Patents

Literature

125results about How to "Less prone to stress concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stress and whitening-resistant filled/modified polypropylene and preparation method thereof

InactiveCN102020806APromote absorptionHigh propylene regularityPolypropylene compositesMechanical property

The invention belongs to the field of polypropylene compound materials, and relates to a stress and whitening-resistant filled / modified polypropylene. The stress and whitening-resistant filled / modified polypropylene comprises the following compositions in parts by weight: 50 to 80 parts of PP, 5 to 25 parts of toughening agent, 10 to 25 parts of minerals, 1 to 5 parts of compatibilizer, 0.1 to 1 part of dispersant; 0.1 to 1 part of antioxygen, and 0.1 to 1 part of light stabilizer, wherein sum of the weight parts of the PP, the toughening agent, the mineral and the compatibilizer is 100. The prepared polypropylene compound material in the invention both has a good stress and whitening-resistant performance and an excellent comprehensive mechanical property. The preparation method in the invention is simple and easy to operate without special processing methods, and can be promoted and applied in large scale.

Owner:SUZHOU SUNWAY POLYMER

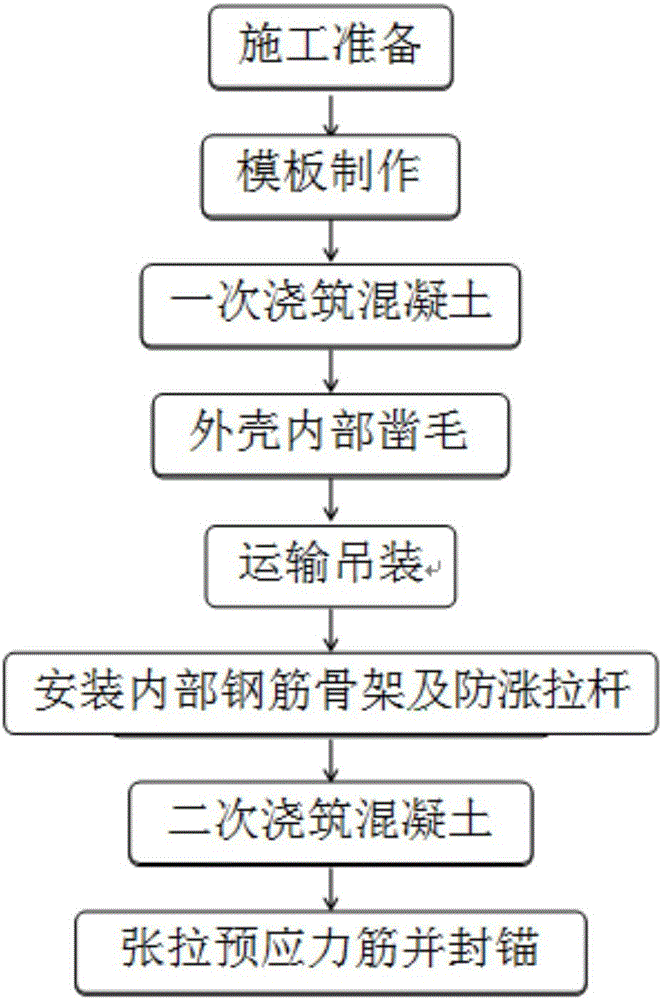

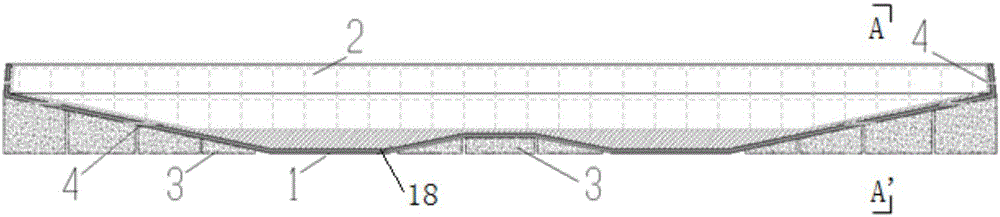

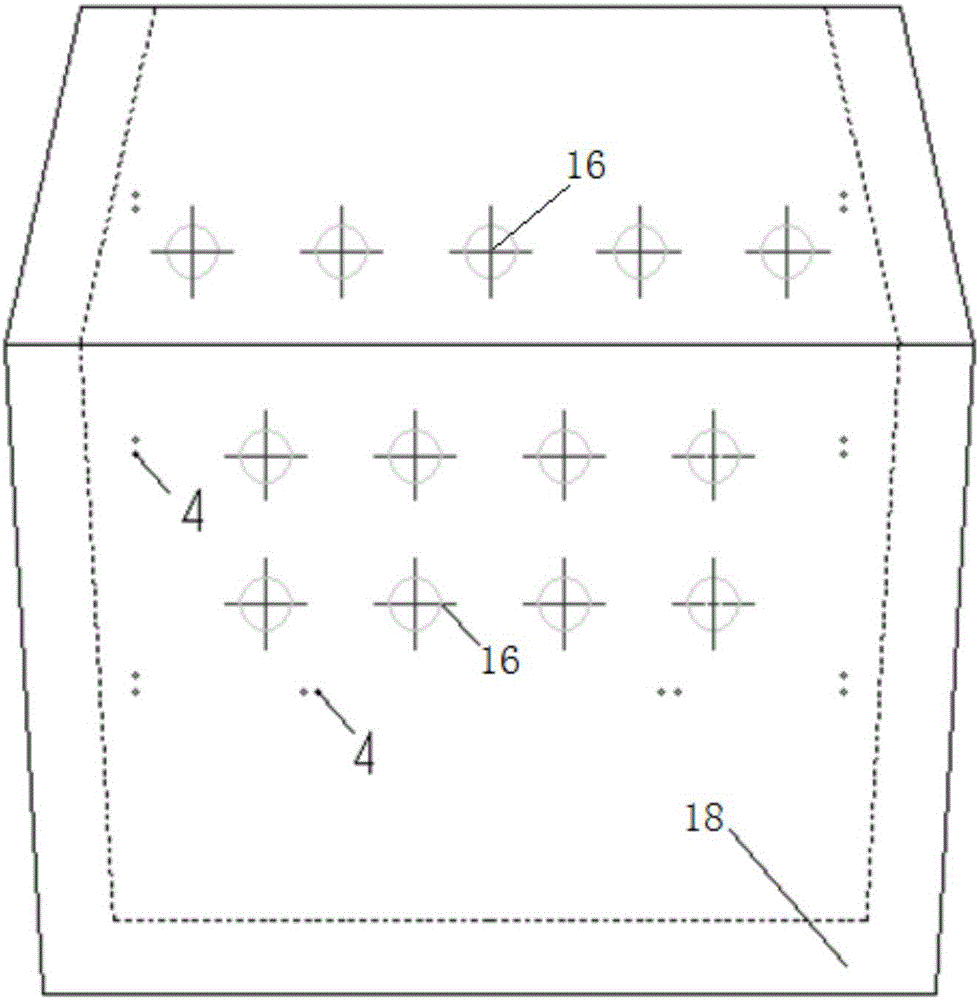

Large-scale bent cap semi-prefabrication construction technical method

InactiveCN106638313AImprove integrityShorten the timeBridge erection/assemblyBridge materialsStress concentrationPre stress

The invention discloses a large-scale bent cap semi-prefabrication construction technical method. Firstly, a bent cap open groove type shell is prefabricated in a prefabrication yard and then transported to a site to be lifted, inner concrete is poured in place with the bent cap open groove type shell as a template, and therefore a large-scale bent cap is manufactured. The method specifically includes the following steps of manufacturing of the open groove type shell template, first-time concrete pouring, rough chiseling, transportation and lifting, reinforcing steel bar framework and anti-expansion pull rod intra-groove installation, second-time concrete pouring, prestressed bar tensioning and anchor sealing. By the adoption of the construction technical method, in the aspect of structure prefabrication, a site support is not needed due to the semi-prefabrication form, and the influence degree of the environment of the construction site is reduced; in the aspect of component safety, the integrity of the prefabricated bent cap shell is better than that of a bent cap prefabricated and spliced segment by segment, and the stress concentration phenomenon is unlikely to happen; and in the aspect of transportation and lifting, the overall weight of the semi-prefabricated bent cap shell is smaller than that of the fully-prefabricated bent cap, and no complex heavy machine is needed during transportation and lifting.

Owner:SHANGHAI INST OF TECH

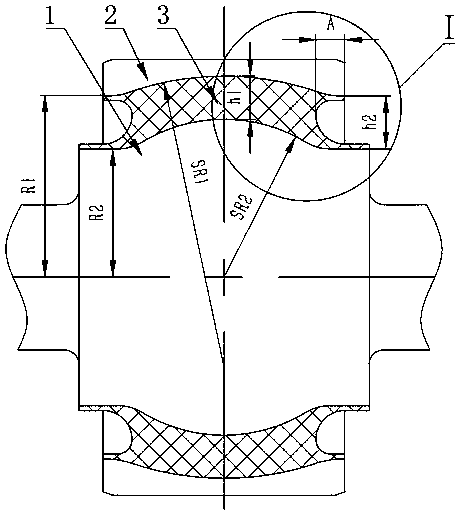

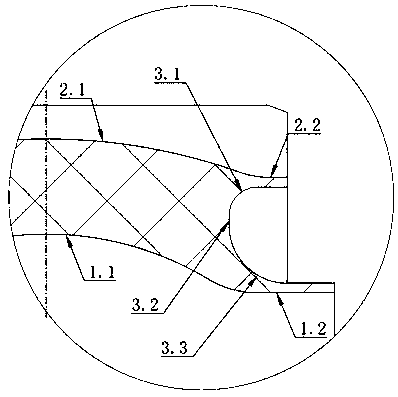

Double-spherical traction rubber joint and making method thereof

ActiveCN108909755AAvoid bending deformationHigh radial stiffness requirementsSpringsBogiesEngineering

The invention discloses a double-spherical traction rubber joint and a making method thereof. The double-spherical traction rubber joint comprises a mandrel, an external sleeve and a rubber layer; themandrel comprises a mandrel spherical section; the external side surface of the mandrel spherical section is a spherical surface; the rubber layer is bonded between the external side spherical surface of the mandrel and the internal side spherical surface of the external sleeve in a vulcanized manner; the thickness of the middle part of the rubber layer is less than or equal to the thicknesses ofthe two ends of the rubber layer; and the sum of the radius of the mandrel spherical section and the thickness of the middle part of the rubber layer is less than or equal to the radius of a spherical section of the external sleeve. During making, the external side surface of the middle part of the mandrel and the internal side surface of the middle part of the external sleeve are machined into spherical surfaces; the rubber layer is bonded between the double spherical surfaces of the mandrel and the external sleeve in a vulcanized manner; and the rubber profiles of the two ends of the rubberlayer are machined into rear proximate rubber profiles and then are pre-compressed in the radial direction to be molded. By applying the double-spherical traction rubber joint and the making method thereof, high radial stiffness requirement can be realized, low deflection stiffness can also be realized, and bending deformation of the rubber can also be avoided.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

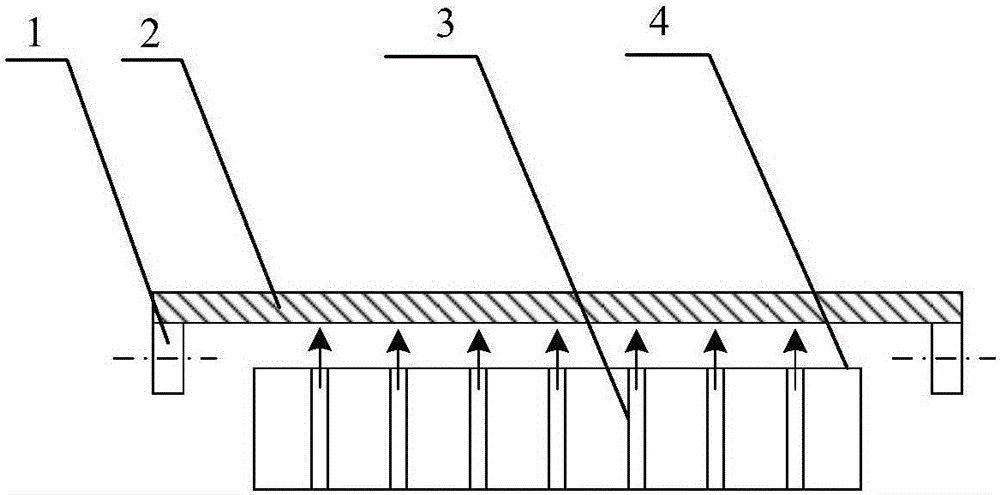

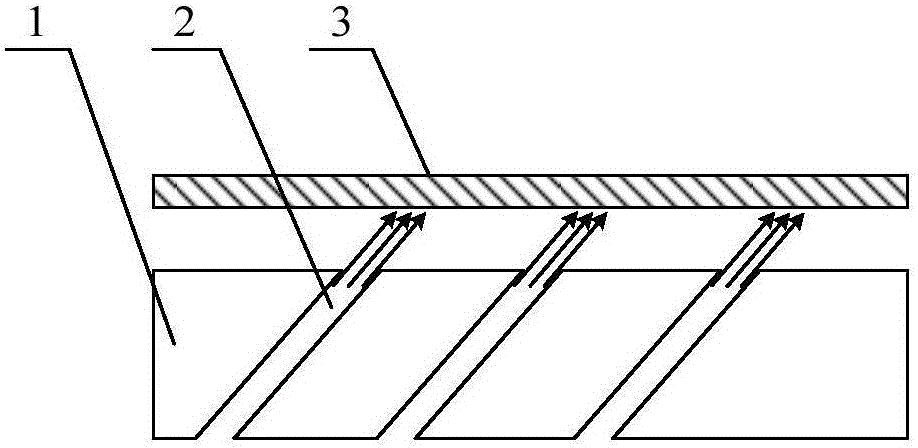

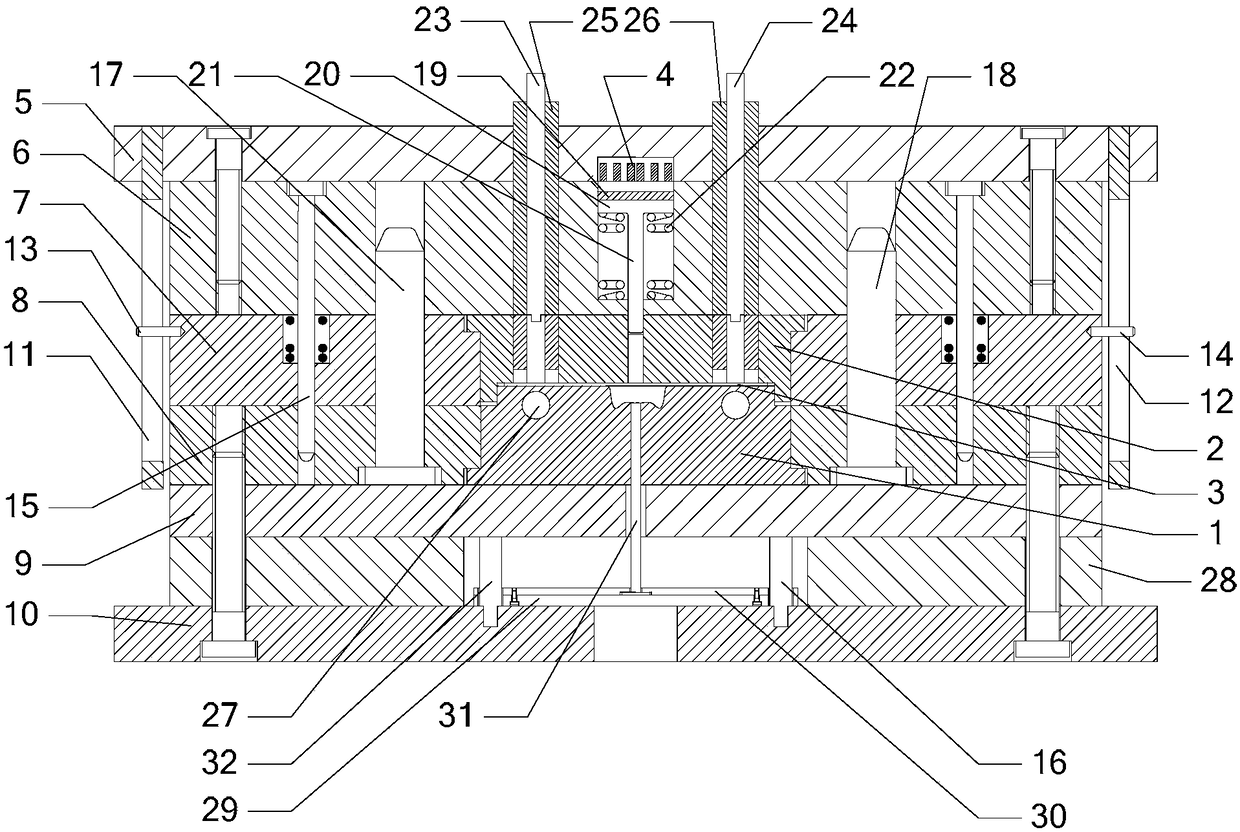

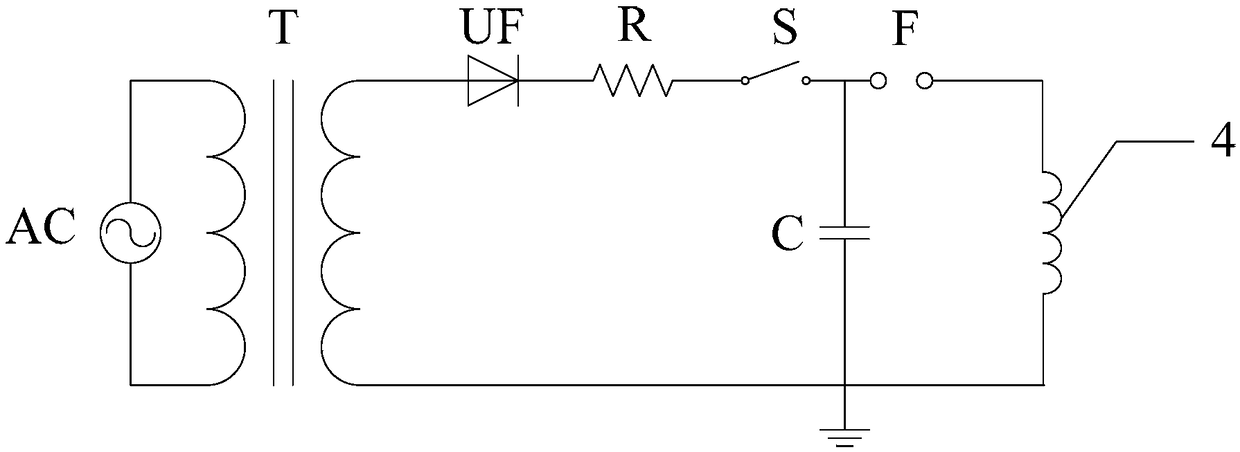

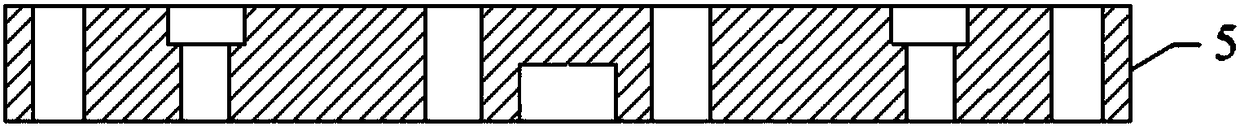

Non-contact transporting and positioning platform device and control method

ActiveCN105712089ANot easy to be polluted by static electricityLess prone to stress concentrationControl devices for conveyorsCharge manipulationAirflowEngineering

The invention discloses a non-contact transporting and positioning platform device and a control method. The device comprises a transporting platform, a fixing platform located below the transporting platform, and a base located below the fixing platform. The fixing platform is connected with the base through a fixing platform support. The transporting platform is provided with a plurality of grooves. Each groove is provided with an air inlet hole and an air outlet hole. Each air outlet hole is connected with an air inlet hose. Each air inlet hose is connected with a positive-pressure air source. Each air outlet hole is connected with an air outlet hose, and each air outlet hose is connected with a negative-pressure air source. According to the non-contact transporting and positioning platform device, due to the fact that air is in a horizontal flowing state in the grooves, the airflow viscosity force can be utilized to the maximum degree to drive a workpiece to move, the high motion acceleration is obtained, and complete non-contact can be truly achieved. When airflow makes contact with the semiconductor workpiece, static pollution is not likely to be generated, and stress concentration is not likely to be caused near a contact point.

Owner:阿尔贝斯(长兴)科技有限公司

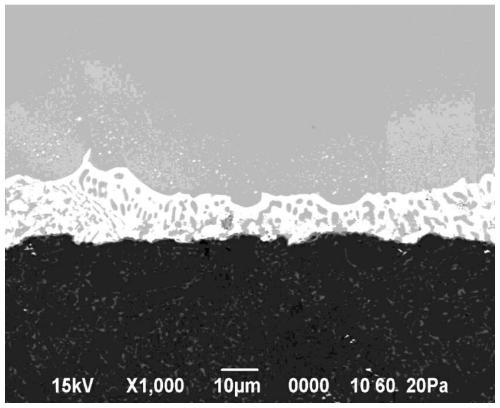

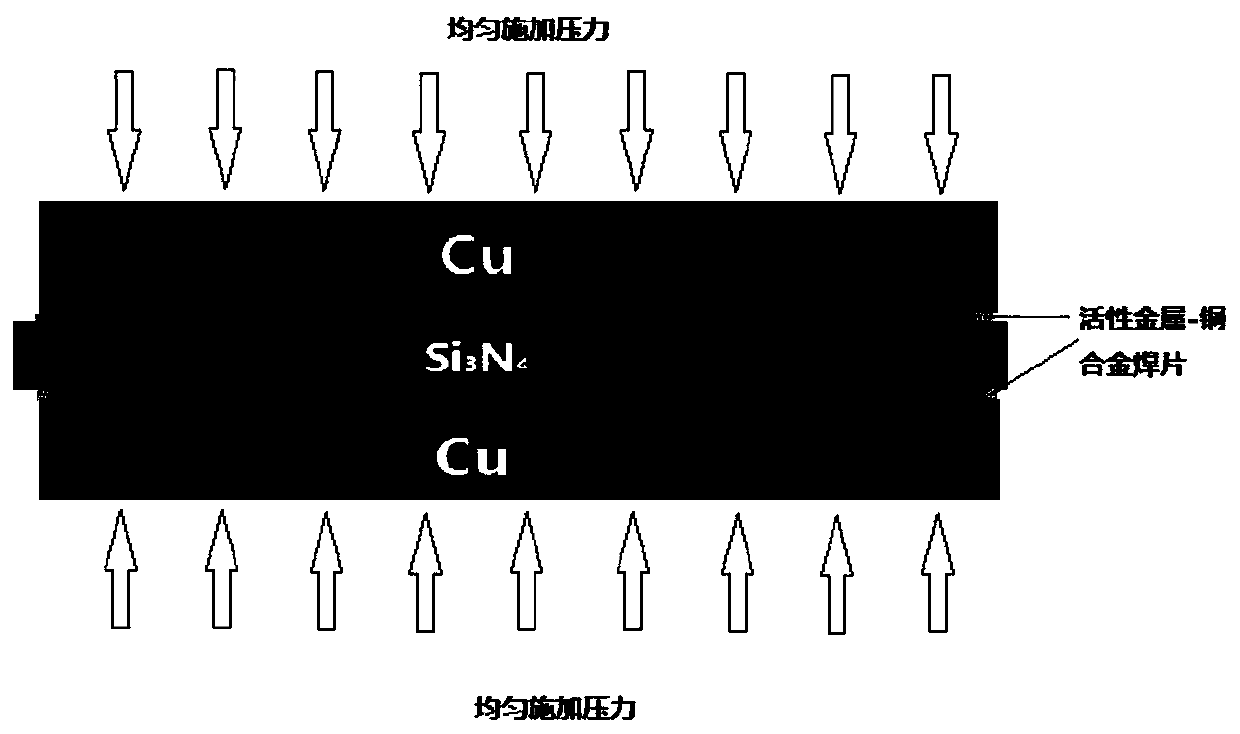

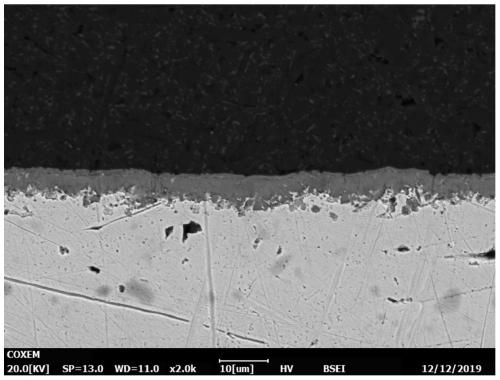

Copper-ceramic interface structure of high-reliability silicon nitride copper-coated ceramic substrate and preparation method of copper-ceramic interface structure

ActiveCN111403347AUniform welding layerLess prone to stress concentrationSemiconductor/solid-state device detailsSolid-state devicesSilicon nitrideTa element

The invention discloses a copper-ceramic interface structure of a high-reliability silicon nitride copper-coated ceramic substrate. The copper-ceramic interface structure comprises copper, a connecting layer, a reaction layer, silicon nitride ceramic, a reaction layer, a connecting layer and copper from top to bottom, the reaction layer is nitride of active metal formed by reaction of active metalelements and silicon nitride, and is used for realizing infiltration and connection of solder, silicon nitride ceramic and copper; the connecting layer is a stress buffer layer for connecting copperand silicon nitride ceramic, and the stress buffer layer is a copper alloy layer of copper and active metal elements; through the optimal design of a welding interface and the use of Ag-free solderinglugs, the uniformity of a welding layer can be effectively improved, and the residual stress between copper-ceramic interfaces is reduced, so that the binding force of the copper-ceramic interfaces is improved, and meanwhile, the risk of environmental pollution is reduced.

