Patents

Literature

186results about How to "Easy to remove formwork" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

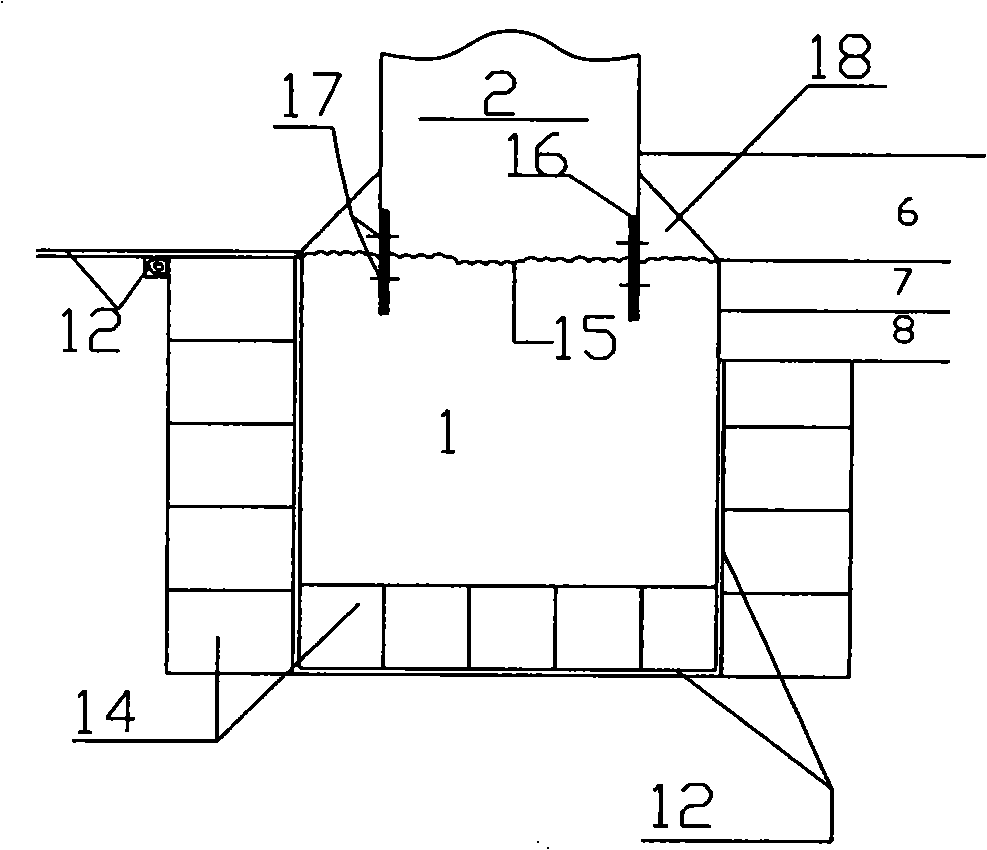

Method and system for basement engineering water proof and water drain

InactiveCN101298782AFree from buoyancyFrom erosionArtificial islandsProtective foundationBasementLine tubing

A basement engineering waterproof and drainage method is provided. The wall footing of the outside wall in basement engineering is embedded in watertight or micro-watertight soil rock layer or cement soil layer. The wall footing intercepts water by a thin-part structure. The cushion of the basement engineering soleplate and the falling layer of the top board are composed of combined water-proof layers. The late poured band, the movement joint and the horizontal construction joint at the lower part of the outside wall are treated by a water-proof structure combined with waterproofing measures. The basement engineering is provided with a drainage system. The groundwater and surface water at the soleplate are drained into city drainage pipelines via a soleplate part of the drainage system. The rainwater of overburden layer bottom of the top board is then drained into city drainage pipelines via the indoor part of the drainage system. The invention is designed by adopting a one-body method of arranging the basement engineering waterproofing, drainage and anti-floating as well as underground engineering space enclosing structure and pipelines, thereby shortening the construction period, reducing the engineering cost, increasing the durability and reliability of underground building space enclosing structure and waterproof layer as well as pipelines.

Owner:朱邃科 +2

A construction method for the communication channel of the broken stratum in the shield tunnel crossing the river

ActiveCN102287198AEnsure normal excavationMake sure the excavation is completeUnderground chambersBlastingEnvironmental resistanceGround contact

The invention relates to a construction method for an underground tunnel, in particular to a construction method for a river-crossing shield tunnel crushed stratum communication channel, which is used for solving the problems of failure of stratum reinforcement, long working period, high cost, poor quality and the like existing in the construction process of the conventional river-crossing shieldtunnel crushed stratum communication channel. The method comprises the following steps of: determining the position of the communication channel; before opening, performing pre-grouting to integrallyconsolidate broken rock outside the excavation outline of the communication channel; forming a high-strength waterproof curtain; before excavation, performing stress conversion; drilling and partitioning to remove a left line pipe sheet, brushing the top, performing tunnel excavation with a combined damping burst technology, and timbering; and drilling and partitioning to remove a right line pipesheet, brushing the top, and performing second lining construction by adopting a combination template. Due to the adoption of the construction method, water seepage is avoided after excavation, the technology is advanced, the blank of a communication channel pre-grouting technology is fulfilled, the working period is short, the mechanical degree is high, the process is simple, construction is environmentally-friendly, collapse is avoided, and over-excavation is greatly lowered; and the method has a wide application range.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

