method-based leather material bacteriostasis effect test method solves the defects of small bacterial colony, nontransparent sample and uneasy observation and recording; the test method is easy to operate, the result is accurate, the repeatability is good, and the test method has a high application value.

Owner:中华人民共和国吴江出入境检验检疫局

Preparation method of edible medicinal and edible traditional Chinese medicine hair dye

ActiveCN112022792AStrong coloring powerIncrease contentCosmetic preparationsHair cosmeticsBiotechnologyColour fastness

The invention provides a preparation method of an edible medicinal and edible traditional Chinese medicine hair dye, relates to a preparation method of a hair dye, and particularly relates to a preparation method of a traditional Chinese medicine hair dye, and aims to solve the problems that toxic and harmful substances are added into an existing hair dye, the existing hair dye is prone to causingcancers and allergy, hair is prone to being damaged and the like. The preparation method comprises the following steps: 1, preparing a gardenia water extract; 2, preparing a fermentation substrate; 3, fermenting to obtain fermented soya beans; 4, preparing a culture solution; 5, preparing a rice bran fermentation solution; 6, carrying out synergistic fermentation to obtain fresh fermented soya beans; 7, preparing a gardenia water solution; and 8, mixing, extracting and drying to obtain the edible medicinal and edible traditional Chinese medicine hair dye. The preparation method has the advantages that the content of polyglutamic acid is increased, and the coloring power is high; the gardenia blue pigment yield is high; the color fastness is not prone to fading. The preparation method is mainly used for preparing the hair dye.

Owner:HEILONGJIANG ACAD OF TCM

Preparation method of composite ceramic material for thermal protection connection

InactiveCN110668825AGood chemical stabilityLow chemical stabilityComposite ceramicChemical stability

The invention relates to a preparation method of a composite ceramic material for thermal protection connection, and belongs to the technical field of ceramic materials. According to the preparation method, silicon nitride is used as a raw material to prepare the composite ceramic material for thermal protection connection; silicon nitride has the advantages of hardness, heat resistance, wear resistance and corrosion resistance of a common ceramic material and has the advantages of good thermal shock resistance, high-temperature creep resistance, good self-lubricating property, good chemical stability and the like, and has excellent dielectric properties such as relatively low density, low dielectric constant, low dielectric loss and the like; the electronegativity of silicon and nitrogenelements in silicon nitride is similar; the steam pressure is high; the diffusion coefficient is very low; silicon nitride is a covalent compound with high bond strength and can form oxide protectivefilms in air, so that good chemical stability is achieved; the reliability of the composite ceramic material for thermal protection connection can be effectively improved by taking silicon carbide asa raw material, and the composite ceramic material for thermal protection connection has good hardness and bearing capacity.

Owner:曾军

High-strength castable for continuous caster tundish

The invention relates to a high-strength castable for a continuous caster tundish, which is prepared from the following components in parts by weight: 20-30 parts of magnesite, 10-20 parts of dolomite, 10-20 parts of zircon, 10-20 parts of graphite, 5-10 parts of phenol formaldehyde resin, 10-20 parts of zirconium oxide fiber and 5-10 parts of yttrium oxide. The magnesite, dolomite, zircon and graphite are mixed to obtain 45-50 parts by weight of particles and 50-55 parts by weight of fine powder; and the zirconium oxide fiber, yttrium oxide and phenol formaldehyde resin are used as additives. The particle size of the particles is 1.2-1.8mm, and the particle size of the fine powder is 0.3-0.8mm.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

Bamboo leaf flavone extracting method by synergy of ultrasonic and surface-active agent

InactiveCN105231249AEasy extractionImprove protectionFood ingredient as antioxidantFood preservationAdditive ingredientSurface-active agents