Owner:江苏富乐华半导体科技股份有限公司

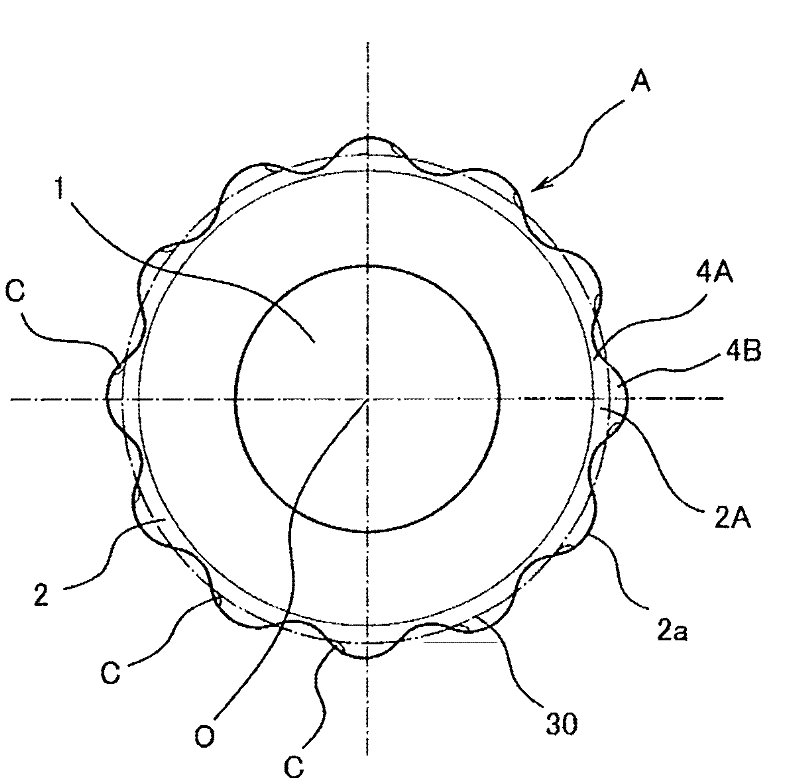

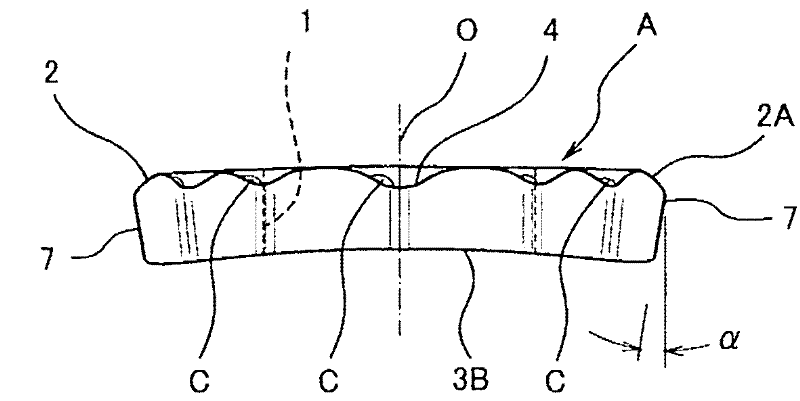

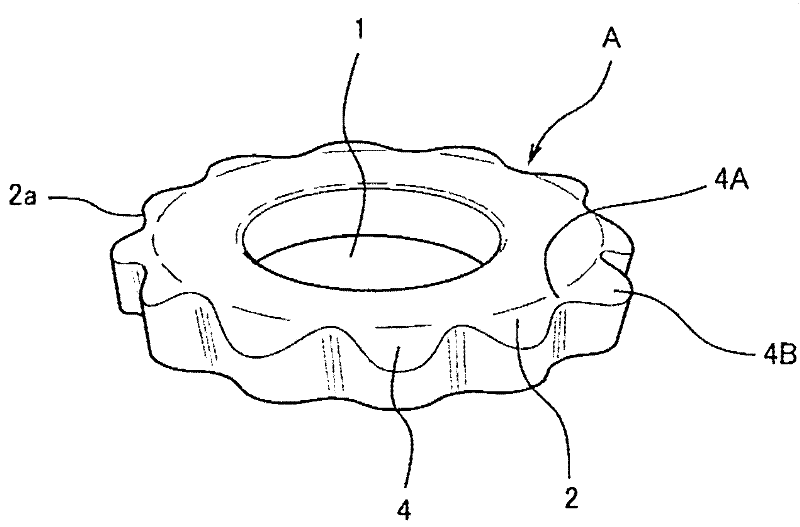

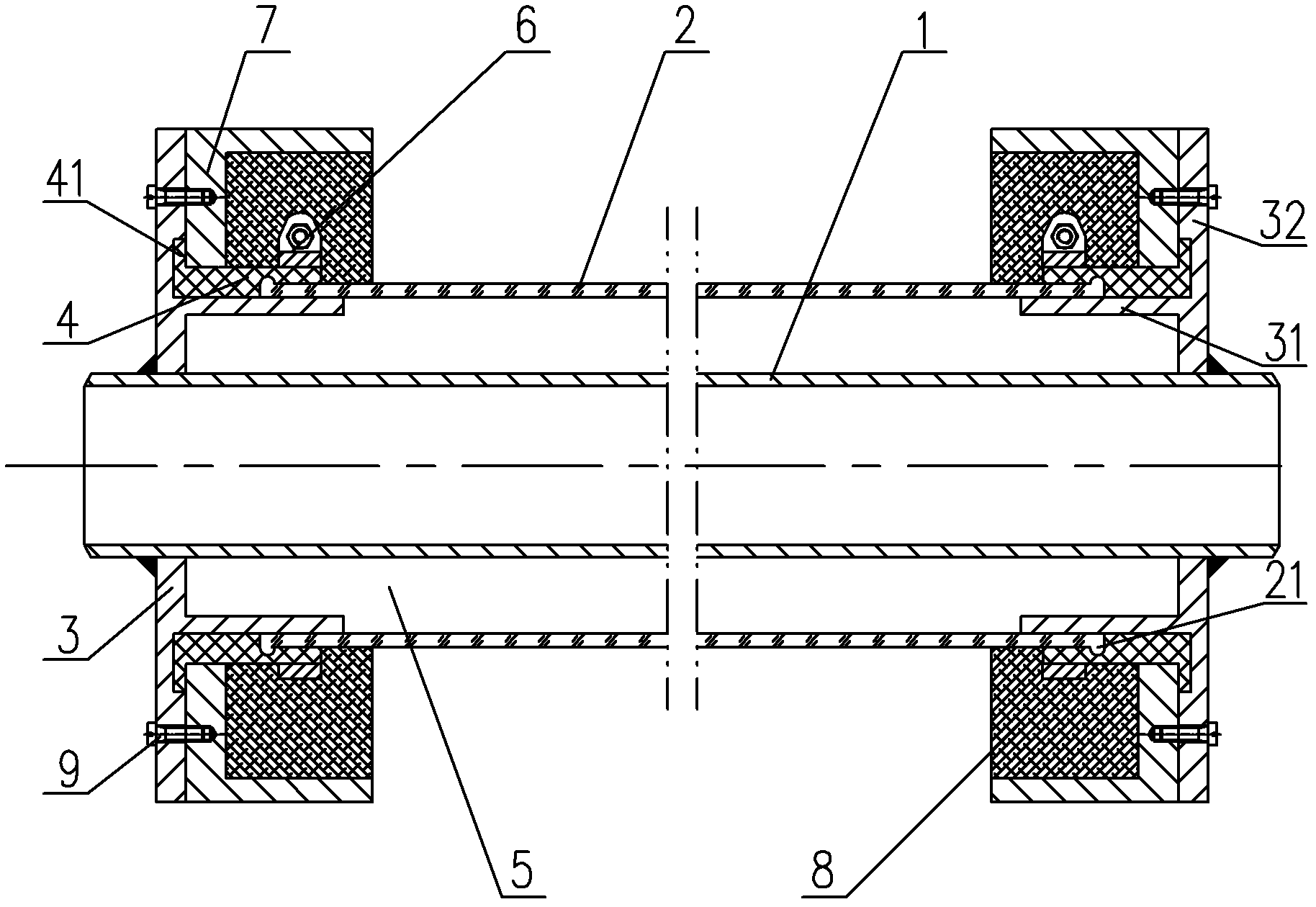

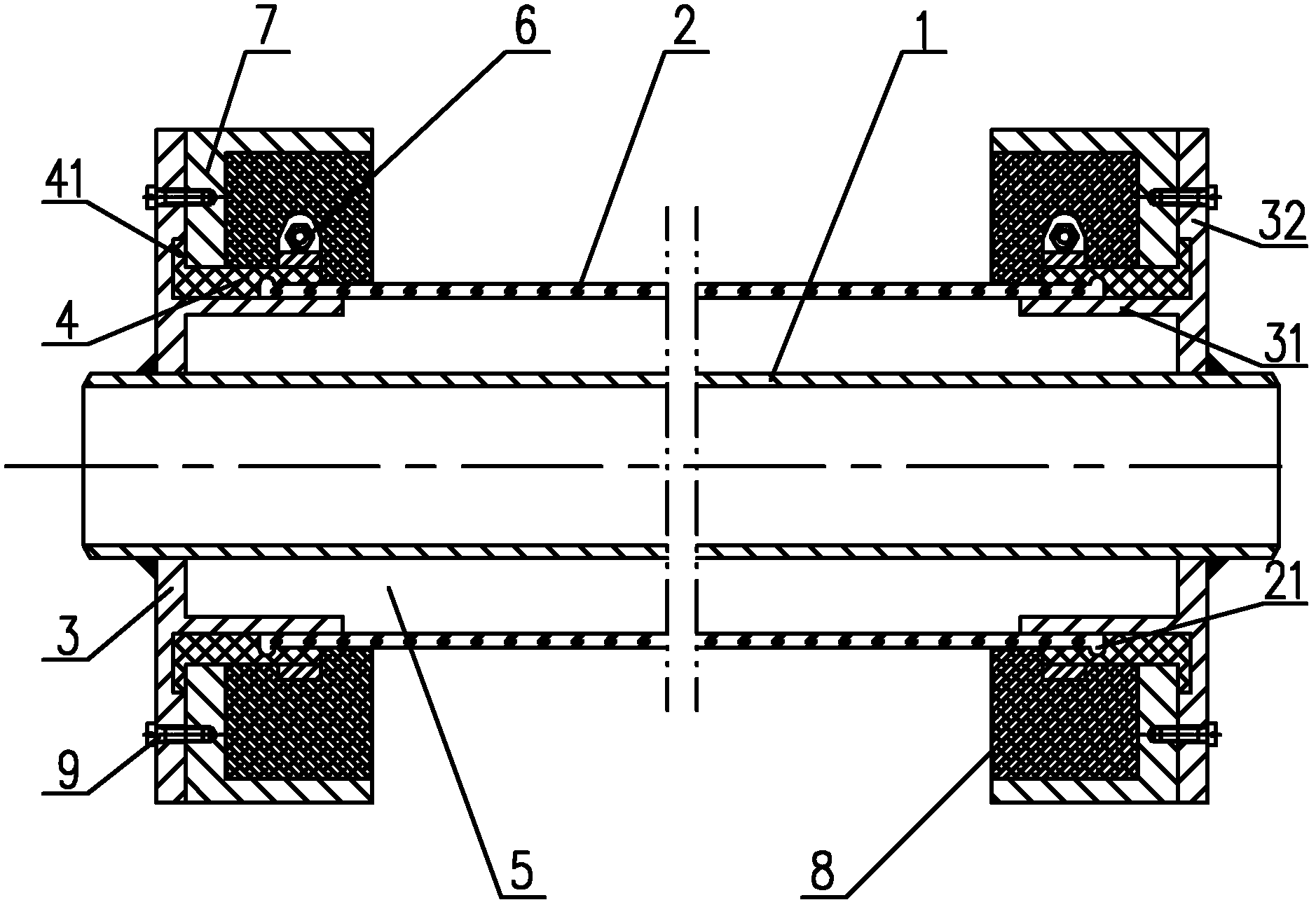

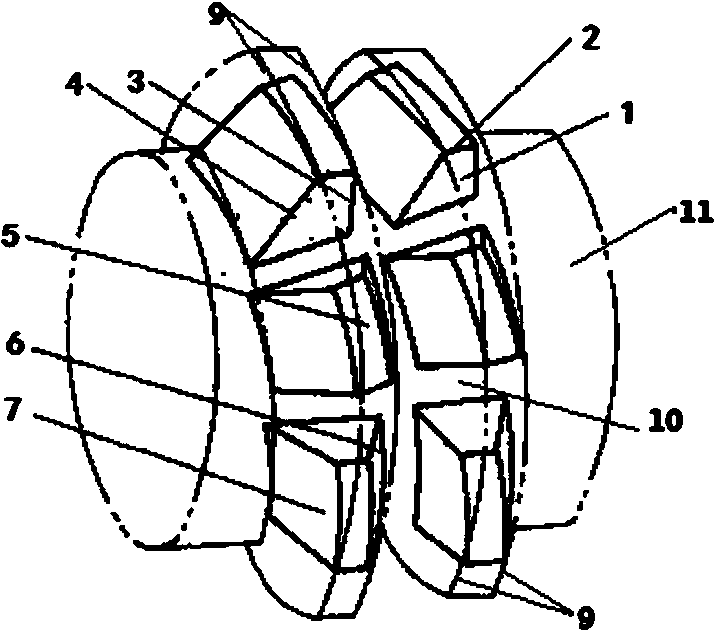

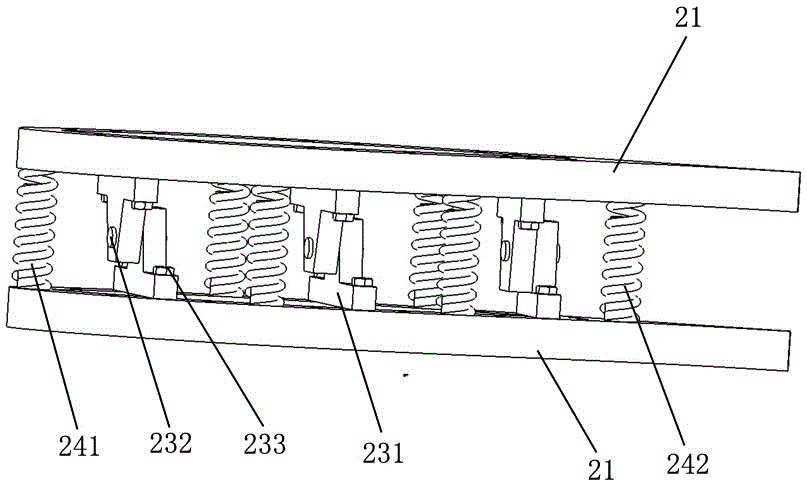

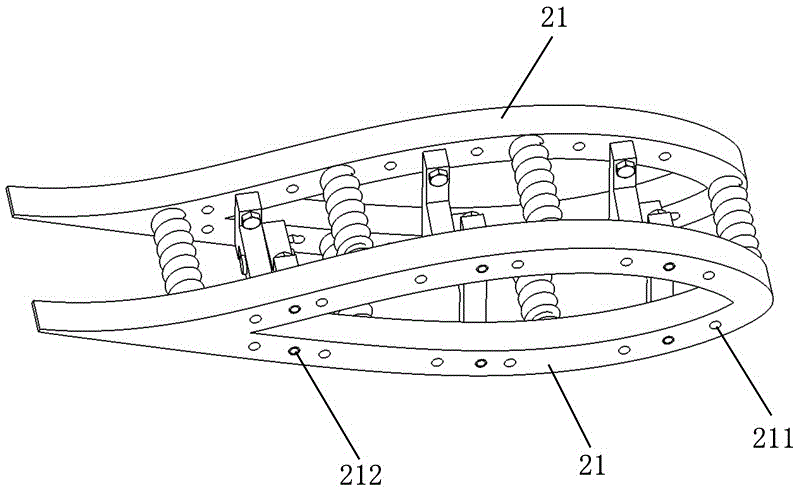

Sleeve for connection and washer for supporting used reacting force and connecting structure

The invention provides a sleeve for connection and a washer for supporting used reacting force, and connection can be made only via nut fixing without washer fixing, furthermore, a connecting structure is provided to connect in a mode that a nut and a bolt are not in a ''corotation''. A sleeve (B) used for a nut connection is provided with: an inner sleeve part provided with a clamping mechanism clamping with a nut, etc.; an outer sleeve part clamping with a washer (A) provided with an outer edge part (2), the outer edge part is provided with clamping tooth and the surface is formed to be a conical surface close to the bottom surface side at the outer edge side; an inner sleeve part (21)and an outer sleeve part (22) are mutually connected via mechanisms capable of rotating in reverse directions. The outer sleeve part is provided with clamping pawls (24) clamping with the clamping tooth, the lower end of the clamping pawl (24) is formed by a conical surface close to the base end side at the inner diameter side. Friction factor increase processing is applied to the face of a bolt head in a contact with the surface of the connected subject.