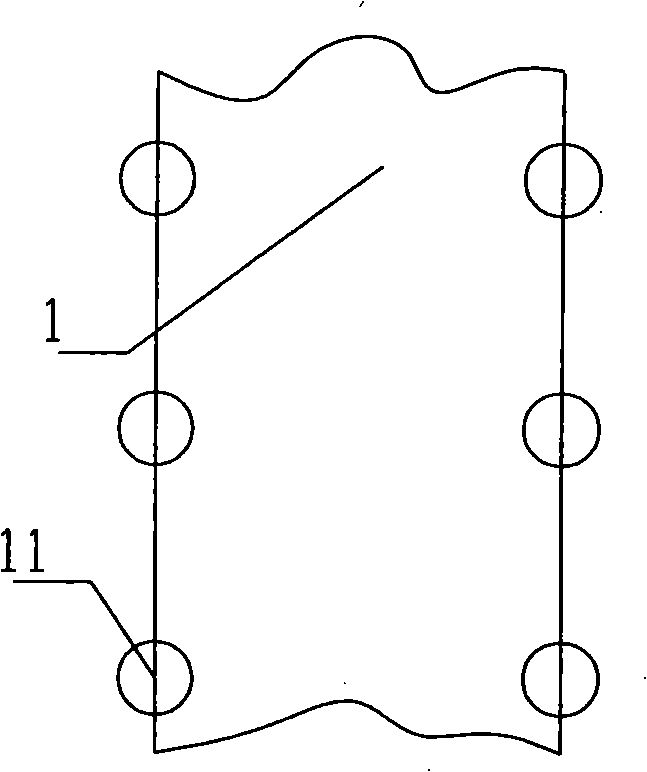

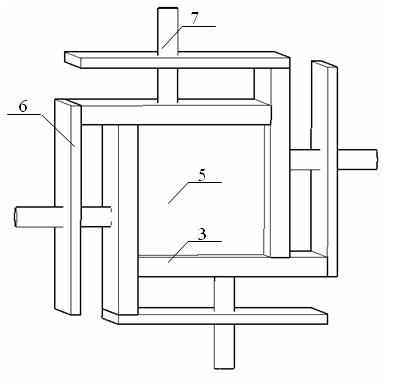

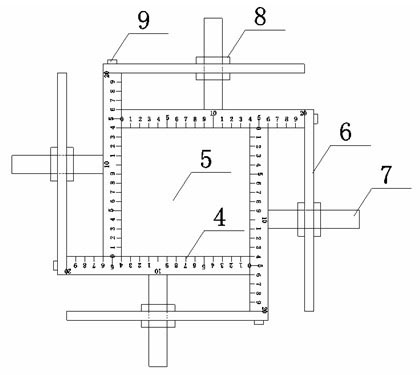

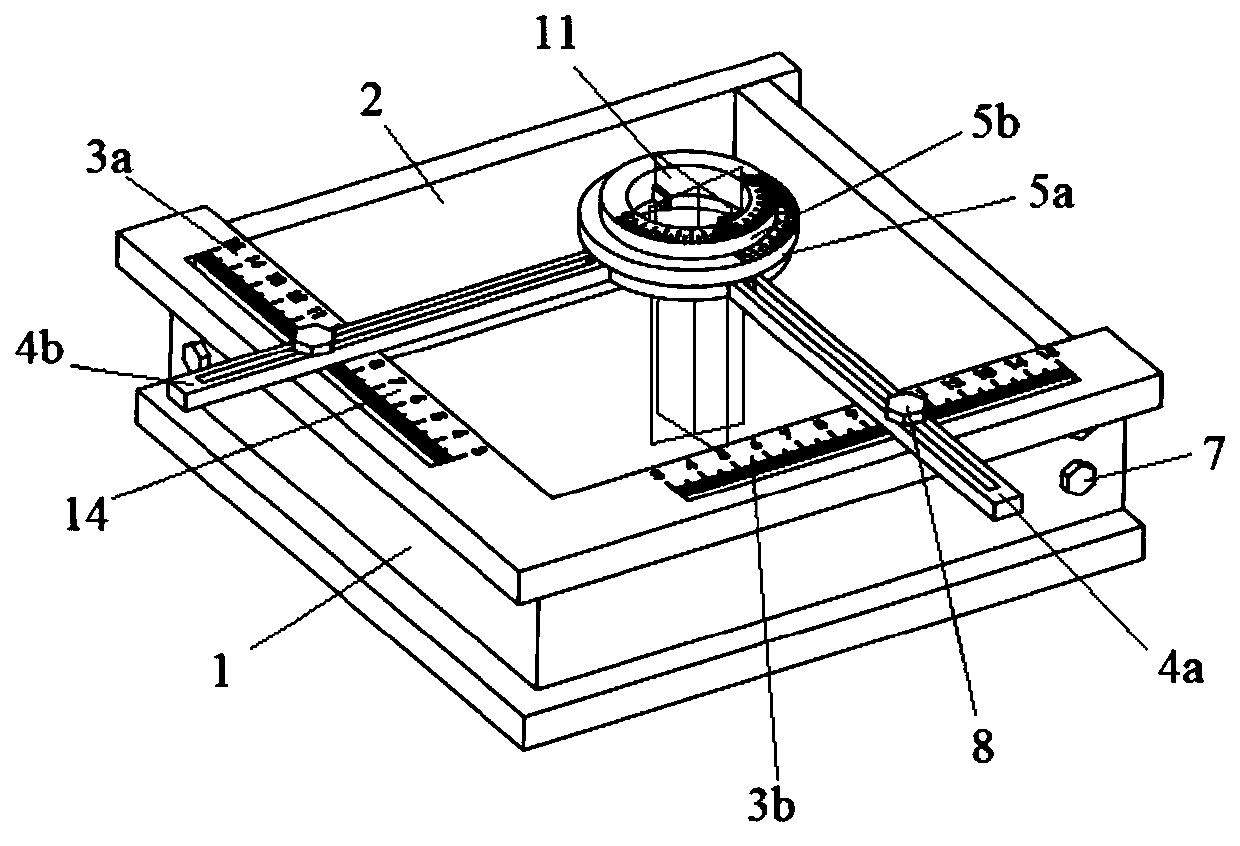

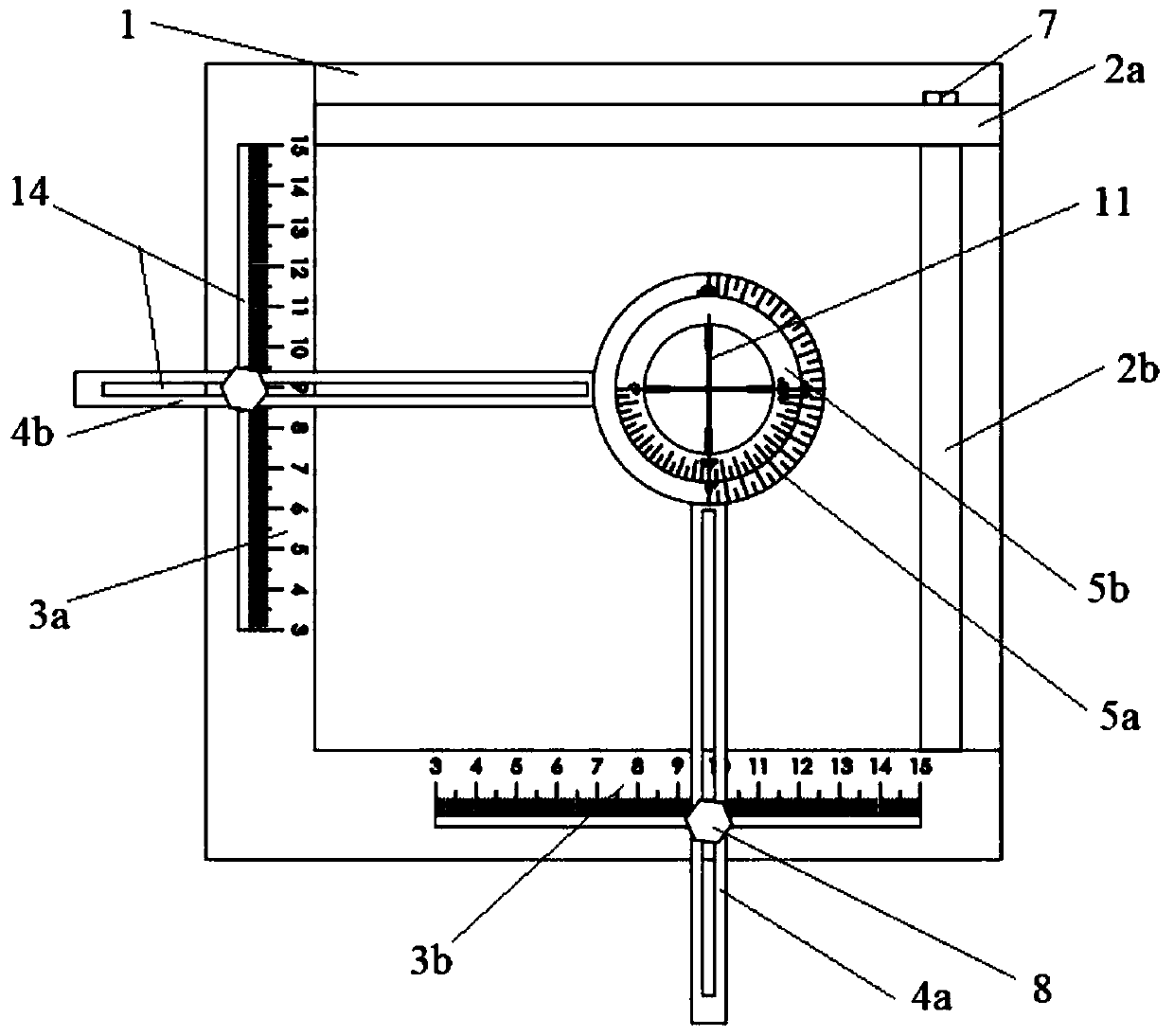

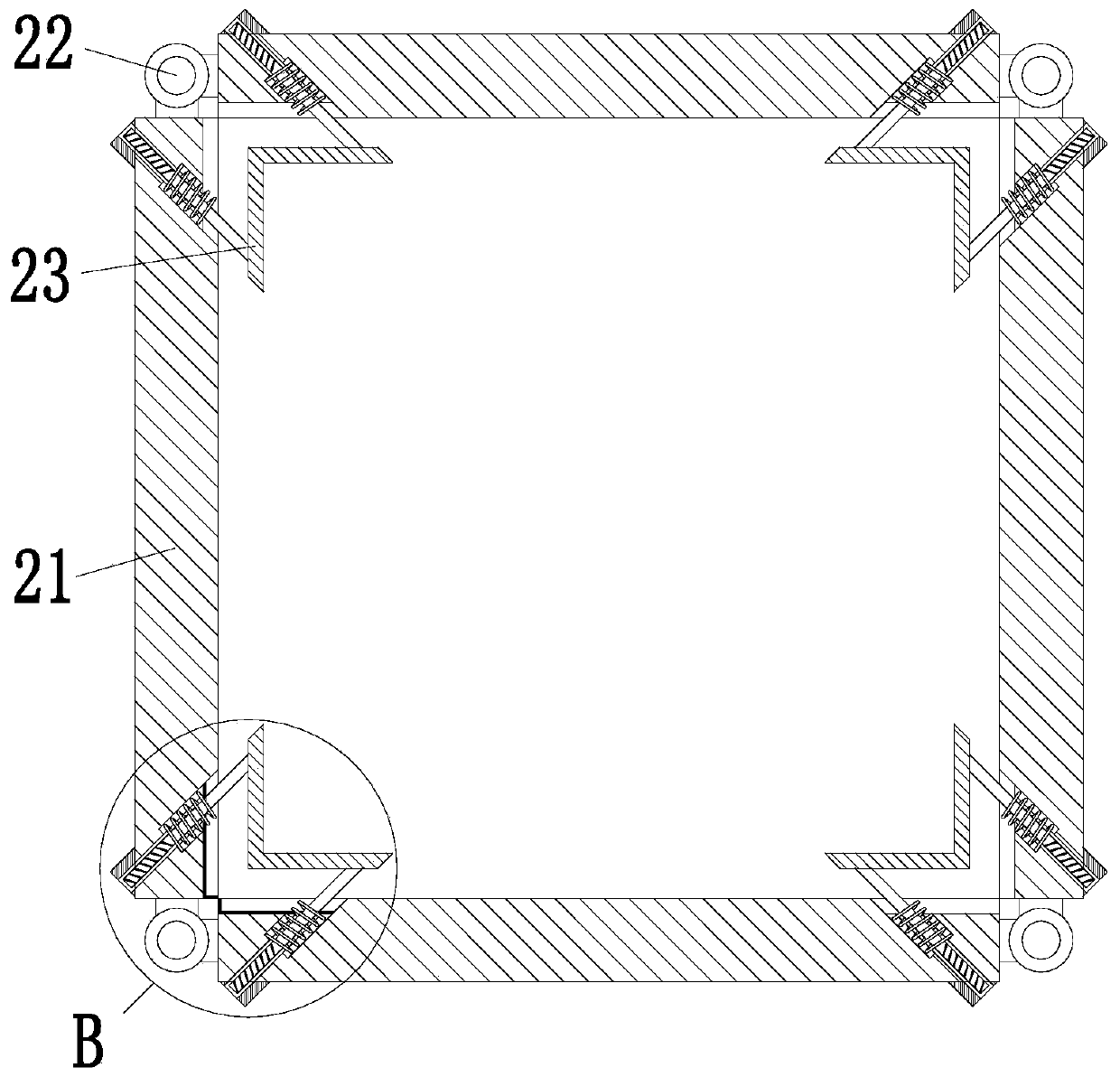

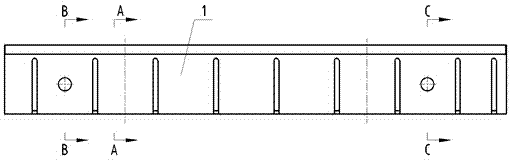

Size-adjustable mold adaptive to concrete samples in various sizes

InactiveCN105699161ASolve the defect that only fixed size test pieces can be madeEasy to makePreparing sample for investigationStructural engineeringEngineering

The invention discloses a size-adjustable mold adaptive to concrete samples in various sizes.The size-adjustable mold is characterized by comprising a size-adjustable frame (8) formed by four side formworks (3) staggered in pairs, a guide device (9) is movably connected with every two adjacent side formworks (3), a scaleplate (4) is arranged on the upper surface of each side formwork (3), and grooves (10) used for installing a bottom plate (1) are formed in the corresponding positions of the four side formworks (3) respectively.The size-adjustable mold adaptive to concrete samples in various sizes is easy to manufacture, facilitates manual demolding and is suitable for processing concrete members and concrete samples in various sizes.The defect that only samples in a fixed size can be manufactured through a concrete mold in the past is overcome, and the concrete samples in various sizes can be manufactured.