The present invention discloses a bamboo leaf flavone extracting method by synergy of ultrasonic and surface-active agent. The method includes the following steps: bamboo leaf powder is added to a mixed solution of ethanol and extraction liquid, the liquid to solid ratio of the extraction liquid to the bamboo leaf powder is 15-20 : 1 mL / g, the liquid to solid ratio of the ethanol and the bamboo leaf powder is 15-20 : 1 mL / g; and the mixture is subjected to a synergic extraction of ultrasonic and surface-active agent at an ultrasound frequency of 40 KHz and an ultrasonic power of 100-450 W for 1-3 times with 20-30 minutes each time to obtain the bamboo leaf flavone. The extraction method has the advantages of being low in equipment requirement, convenient in operation, short in extraction time, needing no heating, and being conductive to protect heat labile component, which solves the problems that the existing solvent extraction method of bamboo leaf flavone is large in solvent consumption volume, is low in efficiency and is high in cost.

Owner:JINAN UNIVERSITY

Organic silicon-fluorine modified resin and coating preparation method

InactiveCN101638512BExcellent comprehensive physical and chemical propertiesReduce surface tensionFibre treatmentLeather surface finishingPolymer scienceOrganosilicon

The invention provides silicon-fluorine modified resin and a method for preparing antifouling and easy-clean surface modified coating by utilizing the silicon-fluorine modified resin, wherein the silicon-fluorine modified resin is a modified surface processing agent which has uniform structure, extremely low surface tension, extremely good drainage and antifouling effect and excellent physical and mechanical properties and solvent resistance. The silicon-fluorine modified resin comprises the following raw materials in percentage by weight: 0.1-20 percent of silicon resin, 0-10 percent of fluororesin, 0.1-20 percent of hydroxyl acrylate resin, 20-50 percent of hydroxyl polyurethane resin and 20-70 percent of solvent. Coating slurry comprises the following components by weight part: 100 parts of silicon-fluorine modified resin, 10-40 parts of curing agent, 10-40 parts of accelerating agent and 10-200 parts of solvent, and the coating is constructed through printing, roller painting, spraying, brushing, dip-coating, and the like. The silicon-fluorine modified resin and the coating thereof have excellent antifouling and easy-clean functions and better comprehensive physicochemical property, and can be widely applied to the fields of furniture, automotive trims and seats, clothes, shoe leather, bags, and the like.