Owner:YUNITAITO

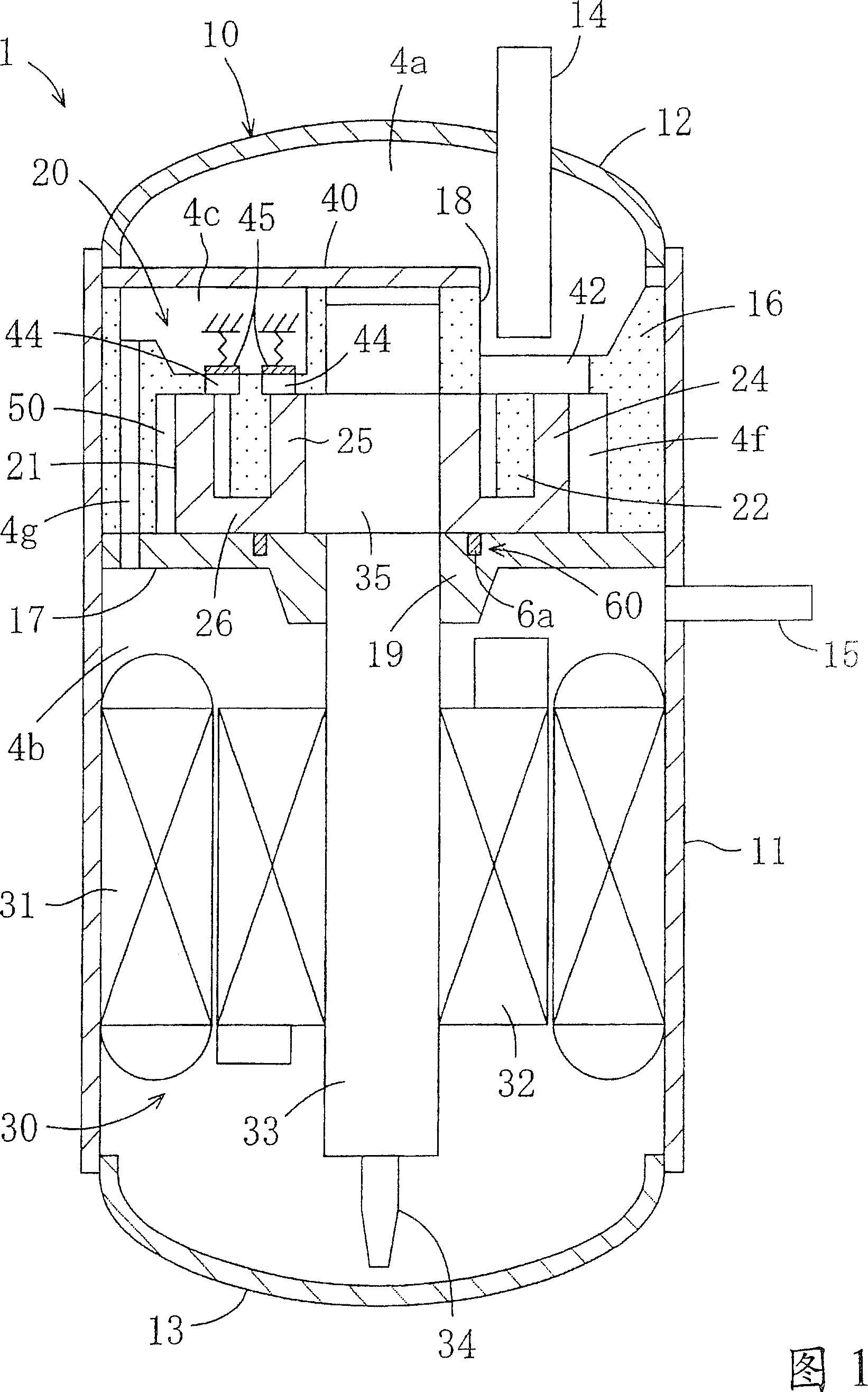

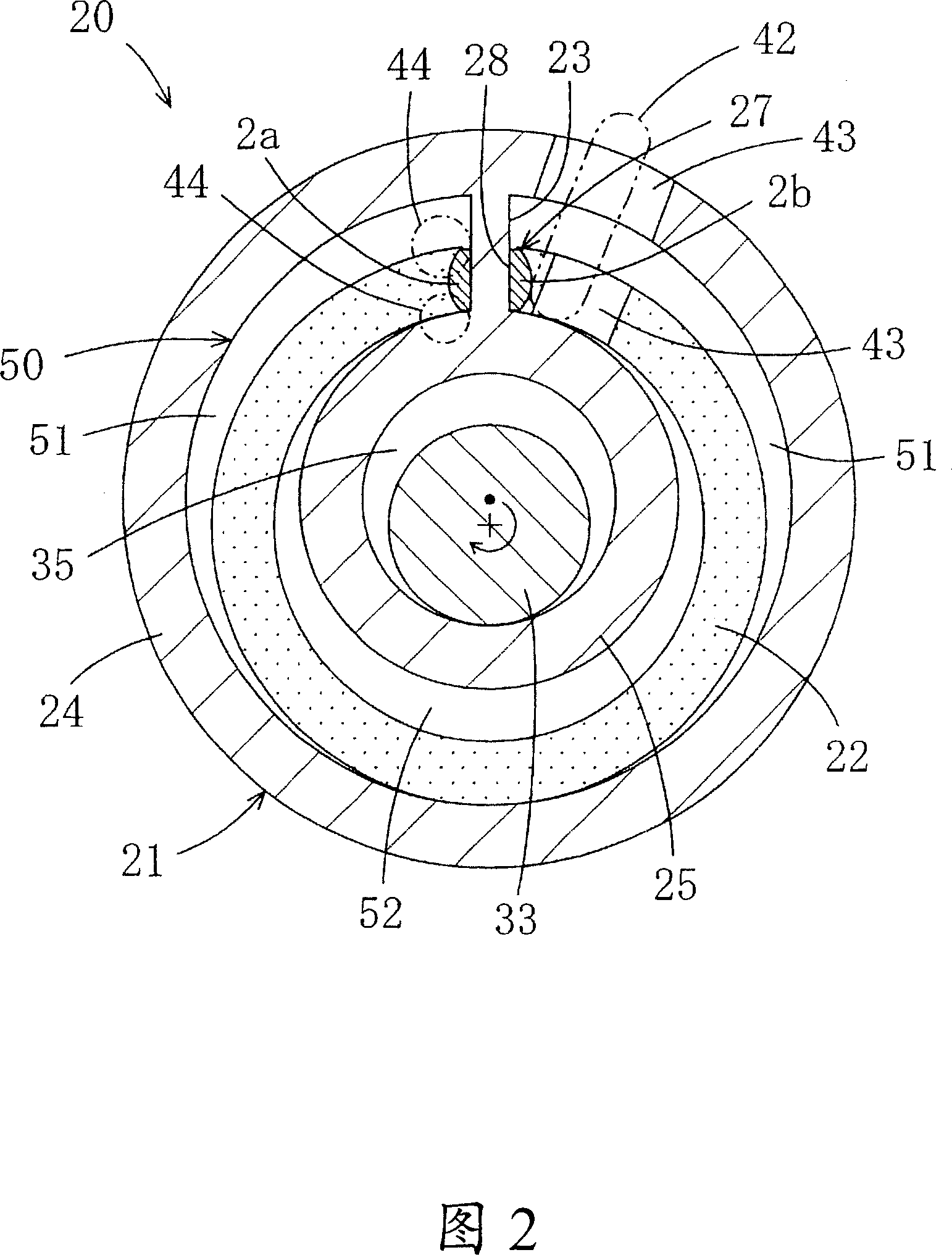

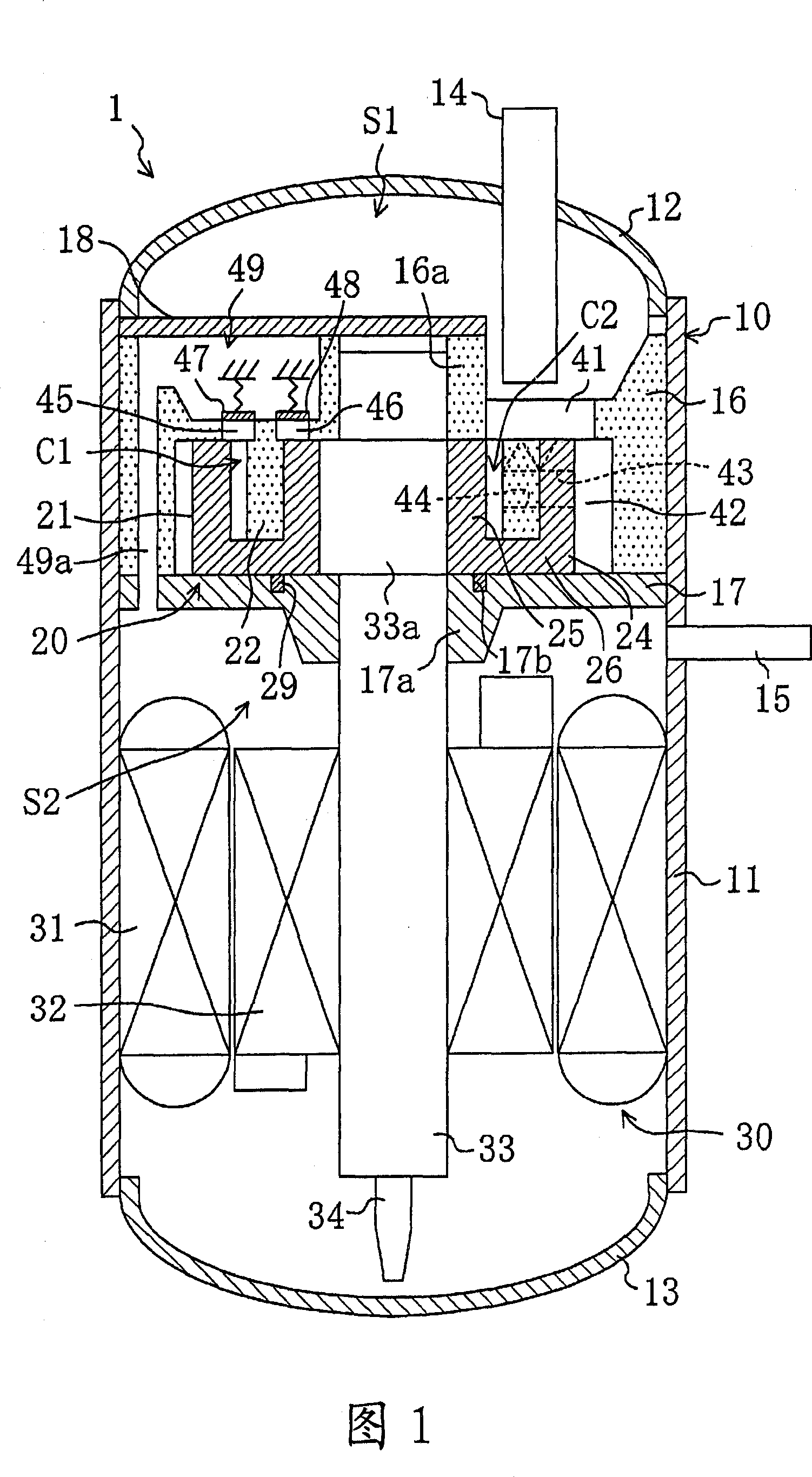

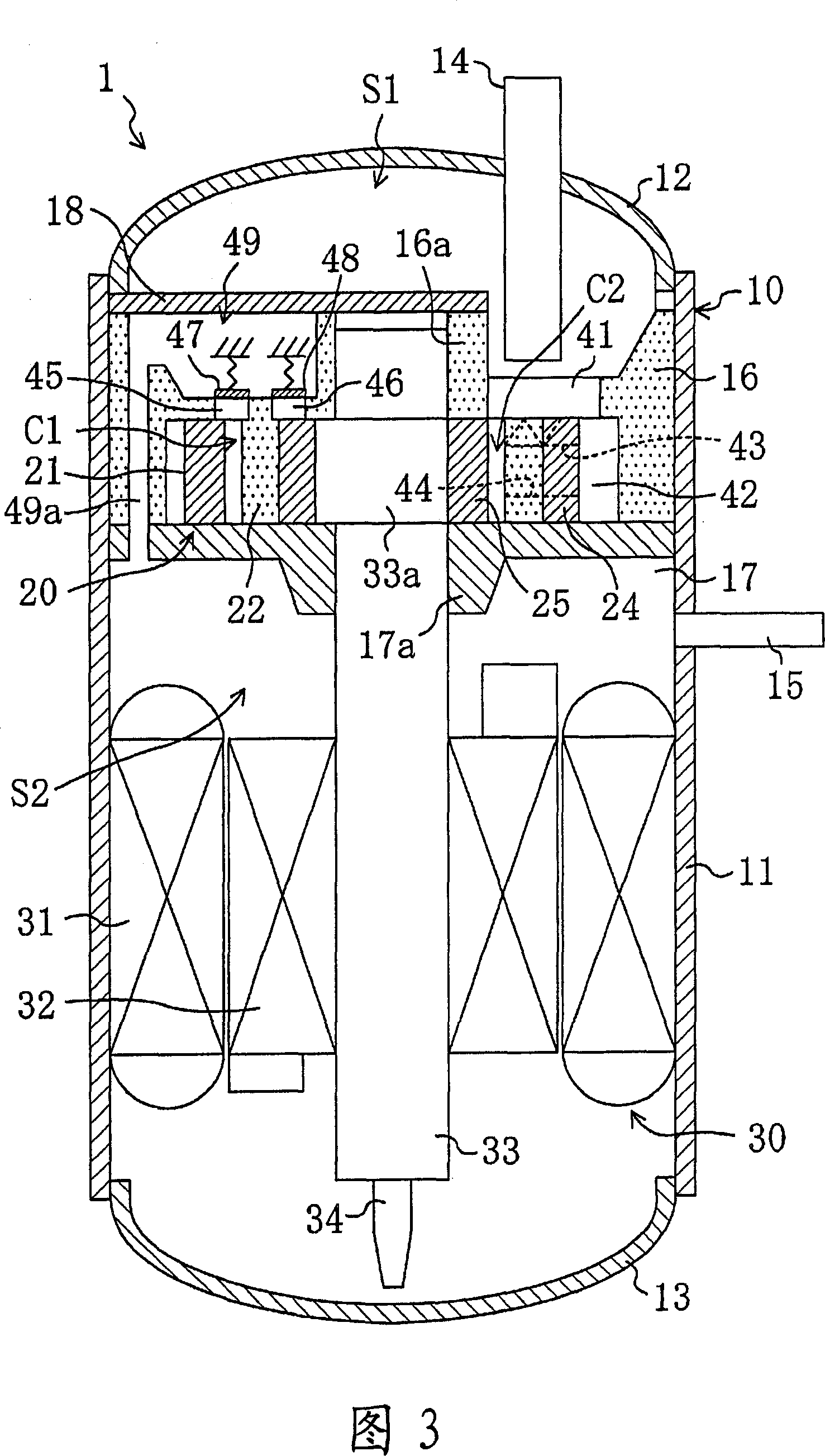

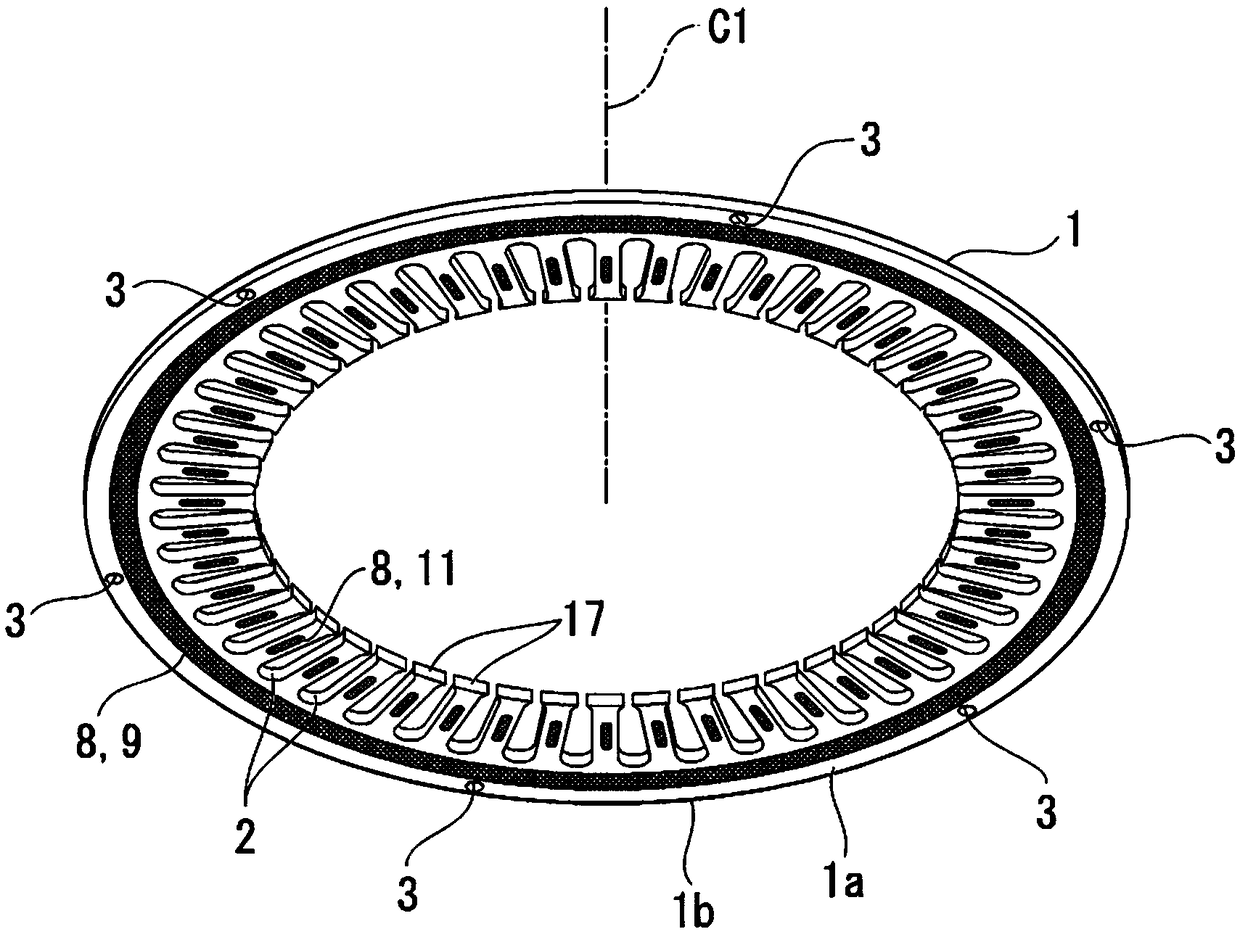

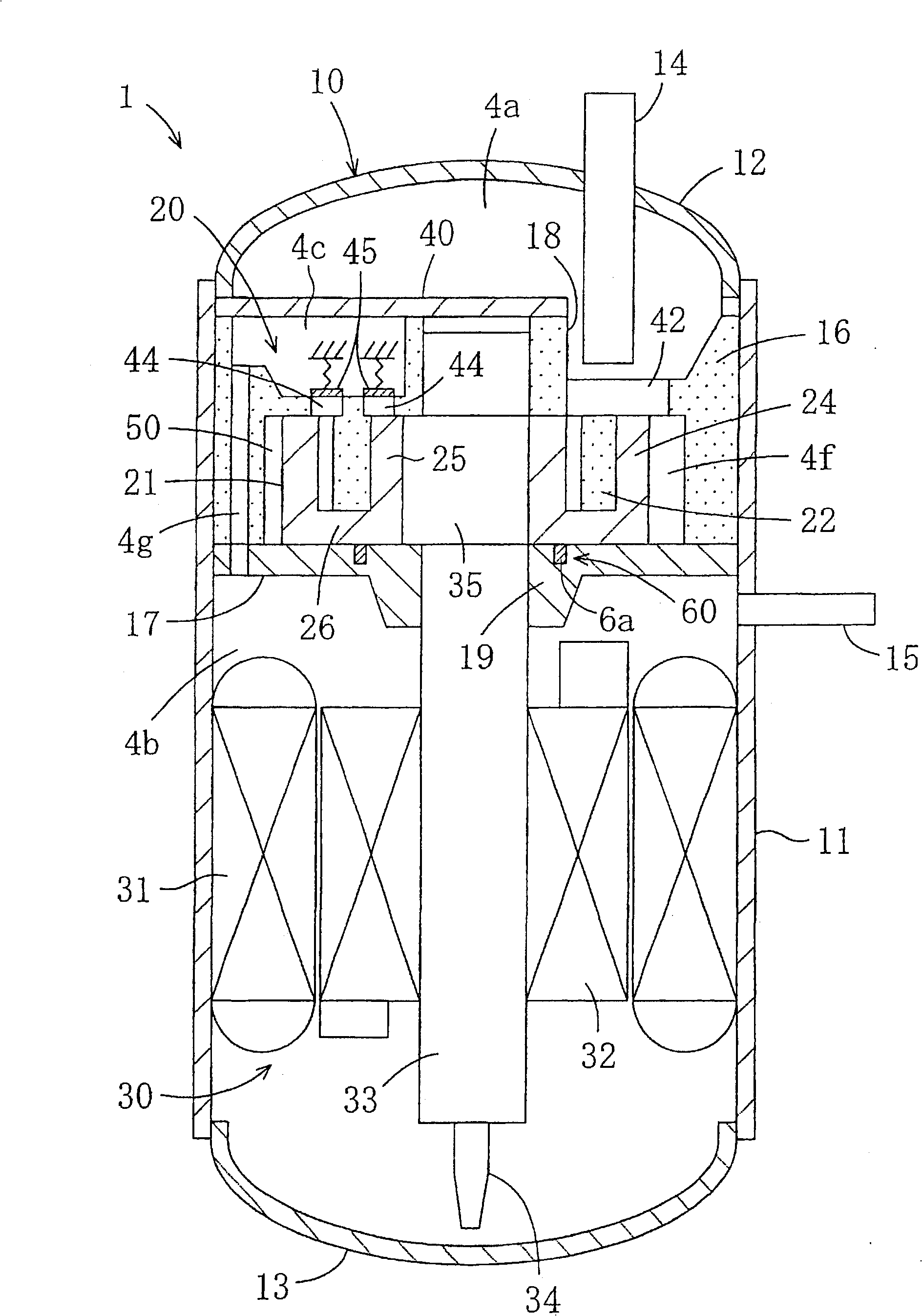

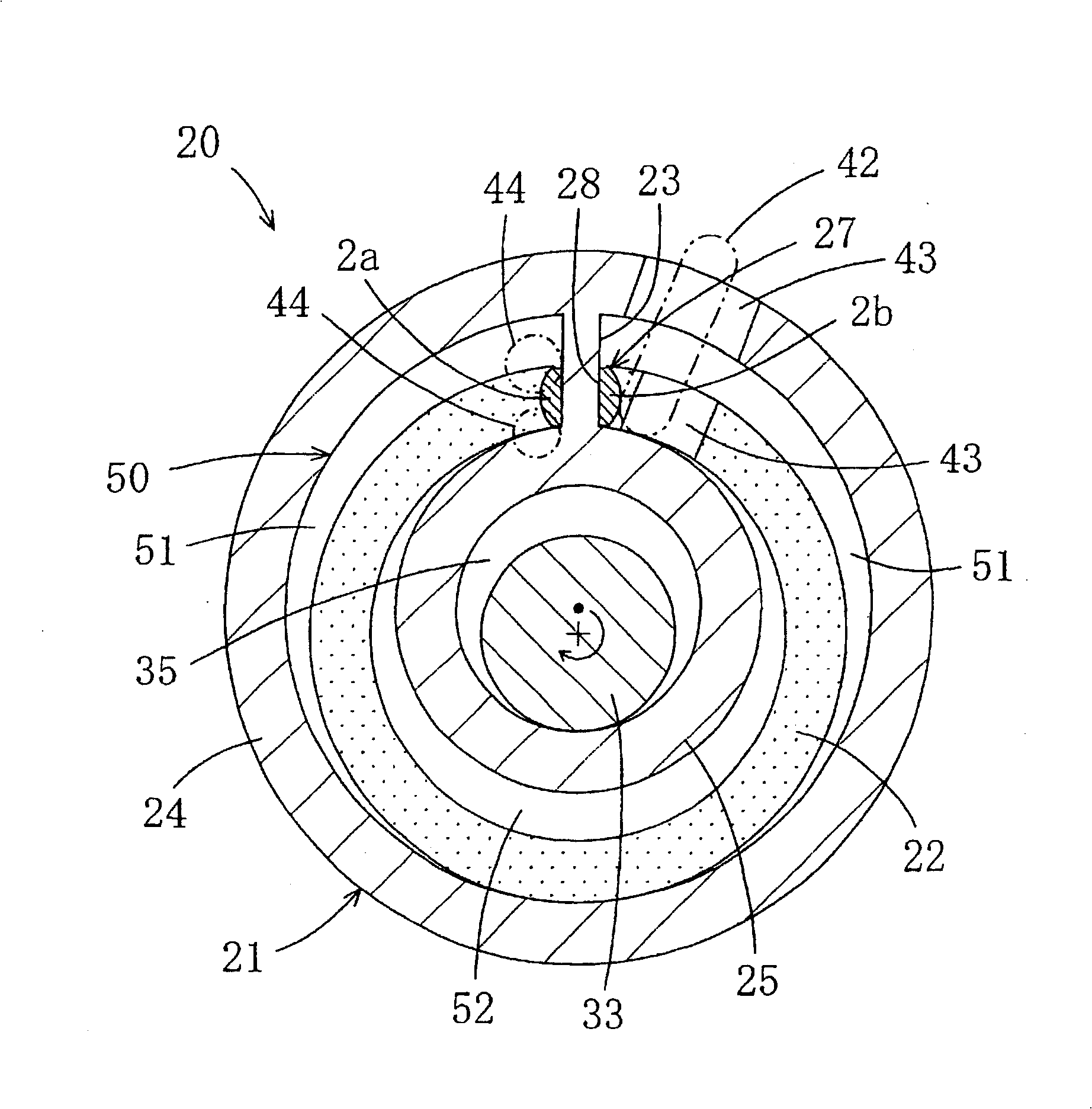

Rotary fluid machine

InactiveCN1981133AContainment leakImprove efficiencyRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsHigh pressureMechanical engineering

A rotary fluid machine, comprising a cylinder (21) having an annular cylinder chamber (50), an annular piston (22) stored in the cylinder chamber (50) eccentrically to the cylinder (21) and partitioning the cylinder chamber (50) into an outer compression chamber (51) and an inner compression chamber (52), and a blade (23) disposed in the cylinder chamber (50) and partitioning the compression chambers (51) and (52) into a high-pressure side and a low-pressure side. The rotary fluid machine also comprises a rotating mechanism (20) for rotating the cylinder (21) and the piston (22) relative to each other. The cylinder chamber (50) is so formed that the width (T1) of the cylinder chamber (50) is varied in one rotation of the cylinder chamber (50) so that a clearance between the wall surface of the cylinder (21) and the wall surface of the piston (22) in rotation becomes a specified value. Also, the piston (22) is so formed that the width (T2) of the piston (22) is varied in one rotation of the piston (22) so that the clearance between the wall surface of the cylinder (21) and the wall surface of the piston (22) in rotation becomes the specified value.

Owner:DAIKIN IND LTD

Groove type condensation solar heat collecting tube with compensation sealing structure and assembling process of groove type condensation solar heat collecting tube

ActiveCN102563931AHas the effect of exerting stressGood deformabilitySolar heating energySolar heat devicesSilicon rubberVacuum chamber

The invention belongs to the technical field of solar thermal utilization, and particularly discloses a groove type condensation solar heat collecting tube with a compensation sealing structure. The groove type condensation solar heat collecting tube is provided with a coated stainless steel tube, a coated borosilicate glass tube is sleeved on the outside of the coated stainless steel tube, stainless steel seal heads are sleeved at both ends of the coated stainless steel tube, and the outer wall of the coated stainless steel tube is hermetically connected with the stainless steel seal heads; the coated borosilicate glass tube is slidably connected with the stainless steel seal heads; high-temperature-resistant silicon rubber compensation sleeves are sleeved on the stainless steel seal heads, and two ends of each high-temperature-resistant silicon rubber compensation sleeve are respectively hermetically connected with the coated borosilicate glass tube and the corresponding stainless steel seal head; and heat-insulation vacuum chambers are disposed among the coated stainless steel tube, the coated borosilicate glass tube and the stainless steel seal heads. The heat collecting tube is provided with the high-temperature-resistant silicon rubber compensation sleeves with cheap prices, stress destruction can be avoided, components of the heat collecting tube are welded and hermetically sealed, and accordingly the groove type condensation solar heat collecting tube is high in reliability and structural tension resistance and fine in heat-insulation performance. In addition, welding operation is seldom carried out in assembling process, yield of finished products is high, the process is simple, and labor cost is low.