Owner:HOHAI UNIV

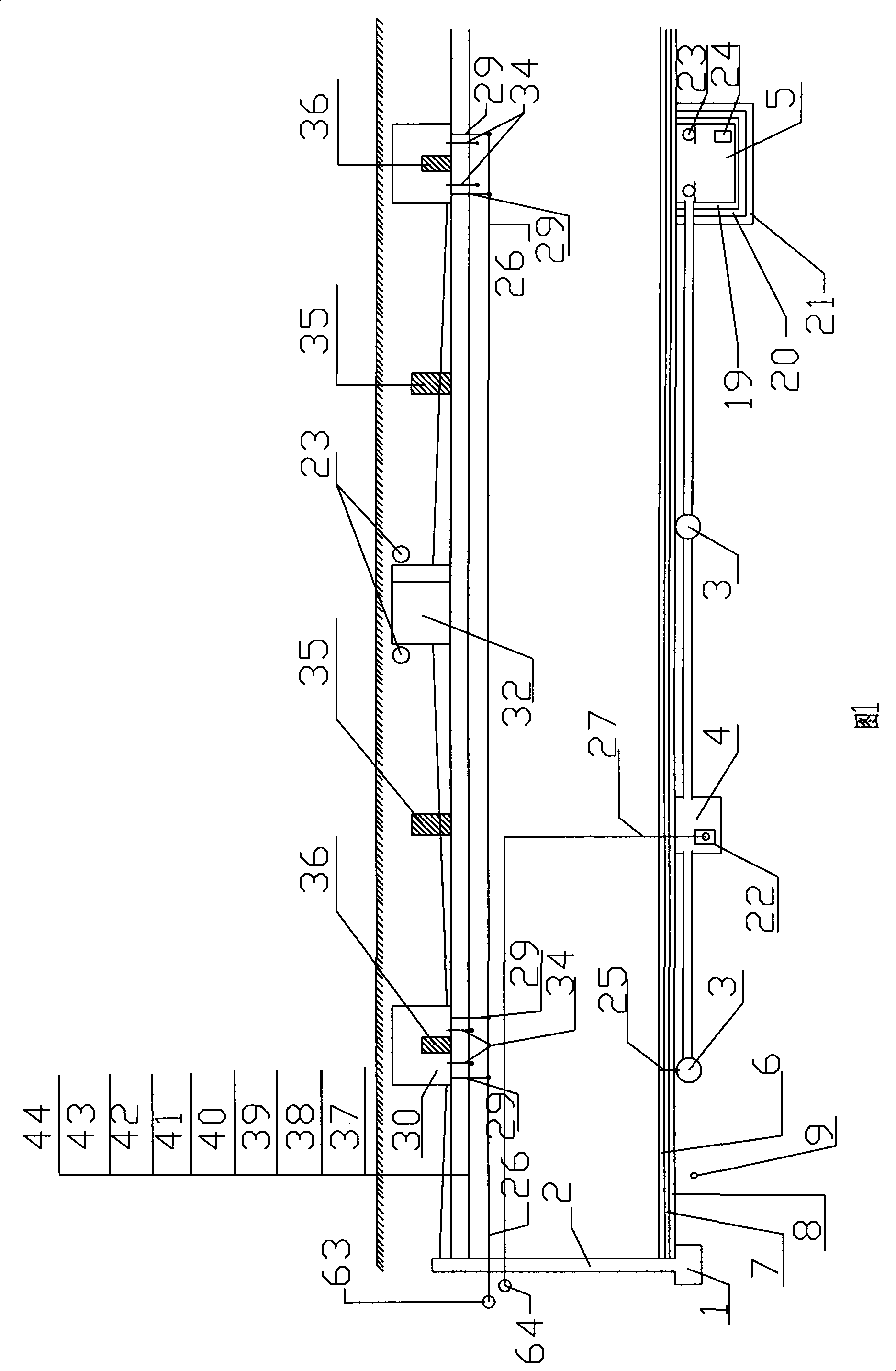

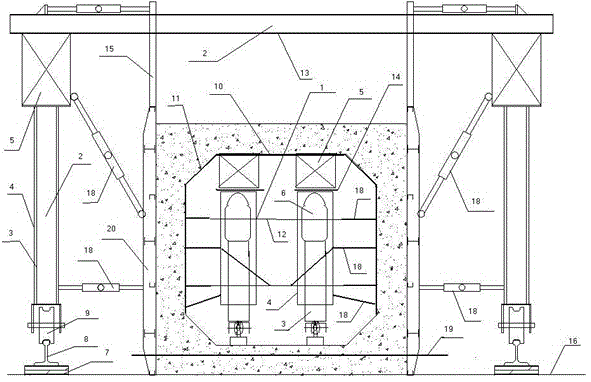

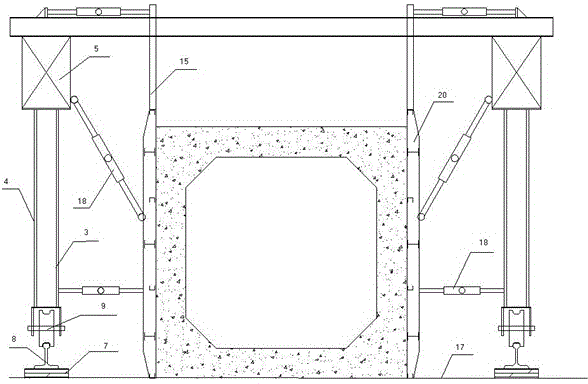

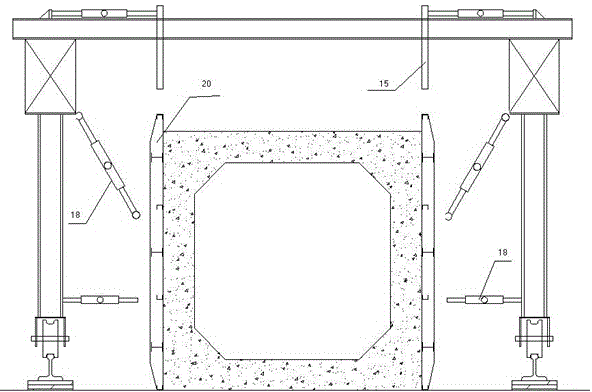

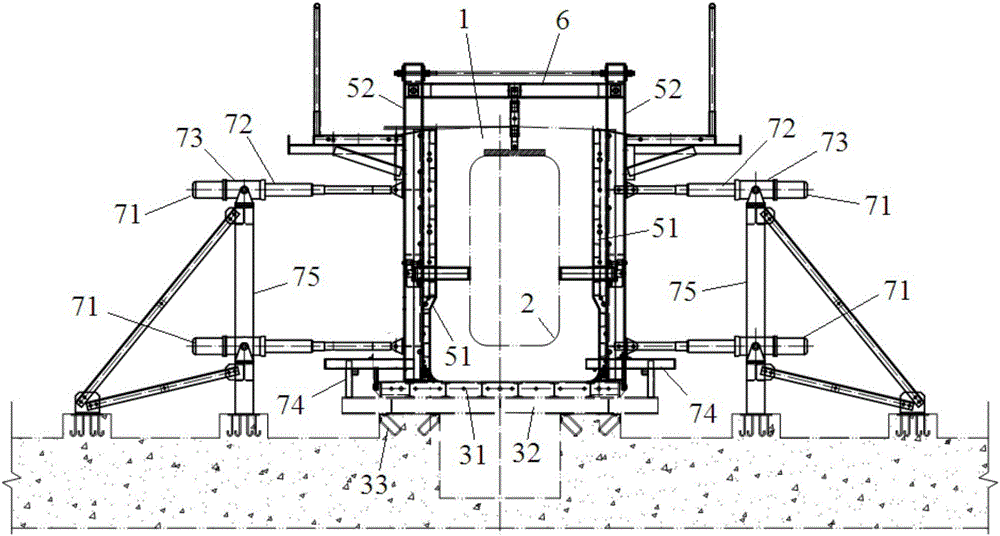

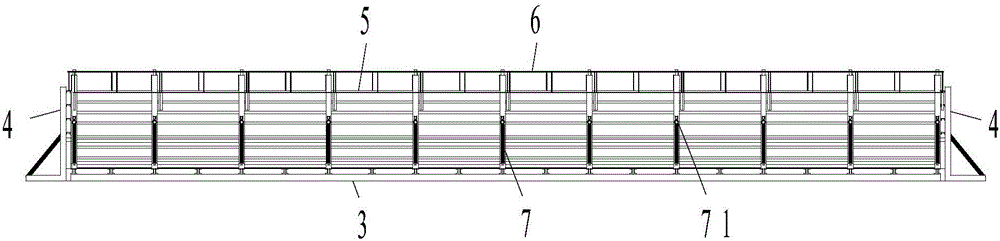

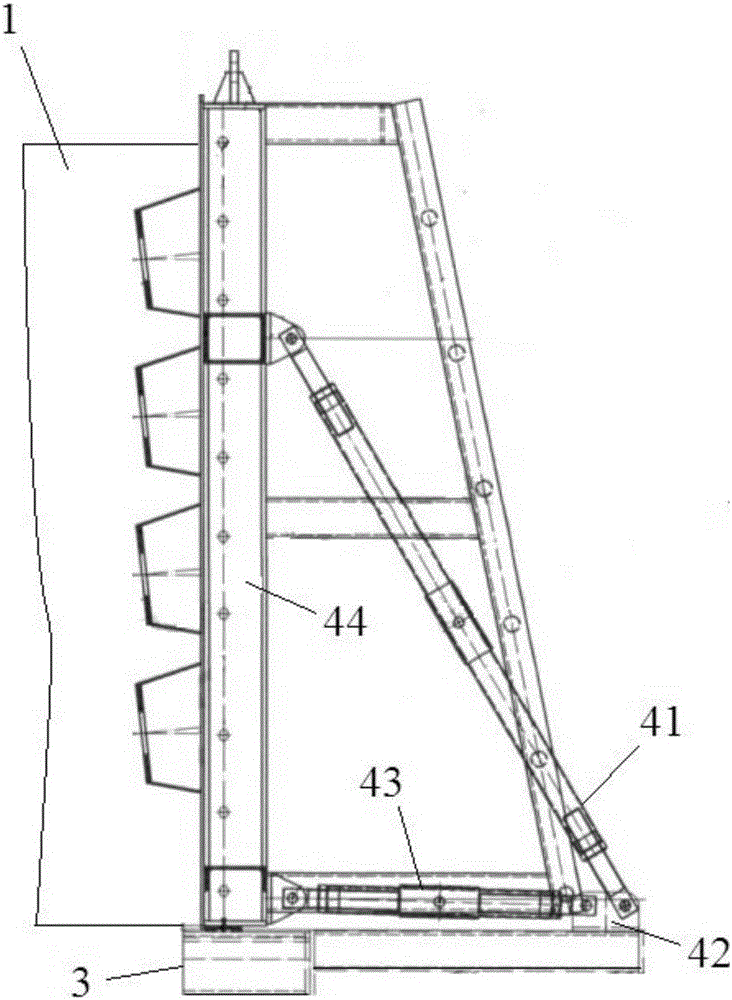

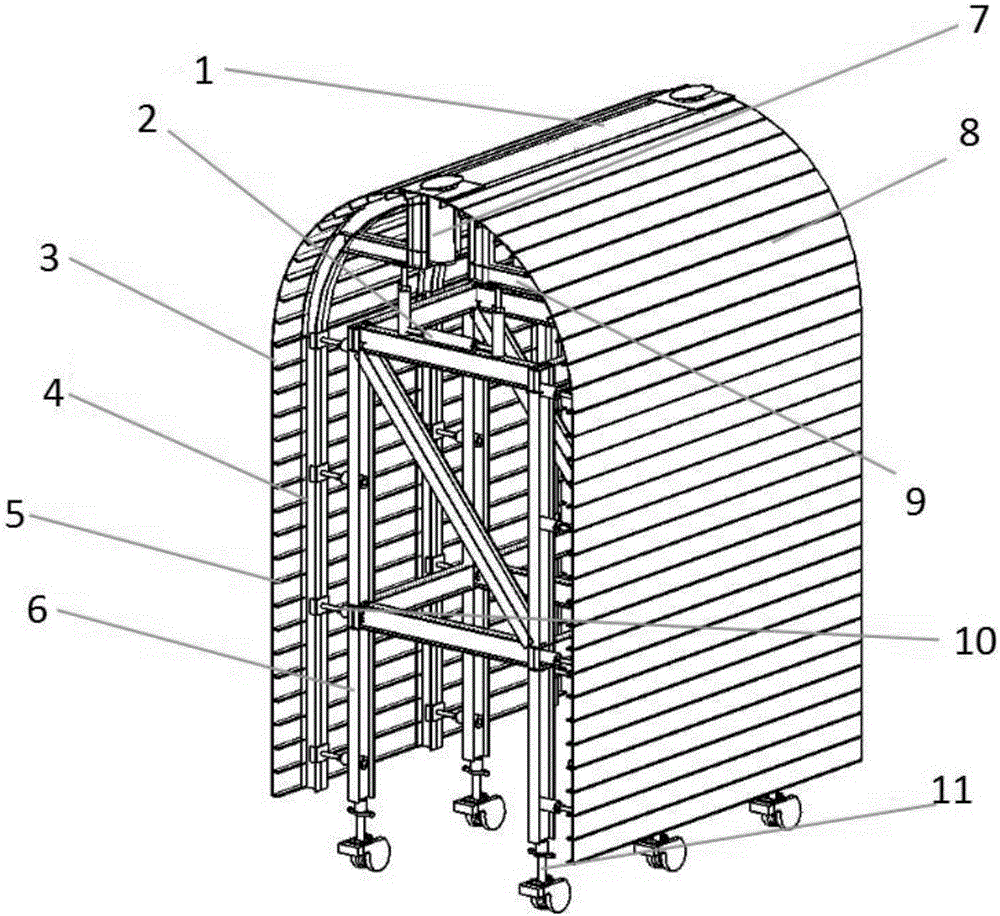

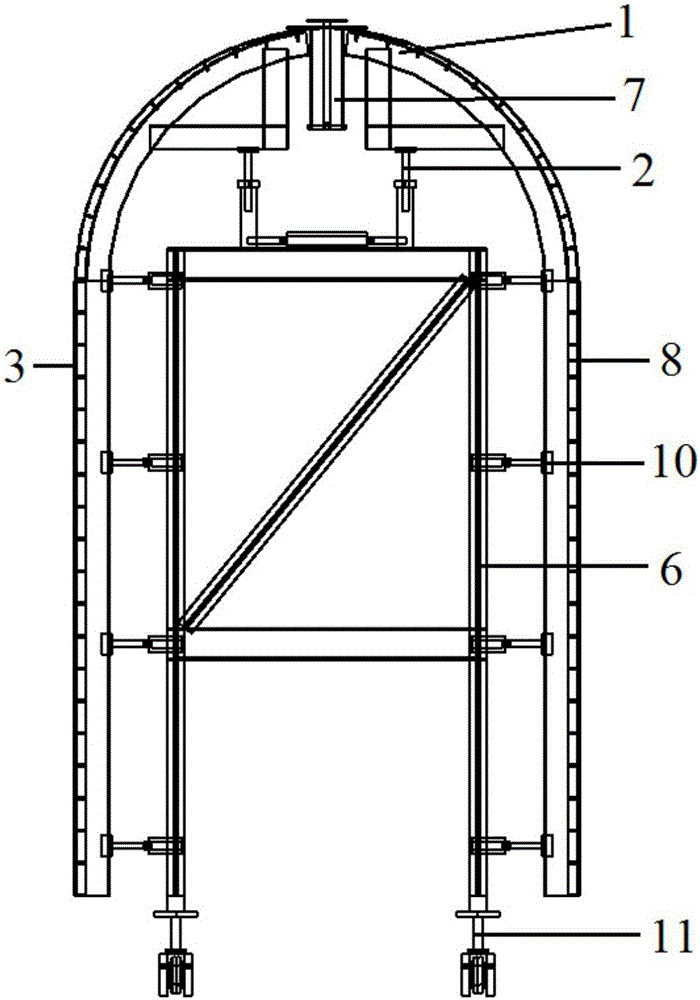

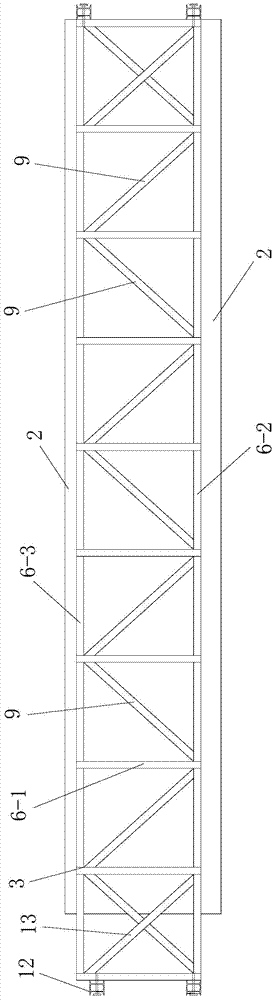

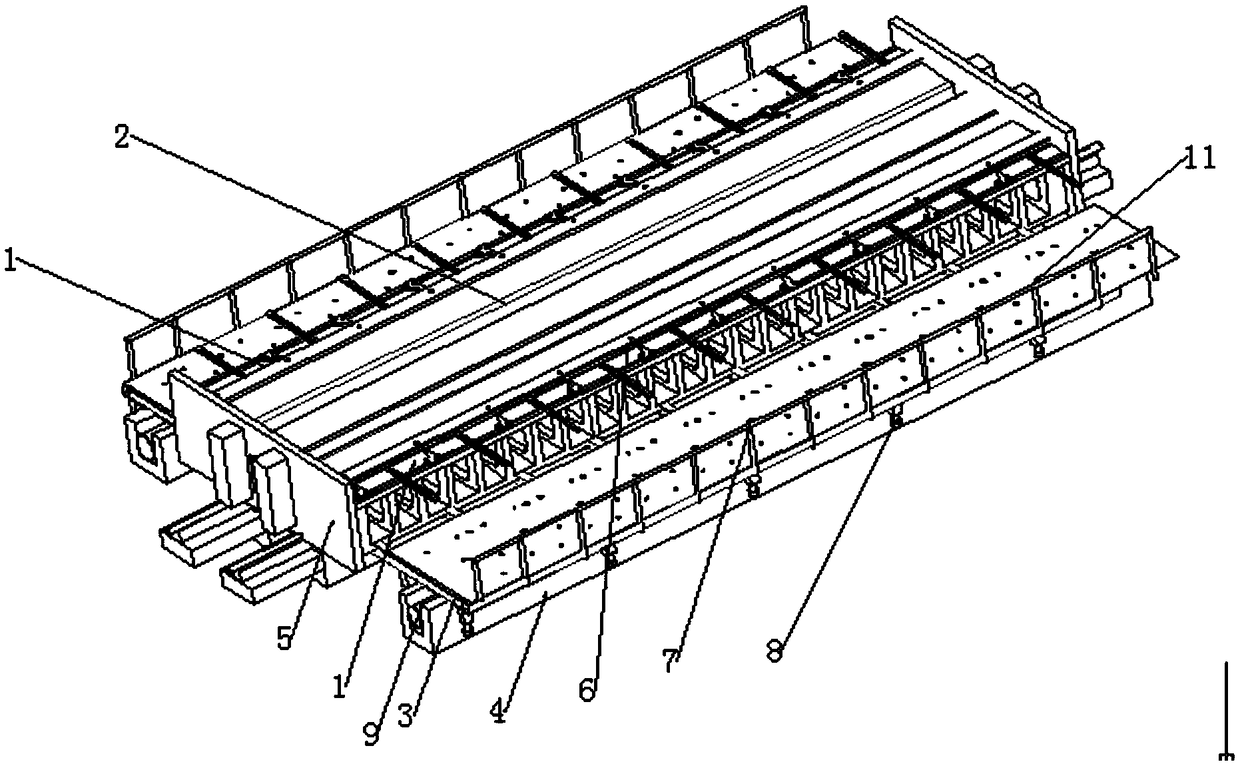

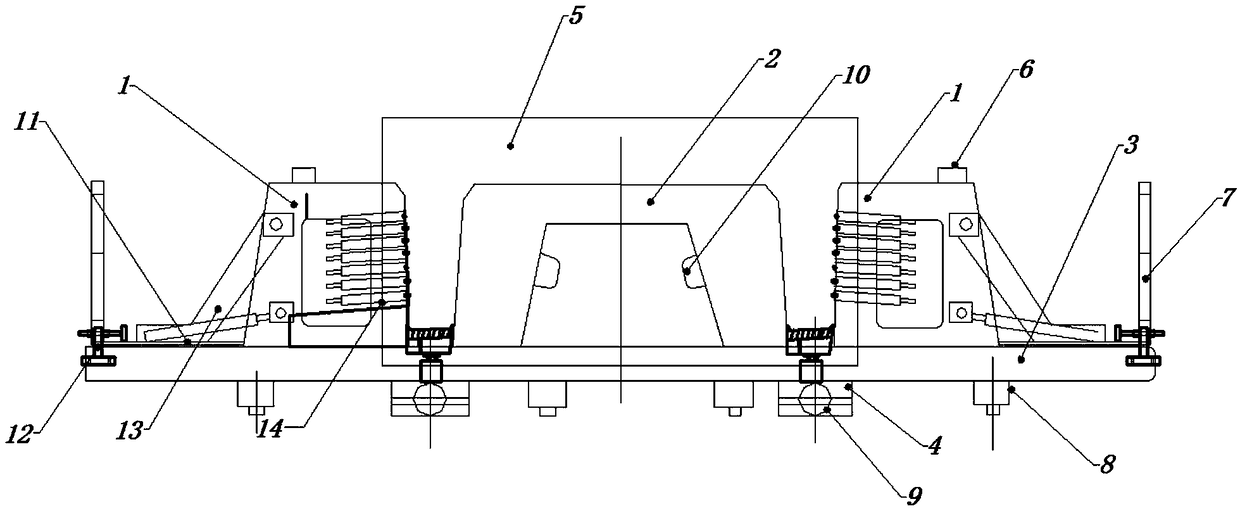

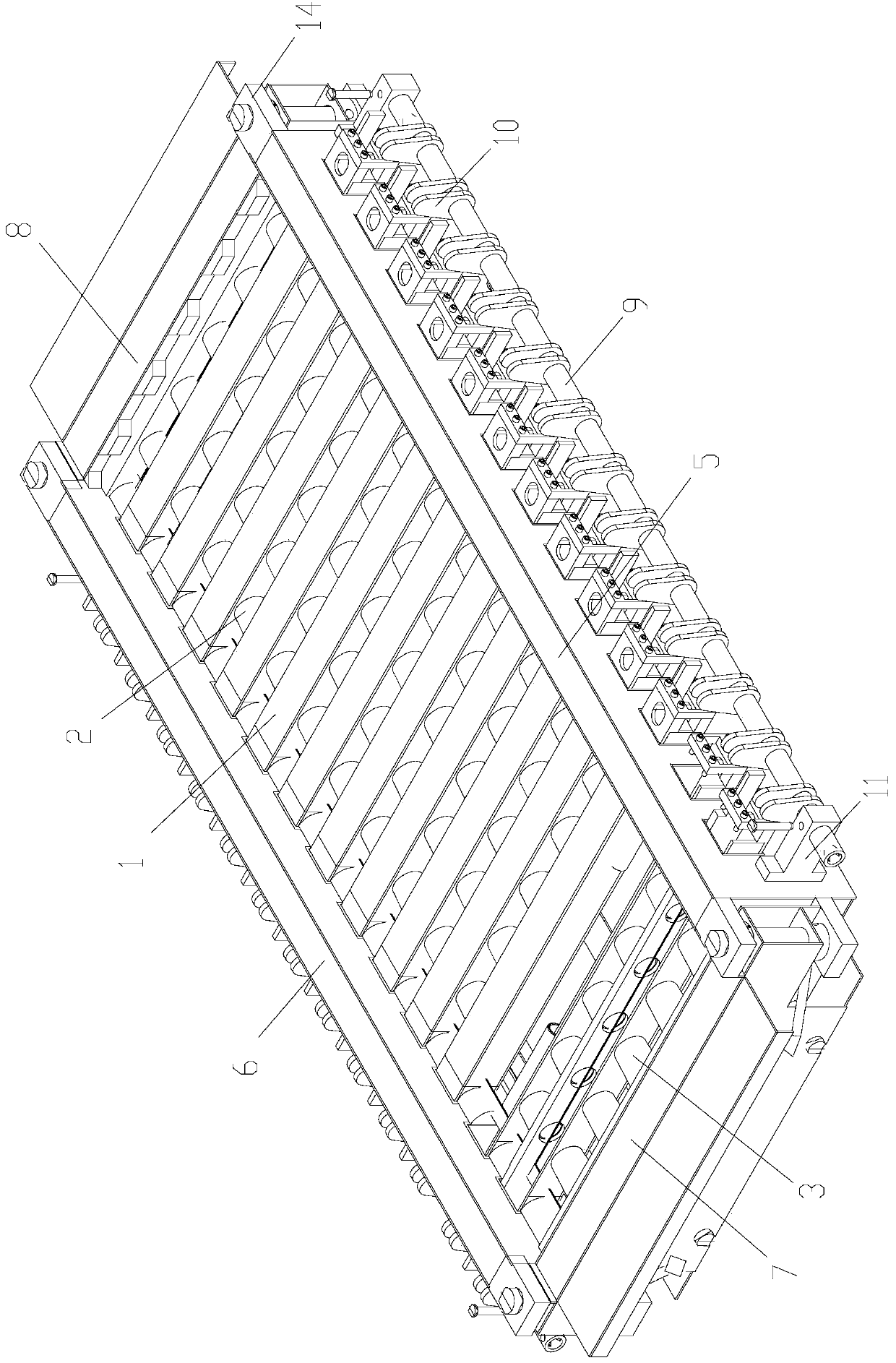

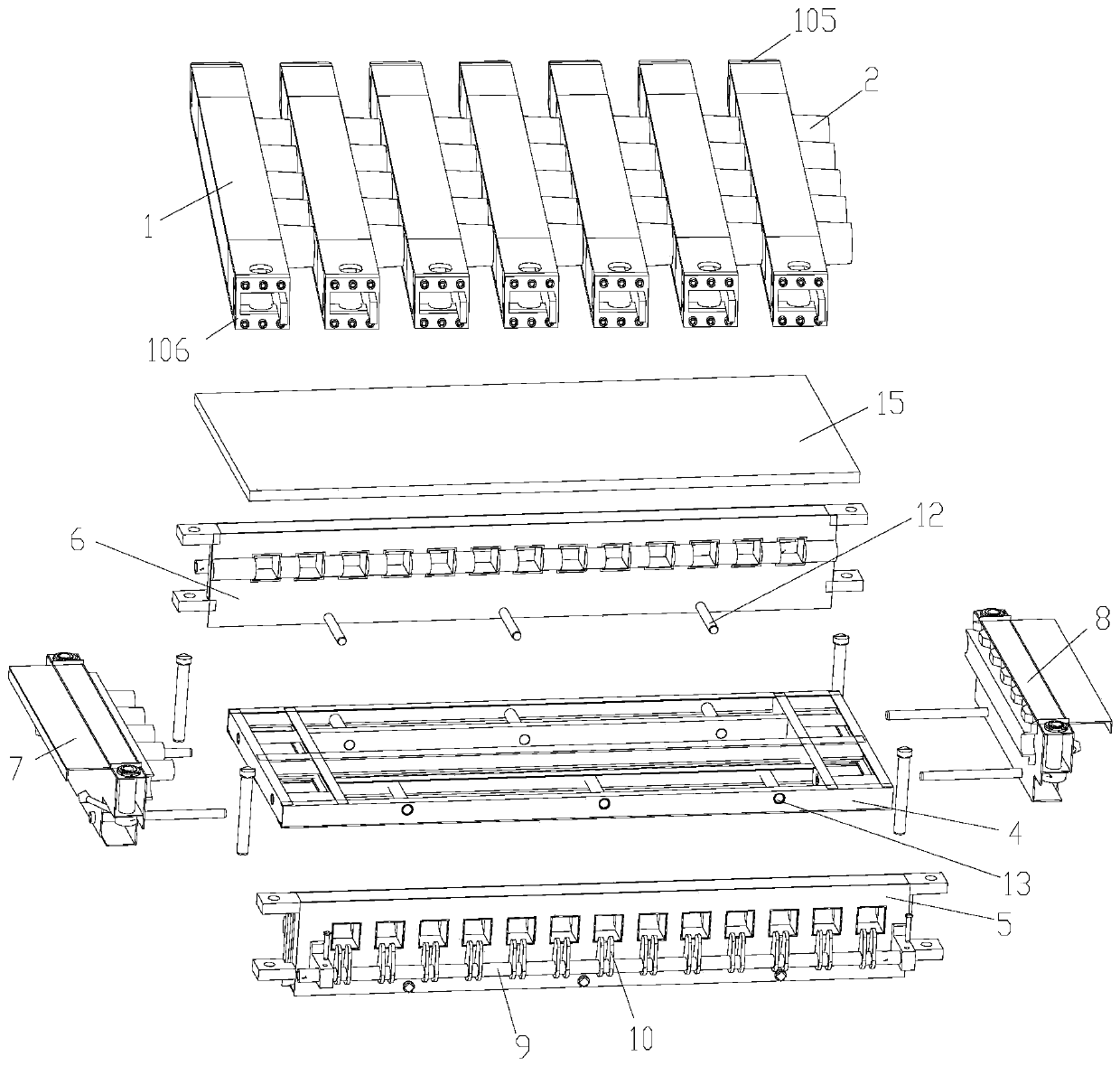

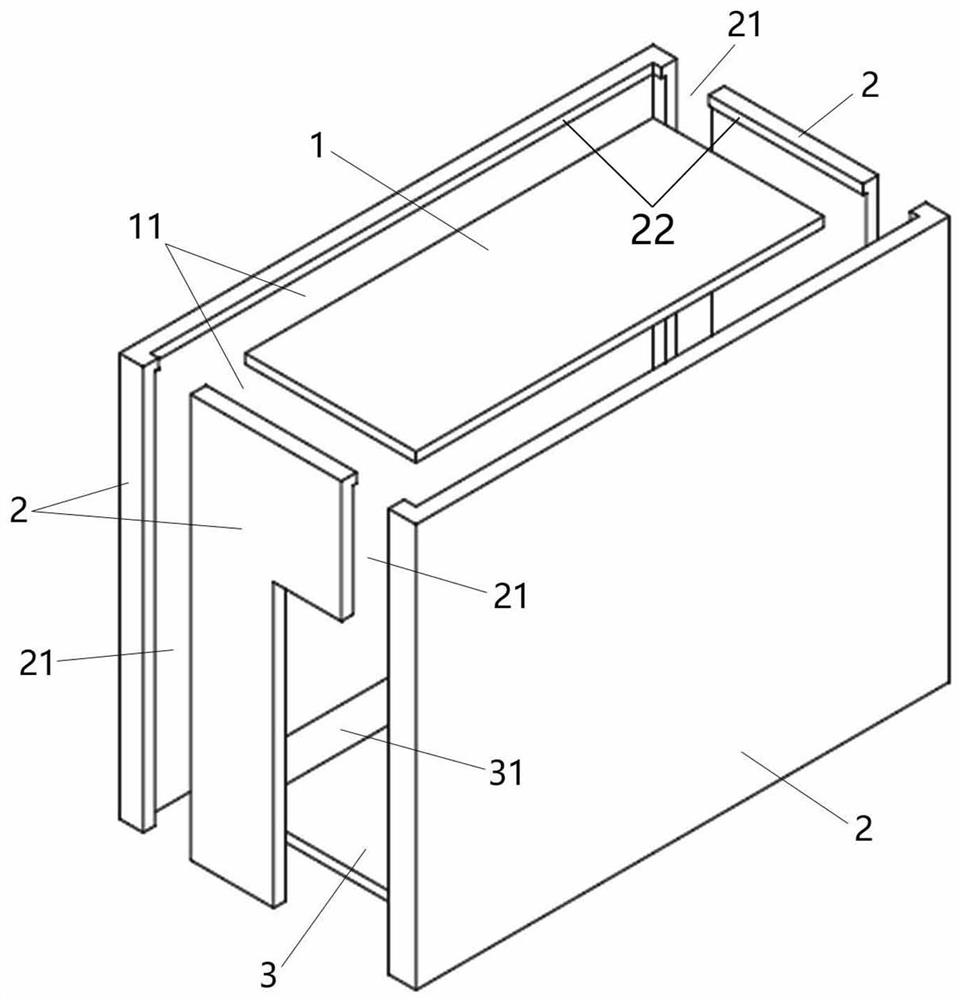

Modularization steel die trolley and construction process thereof

ActiveCN104895584AExcellent anti-rustEasy to remove formworkUnderground chambersTunnel liningSupporting systemEngineering

The invention provides a modularization steel die trolley and a construction process thereof. The trolley comprises an inner die trolley and an outer die trolley. The inner die trolley is of a semi-closed steel structure and comprises a support elevating system and a walking system. The outer die trolley also comprises the same support elevating system and the same walking system. The inner die trolley also comprises a support template. The outer die trolley also comprises a support system, an outer support template and a lead screw. According to the invention, one set of special outer die trolley door frame can be used with multiple sets of common template assemblies.

Owner:金中天建设集团有限公司

Mold for manufacturing hemi-discoid rock-like specimen with fracture surface and manufacturing method

InactiveCN105823663AEasy to adjustAchieve preparationPreparing sample for investigationCircular discEngineering

The invention discloses a mold for manufacturing a hemi-discoid rock-like specimen with a fracture surface. The mold comprises a cylindrical mold groove with the upper portion open, wherein a through downward-concave partition board groove is formed in the bottom surface and side surface of the mold groove along the diameter, a partition board is vertically installed in the partition board groove, and the cylindrical mold groove is divided into two symmetrical parts by the partition board; an inverse-T-shaped sliding groove is formed in the upper end of the partition board in the length direction, a rigid set rule is