High-ductility cement-based material uniaxial stretching die, test piece manufacturing method thereof and test method thereof

A cement-based material, uniaxial tensile technology, applied in the analysis of materials, the preparation of test samples, and the use of stable tension/pressure to test the strength of materials, etc., can solve the evaluation and advance of the strain-hardening behavior of ECC materials Problems such as cracking, stress and strain smaller than the actual value, etc., achieve the effect of easy operation, less stress concentration, convenient mold assembly and mold removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention will be further described below in conjunction with the drawings and embodiments.

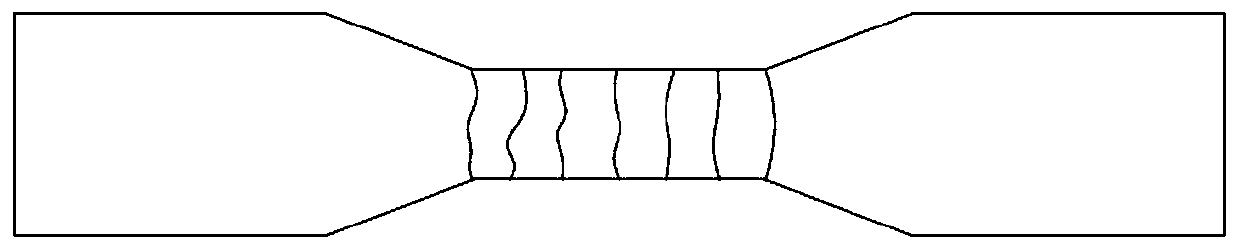

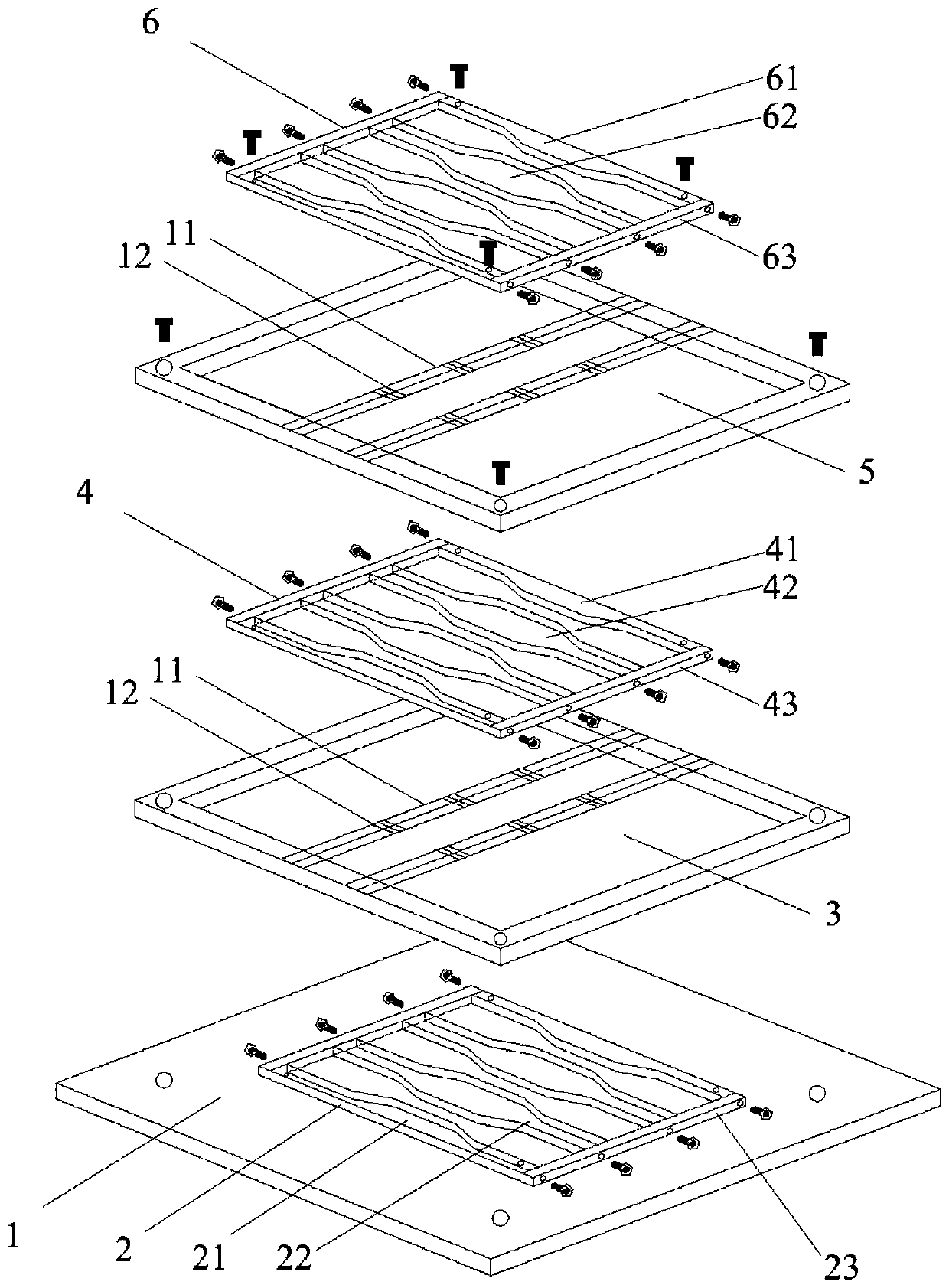

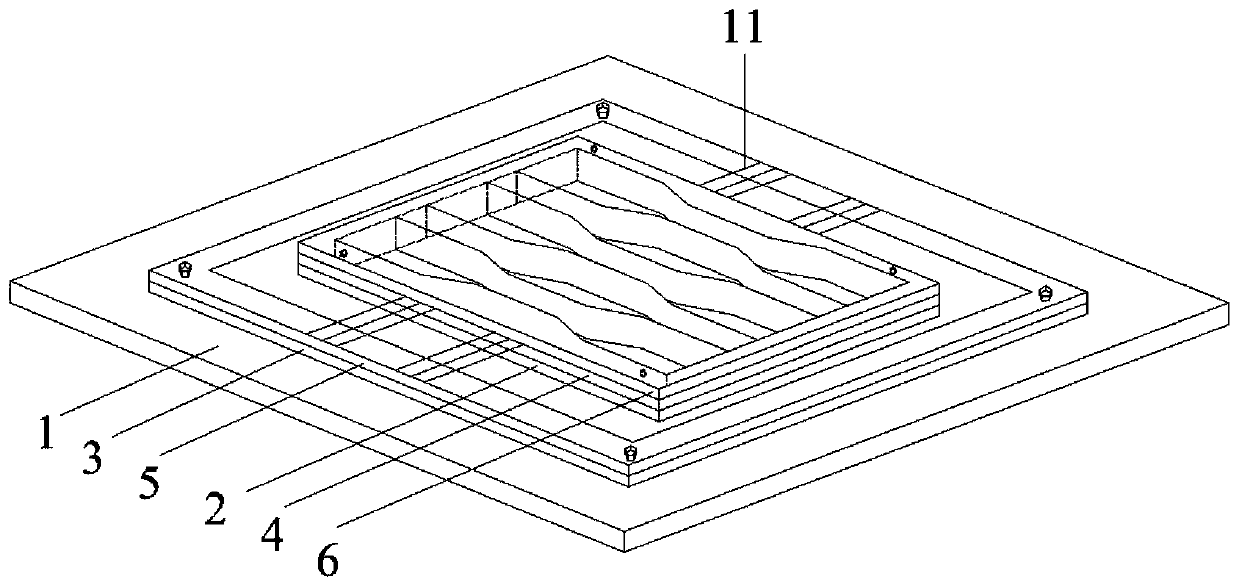

[0038] Such as figure 2 and image 3 As shown, a high-ductility cement-based material uniaxial tensile test piece mold includes a bottom plate 1, a lower test mold assembly 2, a lower frame 3, a pilot test mold assembly 4, an upper frame 5, and an upper test mold assembly 6 , the first fiber 11 and the second fiber 12; the lower trial mold assembly 2, the middle trial mold assembly 4 and the upper trial mold assembly 6 have the same structure after assembly and the internal cavity forms a plurality of dumbbell-shaped trial molds with the same shape. Component area, and fixed on the base plate 1 by screws; the four corners of the lower frame 3 and the upper frame 5 are fixed on the base plate 1 by screws; the first fiber 11 and the second fiber 12 are placed in the lower test mold assembly 2 and Between the trial mold assembly 4 , the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com