Owner:溧阳常大技术转移中心有限公司

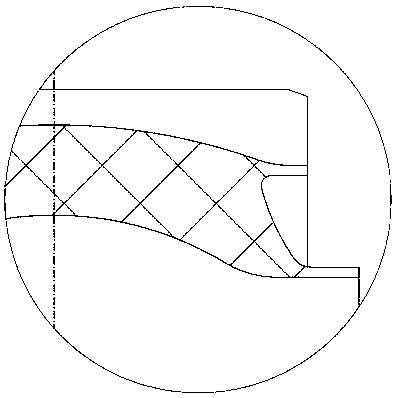

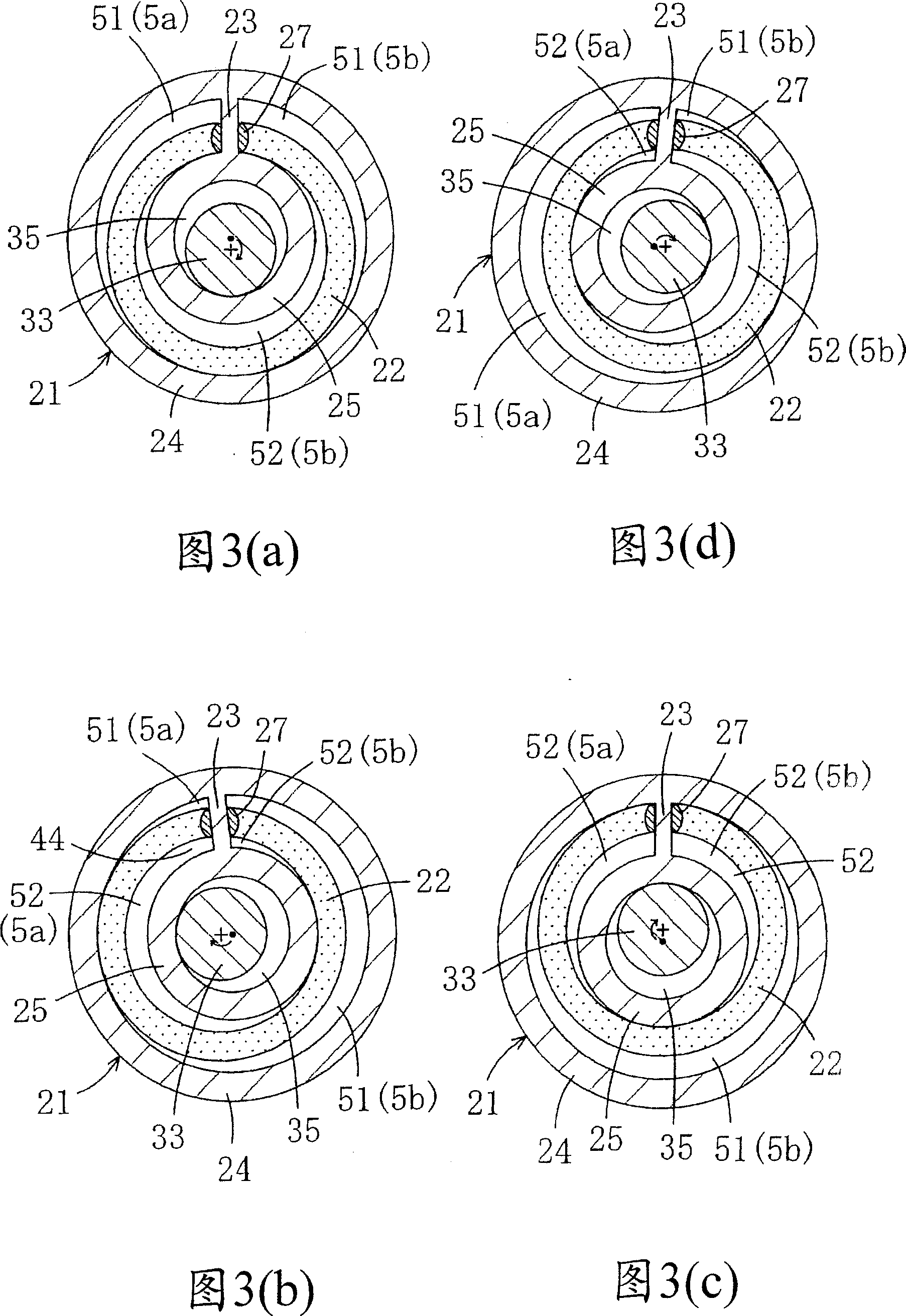

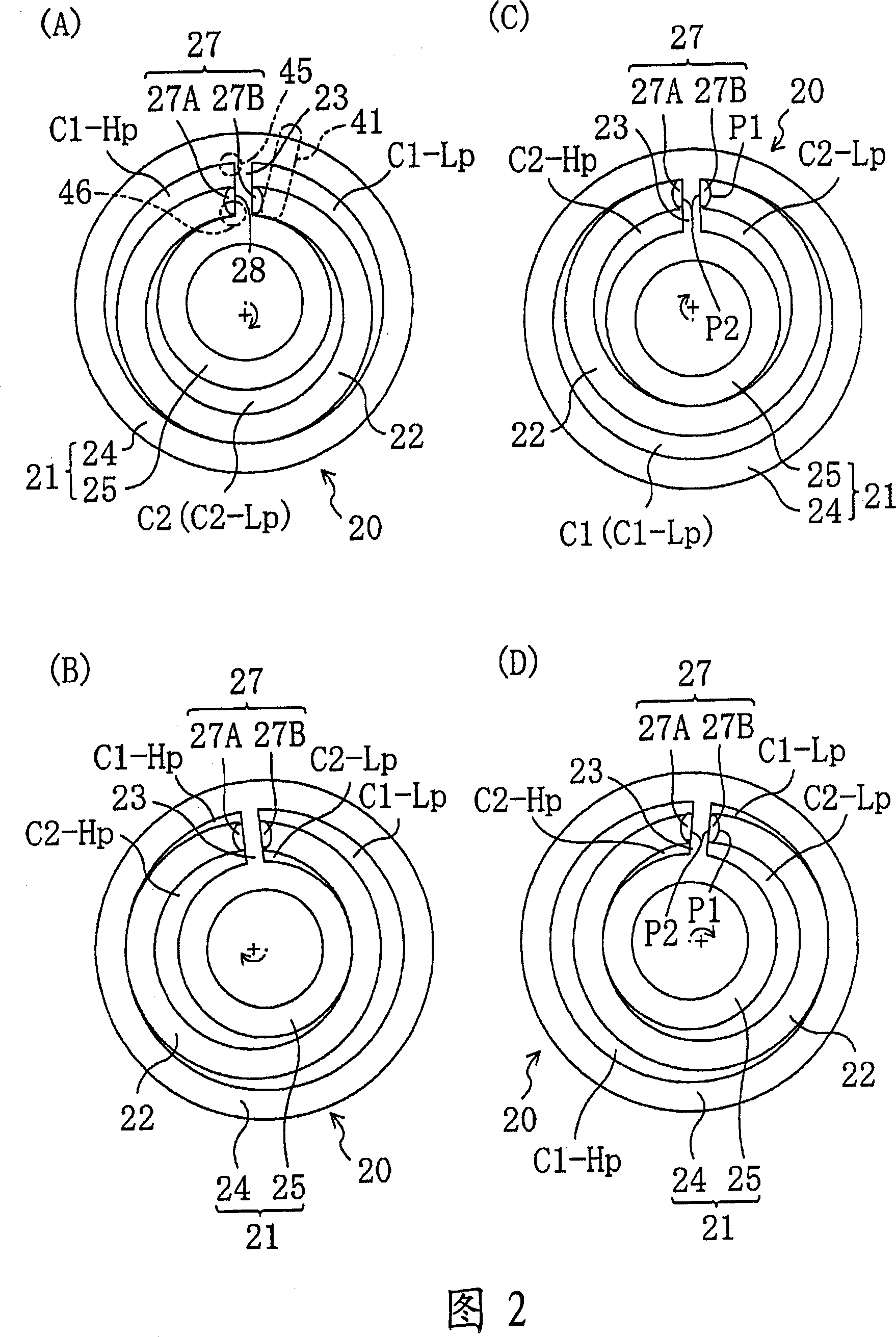

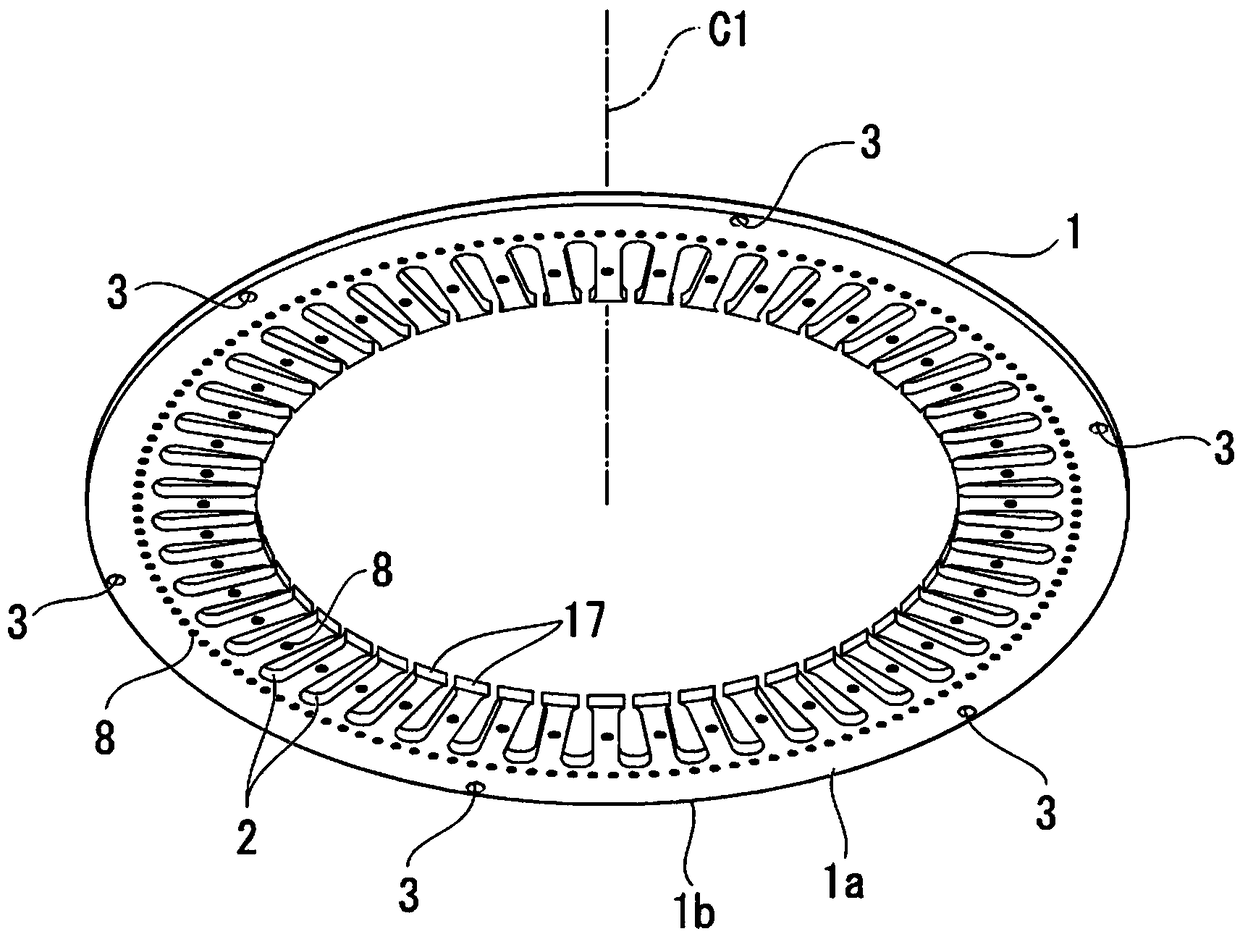

Rotating fluid machine

InactiveCN1946939AReduce dead volume DsNot easy to wearRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringMechanical engineering

A rotating fluid machine is constructed such that an annular piston (22) is received inside annular cylinder chambers (C1, C2) of a cylinder (21) to form an outer cylinder chamber (C1) and an inner cylinder chamber (C2), that the cylinder (21) and the annular piston (22) relatively perform eccentric rotating motion, and that the rotating fluid machine has an eccentrically rotating piston mechanism (20) in which the cylinder chambers (C1, C2) are partitioned into first chambers (C1-Hp, C2-Hp) and second chambers (C1-Lp, C2-Lp). In order to prevent seizure and wear of the blade (23) and the annular piston (22) during operation and to prevent gas leakage between the first chambers (C1-Hp, C2-Hp) and the second chambers (C1-Lp, C2-Lp), the blade (23) and the annular piston (22) are relatively movably connected by an oscillation bush (27), and sliding surfaces (P1, P2) are provided on the blade (23), at sections at which the blade (23) is in contact with the annular piston (22) and the oscillation bush (27).

Owner:DAIKIN IND LTD

Pre-grinding hob for machining micro-segment gears

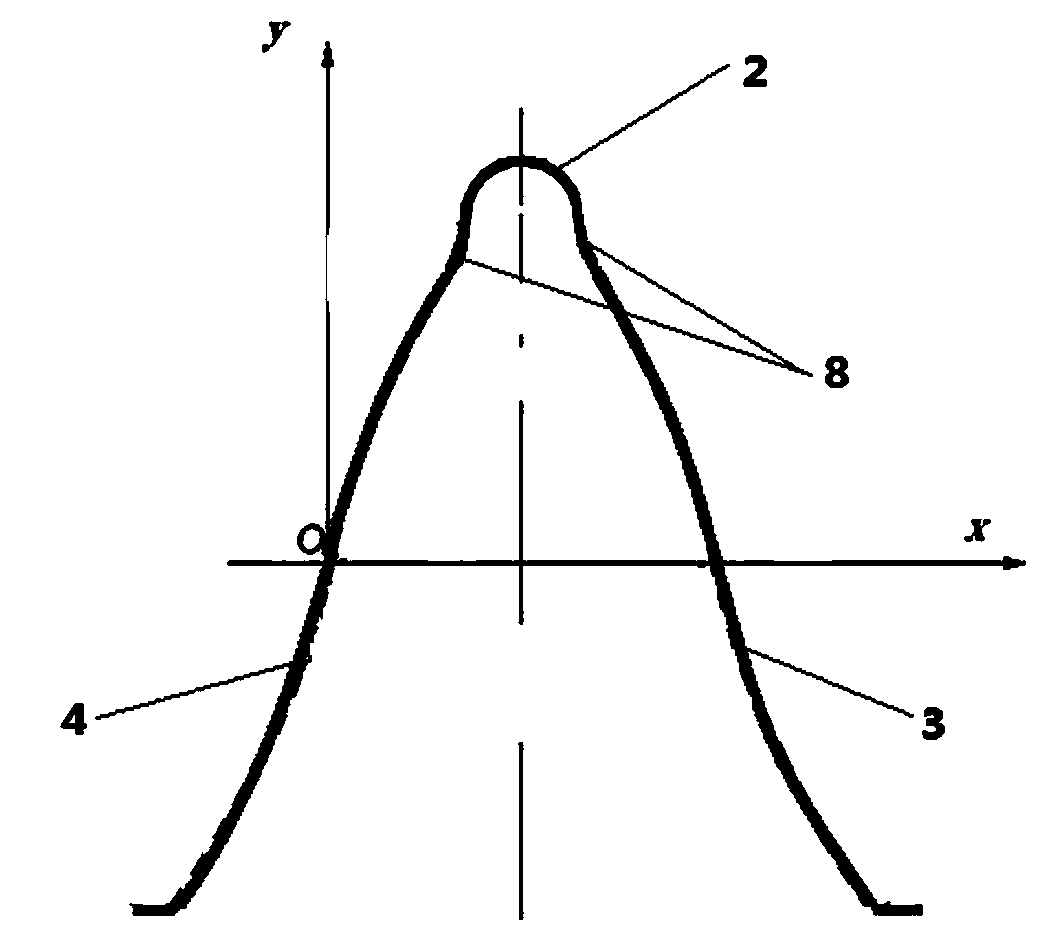

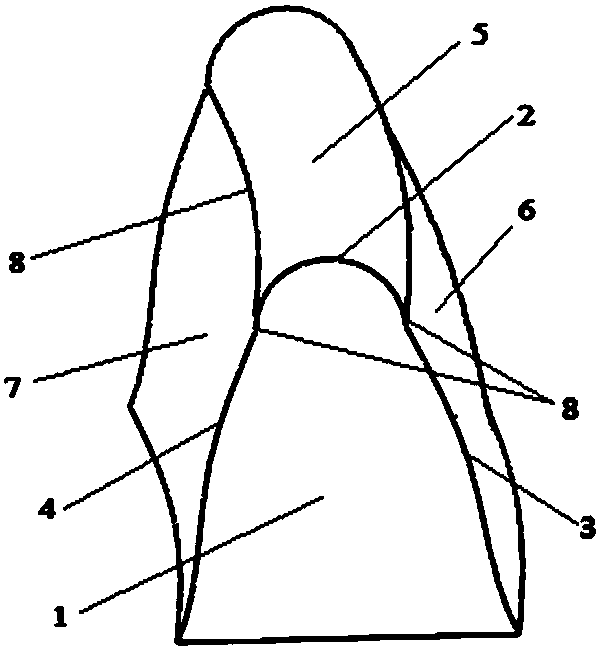

InactiveCN103551674AIncrease production capacityAchieve preparationGear teeth manufacturing toolsGear teethEdge segmentLine segment

The invention relates to a pre-grinding hob for machining micro-segment gears. A cutting edge normal tooth profile of the pre-grinding hob comprises a main cutting edge segment, an addendum arc segment and a characteristic curve connecting segment, the main cutting edge segment is a normal engagement contacting tooth profile curve segment for machining the micro-segment gears, micro-segment curved lines or micro-segment straight lines are smoothly connected to form the main cutting edge segment, the length of the main cutting edge segment is not larger than 1 micrometer, the characteristic curve connecting segment is a connecting curve segment of a pre-grinding hob tooth addendum arc segment and a micro-segment tooth profile segment, and the trend and the length of the characteristic curve connecting segment are related to the modulus, the initial pressure angle, the pressure angle increment, the grinding allowance, the distribution form of the grinding allowance and the like of the micro-segment gears to be machined. The high-precision micro-segment gears can meet specific use requirements and mass production conditions as far as possible according to theoretical calculation and experience of the trends and the lengths of an undercutting arc segment and a characteristic transition curve segment.

Owner:HEFEI UNIV OF TECH

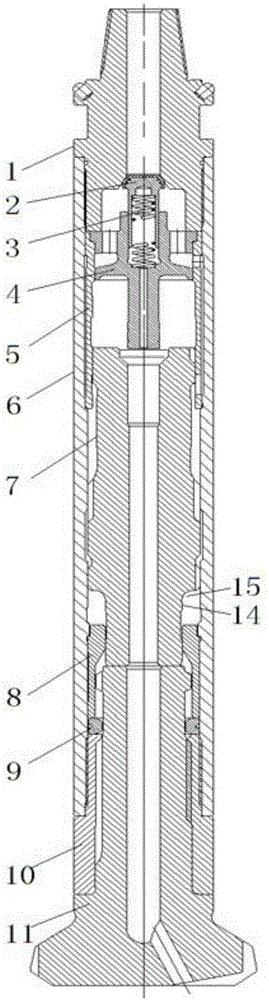

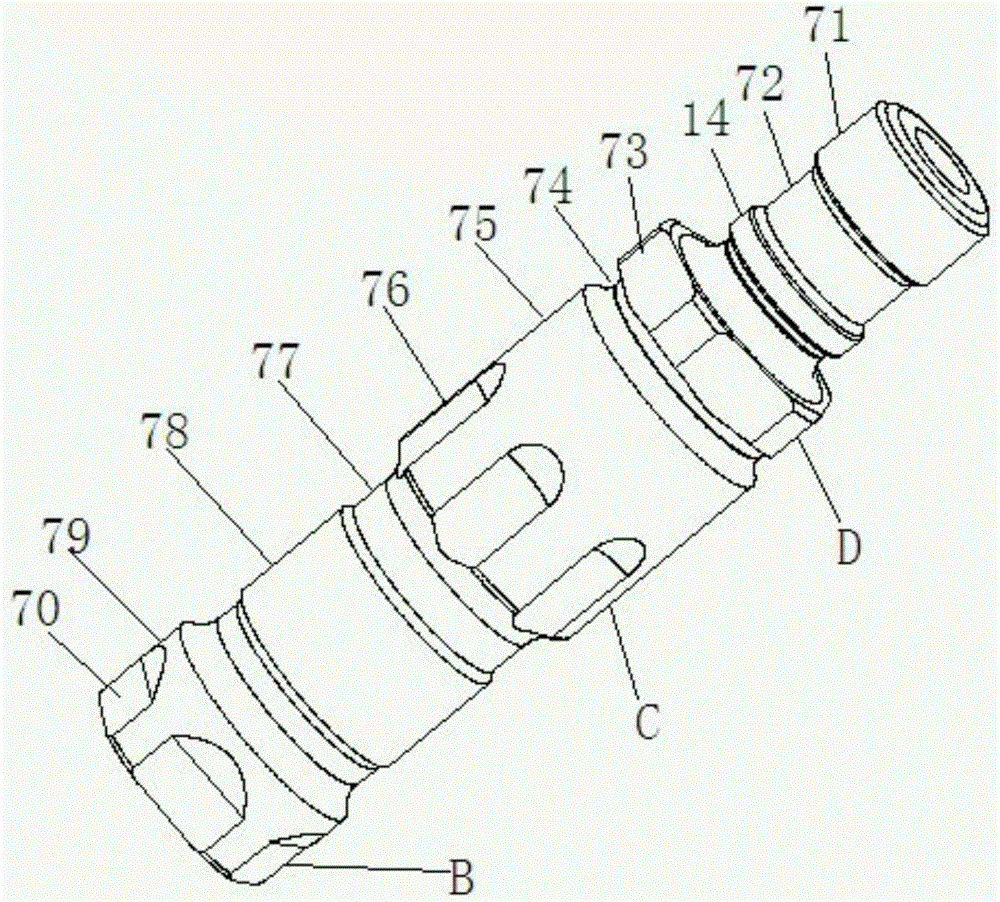

Quick-percussion, wear-resistant and long-service-life down-the-hole percussive drill tool

The invention discloses a quick-percussion, wear-resistant and long-service-life down-the-hole percussive drill tool. A check valve spring is arranged between a check valve and an air distributor; a drill bit sleeves a front joint; a bush is connected with the tail of the drill bit in a sleeving manner; a snap ring is arranged between the front joint and the bush; a piston is a hollow cylinder; a piston large end is arranged on the piston; a piston small path is arranged at one end of the piston large end; a piston tail path is arranged at the other end of the piston large end; one section of the piston large end is a smooth cylinder; the other section of the piston large end is uniformly provided with air grooves; an air polyhedron is arranged between the piston small path and the piston large end; an annular ventilating groove is formed between the air polyhedron and the piston large end; the piston tail path is connected with a cylindrical end; a piston tail end is arranged at the tail end of the cylindrical end; plain-sawn air grooves are uniformly formed in the piston tail end; front air holes are uniformly formed in one end of an inner cylinder; tail oblique air holes are uniformly formed in the other end of the inner cylinder; and a trapping lug boss is arranged on an inner cavity of the inner cylinder. The quick-percussion, wear-resistant and long-service-life down-the-hole percussive drill tool is high in drilling speed, not easy to jam, low in failure rate and low in energy consumption; work efficiency is greatly improved; and energy and cost are saved.

Owner:HUNAN XINJINGANG MACHINERY EQUIP

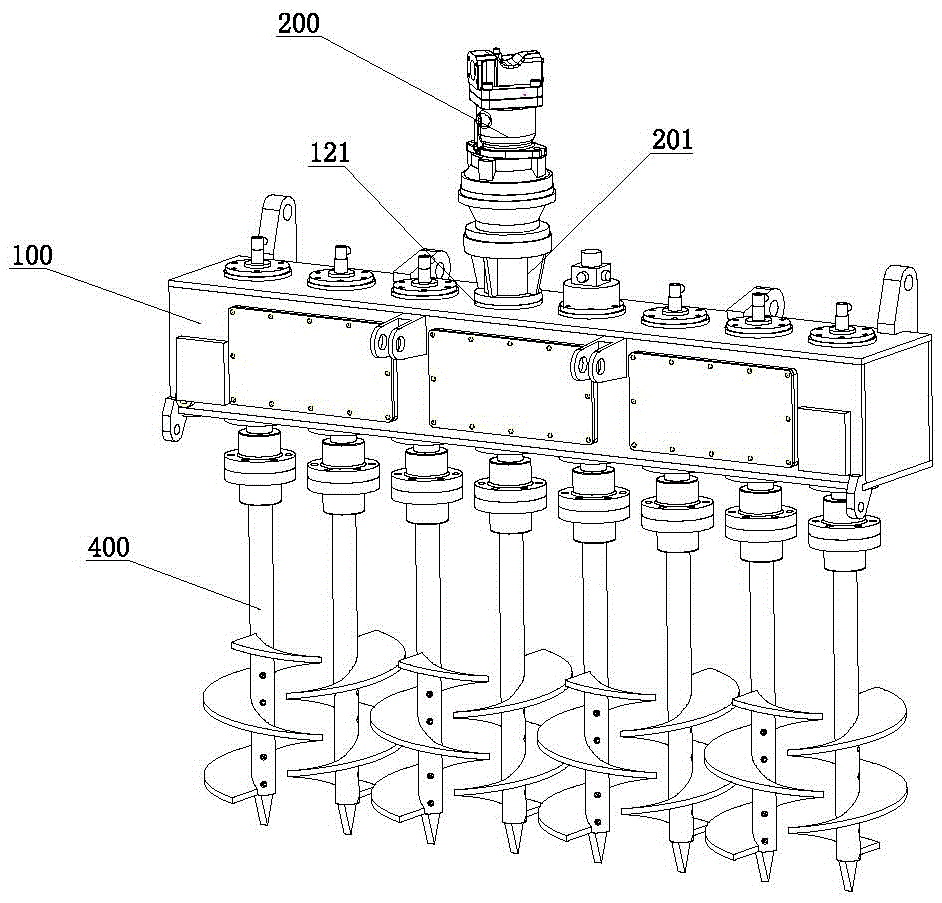

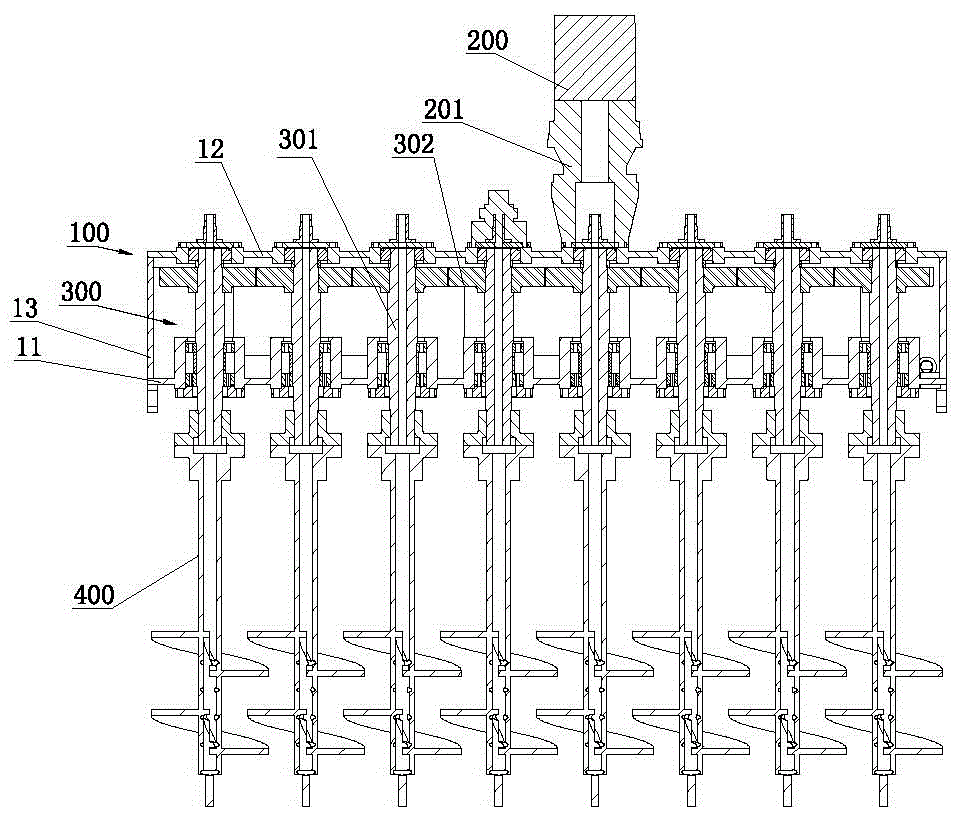

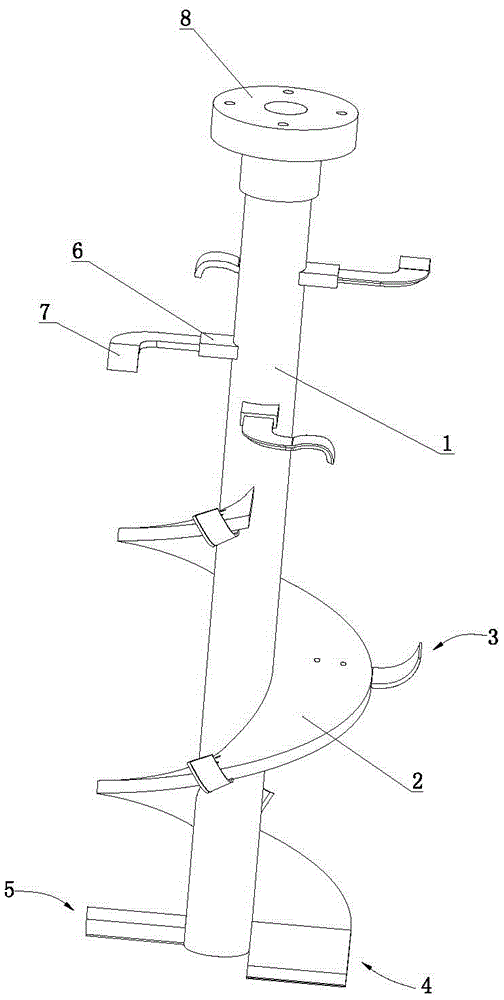

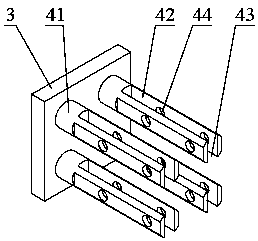

Subsoiling and tilling device

The invention discloses a subsoiling and tilling device. The subsoiling and tilling device comprises a transmission case, wherein more than one transmission shaft is arranged in the transmission case, one end of each transmission shaft extends out of the transmission case, and extending ends of the transmission shafts are connected with a subsoiling and tilling knife tool; the subsoiling and tilling knife tool comprises a knife carrier, a spiral sheet is fixed on the knife carrier, knife blades are mounted on the spiral sheet, a first soil piercing knife blade is fixed at the lower end of the spiral sheet, and a second soil piercing knife blade is fixed at the lower end of the knife carrier; and the lower ends of the first and second soil piercing knife blades are lower than the bottom face of the knife carrier, crushing and leveling knife blades are arranged at the upper end of the knife carrier in a staggered manner, and each crushing and leveling knife blade has an insertion part, a first bent part and a second bent part. According to the subsoiling and tilling device, due to the structure, the subsoiling and tilling knife tool can more easily pierce soil and is more uniformly stressed during soil piercing, and the fluffiness and crushing degrees of land in the vertical direction are different, so that the growth of plants is better facilitated, and leveling re-crushing for topsoil can be better carried out by using the knife tool.