installed in the inverse-T-shaped sliding groove of the partition board in a sliding mode, first rulers are arranged on the two sides of the inverse-T-shaped sliding groove in the upper end face of the partition board, two vertically-through straight slotted holes which are spaced from each other are formed in the middle of the rigid set rule in the length direction, a steel disc positioning device is movably installed in each straight slotted hole, and a steel disc is installed on the lower portion of the steel disc positioning device. The invention further discloses a rock-like specimen manufacturing method. The parameters of the fracture surface of the specimen can be adjusted conveniently, two specimens can be manufactured at a time, machining is easy, repeated use can be achieved, and manufacturing efficiency and precision are improved.

Owner:OCEAN UNIV OF CHINA

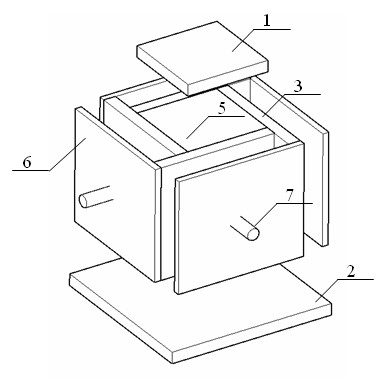

Rock-class test piece mould for field of rock mechanics

InactiveCN102620967AAchieve multi-purposeVersatilePreparing sample for investigationEngineeringModel test

The invention discloses a rock-class test piece mould for the field of rock mechanics, which comprises a base, a middle mould frame and an upper pressure plate. The rock-class test piece mould is characterized in that the middle mould frame comprises four side plates and four guide columns, the four guide columns are arranged on the four side plates, each side plate comprises an inner surface, anouter surface and four side surfaces, the guide columns are arranged on the outer surface of the side plates, and the first side surface of each side plate is arranged on the inner surface of the adjacent side plate. The rock-class test piece mould overcomes the defects that conventional related moulds can be used for preparation of fixed dimension test pieces only by the aid of a slidable dimension-variable device, realizes pressing of dimension-variable test pieces made of similar materials and guarantees mechanic performance of the test pieces made of similar materials effectively. The rock-class test piece mould can be widely applied to geomechanics model testing research in the fields of hydroelectric power, communication, energy resources, resources, national defense and the like, and effectively guarantees high-quality implement of three-dimensional geomechanics model testing.