Owner:浙江康成新材料科技有限公司

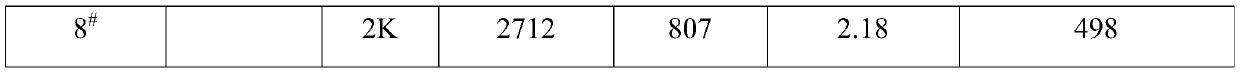

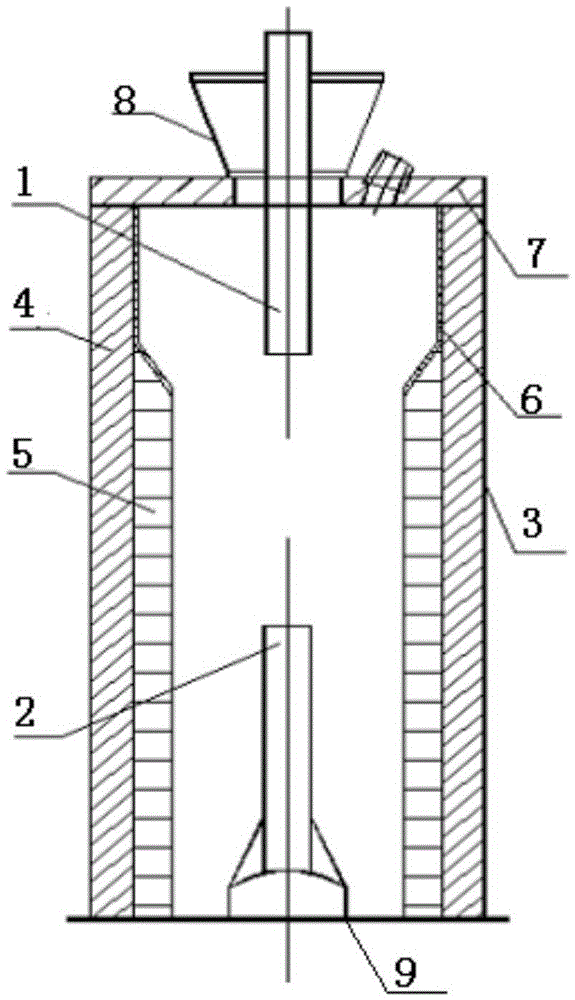

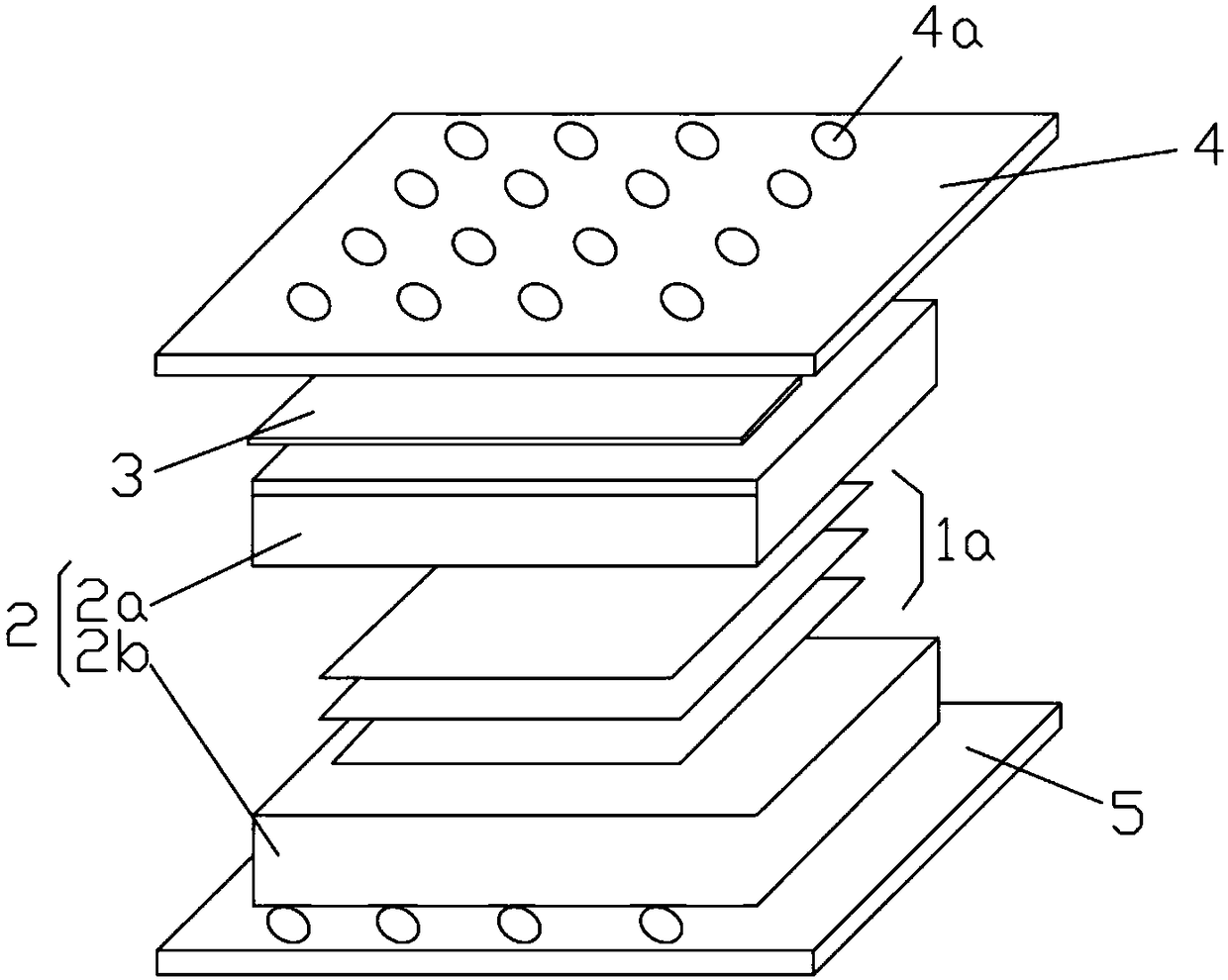

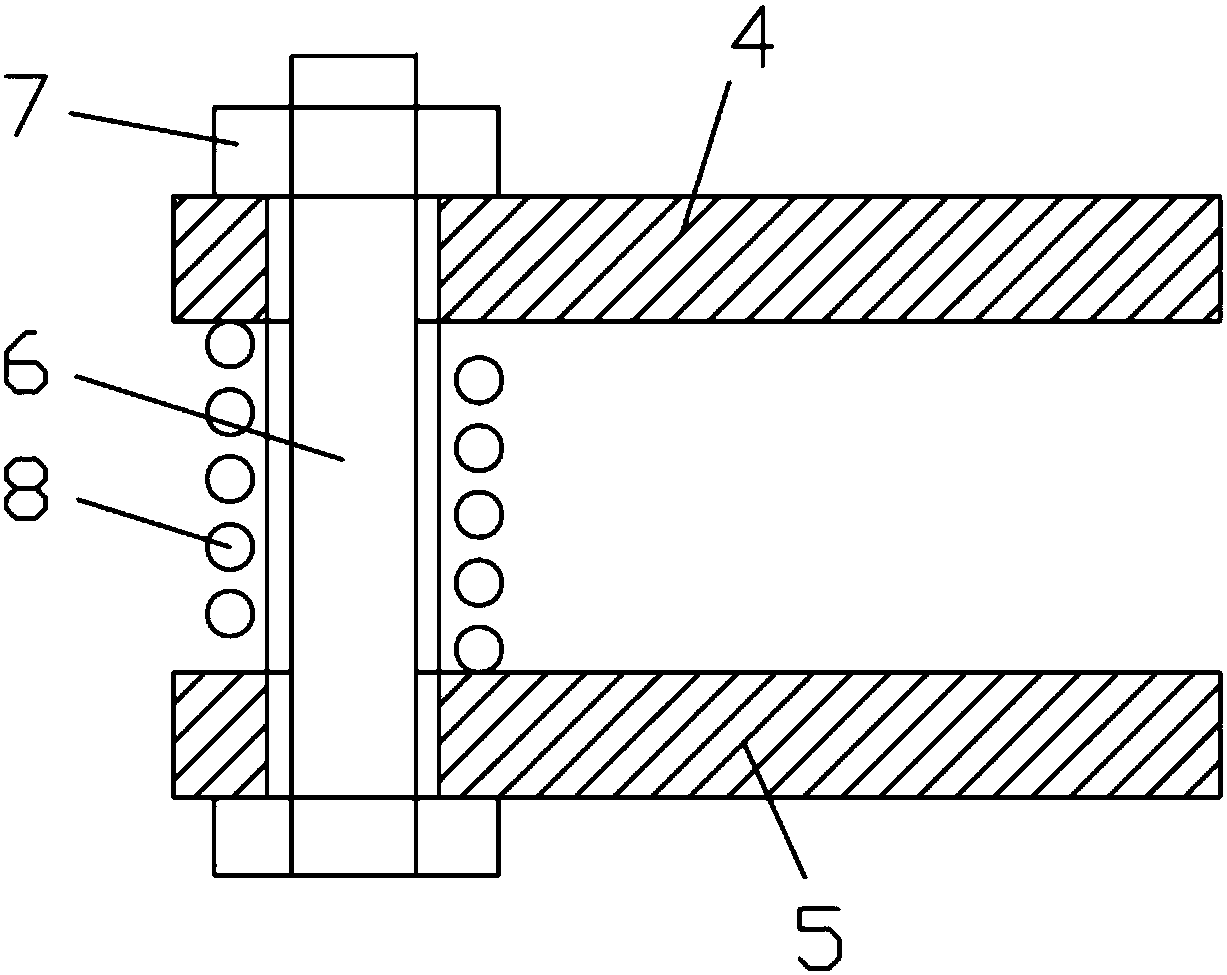

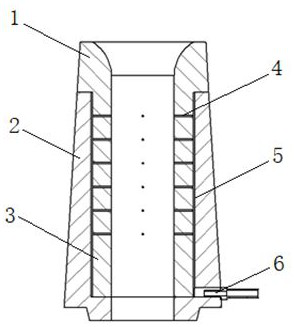

Graphitizing furnace liner structure

The invention relates to a graphitizing furnace liner structure. From outside to inside, the structure sequentially comprises a furnace shell (3), an external liner (4) constructed by a refractory material layer by layer and a carbon brick liner (5), wherein the top of the carbon brick liner (5) is provided with a slope section which gradually transits to the external liner (4); the top of the slope section is about 5.9-6.9m away from the furnace bottom; and the vertical height of the slope section accounts for about 4 / 79-6 / 7 of the height of the whole furnace body. The structure ensures no accumulation of the material, and has favorable flowability. The slope section and one side of the preheating zone towards the inside of the furnace body are respectively coated with an anti-coking paint layer to prevent the preheating zone from coking. No carbon brick is constructed on the section 1000-1500mm below the furnace cover, thereby preventing the top electrode from directly discharging to the carbon bricks due to the electric conductivity increase after the carbon bricks are subjected to high temperature.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Refractory castable for tundish cover

The invention discloses a refractory castable for a tundish cover. The refractory castable is prepared from the following components in parts by weight: 50-80 parts of magnesia, 5-20 parts of dolomite, 5-10 parts of zircon, 1-20 parts of carbon, 2-5 parts of water-free binder and 0.2-1 part of urotropine. The magnesia, the dolomite and the zircon are mixed to prepare particles and fine powder, wherein the part number of the particles is 35-55, the part number of the fine powder is 45-65, the particle size of the particles ranges from 3.0 to 2.0mm, the particle size of the fine powder is 2.0-0.5mm. The refractory castable has excellent thermal shock resistance and breakage and peel resistance.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