Owner:GUANGXI WUFENG MACHINERY CO LTD

Electroplastic-effect-based elastic particle medium assisted electromagnetic forming device and forming method for light-alloy miniature complex component

ActiveCN108555110AImprove plasticityReduces the possibility of irreversible production defects such as cracksShaping toolsElectricityMetallic materials

The invention provides an electroplastic-effect-based elastic particle medium assisted electromagnetic forming device and forming method for a light-alloy miniature complex component and belongs to the field of metal material processing and forming. By means of the device and method, the problem that according to existing miniature complex component forming methods, both the workpiece quality andthe precision cannot be taken into account simultaneously is solved. According to the device, a light-alloy plate is clamped between an elastic particle medium cavity and a die, an electroplastic unitmakes the plate be subjected to the electroplastic effect, a temperature measurement unit measures the plate surface temperature, and an impact unit withstands electromagnetic force from an electromagnetic pulse generating unit and applies impact force to the plate through an elastic particle medium to make the plate be attached to a forming cavity of the die. The method comprises the steps thatthrough the electroplastic unit, the plate is subjected to the electroplastic effect, through cooperation between the electroplastic unit and the temperature measurement unit, the plate surface temperature is controlled, through the electromagnetic pulse generating unit, the electromagnetic force is applied on the impact unit, and through cooperation between the impact unit and the elastic particle medium, the plate is made to be attached to the forming cavity.

Owner:XIANGTAN UNIV

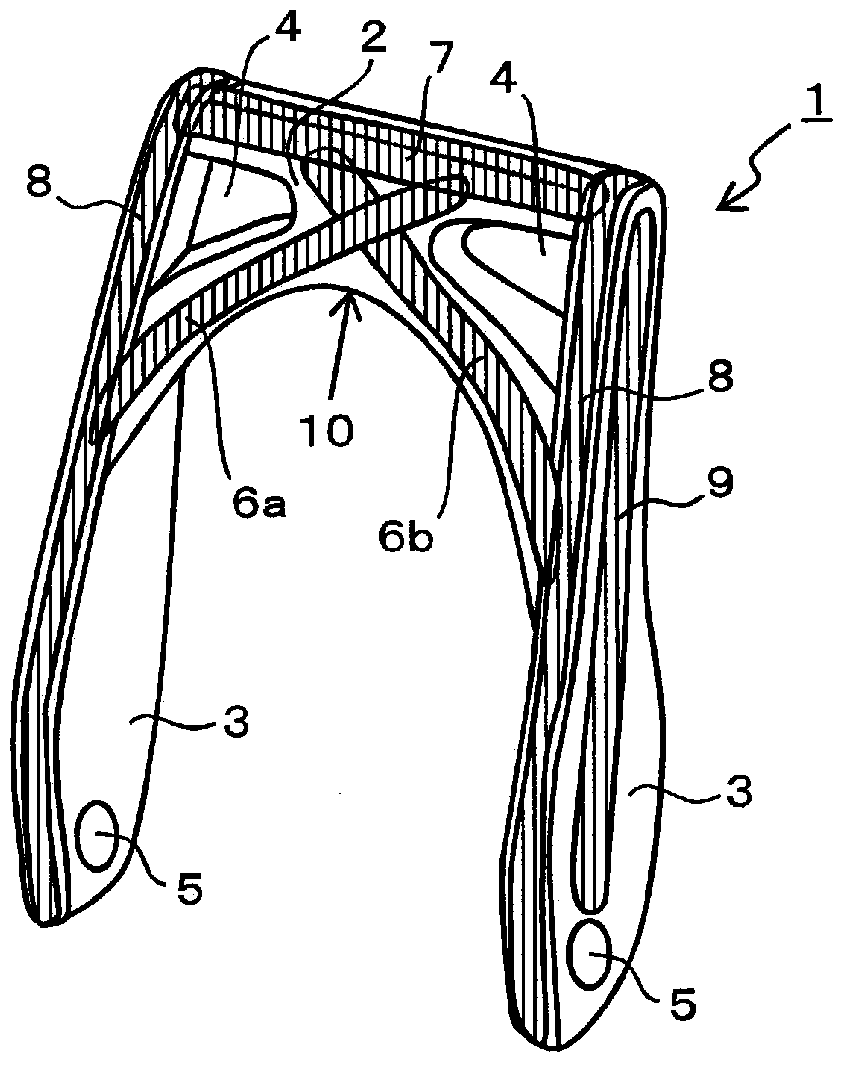

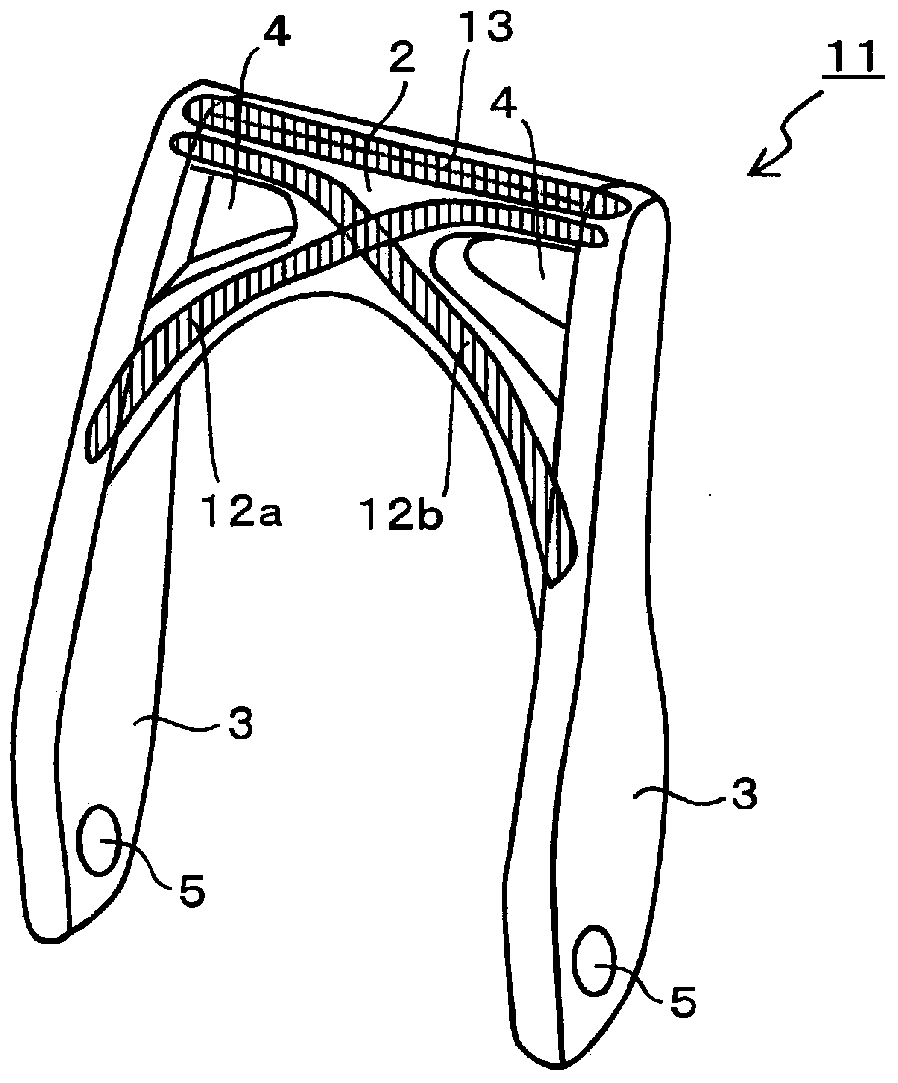

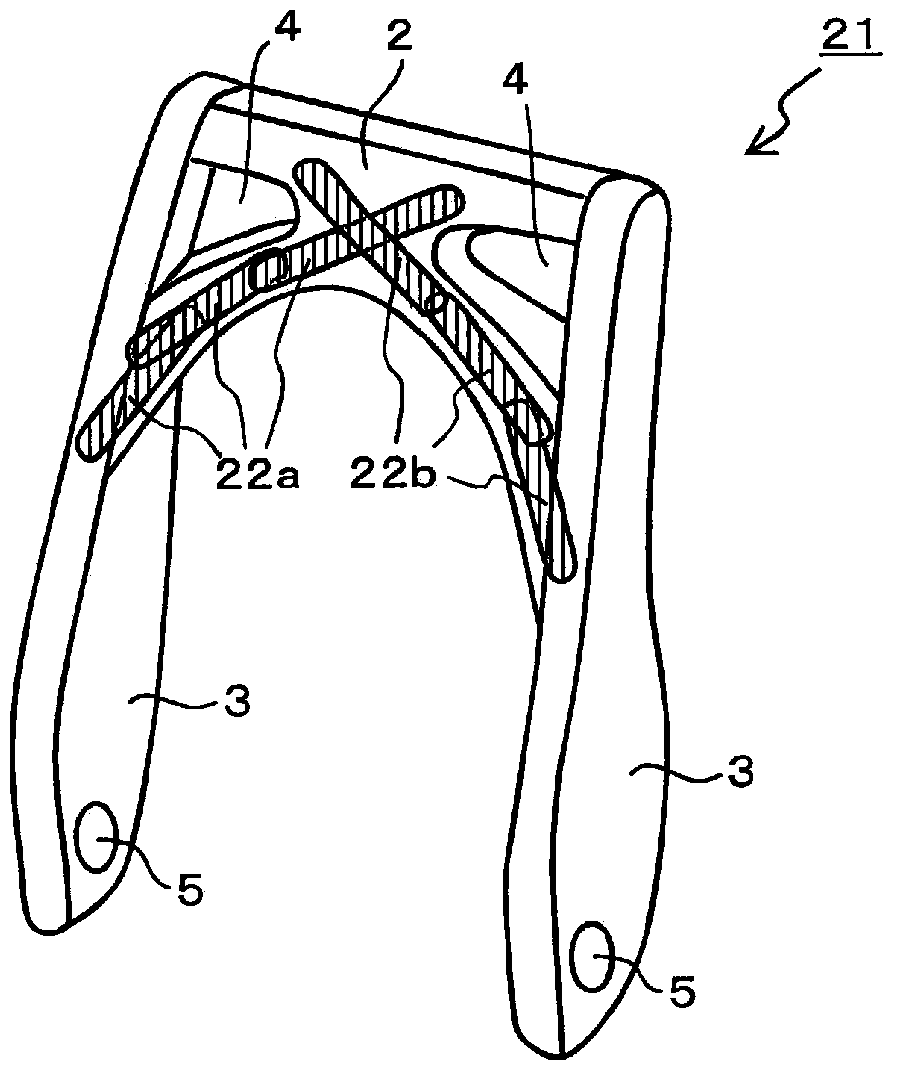

Frame structure for backrest and method for manufacturing same

The present invention provides a resinous frame structure for a backrest and a method for manufacturing the same. The frame structure for the backrest has a configuration in which side frames that extend parallel to each other on both sides and a transverse frame that extends between the tops of both the side frames are integrally connected to form a gate shape as a whole, a belt-shaped FRP sheet in which reinforced fibers are oriented in one direction so as to stretch continuously or intermittently is stuck on the surface of at least the transverse frame between the side frames, and a matrix resin of the stuck FRP sheet and a resin constituting the transverse frame are integrally joined. The stiffness of the transverse frame that serves as a load receiving part and further forms a path for transmitting a load to the side frame side can be improved, and the whole frame structure can achieve high stiffness while ensuring light weight.

Owner:TORAY IND INC

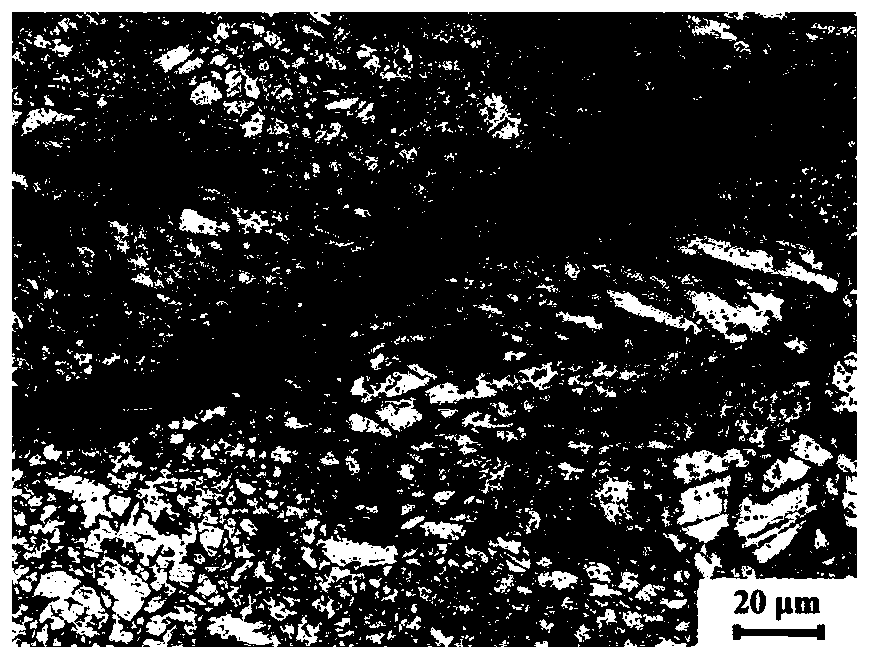

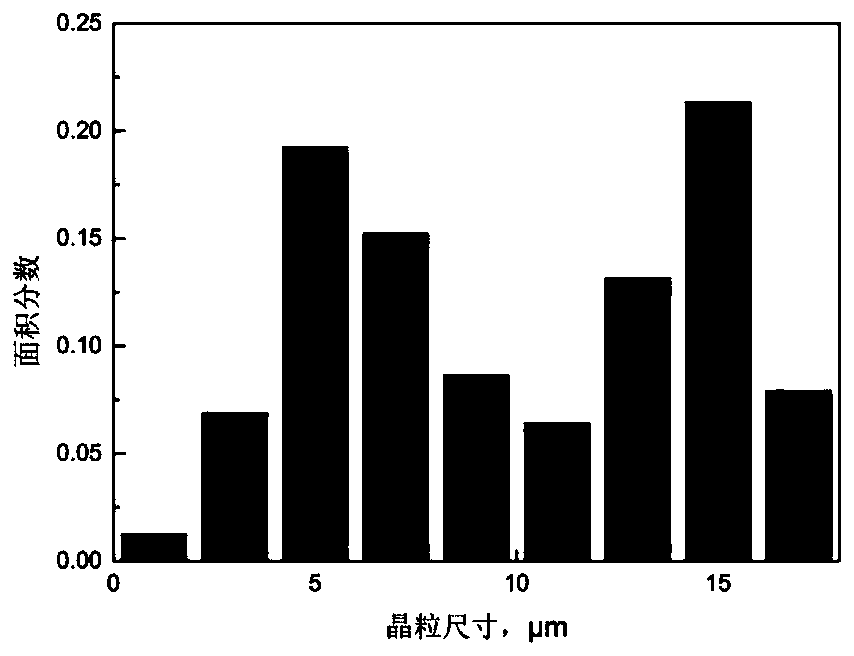

Preparation method of layered double-scale magnesium alloy

The invention provides a preparation method of a layered double-scale magnesium alloy, and belongs to the field of light metal material processing. The method comprises the following steps that isothermal heating is carried out on a magnesium alloy plate blank subjected to heating homogenization at 280-370 DEG C for 20-30 min, then the first pass of rolling deformation is immediately carried out to obtain a deformed plate, wherein the strain rate of rolling is 3.5-4.9s<-1>; and after annealing is carried out on the deformed plate, the second pass of rolling deformation is carried out at 280-340 DEG C, wherein the strain rate of rolling is 6.0-7.1s<-1>. According to the preparation method of the layered double-scale magnesium alloy, the high strain rate and gradient cooling double-pass rolling are adopted so that the high-strength toughened magnesium alloy material with the layered double-scale organizational structure can be obtained, the alternate layered distribution of the ultra-fine crystal layer and the micron crystal layer is achieved, and the strength and the plastic toughness of the magnesium alloy are improved.

Owner:YANSHAN UNIV

Pouring process of vermicular graphite cast iron engine cylinder head

The invention relates to the technical field of metal casting, in particular to a pouring process of a vermicular graphite cast iron engine cylinder head. The pouring process comprises the following steps: assembling die for preheating, adding sand for hardening, coating, assembling a box, preparing pouring liquid, pouring, and taking an obtained casting. Compared with the prior art, the pouring process has the advantages that an iron sand box sand coating process is applied to casting of the vermicular graphite cast iron engine cylinder head, and as a rigid sand mold shell is obtained through sand-coating casting of the iron sand box, the overall strength of the sand mold is high to avoid deformation, deformation in the pouring process of the casting is reduced, the positioning is reliable, the precision is high, and the casting is more easily to demould.

Owner:CHONGQING HONGQI CYLINDER HEAD MFG

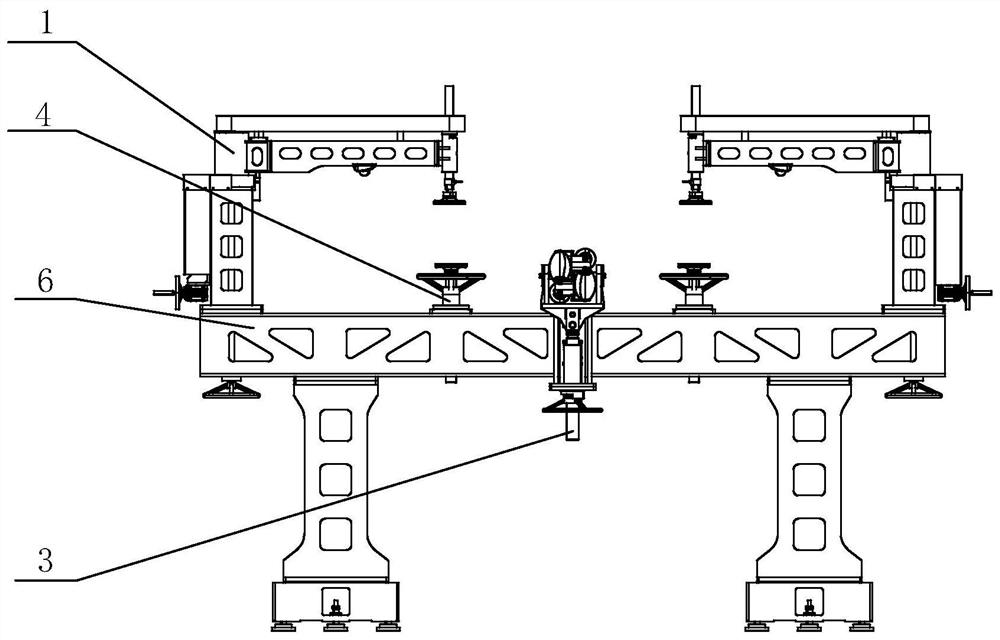

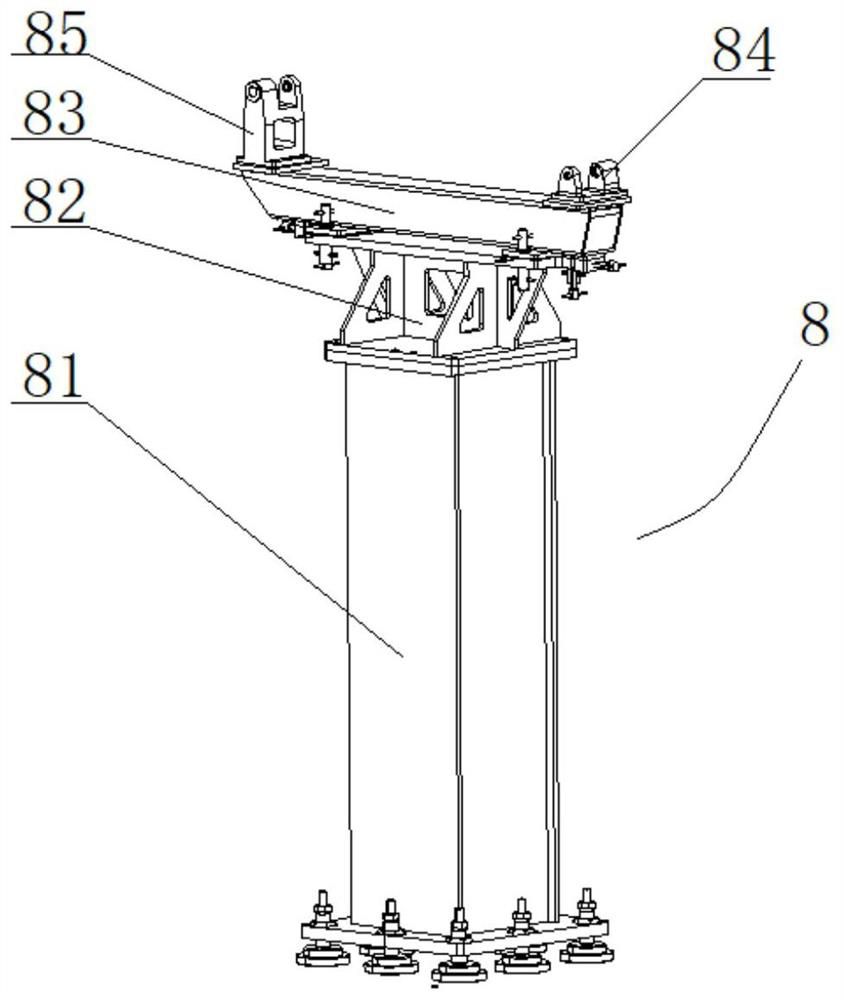

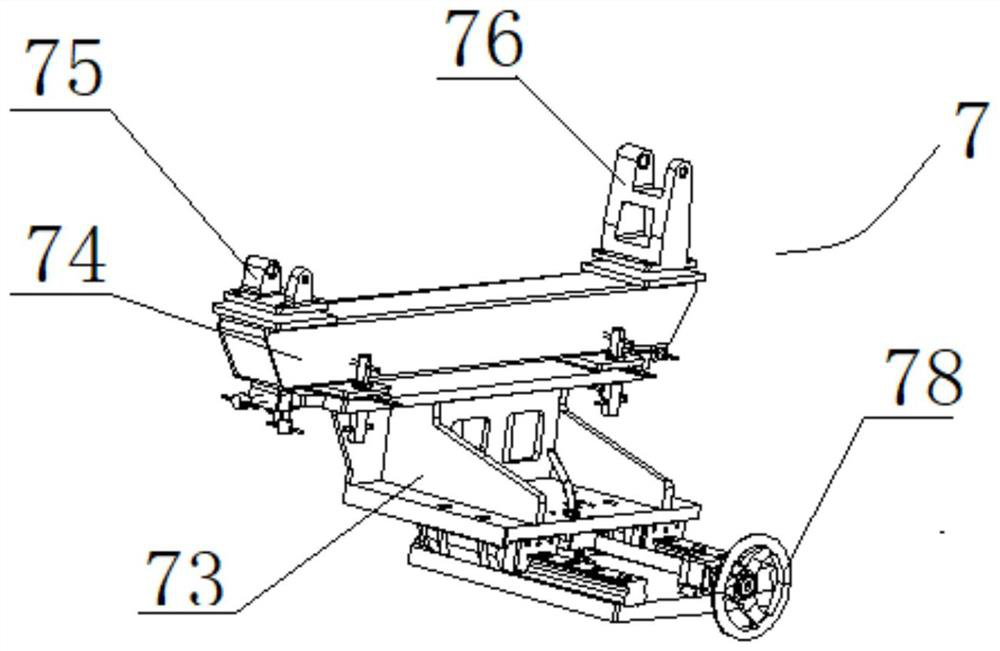

Aircraft outer wing positioning and clamping device

ActiveCN112975794AGuaranteed stabilityRealize multi-degree-of-freedom attitude adjustmentWork holdersAircraft assemblyDetentAirplane

The invention discloses an aircraft outer wing positioning and clamping device, and belongs to the field of aircraft digital assembly finish machining. The aircraft outer wing positioning and clamping device comprises a fixed base, a roller adjusting assembly detachably fixed to the fixed base and used for adjusting the posture, a supporting assembly used for supporting, an outer wing positioner used for positioning, and a pressing assembly used for being matched with the supporting assembly for fixing. The outer wing positioner comprises a mounting seat detachably fixed on the fixed base, a guide rail slide block assembly slidably fixed on the mounting seat and a detachable positioning block detachably fixed on the guide rail slide block assembly. The guide rail slide block assembly and the mounting seat are matched and fixed through positioning holes and bolts. The detachable positioning block is used for limiting a wing drill plate through a positioning pin. By means of the aircraft outer wing positioning and clamping device, the problems of wing deformation, collision damage and the like in the clamping and positioning process can be avoided, and the safety and machining precision of wing automatic machining are improved.