Owner:HOHAI UNIV

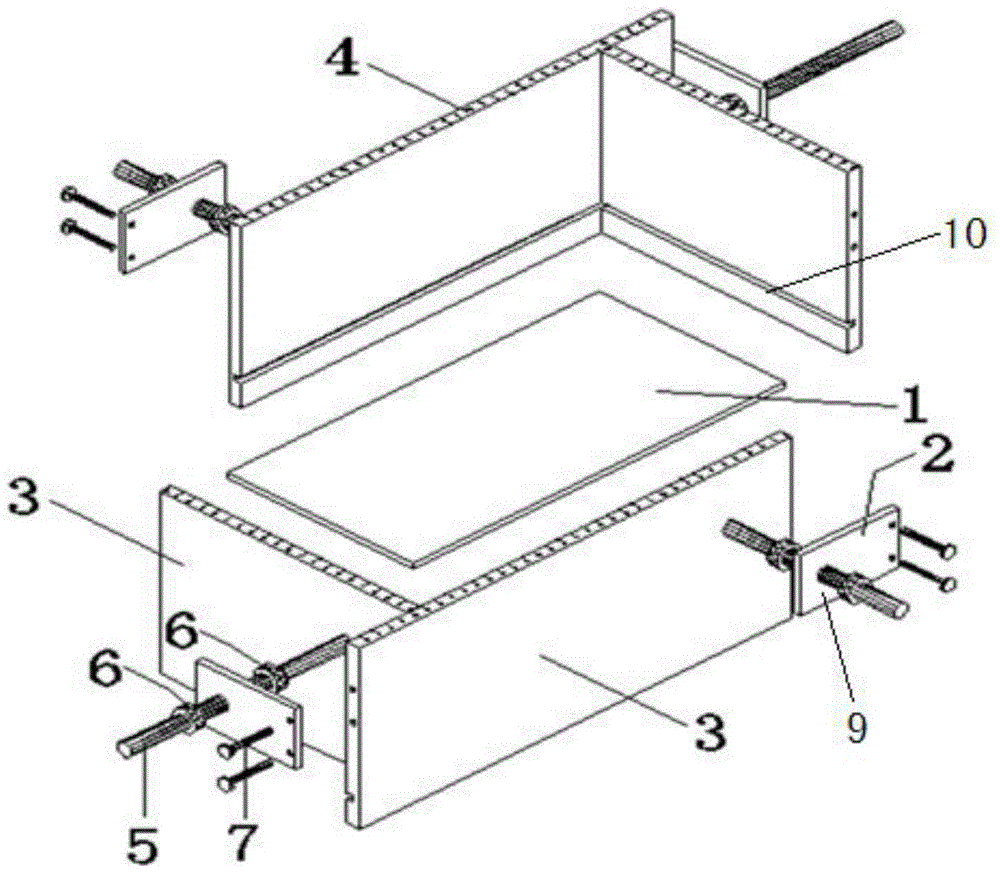

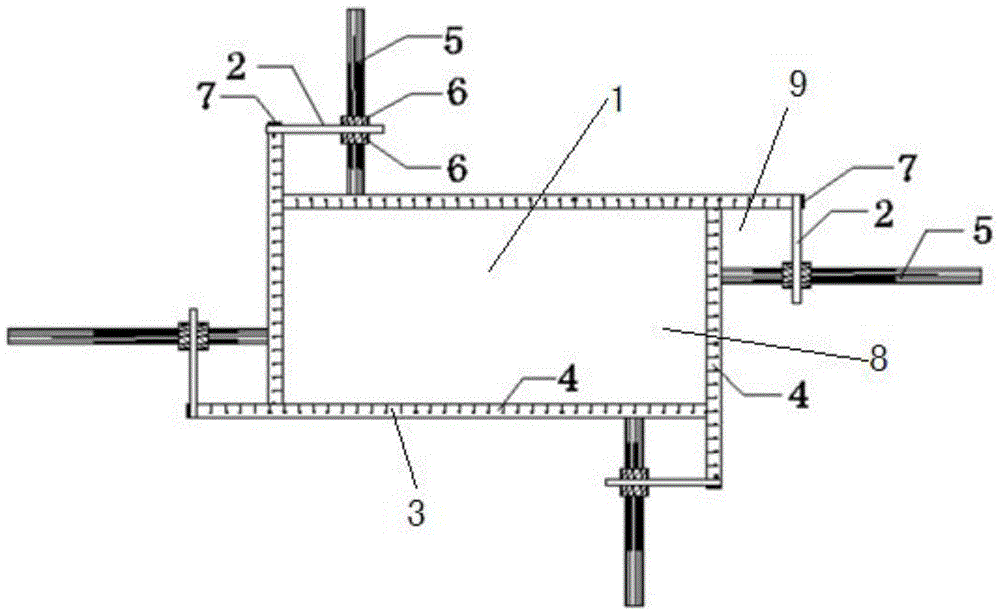

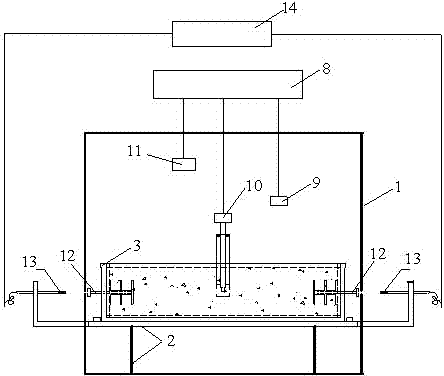

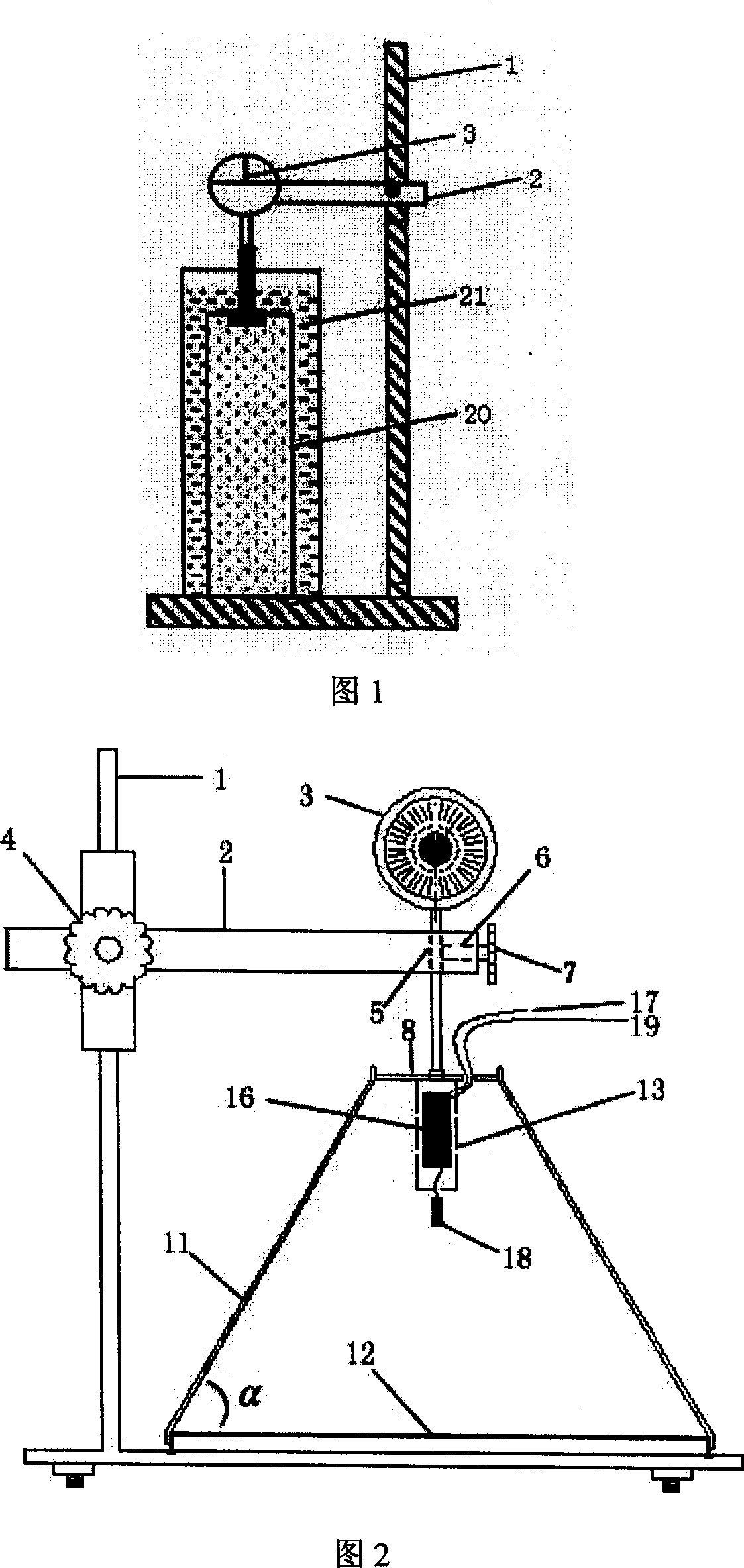

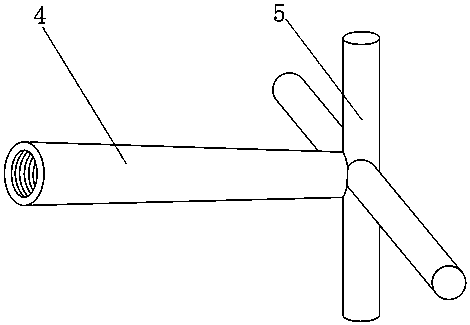

Method and apparatus for measuring early-stage autogenous shrinkage of cement-based material

InactiveCN103837670AAvoid errorsAutomatic adjustment of curing temperaturePreparing sample for investigationMaterial testing goodsEngineeringThreaded rod

The invention discloses an apparatus for measuring early-stage autogenous shrinkage of a cement-based material. The apparatus comprises a test piece die, a pre-embedded target and a displacement measurement system, wherein the test piece die comprises an outer die and an inner die, the outer die is a box-like cuboid with an open upper end, the inner die is a rectangular frame which can be accommodated in the outer die, corresponding positions of two opposite end faces of the outer die and two opposite end faces of the inner die are respectively provided with a circular through hole, the pre-embedded target comprises an internal thread open tube and a threaded rod mutually fitting, the threaded rod can pass through the circular through holes in the inner die and the outer die, the displacement measurement system is a non-contact displacement measurement system and comprises a displacement sensor and a displacement signal acquisition and processing unit, and the displacement sensor can monitor displacement of the pre-embedded target and transmits monitored displacement information to the displacement signal acquisition and processing unit for processing. The invention further discloses a method for measuring early-stage autogenous shrinkage of the cement-based material. According to the invention, testing can be carried before prehardening, and the apparatus has the advantages of a simple structure and low cost.

Owner:HOHAI UNIV

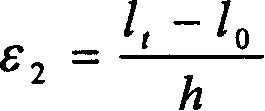

Measuring apparatus for rate of self-contraction of cement concrete

InactiveCN1963503AReduce resistanceEasy to moldElectrical/magnetic solid deformation measurementMaterial thermal analysisAutomatic controlData acquisition

Owner:BEIJING UNIV OF TECH

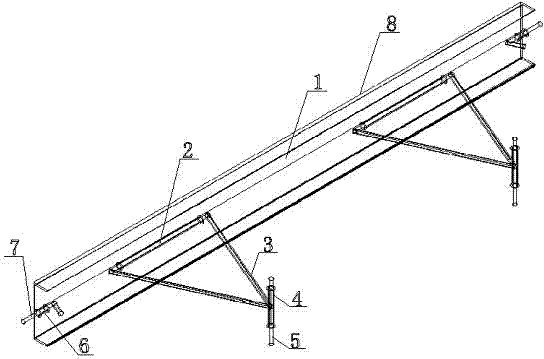

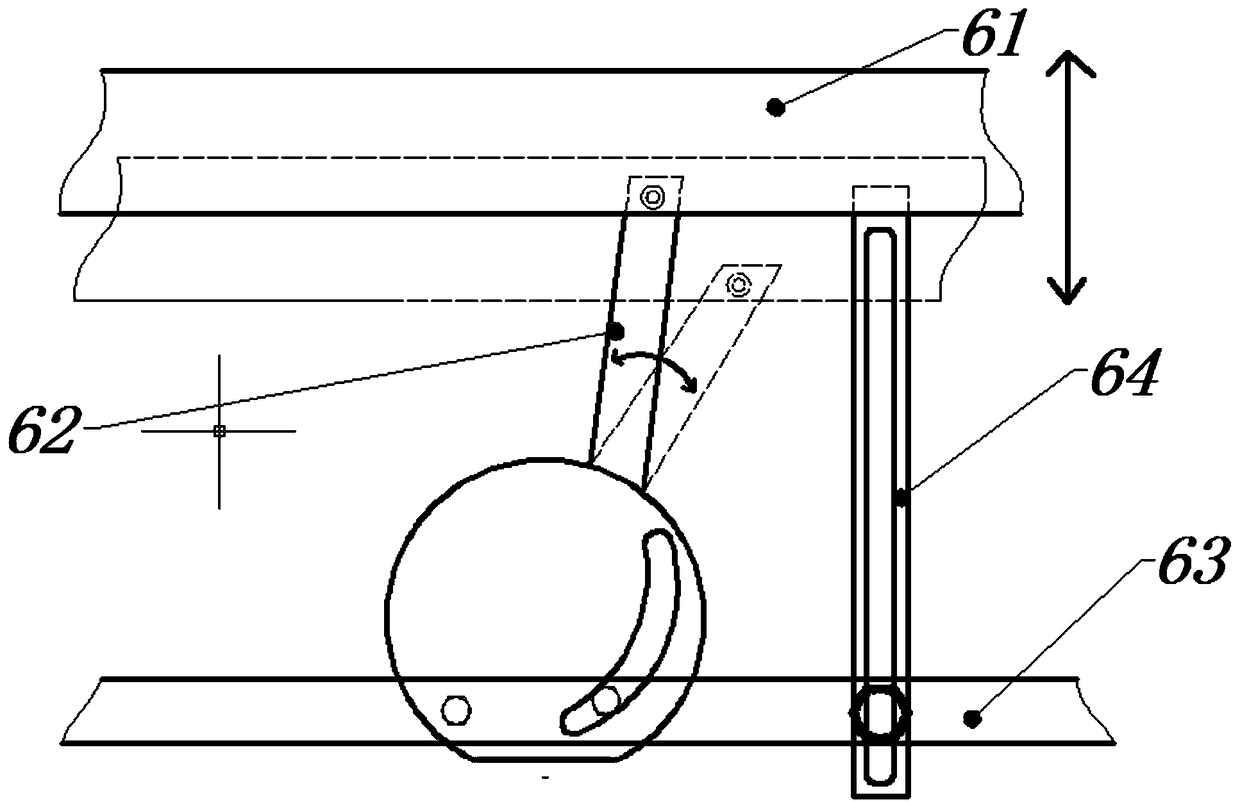

Automatic template system for maglev curve track beam and use method of automatic template system

InactiveCN104999547AImprove prefabrication efficiencyImprove efficiencyMould separation apparatusMouldsLow speedLateral displacement

The invention discloses an automatic template system for a maglev curve track beam and an use method of the automatic template system. The template system comprises a bottom die, a side die, end dies, a regulating component and a control component, wherein the bottom die is used for bearing the track beam; the side die comprises flexible side die panels arranged along the two longitudinal sides of the track beam, and a plurality of frameworks are arranged on the outer side of each side die panel; the end dies are arranged at the two end parts of the track beam, and each end die is provided with a translational assembly which can enable the end die to translate in the longitudinal direction of the track beam; the regulating component comprises at least two electric push rod assemblies on the outer side of each framework, each electric push rod assembly is used for regulating the lateral displacement relative to the track beam and the perpendicularity relative to the bottom die of the corresponding framework position; the control component is used for controlling and regulating each electric push rod assembly and each translational assembly. The side die curvature of each electric push rod assembly is automatically regulated through the control component, and the template system is high in regulation precision, high in efficiency and good in reliability due to the intelligent control, can be recycled, is energy-saved and environmental-friendly, and is particularly appropriate for prefabrication of medium and low speed curve track beams.

Owner:CHINA RAILWAY 23RD CONSTR BUREAU LTD

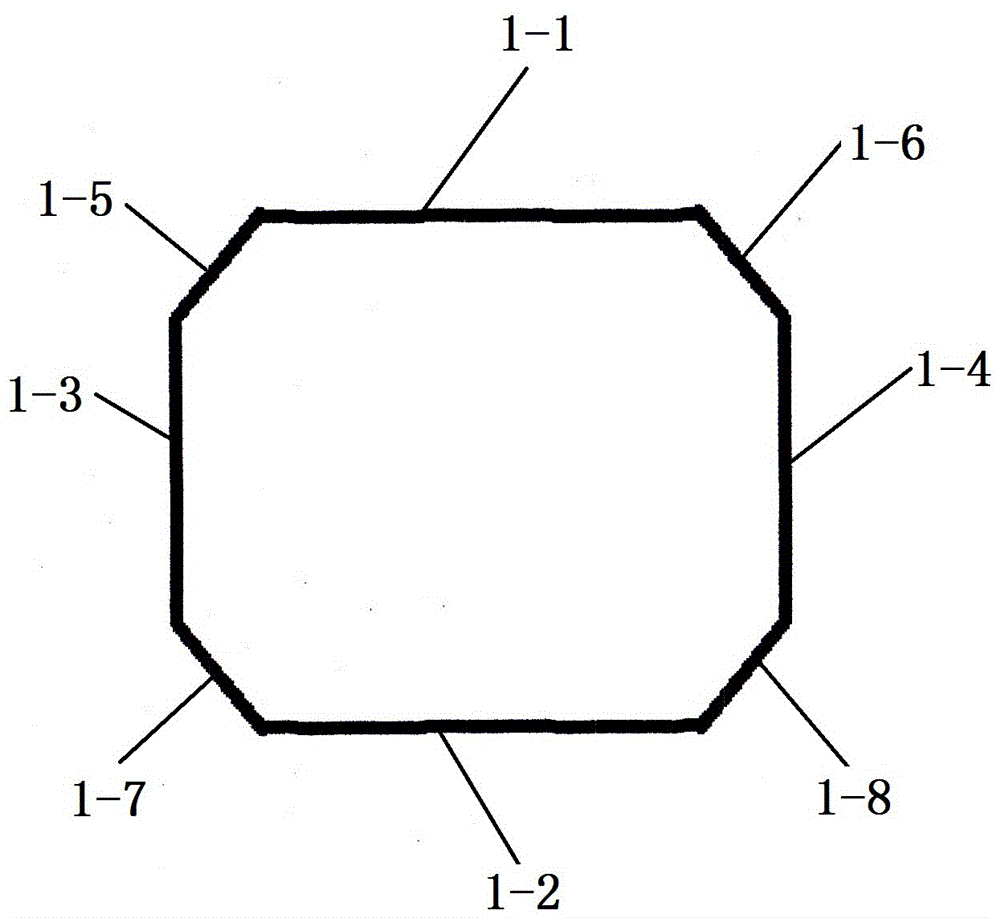

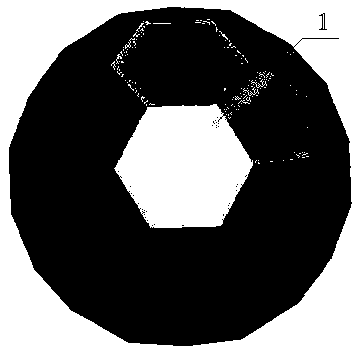

Ultra-high performance concrete column permanent formwork and preparation method thereof

The invention discloses an ultra-high performance concrete column permanent formwork which comprises a hollow columnar ultra-high performance concrete layer and a steel reinforcement cage arranged in the ultra-high performance concrete layer. Dents with the depth not lower than 5 mm are formed in the inner surface of the ultra-high performance concrete layer. The cross section of the ultra-high performance concrete layer is in the shape of a hollow column and a hollow square column. The dents are in strip, grid, dot and spiral shapes. The invention further discloses a preparation method of the ultra-high performance concrete column permanent formwork. By preparing the ultra-high performance concrete column permanent formwork with the dents with the depth not lower than 5 mm in the inner surface, the binding powder between ultra-high performance concrete and post-cast core concrete is enhanced, so that the column component bearing capacity is improved; the ultra-high performance concrete column permanent formwork is good in integrality, convenient to prepare, low in cost, remarkable in economic benefit and excellent in endurance quality.