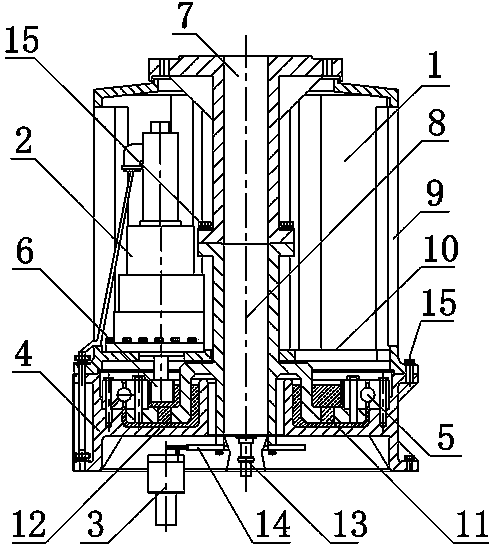

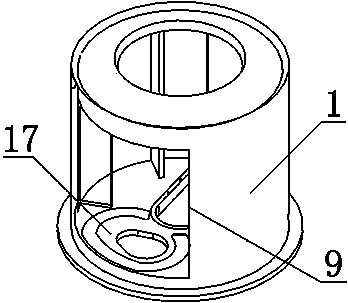

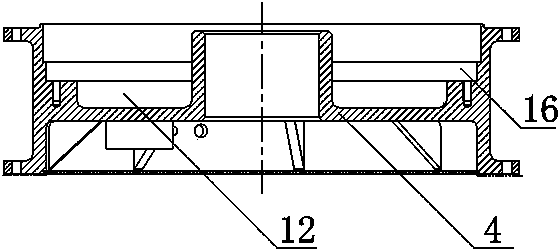

Novel oil bath rotary table

The invention relates to a novel oil bath rotary table. The novel oil bath rotary table comprises a rotary table outer shell (4), a rotary table outer cover (1), an upper main shaft (7), a lower main shaft (8) and a direction speed reducer (2). An oil tank (12) is arranged on the upper portion of the rotary table outer shell (4), an annular step groove (16) is formed in the outer wall of the oil tank (12), a bearing (5) is installed in the annular step groove (16), the lower main shaft (8) is installed in an inner ring of the bearing (5), the lower end face of the rotary table outer cover (1) is fixedly connected with the upper end face of the rotary table outer shell (4), at least one door (9) is formed in the outer wall of the rotary table outer cover (1), the direction speed reducer (2) is vertically installed on a direction speed reducer installation face (17), a power gear (6) at the output end of the direction speed reducer (2) is meshed with an inner ring gear of the bearing (5), and a direction transmitter (3) is further arranged at the bottom of the rotary table outer shell (4). The novel oil bath rotary table has the advantages that the rotary table does not leak oil, the maintenance is convenient, and the service life is long.

Owner:CHENGDU JINJIANG ELECTRONICS SYST ENG

Sterilization detection device

InactiveCN108273104ANot easy to absorbNot easy to infiltrateLavatory sanitoryDisinfectionBiomedical engineering

The invention provides a sterilization detection device which comprises multiple hydrophobic non-woven fabrics and an indicator; multiple hydrophobic non-woven fabrics are overlaid together and coat the indicator. The sterilization detection device provided by the invention can be repeatedly used, so that the device cost can be lowered, and environmental pollution can also be avoided.

Owner:3M INNOVATIVE PROPERTIES CO

Water Quality Monitoring Device

The invention relates to a water quality monitoring device, which includes a test sensor, a processing chip and a positioning transmission unit. The test sensor includes a light source emitter, a sample flow cell and a light source detector. The light path inlet end and the light path outlet end of the sample flow cell are respectively provided. There is a light-transmitting sheet, the surface of which is polished and coated with a light-transmitting hydrophobic film. By polishing the surface of the light-transmitting sheet and adding a transparent hydrophobic film, the present invention can make the light-transmitting sheet hydrophobic, reduce the tiny bubbles attached to the surface of the light-transmitting sheet, thereby reducing light refraction, diffuse reflection and other phenomena, and can improve the performance in the ultraviolet-visible light band. The transmittance is increased, and the surface contact angle between water and the light-transmitting hydrophobic film is increased, making the surface of the light-transmitting sheet less likely to be wetted by water, reducing the possibility of adsorbing dust in the water, thereby improving the light transmittance, etc.