Owner:ZHEJIANG UNIV

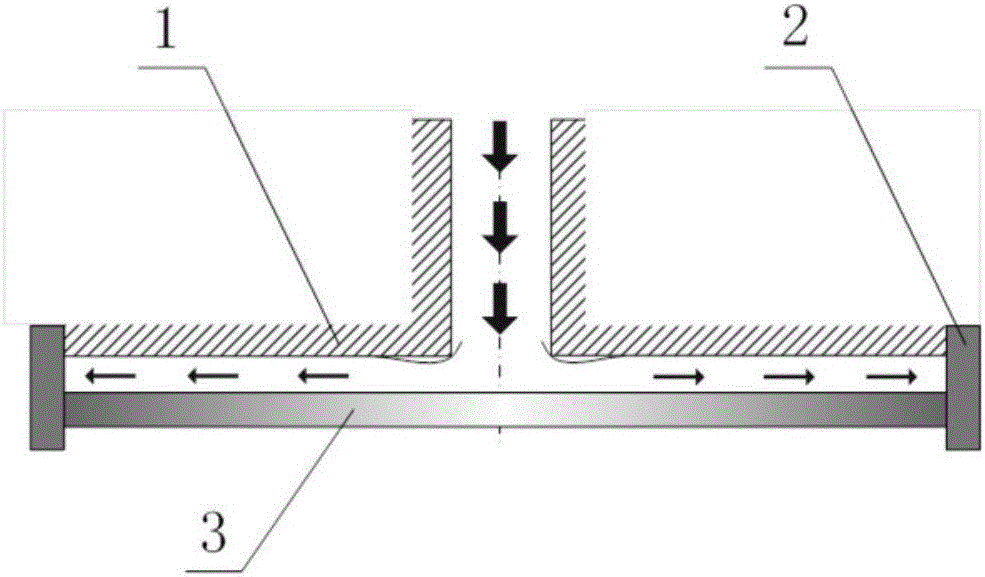

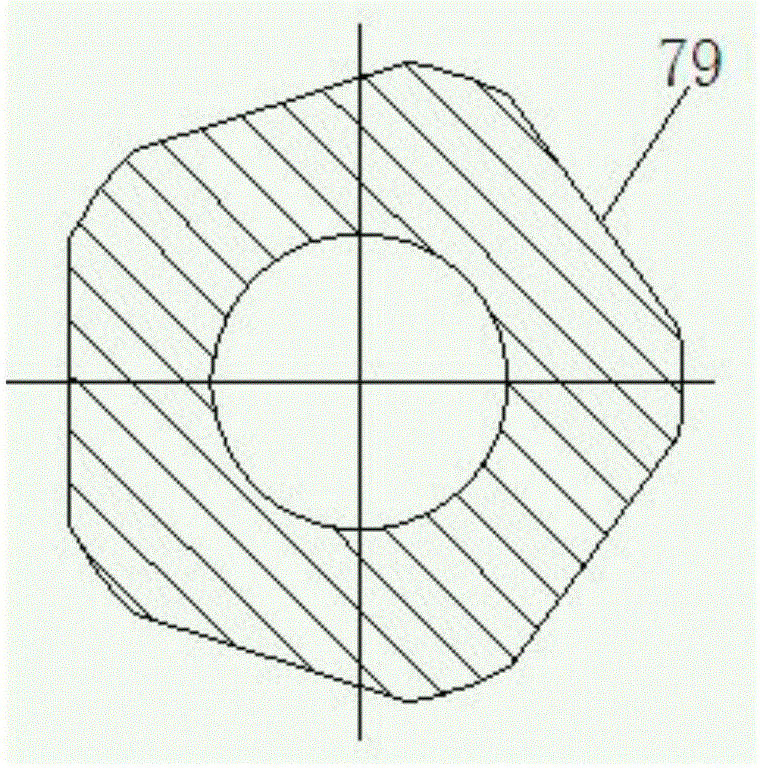

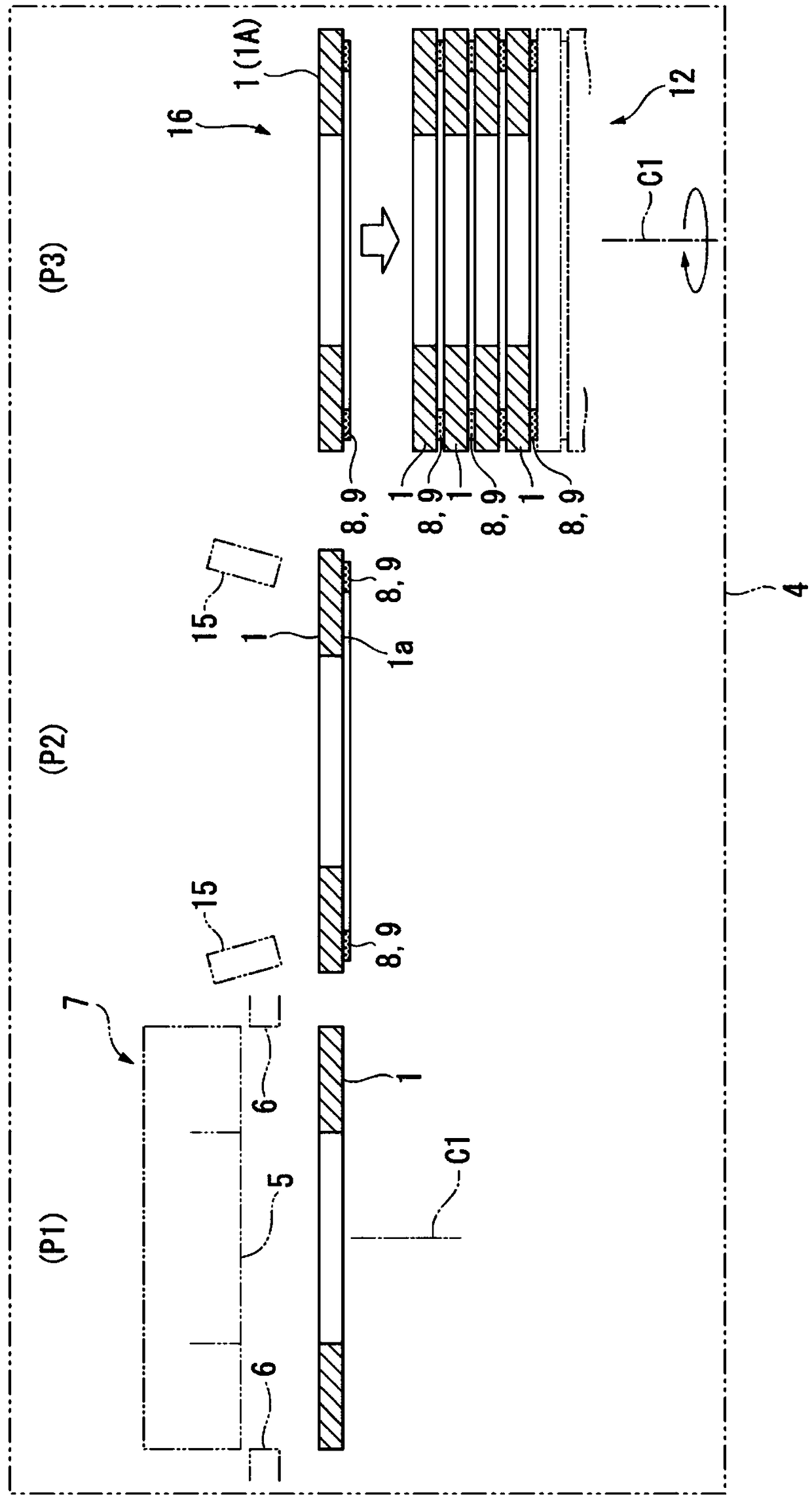

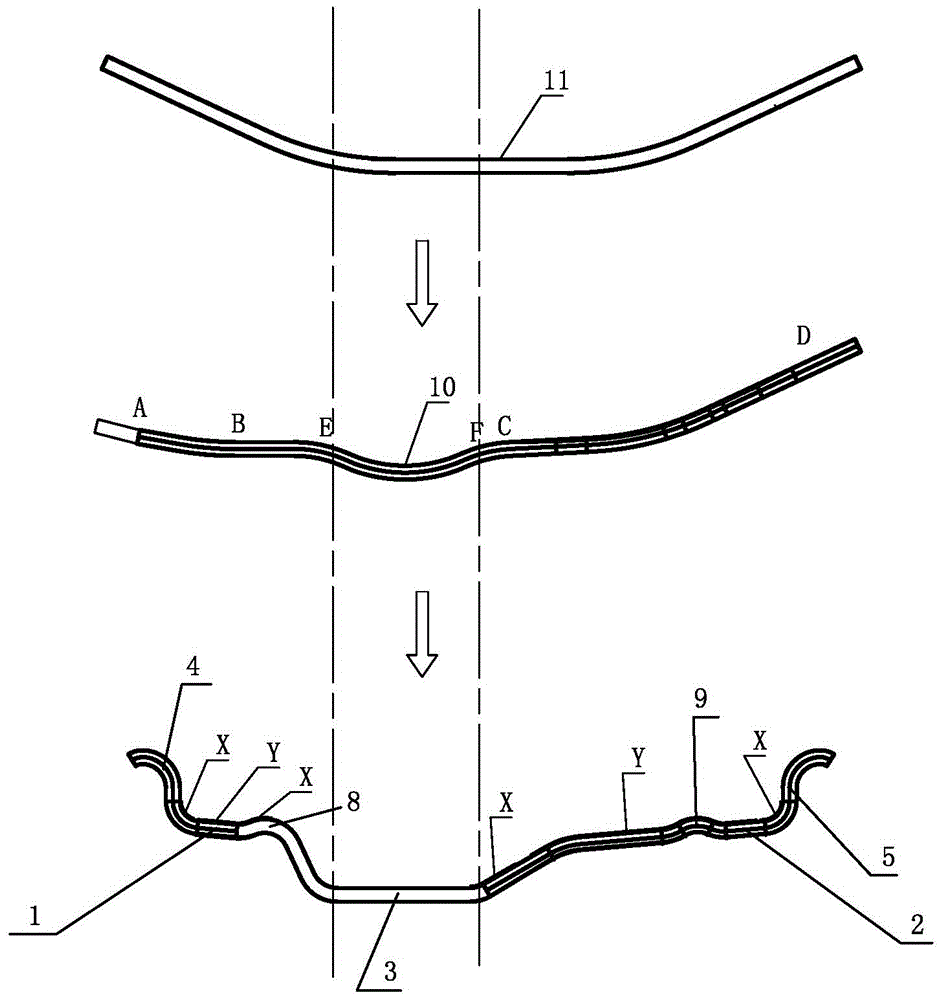

Manufacturing method of laminated steel and laminated steel manufacturing apparatus

ActiveCN109263235ALess prone to stress concentrationNot easy to shiftLaminationMagnetic circuit stationary partsSheet steelSteel plates

Provided is a method of manufacturing laminated steel plates by laminating a plurality of steel plates, the method including an application process of applying an adhesive agent on a surface of each of the steel plates, and a lamination process of laminating a steel plate, to which the adhesive agent is applied, and another steel plate while shifting positions of the steel plates about an axis with each other, and causing the steel plate to adhere to a laminated body using the adhesive agent, wherein, in the application process, the adhesive agent is applied such that the adhesive agent becomes in a shape that is continuous about a central axis when the steel plate and the other steel plate are adhered by the adhesive agent in the lamination process.

Owner:HONDA MOTOR CO LTD +1

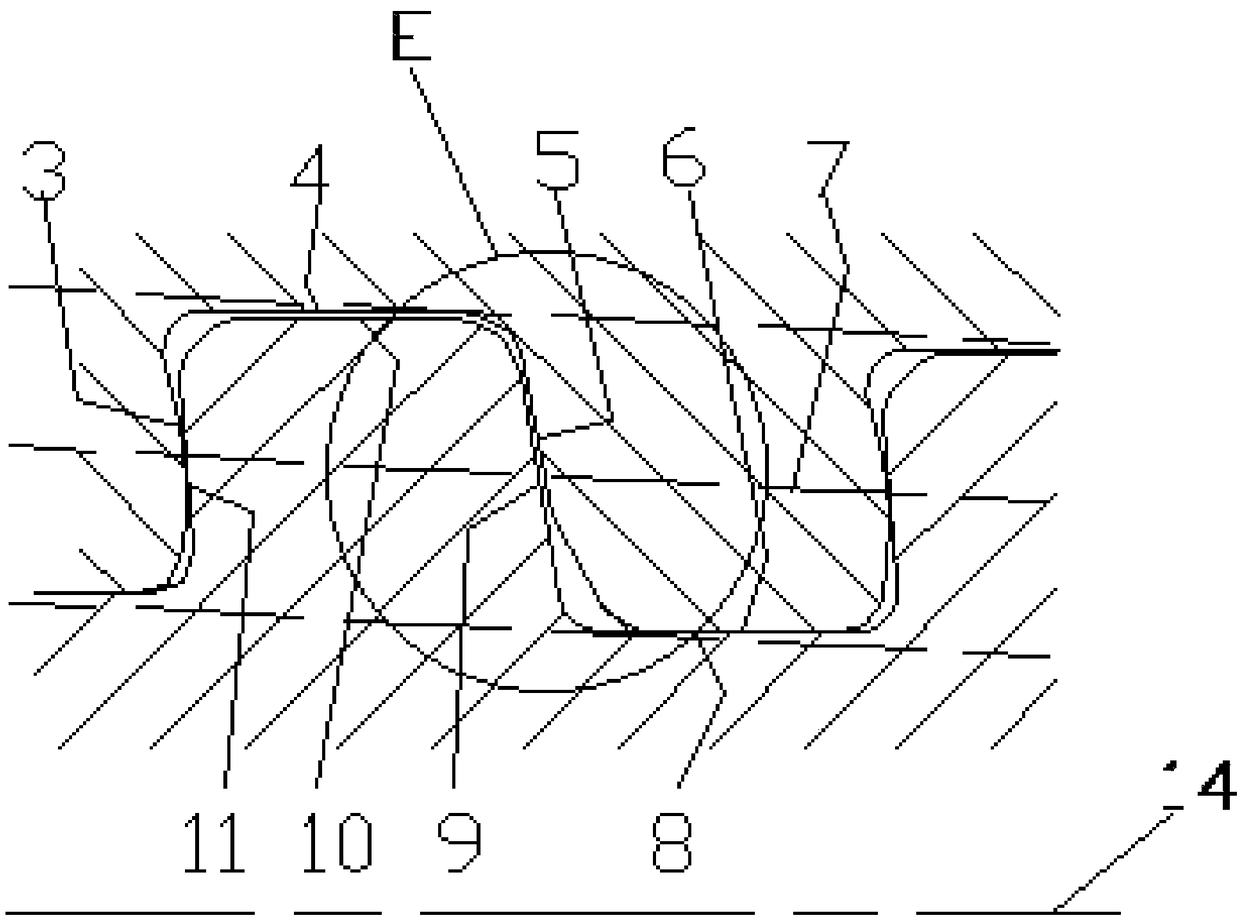

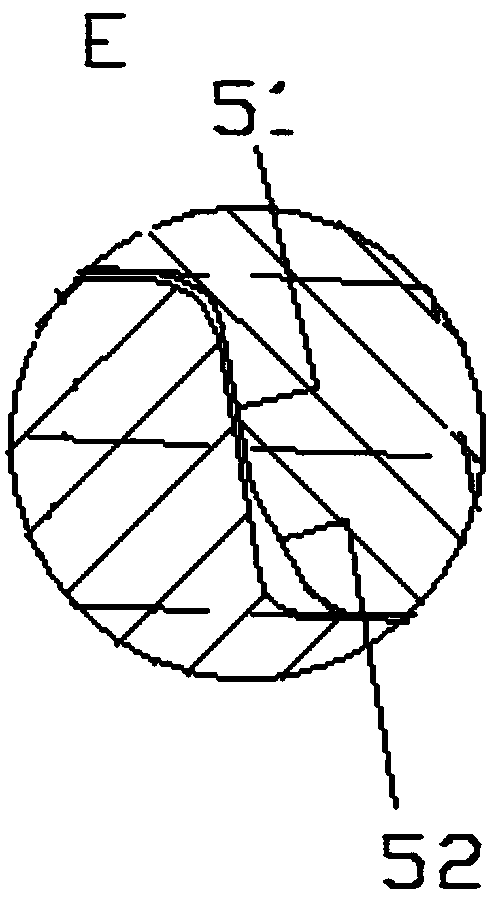

Rotary fluid machine

InactiveCN100443727CContainment leakImprove efficiencyRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringHigh pressure

The invention provides a rotary fluid machine, especially a rotary fluid machine which solves the problem of the gap between the cylinder and the piston. The rotary fluid machine includes a rotary mechanism (20) including a cylinder (21) having an annular cylinder chamber (50), and being housed in the cylinder chamber and eccentric to the cylinder, and partitioning the cylinder chamber to the outside The annular piston (22) of the compression chamber (51) and the inner compression chamber (52), and the vane (23) arranged in the cylinder chamber to divide each working chamber (51, 52) into a high-pressure side and a low-pressure side , and the cylinder and the piston rotate relative to each other. In addition, the cylinder chamber width ( T1 ) changes around the cylinder chamber so that the gap between the cylinder wall surface and the piston wall surface becomes constant during rotation. Furthermore, the piston width (T2) changes around the piston so that the gap between the cylinder wall surface and the piston wall surface becomes a constant value during the rotation of the piston.

Owner:DAIKIN IND LTD

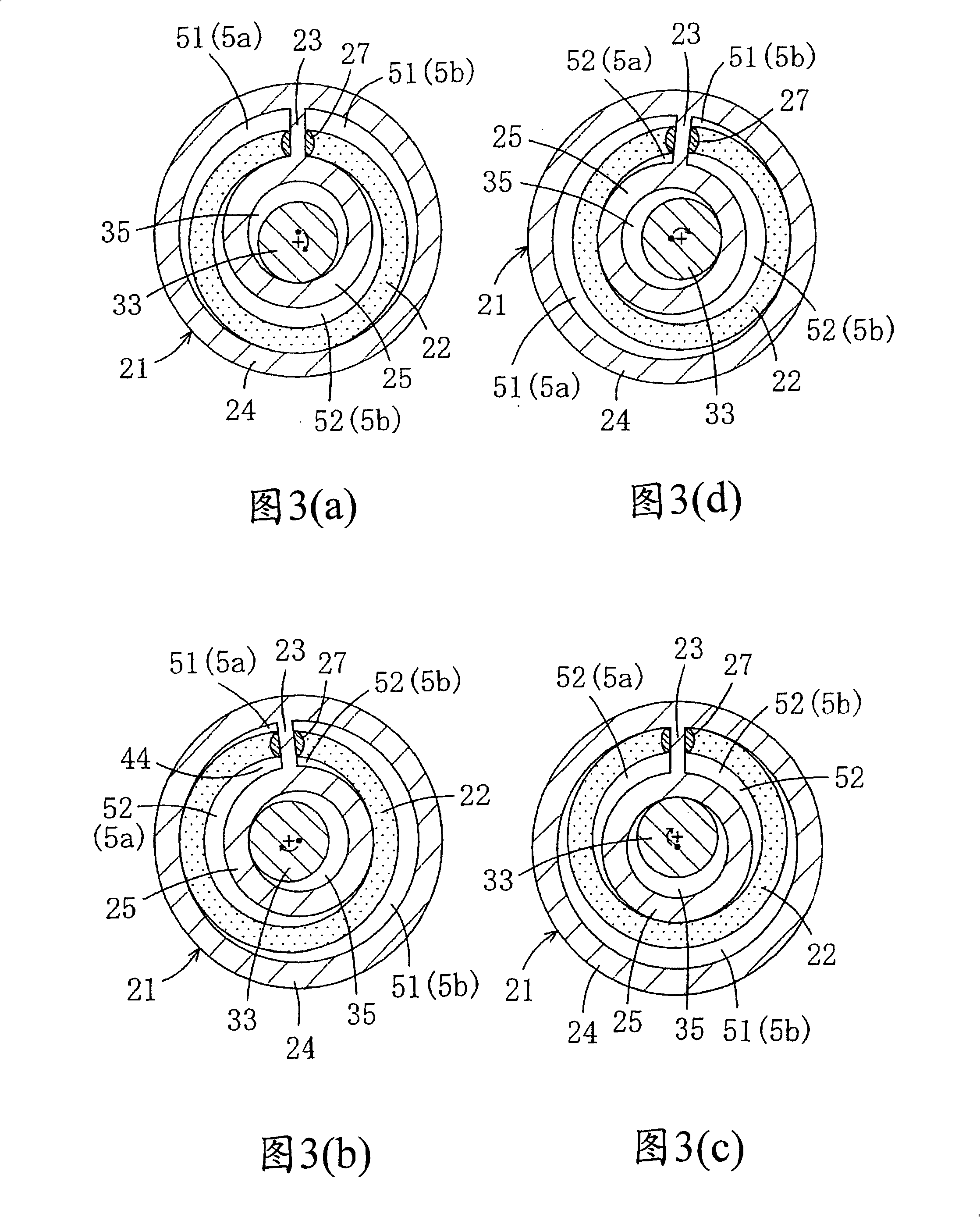

Machining method for rim blank for spinning rim

The invention relates to a machining method for a rim blank for spinning rim. The machining method is used for conducting segmented spinning machining on the flaring rim blank, wherein the middle of the rim blank is a flat bottom, and the two sides of the rim blank extend obliquely. The method includes the steps that firstly, the EF segment is rolled to form positioning protrusions, and the positioning protrusions are used for positioning a workpiece; secondly, the AB segment is spun to be thinned; and thirdly, the CD segment is spun to be thinned, the width of the workpiece is widened while spinning is conducted, and the increased maximum width is 40 mm. By means of the manner, spinning force is smaller, energy is greatly reduced, and abrasion on a die is smaller; the molding quality can be effectively improved, and stability after forming is further enhanced; and in addition, the quality qualification rate is also increased, the production takt is faster, and the production efficiency is higher.

Owner:ZHEJIANG JINGU CO LTD

Shock-resistance segmented wind power blade and assembly method thereof

ActiveCN106438193AEasy to installImprove impact resistanceFinal product manufactureWind motor assemblyElectricityShock resistance

The invention discloses a shock-resistance segmented wind power blade and an assembly method thereof. The blade comprises at least two blade sections; a connecting device is connected between the blade sections, and includes two connecting frames; the connecting end surfaces of the connecting frames and the blade sections are matched in shape; first mounting holes are formed in the connecting frames; first bolts for tightly connecting with the blade sections are arranged in the first mounting holes; multiple hinge pieces for buffering are connected between two connecting frames; the rotating direction of all the hinge pieces is consistent with the stress direction of the blade sections; and limiting pieces for limiting swing of the blade sections are connected between the two connecting frames. The method comprises the steps of: (S1) manufacturing and transportation; (S2) installation; and (S3) building of pneumatic shape of the blade. The shock-resistance segmented wind power blade has the advantages of convenience for assembly and disassembly, high connecting strength and high reliability.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

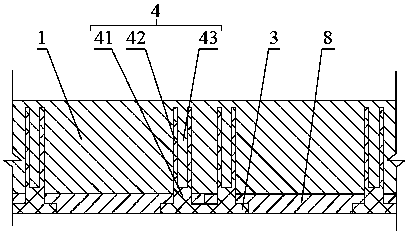

External cast-in-situ heat preservation wall and construction method thereof

InactiveCN109057061AEasy to installNot easy to fall offHeat proofingEngineeringBuilding construction