Owner:广东利盈投资集团有限公司

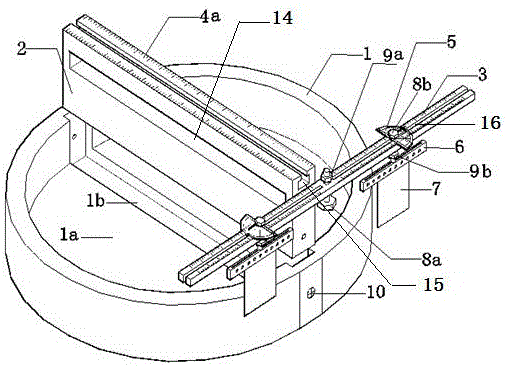

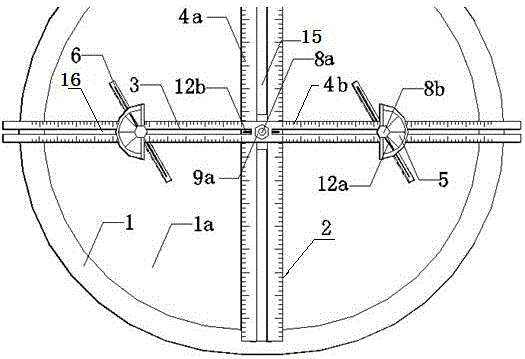

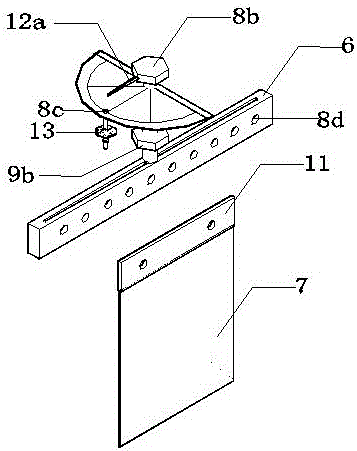

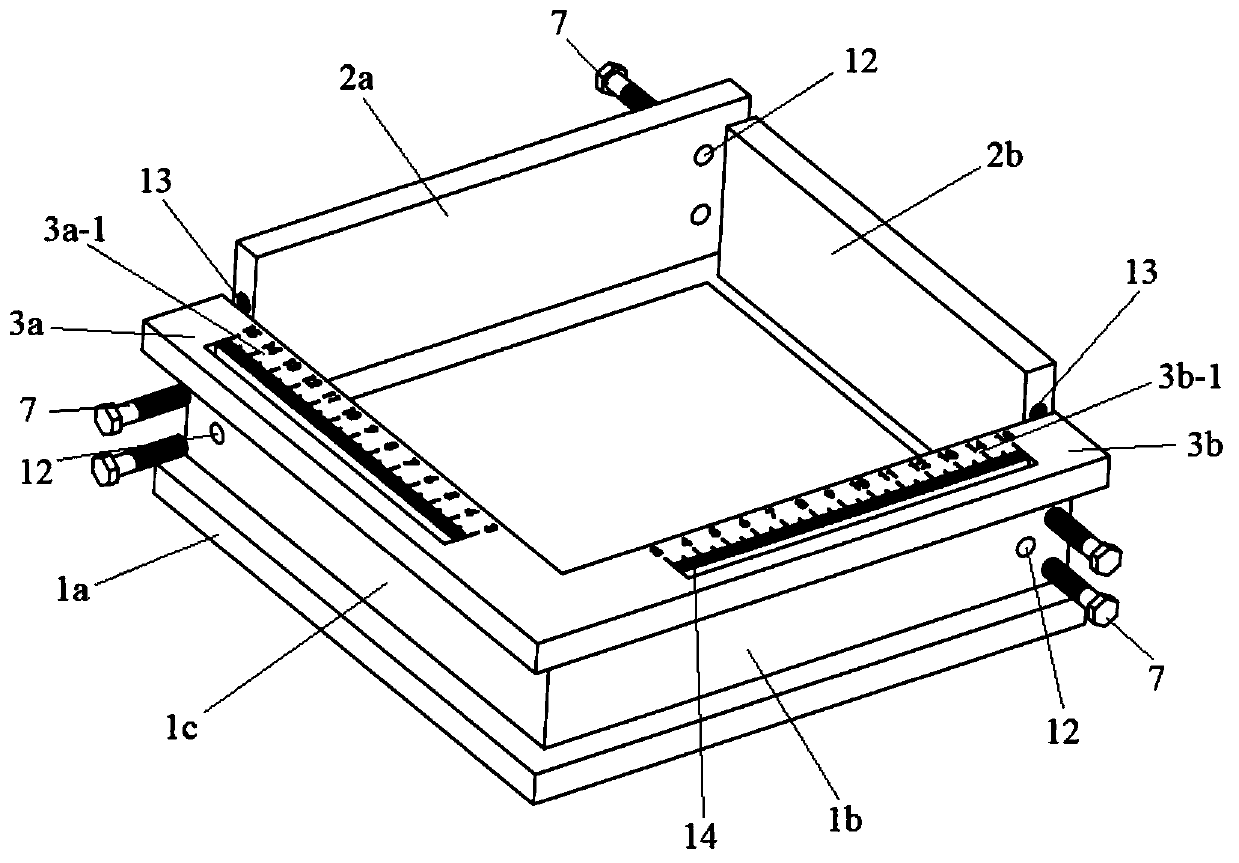

Rock test piece manufacturing mold capable of adjusting joint angle and position and using method

ActiveCN111207972AEasy to makeEasy to processPreparing sample for investigationPolystyreneMechanical engineering

The invention discloses a rock test piece manufacturing mold capable of adjusting the joint angle and position and a using method. The manufacturing mold comprises a detachable rectangular mold groove, a position adjusting device composed of a steel plate ruler and a positioning sliding straight rod, an angle adjusting device internally provided with a mold piece fixing plate, and a mold piece made of polystyrene, wherein all the components are connected and fixed through self-tightening bolts, nuts and other parts, mold dismounting is convenient, and manufacturing of rock-like test pieces isfacilitated. The manufacturing mold is advantaged in that a rock-like sample of a prefabricated cross joint can be manufactured, the included angle and the position of the cross joint can be accurately controlled, research on diversified joint forms of the rock-like sample is facilitated, the obtained result is accurate in size data, and the manufacturing mold is simple in manufacturing mode, capable of being repeatedly used and beneficial to popularization.

Owner:SHANDONG JIANZHU UNIV

Liquid and plastic limit combined determinator sample cup and sample preparation method of sample cup

ActiveCN106769320AEasy to installEasy to disassemblePreparing sample for investigationEngineeringMechanical engineering

The invention relates to a liquid and plastic limit combined determinator sample cup, in particular to a novel liquid and plastic limit combined determinator sample cup in a soil test and a method for preparing a sample by using the sample cup. The liquid and plastic limit combined determinator sample cup comprises a sample container, a sleeve, a sample pushing piston and a tray, wherein one end of the sample container is connected with the sleeve; the other end of the sample container is connected with the tray; the sample pushing piston is arranged in the sleeve to press a soil sample during operation; the sample container is a cylindrical cup; the sleeve is a cylindrical barrel; a wide mouth is arranged at one end, connected with the sleeve, of the sample container; a sample container bottom plate is arranged at one end, connected with the tray, of the sample container; a plurality of small holes are formed in the sample container bottom plate. When the sample cup is used for preparing the sample, whether the sample is successfully prepared can be judged by observing the shape of the sample extruded from the small holes in the sample container bottom plate. A study indicates that the method can greatly reduce the discreteness of liquid and plastic limit data of the sample.

Owner:江苏拓嘉工程设计研究院有限公司

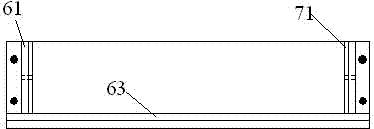

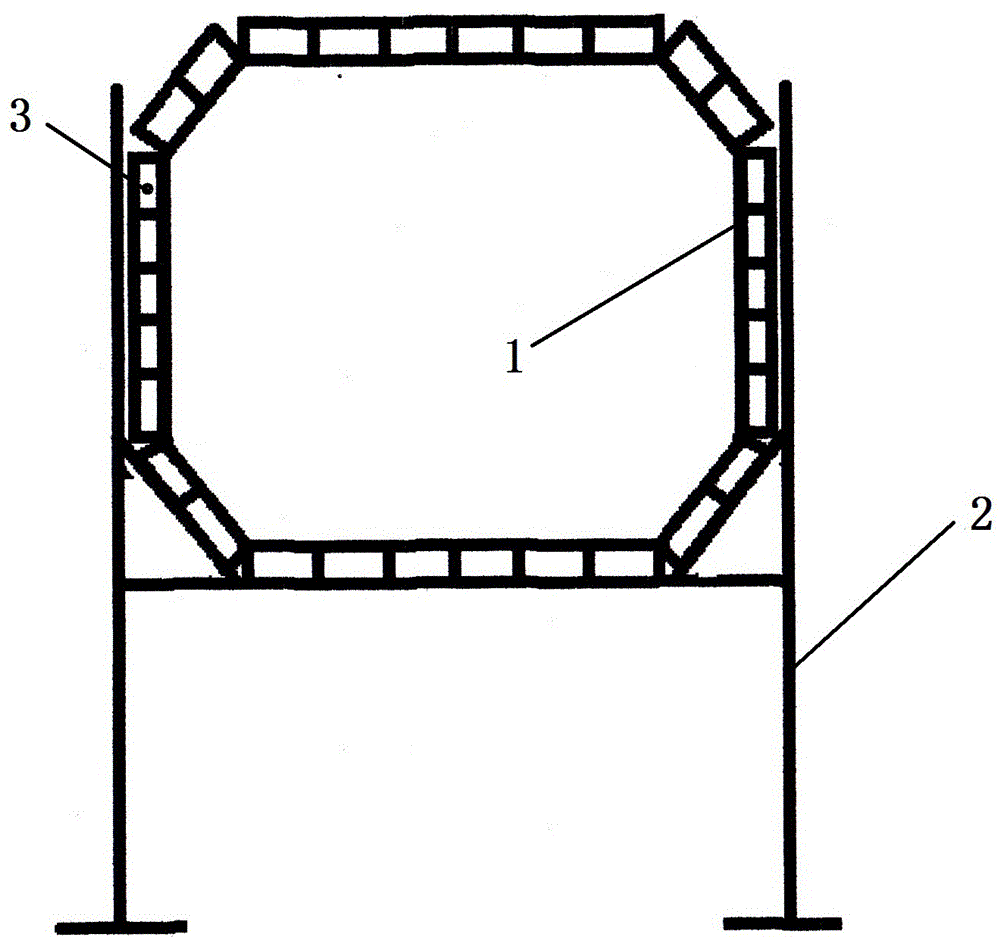

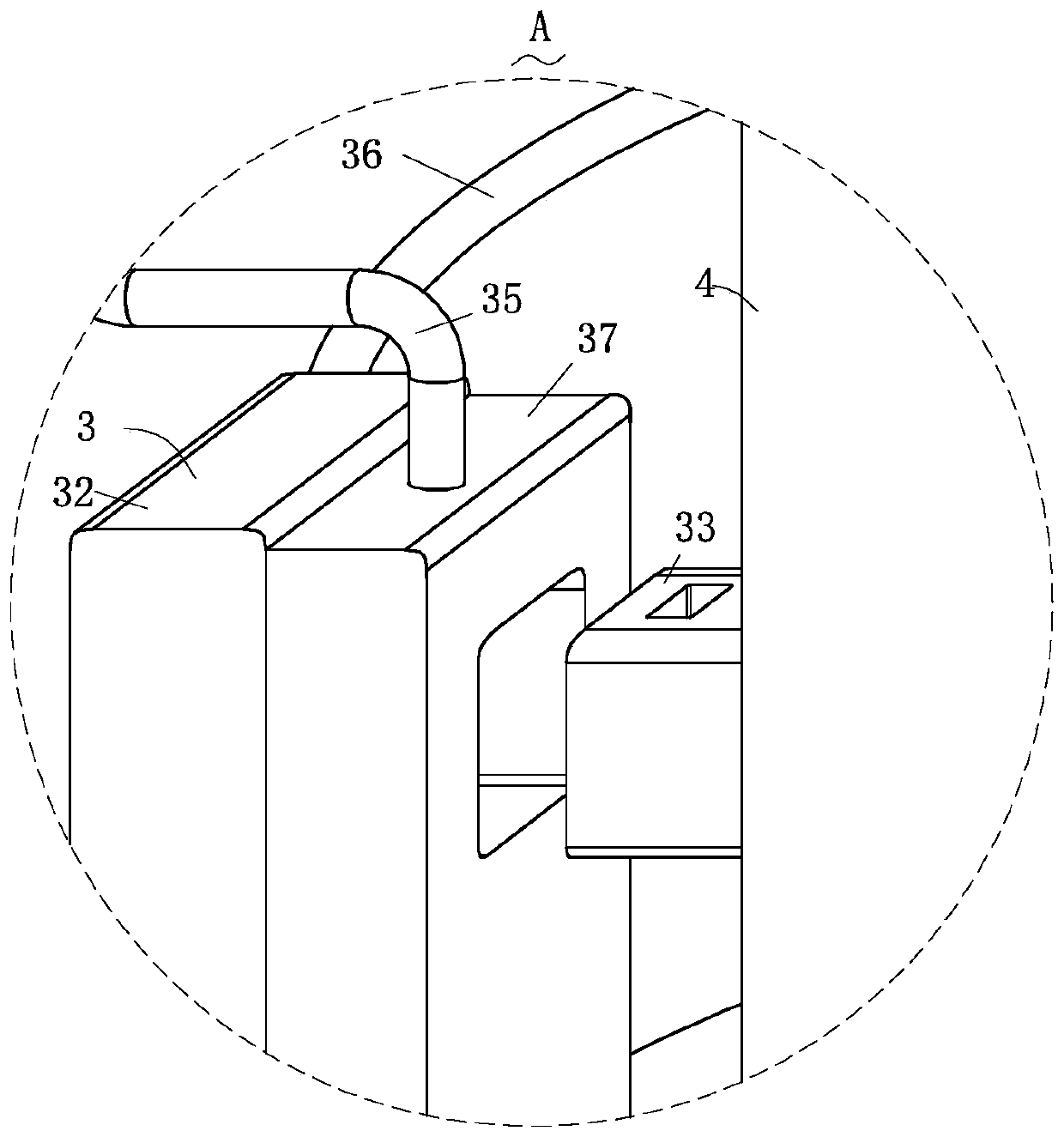

Gallery separating type steel formwork trolley

InactiveCN106640138AImprove the finishGuaranteed integrityUnderground chambersTunnel liningUltimate tensile strengthClerestory

The invention relates to a gallery separating type steel formwork trolley which comprises a portal body, a top formwork and two side formworks. A hydraulic traveling device is installed below the portal body; the top formwork and the two side formworks are located on the portal body; the side formworks are connected with the portal body through a side formwork hydraulic device and a vault hydraulic device; and the top formwork is embedded between the upper portions of the two side formworks. Compared with the prior art, the large steel formworks are adopted, so that the gallery separating type steel formwork trolley is simple in structure, high in strength, low in weight, and adjustable and high in lining quality; the mechanization construction degree is high, labor intensity is relieved, and work efficiency is improved; the two side formworks shrink inwards, the deformation space is large, collision is effectively reduced during demoulding and movement, and the movement speed is increased; and detachable grouting valves are arranged on the top formwork, so that the pouring quality is improved and the demoulding difficulty is reduced.

