High-weather-resistance PE pipe and manufacturing method thereof

A high weather resistance and modification technology, applied in the field of polyethylene pipe production, can solve the problems of shortening the service life of PE pipes, accelerated aging and degradation of polyethylene pipes, etc. The effect of increasing the gathering density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

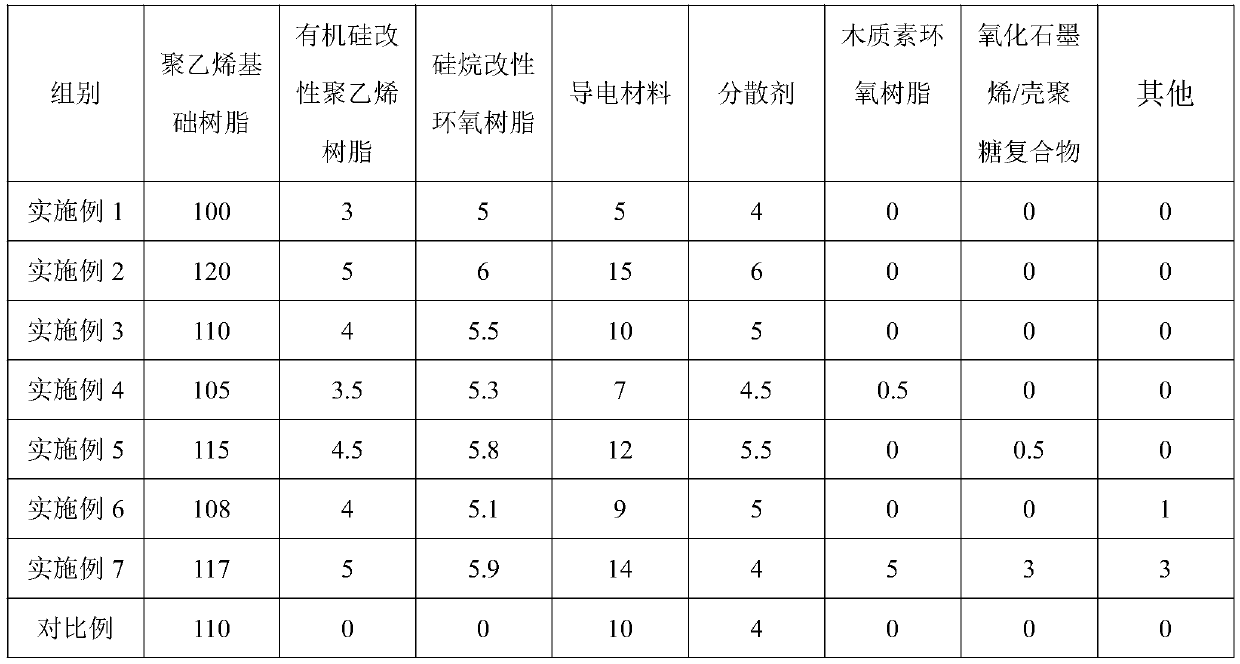

[0027]A high weather resistance PE pipe, the raw material components are shown in Table 1, and all components are expressed in parts by weight. Prepared through the following steps: Weigh polyethylene base resin, polydimethylsiloxane grafted polyethylene resin, silane-modified epoxy resin, bamboo charcoal and polyethylene wax in parts by weight and mix uniformly, extrude with a single screw The extruder is extruded to form a pipe, and the temperature of the mixture melt is controlled at 180-200°C during extrusion. The linear low density polyethylene resin of this embodiment is a polyethylene resin obtained by copolymerization of ethylene and 1-butene.

Embodiment 2

[0029] A high weather resistance PE pipe, the raw material components are shown in Table 1, and all components are expressed in parts by weight. Prepared through the following steps: Weigh polyethylene base resin, polymethylphenylsiloxane grafted linear low-density polyethylene resin, silane-modified epoxy resin, carbon nanotubes and paraffin wax in parts by weight and mix uniformly, A single-screw extruder is used to extrude a pipe, and the temperature of the mixture melt is controlled at 180-200°C during extrusion. The linear low density polyethylene resin of this embodiment is a polyethylene resin obtained by copolymerization of ethylene and 1-hexene.

Embodiment 3

[0031] A high weather resistance PE pipe, the raw material components are shown in Table 1, and all components are expressed in parts by weight. Prepared through the following steps: Weigh polyethylene base resin, methyl vinyl polysiloxane grafted linear low-density polyethylene resin, silane-modified epoxy resin, lanthanum chromate and silicone oil in parts by weight and mix them uniformly, A single-screw extruder is used to extrude a pipe, and the temperature of the mixture melt is controlled at 180-200°C during extrusion. The linear low density polyethylene resin of this embodiment is a polyethylene resin obtained by copolymerization of ethylene and 1-octene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com