Owner:四川恒达兴铁科技有限公司

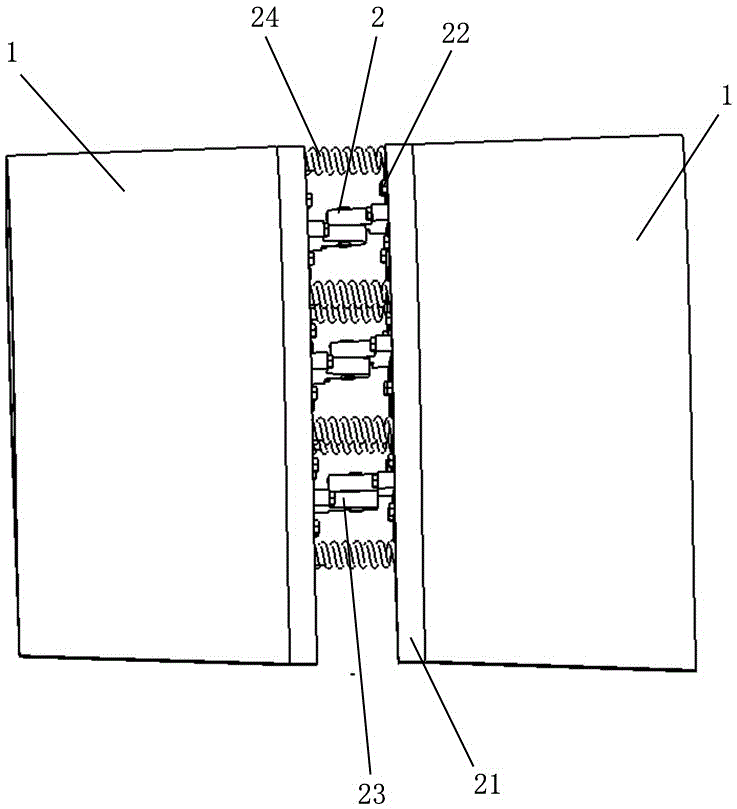

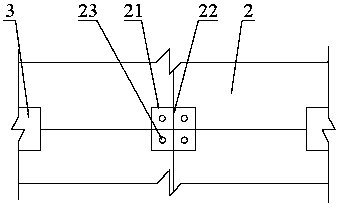

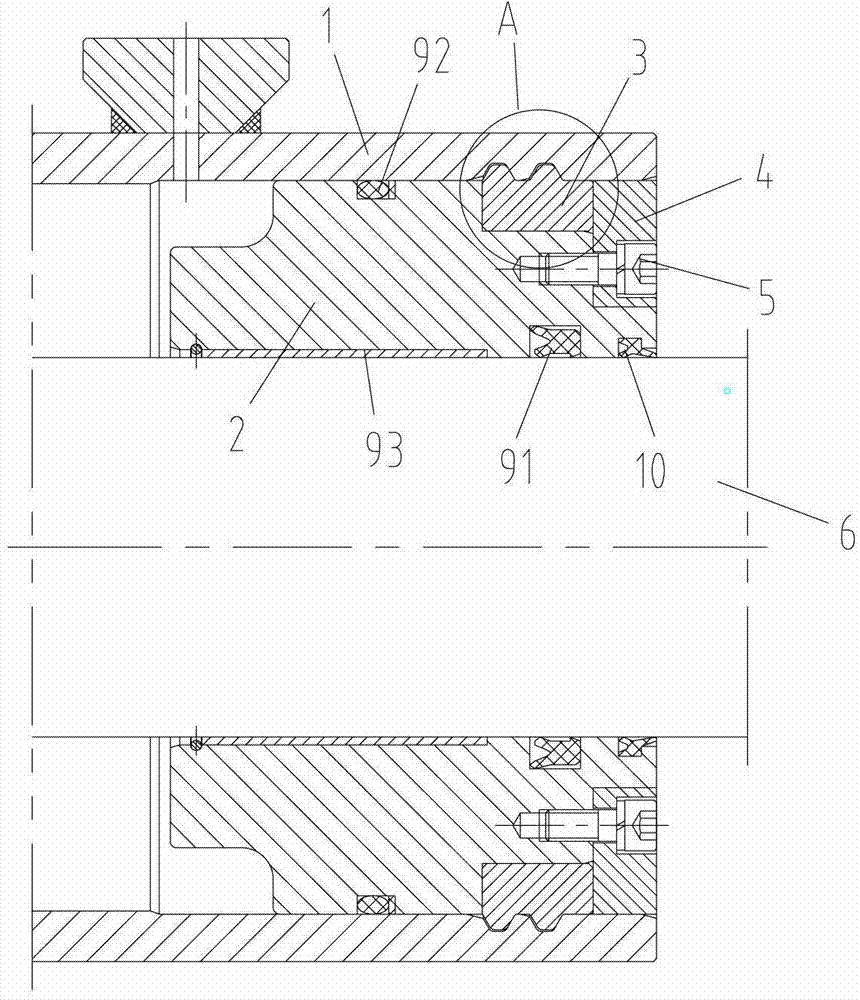

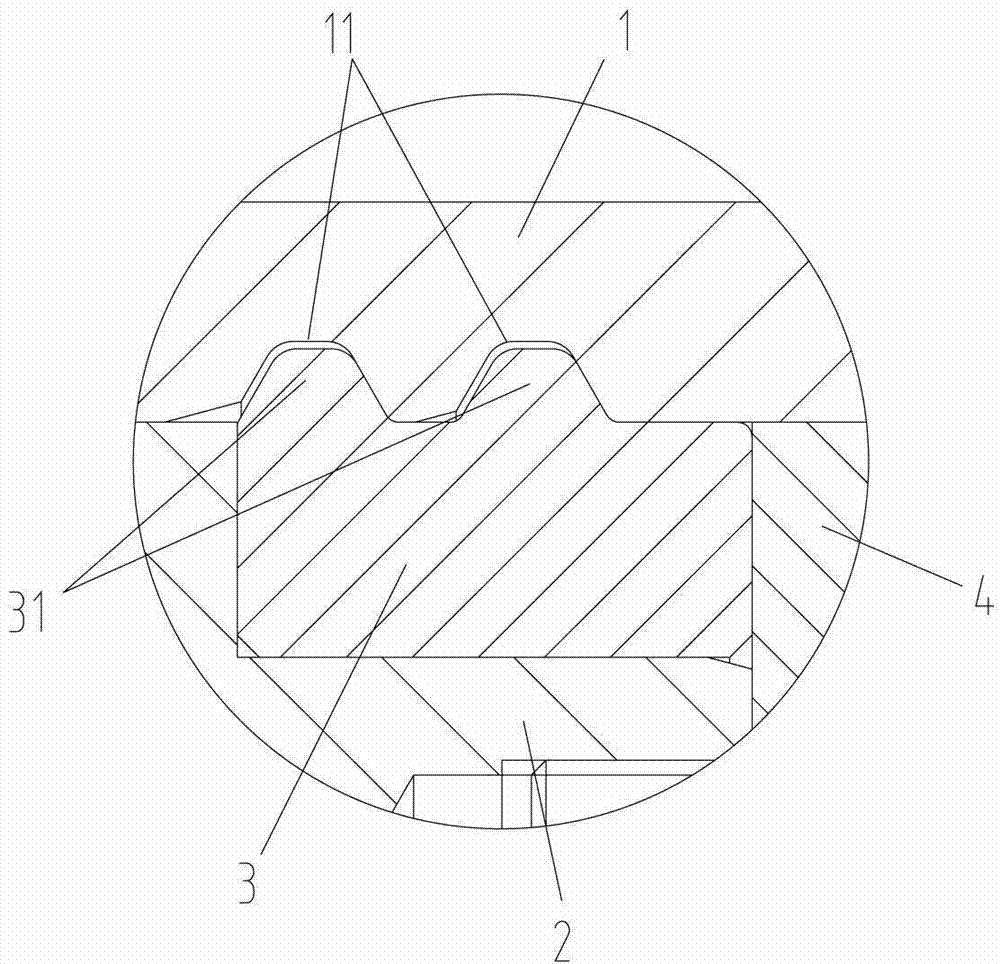

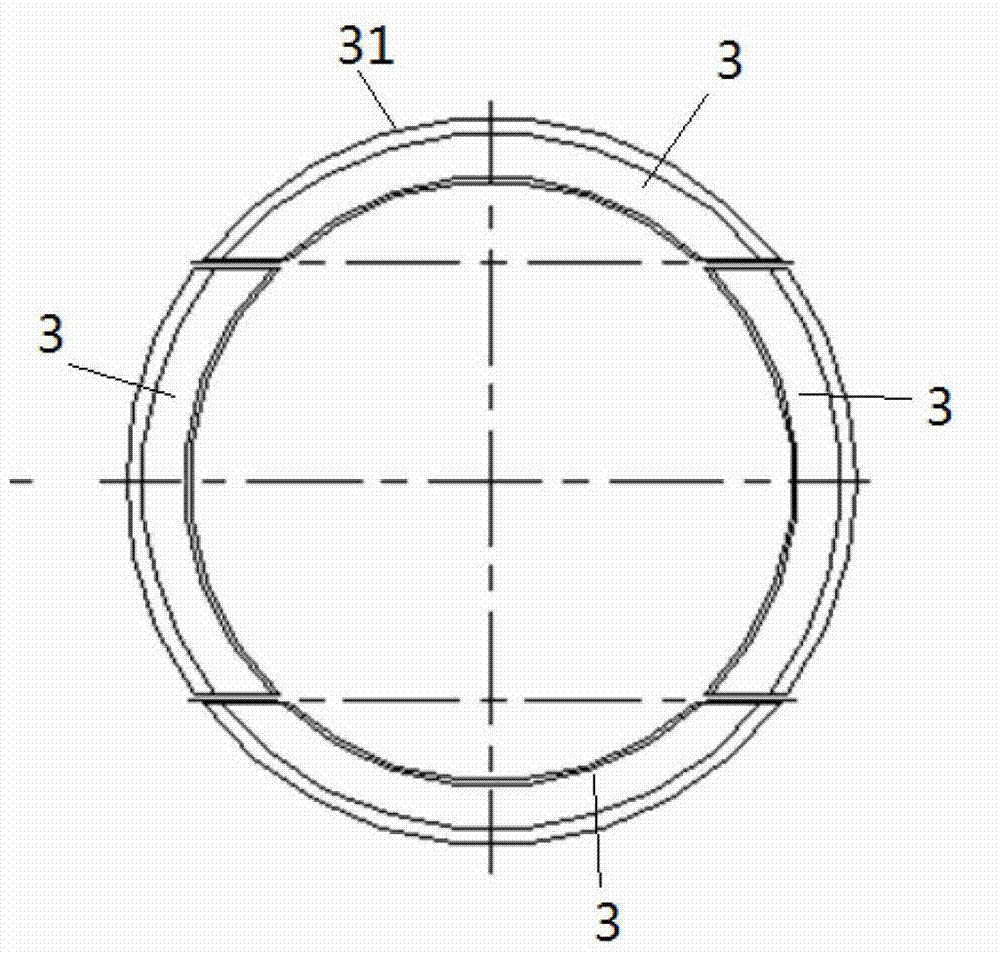

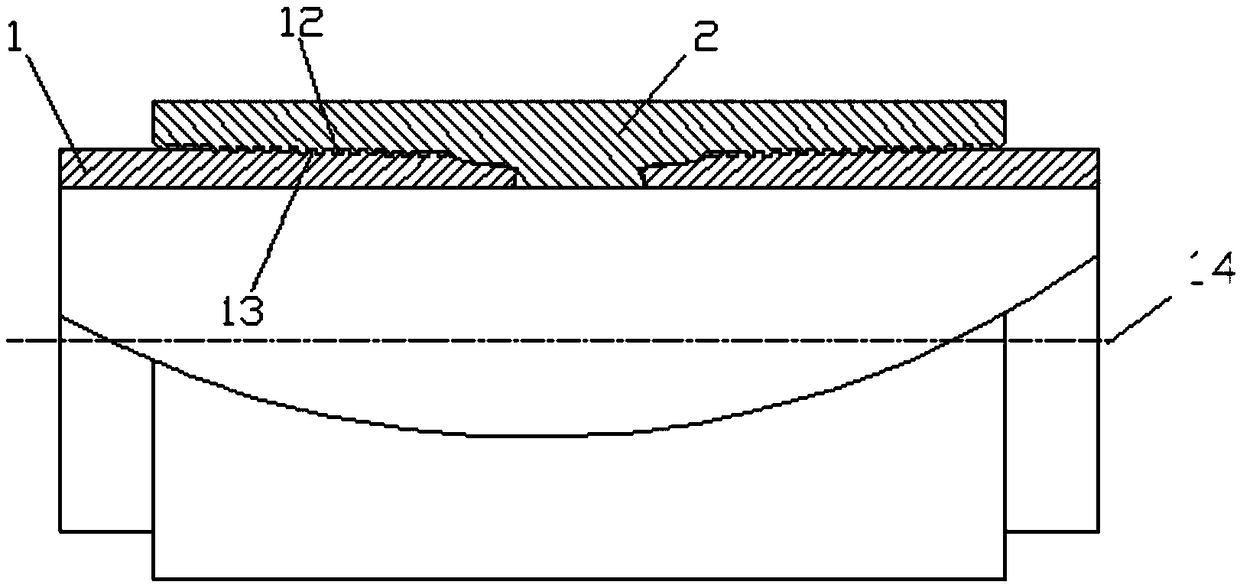

Guide sleeve mounting structure of driving cylinder, driving cylinder and blocking key

ActiveCN102852902AReasonable forceLess prone to stress concentrationFluid-pressure actuatorsEngineeringElectrical and Electronics engineering

The invention discloses a guide sleeve mounting structure of a driving cylinder. The guide sleeve mounting structure comprises a cylinder barrel (1) and a guide sleeve (2) which is hermetically arranged on the end of the cylinder barrel; a blocking key (3) is arranged between the cylinder barrel and the guide sleeve; a key slot (11) for containing the blocking key is arranged in the cylinder barrel, wherein the key slot is an arc slot; and a plurality of arc protrusions (31) contained in the key slot in a way of being matched with the key slot in shape are arranged on the blocking key along a radial direction. The invention also provides a driving cylinder with the guide sleeve mounting structure and a blocking key; a plurality of arc protrusions arranged in an axial direction are arranged on the blocking key; the section areas of the arc protrusions are gradually reduced towards the outside along the radial direction. With the adoption of the arc protrusions formed on the blocking key of the guide sleeve mounting structure in the radial direction, the stress of the key slot matched with the blocking key in shapes can be reasonable, and the stress concentration is unlikely to occur, so that the guide sleeve mounting structure cannot be damaged and is longer in service life, in addition, the service life of the driving cylinder is prolonged.

Owner:HUNAN TELI HYDRAULIC

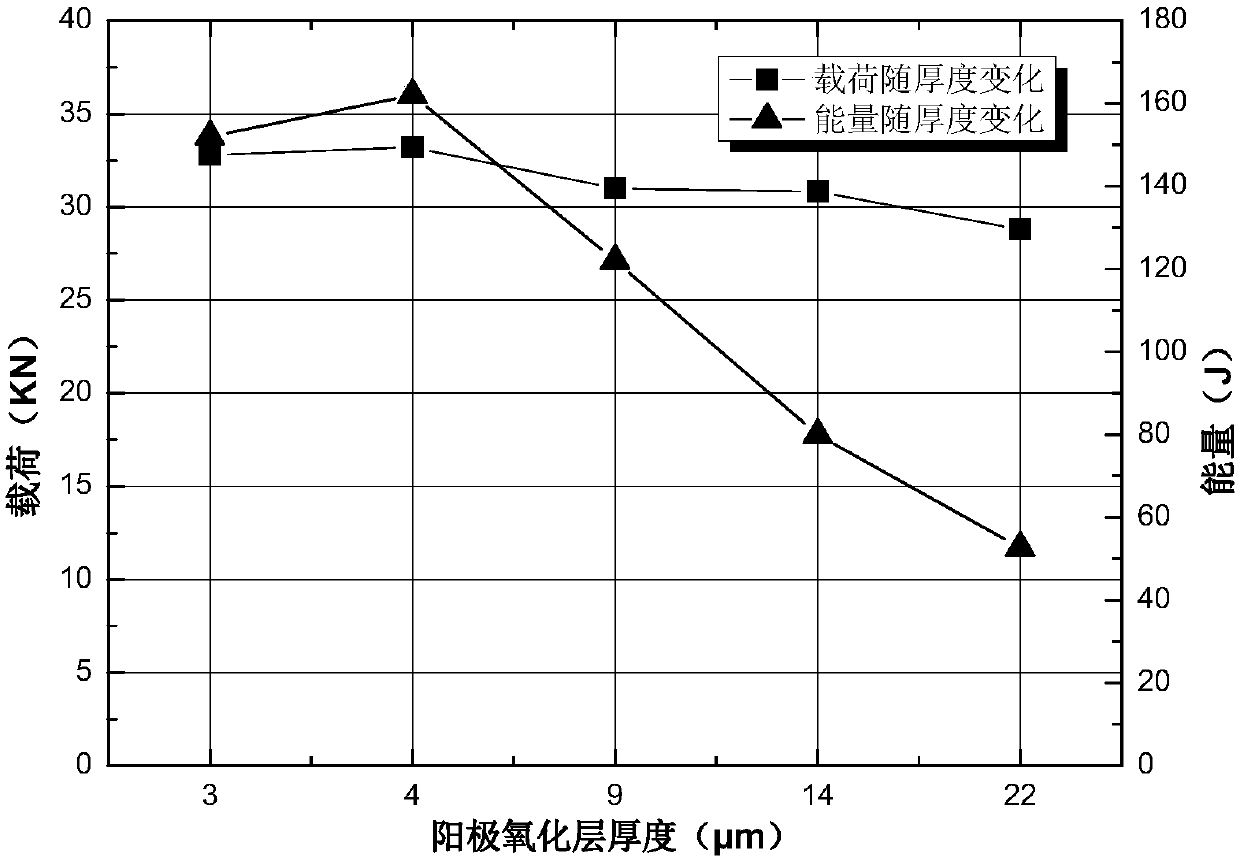

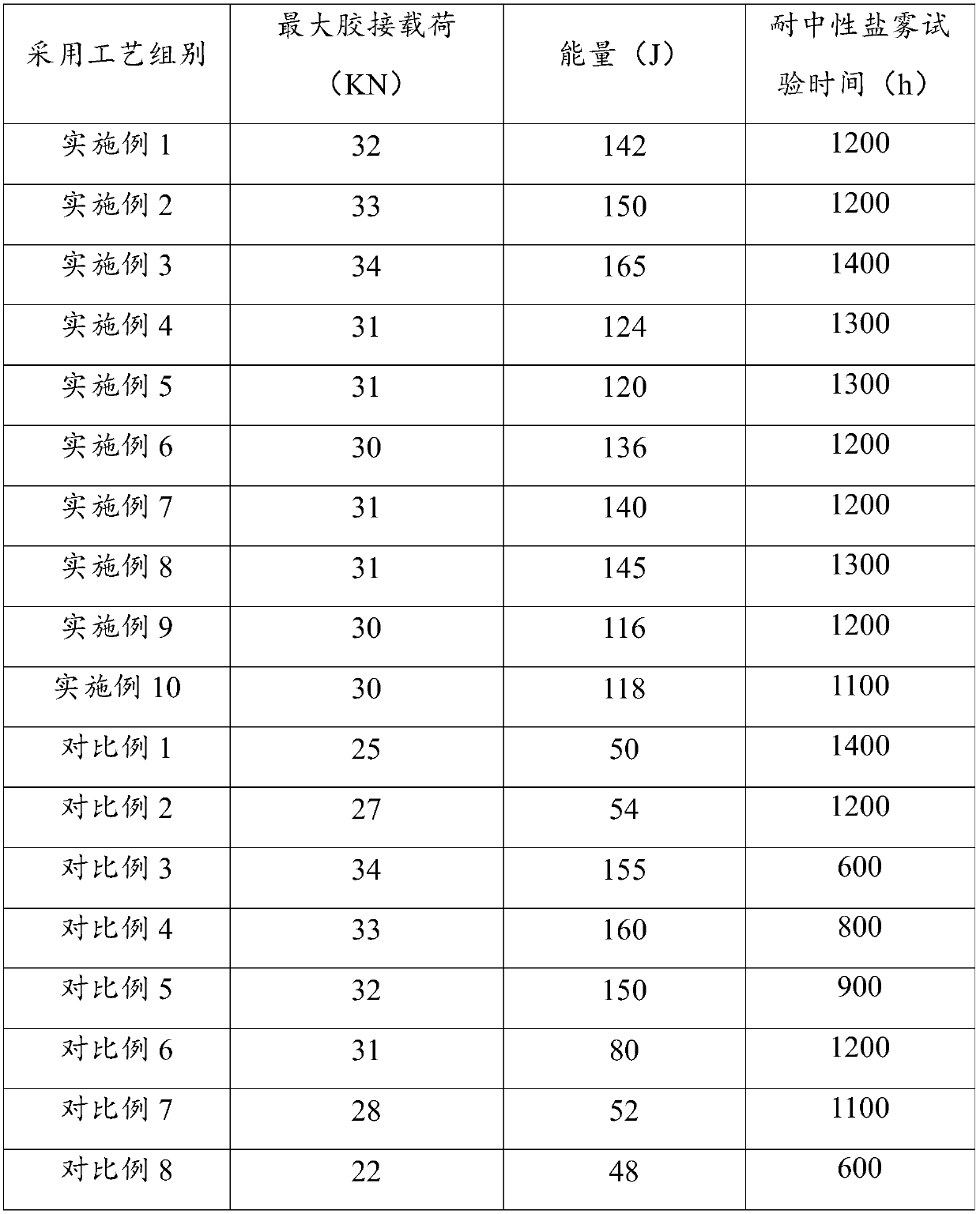

Surface treatment process before bonding of aluminium alloy automobile body component, aluminium alloy automobile body component, automobile body component connecting method, automobile body and automobile

InactiveCN107557837AImprove corrosion resistanceGood bonding propertiesAnodisationSuperstructure subunitsPower flowAfter treatment

The invention discloses a surface treatment process before bonding of an aluminium alloy automobile body component, the aluminium alloy automobile body component, an automobile body component connecting method, an automobile body and an automobile, and relates to the technical field of aluminium alloy automobile body component connecting. The surface treatment process comprises an anodic oxidationtreatment step and a sealing treatment step; when the anodic oxidation treatment step is performed, an anodic oxidation fluid contains H2SO4, the current density is 1.4 to 1.6 A / dm<2>, the oxidizingtemperature is 17 to 20 DEG C, and the thickness of an oxidation film after treatment is 2 to 10 [mu]m; the sealing treatment is performed by using hot water at the temperature of 96 to 100 DEG C; andthe sealing time is 10 to 45 minutes. According to the surface treatment process before the bonding of the aluminium alloy automobile body component, the aluminium alloy automobile body component, the automobile body component connecting method, the automobile body and the automobile, the defects that conventional universal process conditions cannot fully play the strength and performance of thebonding, the requirements on connection performance of an overall aluminium automobile body cannot be met, and the comprehensive performance of the connected automobile body is poor are relieved. Thebonding performance is higher than the welding performance and the corrosion resistance is improved after the bonding of the automobile body component which is treated by the treatment process disclosed by the invention.

Owner:ZHEJIANG YINGLUN AUTOMOBILE CO LTD +2

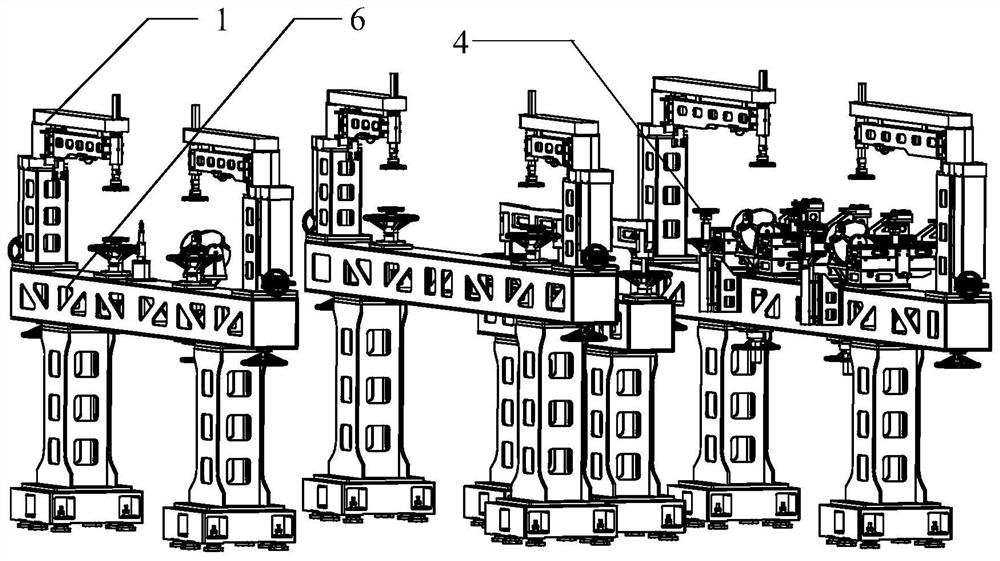

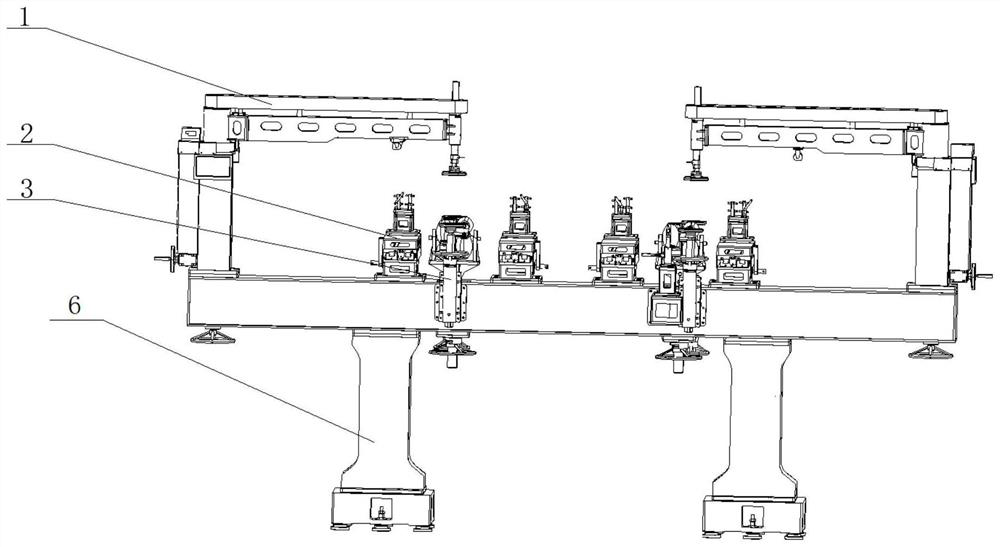

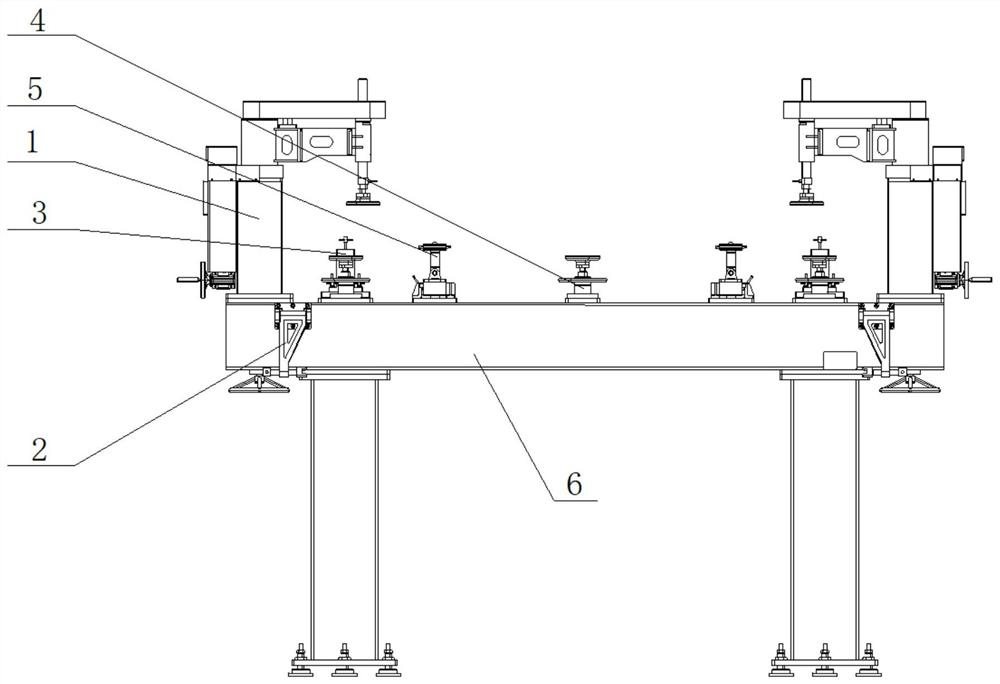

Aircraft central wing positioning and clamping device and method

ActiveCN113071702AGuaranteed stabilityIncrease frictionWork holdersAircraft assemblyBraced frameDetent

The invention discloses an aircraft central wing positioning and clamping device and method, and belongs to the field of aircraft digital assembly finish machining. The aircraft central wing positioning and clamping device comprises a supporting frame used for supporting and fixing, and a front hanging point positioning device, a rear hanging point positioning device and an intersection point positioner which are used for supporting and positioning; a bottom supporting assembly used for supporting, a pressing assembly used for being matched with the bottom supporting assembly for pressing and fixing, an adjusting and positioning assembly used for positioning, a front-back adjusting assembly used for adjusting the direction and a wingspan adjusting assembly are detachably fixed to the supporting frame. By means of the method, interference between the central wing and external tool equipment in the clamping and positioning process can be avoided, and meanwhile the problems of wing deformation, collision damage and the like in the clamping and positioning process are avoided.