Owner:中国人民解放军63926部队

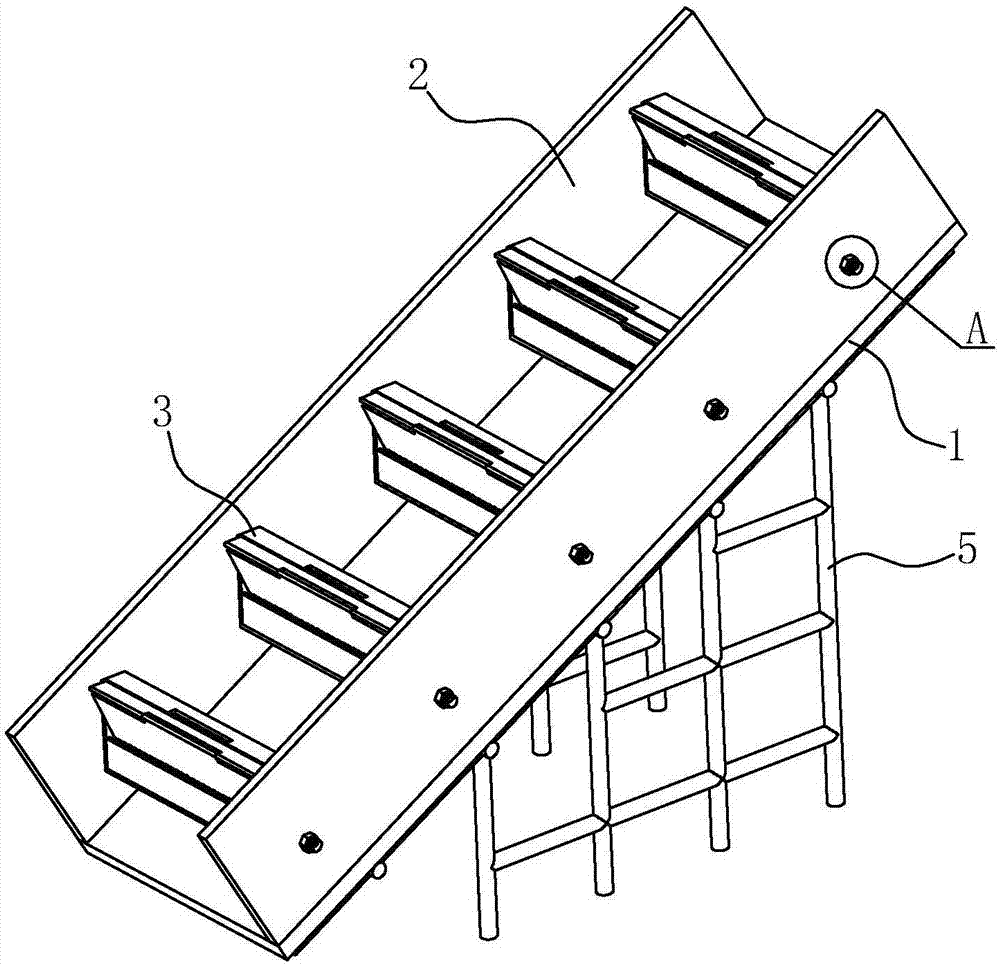

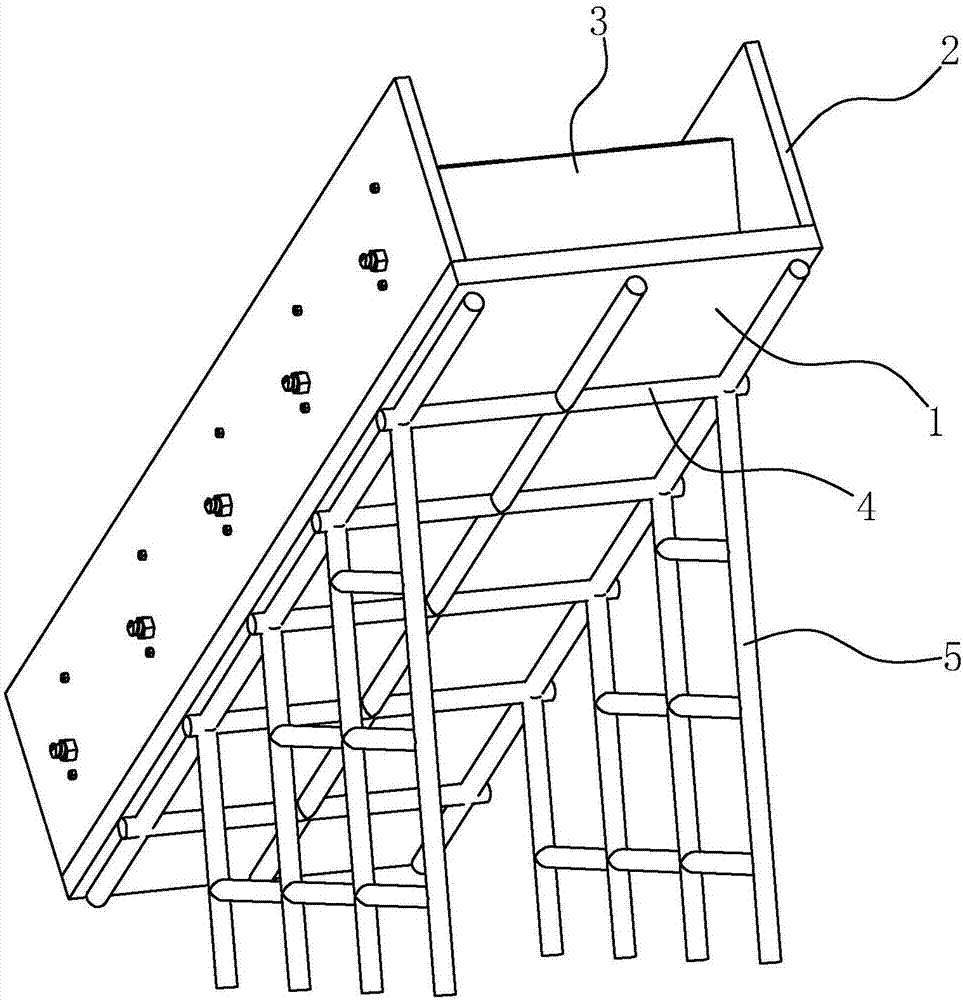

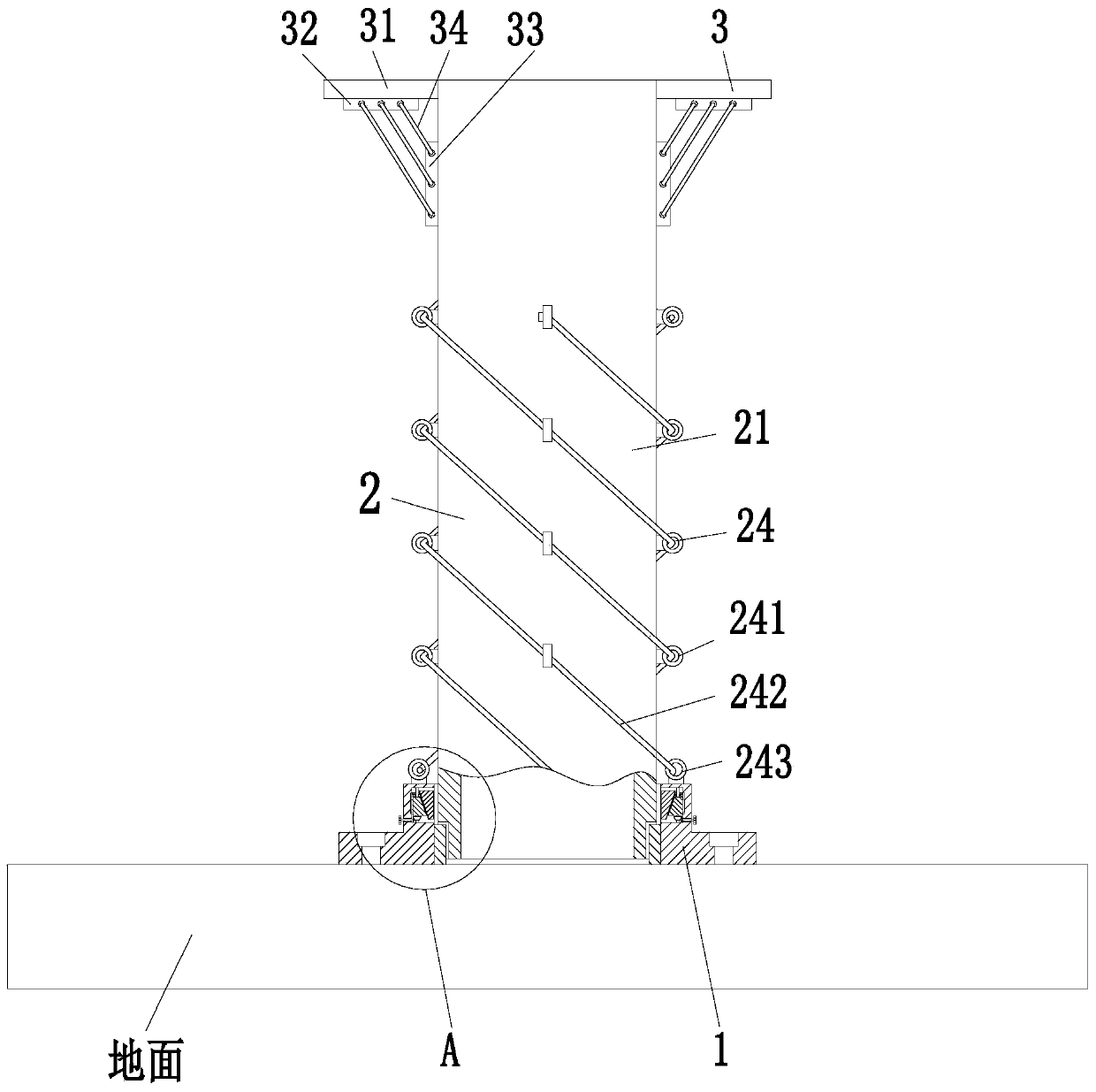

Stair formwork structure and stair construction method adopting same

ActiveCN106988529ANot easy to damageExtended service lifeTreadsForms/shuttering/falseworksSteel platesStairs

The invention discloses a stair formwork structure and a stair construction method adopting the same. The formwork structure comprises stair side formworks, a stair bottom formwork and a supporting structure for the stair bottom formwork; a plurality of stair spacing formworks are further included, each stair spacing formwork is of a rectangular structure, and the stair spacing formworks are formed by cutting, bending and welding steel plates; one side of each stair spacing formwork is a plane and used for blocking concrete; the other side of each stair spacing formwork forms a groove-shaped structure with side walls, wherein the side walls comprise the upper and lower long side walls and the left and right short side walls; mounting holes are formed in each short side wall, and the stair spacing formworks are fixedly connected to the stair side formworks through screws penetrating through the mounting holes; each stair side formwork is a batten; and a prying opening is formed in the upper long side wall of each stair spacing formwork. The formwork has the advantages of being convenient to construct and remove, not prone to being damaged and long in service life.

