External cast-in-situ heat preservation wall and construction method thereof

A construction method and external thermal insulation technology, applied in thermal insulation, building components, buildings, etc., can solve problems such as affecting the service life of the thermal insulation layer, easy falling off and failure of thermal insulation boards, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

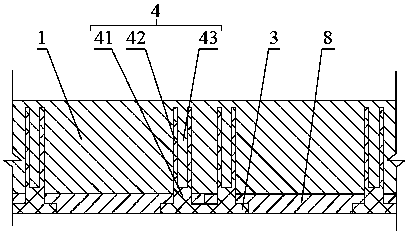

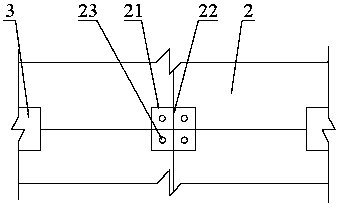

[0037] like Figure 1-5As shown, a cast-in-place external thermal insulation wall includes a wall 1 and several rectangular thermal insulation boards 2 arranged on the surface of the wall 1. The outer edge of each thermal insulation board 2 is provided with a step 21 that runs through the edge of the thermal insulation board 2. A groove is formed after the adjacent insulation boards 2 are in contact, and the splicing gap 22 between the adjacent insulation boards 2 is located in the groove, and a connecting plate 3 adapted to the groove is also included, and on the connecting plate 3 Several connecting pieces 4 are provided, one end of the connecting piece 4 is fixedly connected with the connecting plate 3 , and the other end extends into the wall body 1 after passing through the bottom of the groove.

[0038] A cast-in-place external thermal insulation wall of this embodiment, by setting steps 21 on the thermal insulation board 2, the thermal insulation board 2 is spliced to...

Embodiment 2

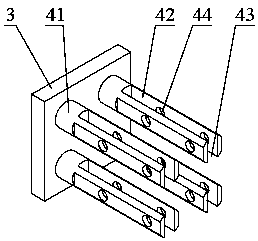

[0043] like Figure 1-5 As shown, a cast-in-place external thermal insulation wall of this embodiment has the same structure as that of Embodiment 1, the difference is that the number of the reinforcement boards 42 is at least two, and the reinforcement boards 42 are formed between two adjacent reinforcement boards The gap 43 through which the concrete slurry passes.

[0044] A kind of cast-in-place external thermal insulation wall body of this embodiment preferably arranges two reinforcing plates 42 of plate-like structure on the same connecting column 41. The height directions are parallel, so that the two reinforcing plates 42 extend into the wall 1 at the same time, and are fixed by the concrete slurry, so that the connection between the connecting plate 3 and the wall 1 is more stable, so that the setting of the insulation board 2 is more stable. The service life of the cast-in-place external thermal insulation wall of this structure is further extended. At the same time...

Embodiment 3

[0048] like Figure 1-5 As shown, a cast-in-place external thermal insulation wall of this embodiment has the same structure as that of Embodiment 1, the difference is that several reinforcing columns 5 are arranged inside the wall 1, and the reinforcing columns 5 are arranged along the splicing gap. 22 settings.

[0049] A cast-in-place external thermal insulation wall in this embodiment is provided with reinforcing columns 5 along the splicing gap 22 in the wall 1, on the one hand, the splicing gap between the thermal insulation boards 2 is fixed from the inner side of the wall 1 through the reinforcing columns 5 22 to carry out sealing treatment to prevent the moisture in the concrete slurry from entering the gap and affect the overall thermal insulation effect of the thermal insulation layer 8. At the same time, it is also beneficial to increase the overall strength of the thermal insulation layer 8 through the setting of the reinforcing column 5, so as to prevent the ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com