Owner:杭州艾美依航空制造装备有限公司

Preparation method of low-temperature composite foam glass

InactiveCN107601903AHigh viscosityFine pore structureGlass shaping apparatusVegetable oilFoaming agent

The invention discloses a preparation method of low-temperature composite foam glass and belongs to the technical field of foam glass preparation. The preparation method comprises adding boric acid into a sodium silicate solution, carrying out uniform mixing to obtain high-viscosity liquid sol in the premise of no gelling, then adding a vegetable oil emulsion into a solution, carrying out uniformstirring, adding fermented broth obtained by fresh grape skin fermentation into the solution, adding the fermented broth into the liquid sol, drying the composite liquid sol to obtain composite solidsol, adding limestone as a foaming agent into the sol, adding borax as a cosolvent into the sol, uniformly mixing the sol, foaming agent and borax to obtain mixed sol, designing unit weight of 260-270kg / m<3>, putting the fine composite solid sol corresponding to the designed unit weight into a mold, sealing the mold, transferring the sealed mold into a heating device, carrying out preheating, carrying out melting heat-preservation foaming in an oven, carrying out cooling to the room temperature and carrying out annealing and demolding to obtain the low-temperature composite foam glass.

Owner:薛向东

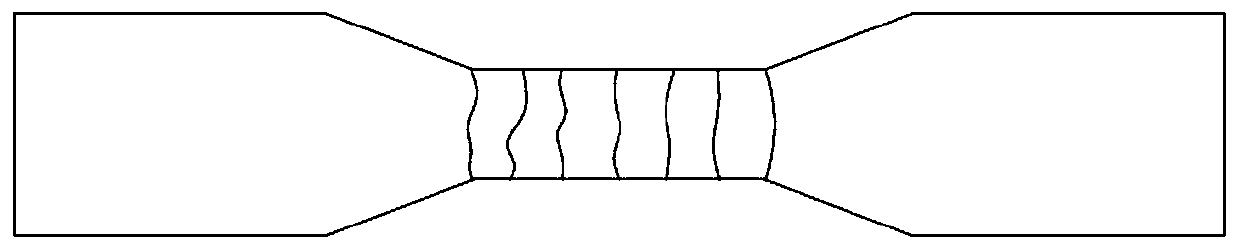

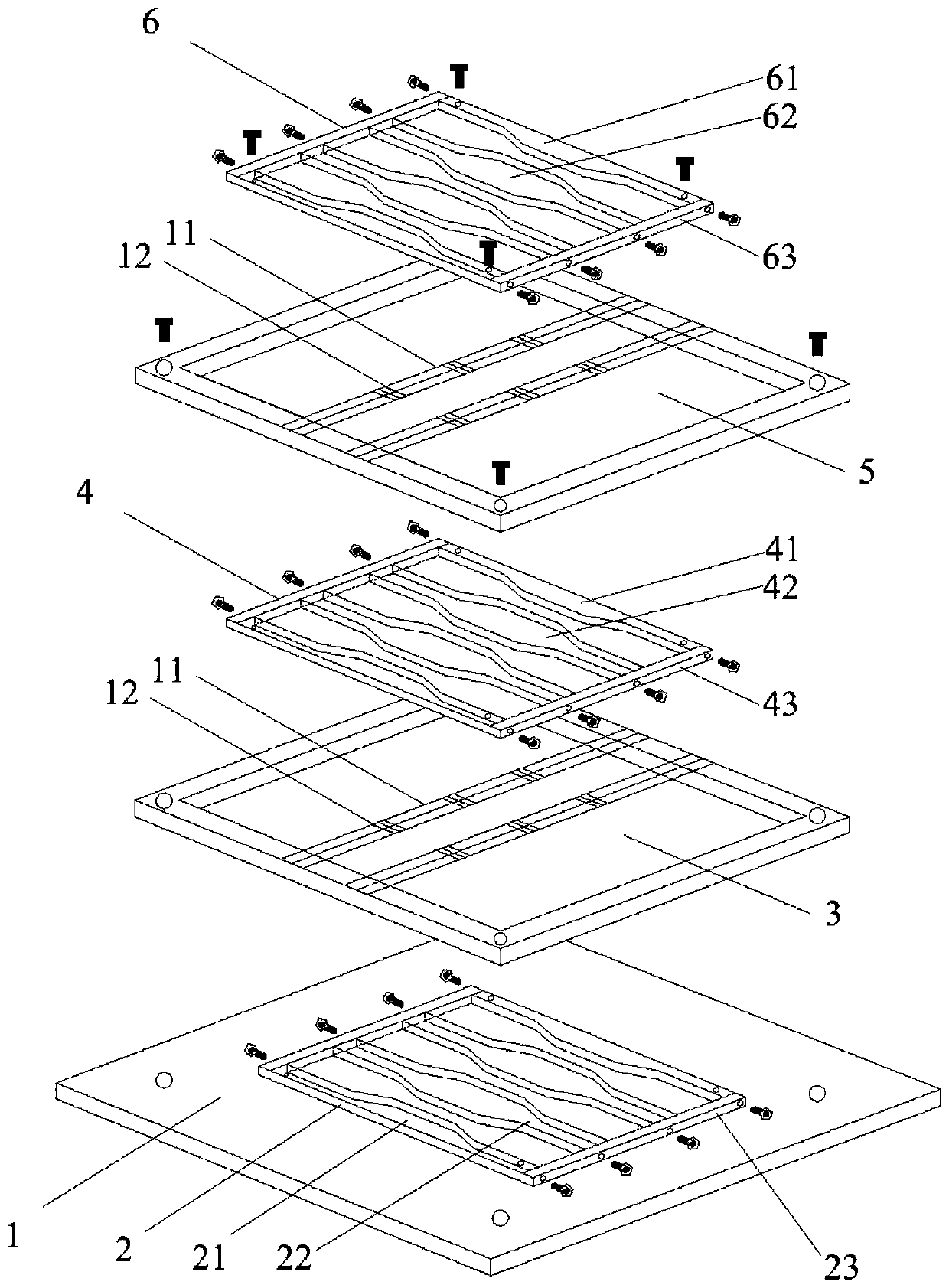

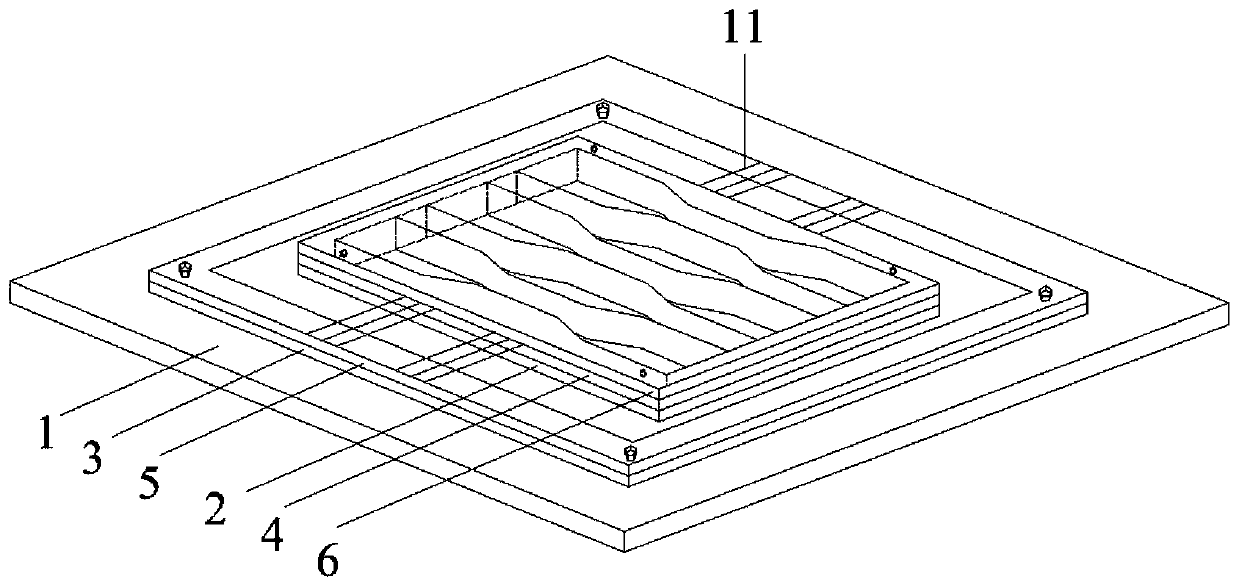

High-ductility cement-based material uniaxial stretching die, test piece manufacturing method thereof and test method thereof

ActiveCN110530722ALess prone to stress concentrationHigh tensile strengthPreparing sample for investigationMaterial strength using tensile/compressive forcesDuctilityEngineering

The invention discloses a high-ductility cement-based material uniaxial stretching die, a test piece manufacturing method thereof and a test method thereof. The die comprises a bottom plate, a lower test die assembly, a lower frame, a middle test die assembly, an upper frame, an upper test die assembly, first fibers and second fibers. The lower test mold assembly, the middle test mold assembly andthe upper test mold assembly are assembled to form a consistent structure and a plurality of dumbbell-shaped test piece areas are formed in inner cavities; and the lower test mold assembly, the middle test mold assembly and the upper test mold assembly are fixed on a bottom plate by bolts. The lower frame and the upper frame are fixed on the bottom plate through screws; and the first fibers and the second fibers are arranged at the narrow-down parts of the test piece areas uniformly vertically and horizontally. In addition, the test piece manufacturing method includes steps of casting and dieremoval; dumbbell-shaped test pieces of the first fibers and the second fibers are encrypted at variable cross-sections. According to the invention, multiple test pieces can be cast at a time and assembling and mold disassembling become convenient; the fibers which are uniformly arranged vertically and horizontally to add ribs at the variable cross-sections of the test pieces, so that the tensilestrength of the test piece is enhanced; and the strain-hardening behavior of the high-ductility cement-based material is favorably evaluated.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Low-stress threaded connection structure

InactiveCN108952594AImprove stress resistanceAvoid gluingDrilling rodsDrilling casingsStress concentrationEngineering

The invention discloses a low-stress threaded connection structure. The low-stress threaded connection structure comprises an outer threaded part and an inner threaded part, the outer threaded part isprovided with an outer thread, the inner threaded part is provided with an inner thread, and the outer thread and the inner thread are engaged with each other in a screwed state; the guide surface ofthe inner thread is composed of an upper half-section inclined surface and a lower half-section inclined surface, the inclination angle of the upper half-section inclined surface is beta, the inclination angle of the lower half-section inclined surface is gamma, and beta is smaller than gamma; and the guide surface, corresponding to the guide surface of the inner thread, of the outer thread is aninclined surface with the inclination angle of beta. The lower half-section inclined surface of the guide surface of the inner thread is smooth so that buckle aligning can be convenient, and the upper half-section inclined surface of the guide surface of the inner thread is steep, so that the thread has good compression resistance; and the guide surface of the outer thread corresponding to the inner thread is only provided with one section with the inclination angle of beta so that buckle aligning can be convenient and buckle staggering is not liable to occur during buckling, stress concentration is not liable to occur on the guide surfaces, and thus the guide surfaces are prevented from being stuck.

Owner:JIANGSU CHANGBAO STEELTUBE CO LTD

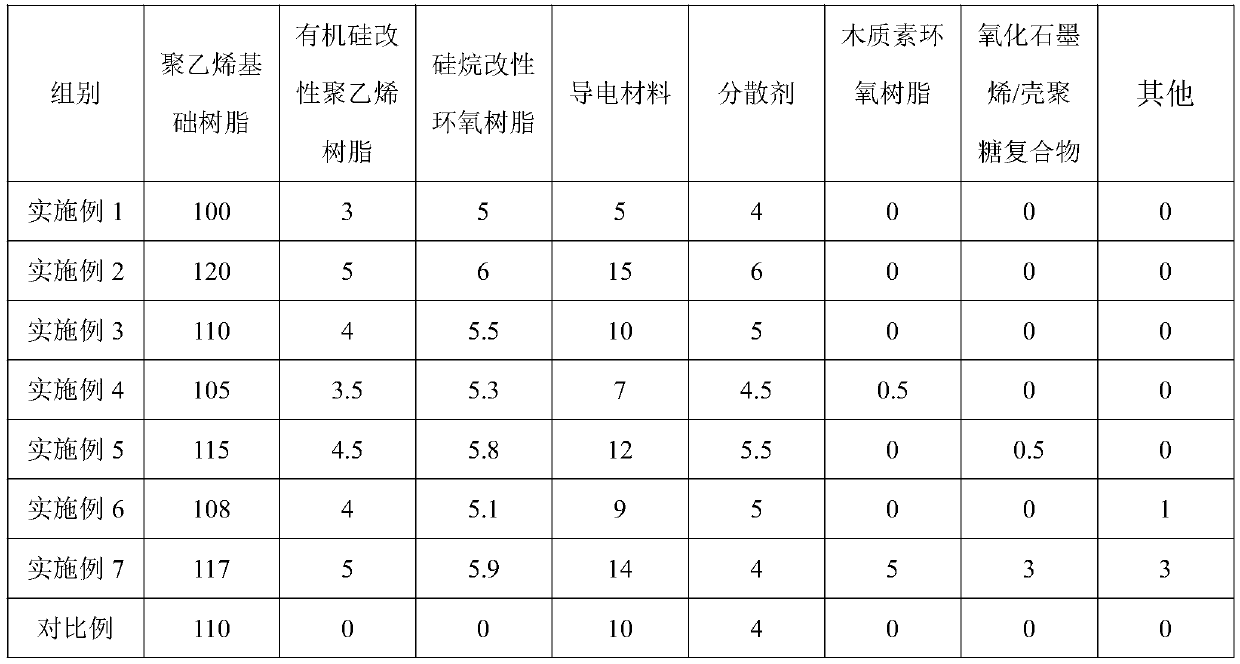

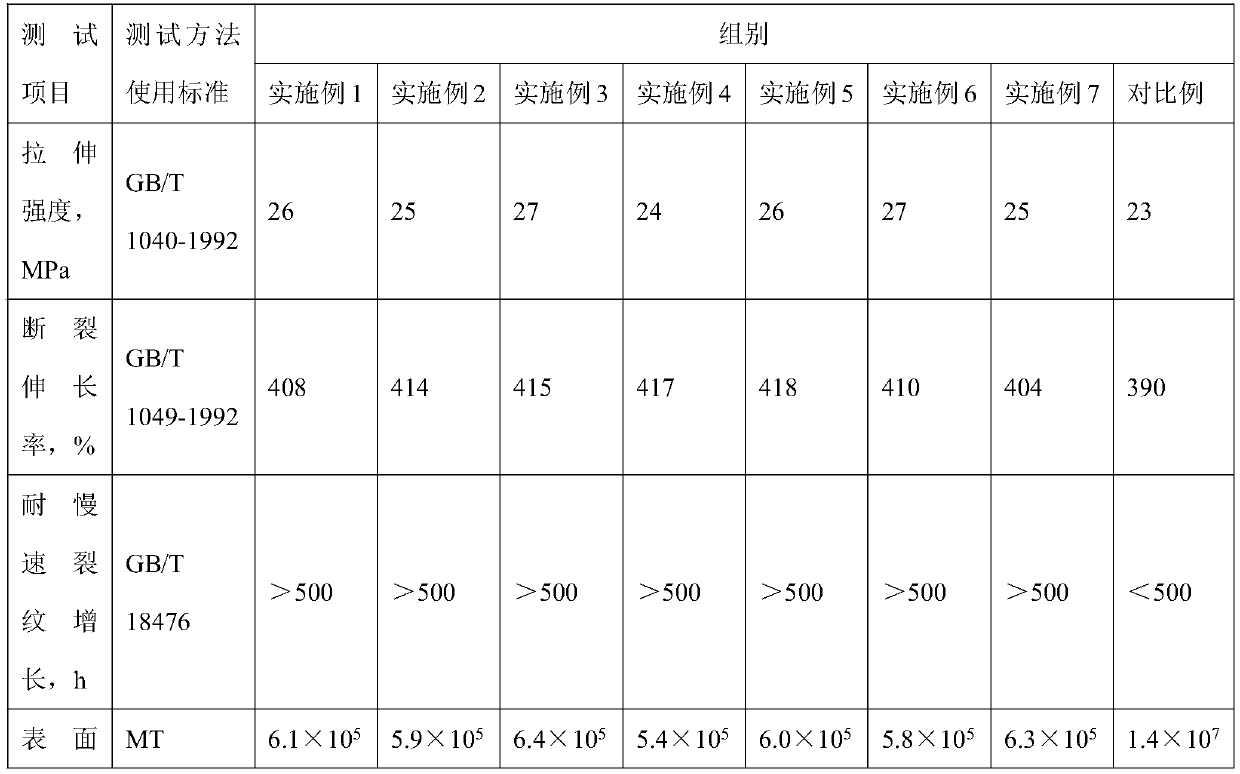

High-weather-resistance PE pipe and manufacturing method thereof

The invention belongs to the technical field of polyethylene pipe production, and discloses a high-weather-resistance PE pipe and a manufacturing method thereof. The high-weather-resistance PE pipe isprepared from, by weight, 100-120 parts of polyethylene base resin, 3-5 parts of organosilicone modified polyethylene resin, 5-6 parts of silane modified epoxy resin, 5-15 parts of a conductive material and 4-6 parts of a dispersing agent; wherein the polyethylene base resin is polyethylene resin polymerized by taking ethylene as a monomer; polyethylene resin in the organosilicone modified polyethylene resin is linear low-density polyethylene resin, and polyethylene resin is obtained through copolymerization of ethylene and alpha-olefin. The high-weather-resistance PE pipe has high weather resistance and can effectively resist the influence of surrounding environment media, and the service life of the PE pipe is prolonged.

Owner:湖北凯科塑业有限公司

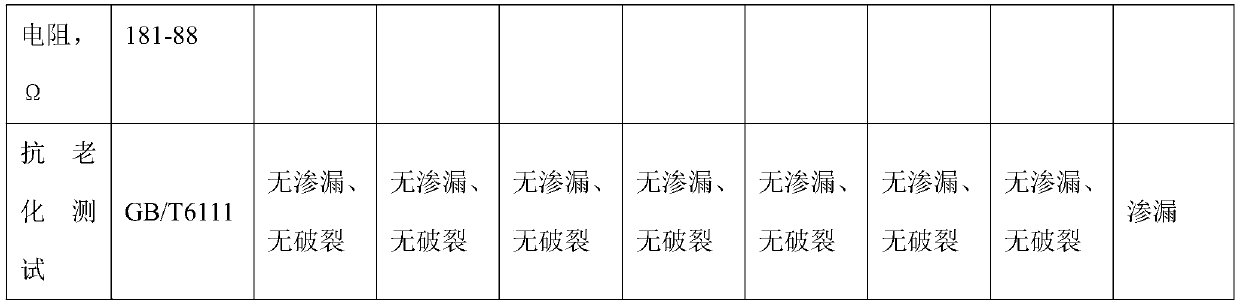

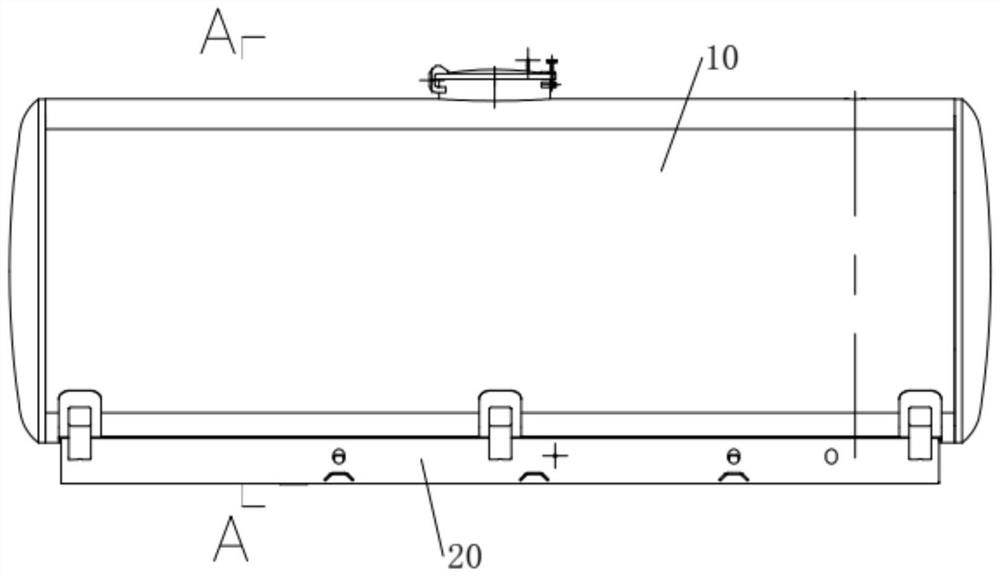

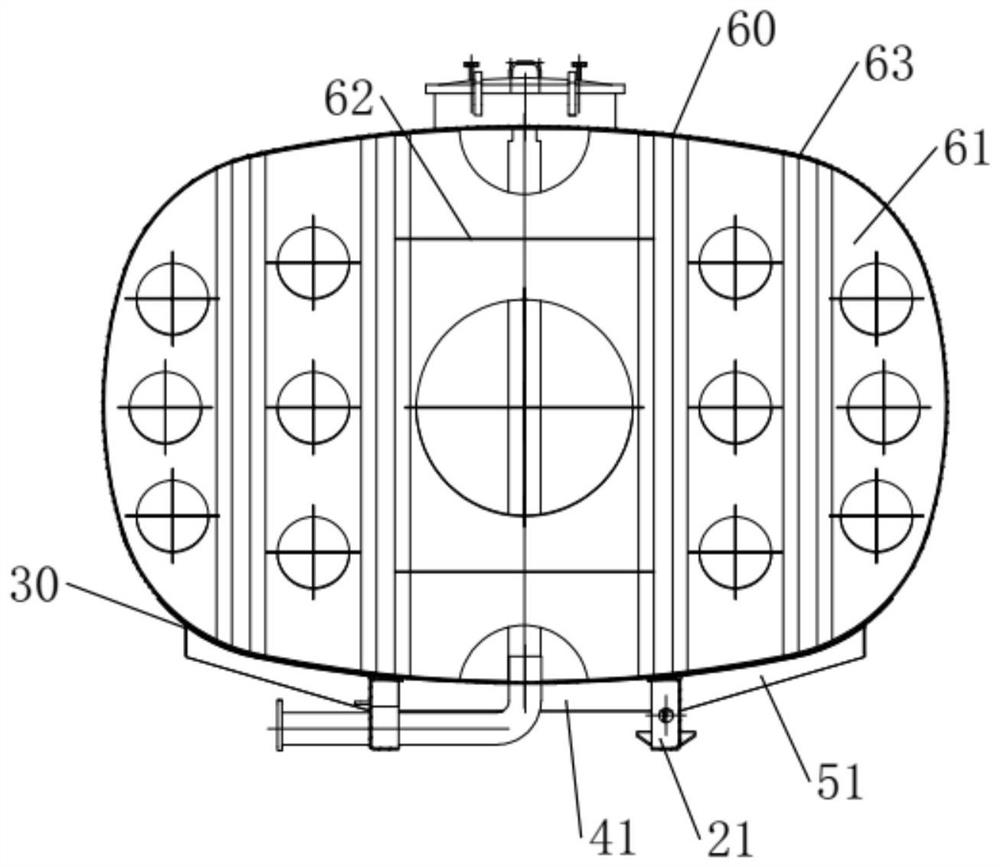

Water tank structure of cleaning vehicle

PendingCN114228603AImprove stabilityEasy to fixTank vehiclesLarge containersStress concentrationStructural fatigue

The invention discloses a water tank structure of a cleaning vehicle. The water tank structure comprises a bearing bottom frame for bearing and fixing and a tank body for containing cleaning water. The bearing bottom frame is arranged on the chassis in the length direction of the chassis of the cleaning vehicle and comprises longitudinal frameworks and transverse frameworks which are arranged in the length direction and the width direction of the chassis in a criss-cross mode, and the longitudinal frameworks and the transverse frameworks are connected to form an inwards-concave containing interval which is inwards concave from the top and used for containing the limiting tank body. And the tank body is welded and fixed in the inwards-concave containing section along the length direction of the bearing bottom frame, so that the tank body is stably supported on the chassis under the supporting and fixing effects of the bearing bottom frame and the containing and limiting effects of the inwards-concave containing section. According to the water tank structure of the cleaning vehicle, the tank body is evenly stressed, stress concentration is not prone to occurring at the welding joint, the risk of structural fatigue damage and the risk of water leakage of the tank body are reduced, the tank body can be stably fixed to the chassis, the stability of the water tank structure of the cleaning vehicle is enhanced, and the safety and reliability of structure operation are improved.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com