Owner:力德(中山)环境科技发展有限公司

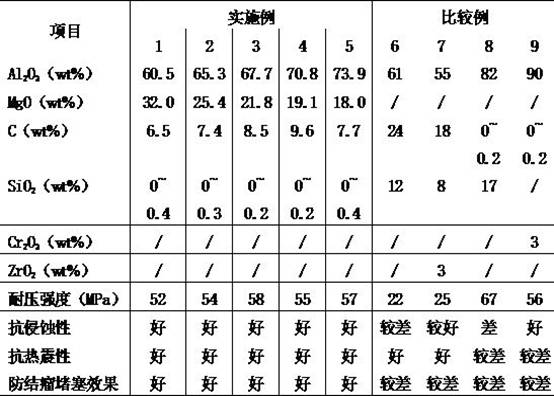

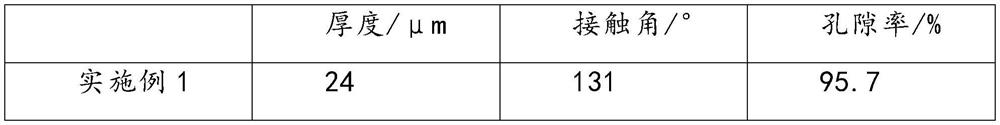

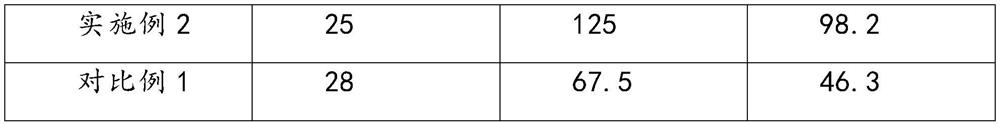

Anti-nodulation tundish ventilation upper nozzle

InactiveCN113458377AImprove corrosion resistanceGuaranteed corrosion resistanceMelt-holding vesselsEngineeringAnti oxidant

Owner:BAOSHAN IRON & STEEL CO LTD

Environment-friendly aqueous battery and preparation method thereof

ActiveCN114361708AStable charging and dischargingReduced risk of short circuitsFinal product manufactureCell component detailsElectrolytic agentPolyimide substrate

The invention relates to an environment-friendly aqueous battery and a preparation method thereof, and belongs to the technical field of aqueous batteries. The hydrophobic reinforced diaphragm taking polyimide as a base material is adopted in the battery, and fluorinated nano silicon dioxide is added into the diaphragm to serve as a reinforcing filler, so that the strength of the diaphragm material is improved, the diaphragm is prevented from being punctured, and the battery is ensured to still operate after being impacted or extruded by the outside, and the diaphragm is endowed with good hydrophobicity by a fluorine-containing group, so that the service life of the battery is prolonged. The diaphragm is not easy to infiltrate by the electrolyte, so that the problem of poor water resistance of the polyimide base material is solved, the contact angle between the diaphragm and the aqueous electrolyte is over 125 degrees through testing, and the diaphragm can be stably applied to an aqueous battery; the diaphragm is prepared by adopting two-step electrostatic spinning, fluorinated nano silicon dioxide is dispersed in a prepolymer to prepare a spinning solution, a membrane material is prepared by virtue of electrostatic spinning, and finally, a staggered three-dimensional network structure coated with nano silicon dioxide is formed by virtue of heating imidization reaction and has fine and high-strength pores, and the pore structure is maintained to be not deformed.

Owner:池州精研新能源科技有限公司

Preparation method of positive electrode suitable for solid-state battery

PendingCN113823768APromote infiltrationReduce crystallinityElectrode manufacturing processesSecondary cellsElectrolytic agentEngineering

The invention belongs to the technical field of chemical power sources, and particularly relates to a preparation method of a positive electrode suitable for a solid-state battery. The method comprises the following steps: adding a solvent and an adhesive into a homogenate container, fully stirring for dissolving, and then adding a conductive agent and positive active material powder, wherein the positive active material powder accounts for 50-99.85% the weight of of the solid content of slurry; coating an aluminum foil with uniformly stirred slurry, wherein the coating amount of a positive electrode is 30-60 mg / cm<2>; then drying and rolling, and matching the prepared positive electrode with a diaphragm and a negative electrode to prepare a lithium ion battery cell; and adding a prepared concentrated salt electrolyte into the battery cell, sealing, standing, and carrying out charging formation on the battery. The prepared solid-state battery not only has excellent safety, but also is comparable to the existing lithium ion battery adopting the conventional electrolyte in the aspect of electrical performance.

Owner:TIANJIN SPACE POWER TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com