Owner:闫相明

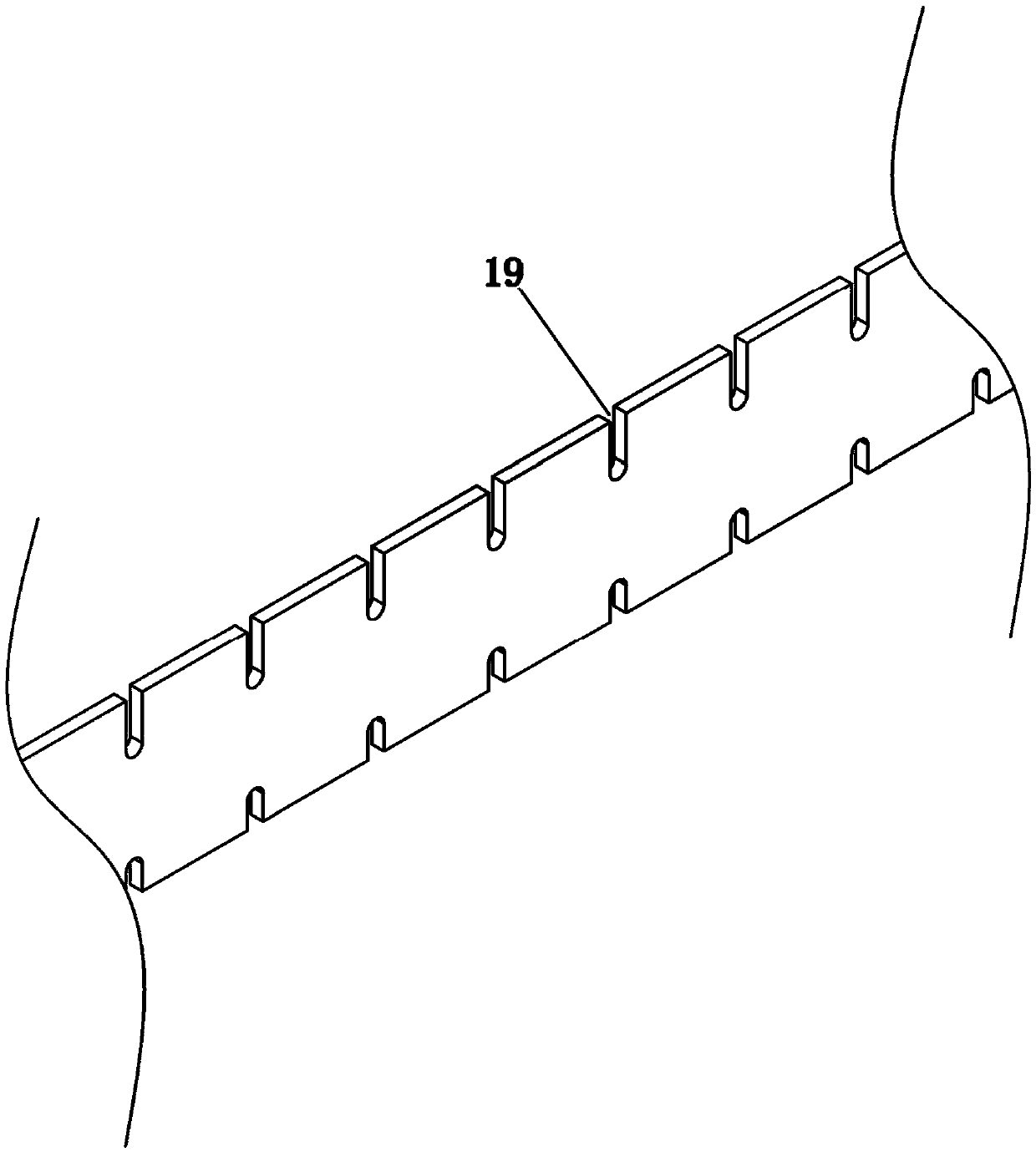

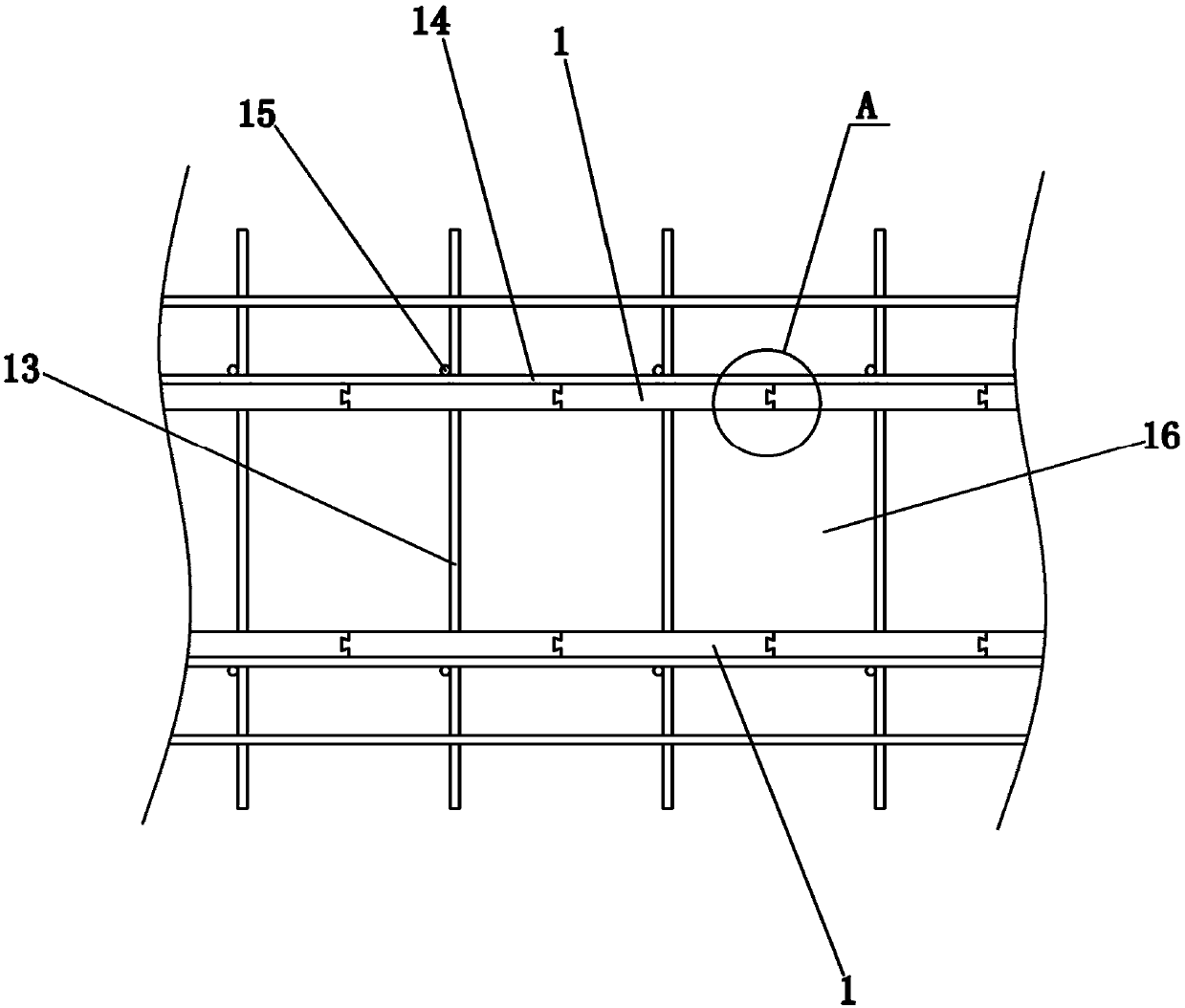

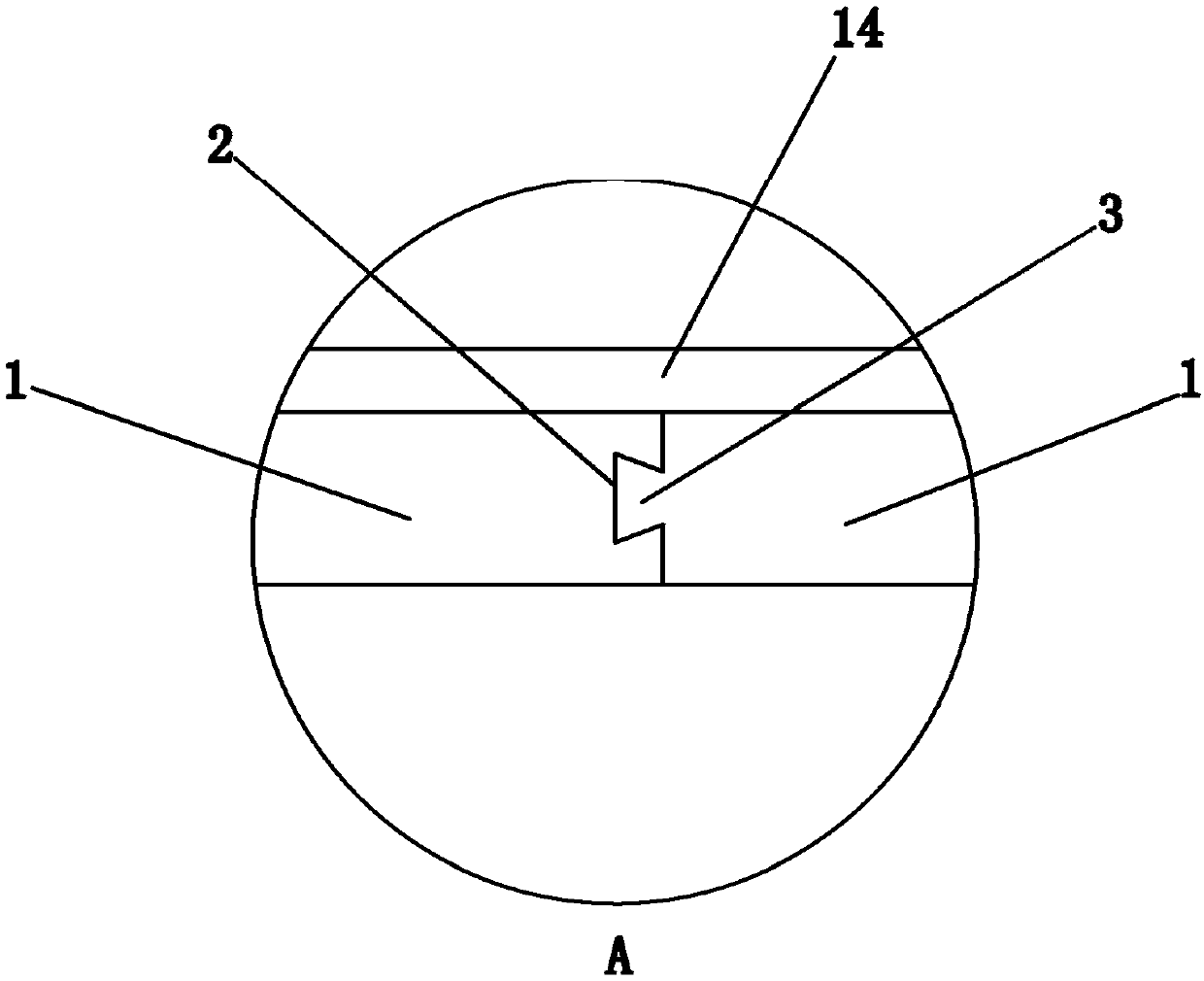

Pre-tensioning method hollow board core extraction type square steel inner mold construction method

The invention relates to a core extraction type square steel inner mold construction method during the construction of a pre-tensioning method hollow board. The method is mainly invented by solving the problems that in the prior art, a hollow board core mold constructed by using a pre-tensioning method uses a polystyrene board core mold, and can easily float up; a combined steel core mold easily deforms, and the like. Used materials comprise a square steel pipe, a steel bar support frame, a plastic thin film, a steel belt and positioning molds, wherein square steel inner molds are spliced; a plurality of positioning molds are taken and are arranged in the front side and the back side; the square steel pipe is laid on the positioning mold; the steel bar support frame is arranged on the square steel pipe; the steel pipe is arranged in a way of attaching to the steel bar support frame; after the splicing of the square steel pipe and the steel bar support frame is completed, a plastic thin film is used for tightly covering the outside of the steel pipe. A packaging machine and the steel belt are used for tightly clamping the steel square inner molds; after the hollow board bottom board concrete casting is completed, the square steel inner molds are conveyed to an installation position; the top board steel bars are bound; the web board and top board concrete is cast; after the concrete intensity reaches the square steel inner mold dismounting requirement, the steel bar support frame and the square steel pipe are extracted out. The method has the advantage that the upward floating and the deformation cannot easily occur.

Owner:中铁十九局集团华东工程有限公司 +1

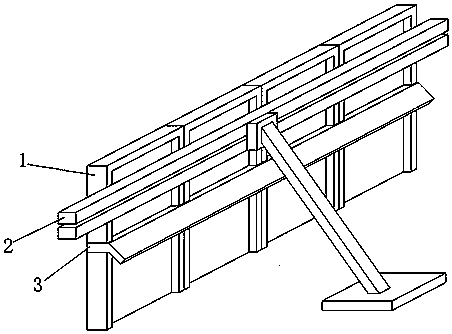

Pavement concrete channel steel forming formwork

ActiveCN102776826AEasy to remove formworkHigh number of reusesRoads maintainenceConcave surfaceRoad surface

The invention provides a pavement concrete channel steel forming formwork which comprises a channel steel and a triangular support, wherein the triangular support is connected with the steel channel through a sleeve welded on the concave surface of the channel steel; the other end of the triangular support is connected with a straight sleeve; an inserting rib is arranged in the straight sleeve; formwork joint sleeves are arranged at two ends of the channel steel; and joint inserting pins are arranged in the formwork joint sleeves. According to the steel channel forming formwork for pavement concrete construction, the formwork is convenient to build and remove; and the steel channel forming formwork can be repeatedly utilized, has low cost, and is beneficial to control the forming quality of the concrete.

Owner:SINOHYDRO BUREAU 14 CO LTD

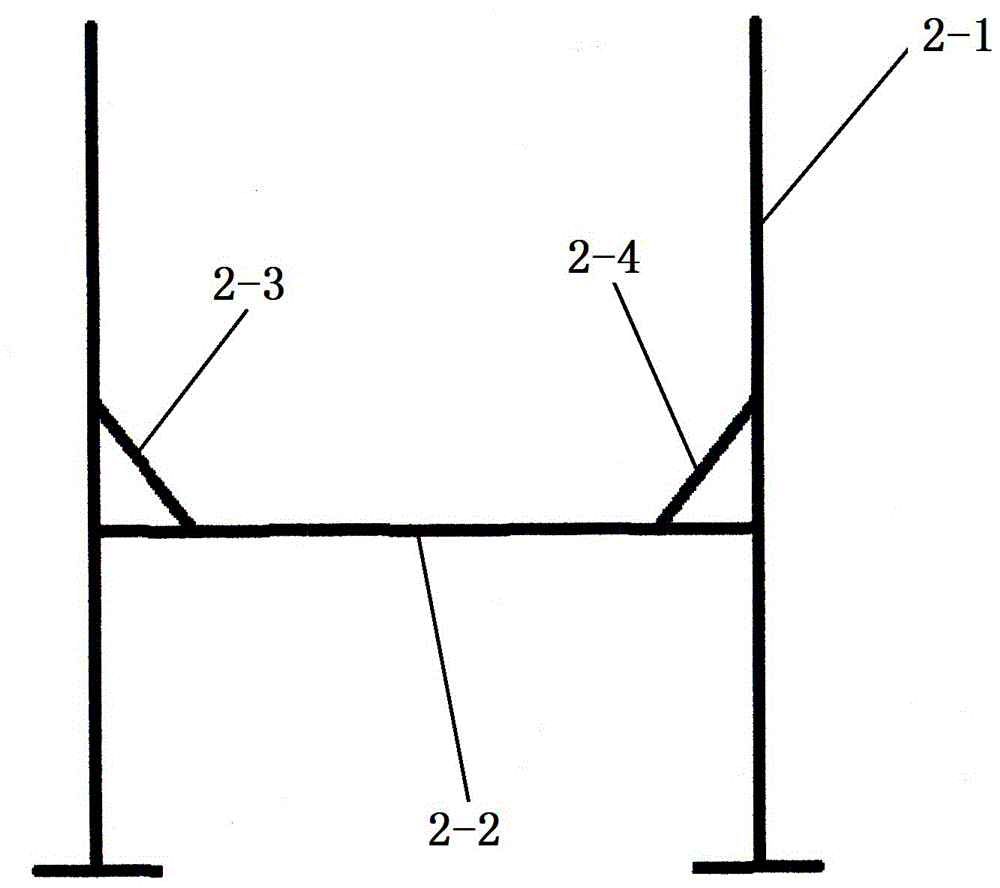

Building beam column construction pouring construction steel formwork

ActiveCN110748159ASolve problems such as difficult formwork removal and affecting construction efficiencyAvoid deformationForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksArchitectural engineeringBeam column

The invention relates to a building beam column construction pouring construction steel formwork. The building beam column construction pouring construction steel formwork comprises an installation seat, a steel formwork frame and a support frame, wherein the installation seat is installed on the ground, the steel formwork frame is installed in the middle of the upper end of the installation seat,and the support frame is installed at the upper end of the steel formwork frame. The building beam column construction pouring construction steel template can solve the problems that when the existing steel formwork is used, the conventional splicing effect between the steel formworks is poor, the installation and the disassembly are inconvenient, the stability effect of the spliced steel s is poor, and the steel formworks are easy to shake, so that the poured beam and column are easy to deform and the quality of the beam and column is influenced; in addition, in the pouring process of the existing steel formworks, gaps usually exist between the steel formworks, the sealing effect of the steel formworks is poor, liquid leakage phenomenon is easy to occur in the pouring process, and a large amount of concrete is wasted; meanwhile, the cast formed steel formworks are not easy to dismantle, and the construction efficiency is affected; and the like.

Owner:SHENZHEN YUEZHONG GRP

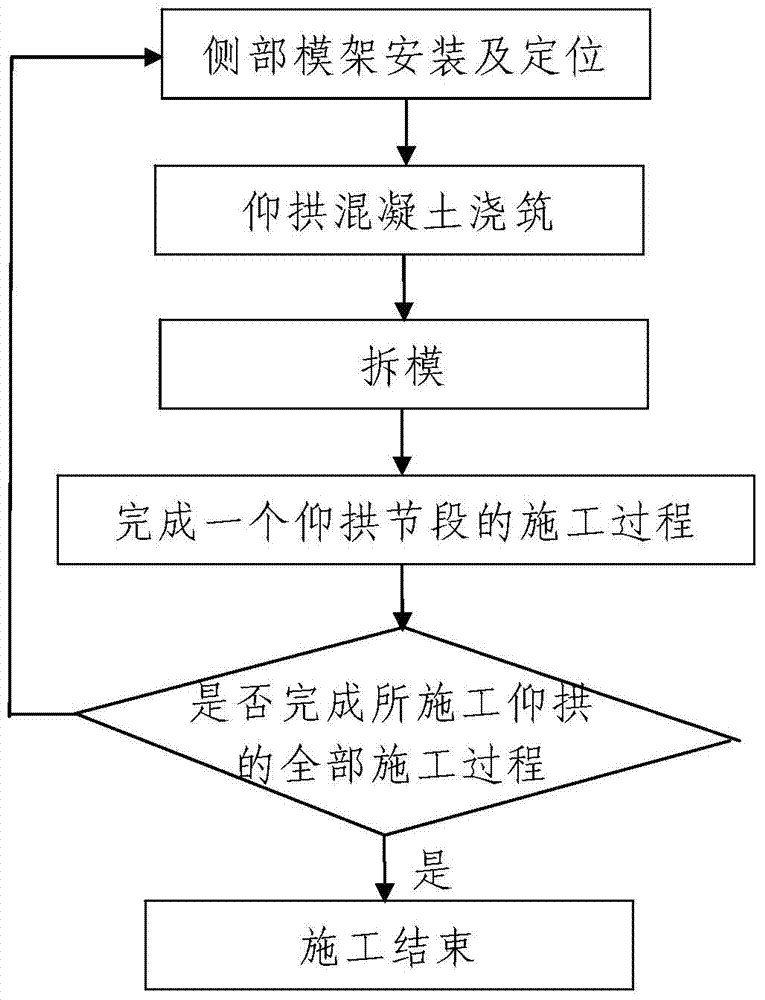

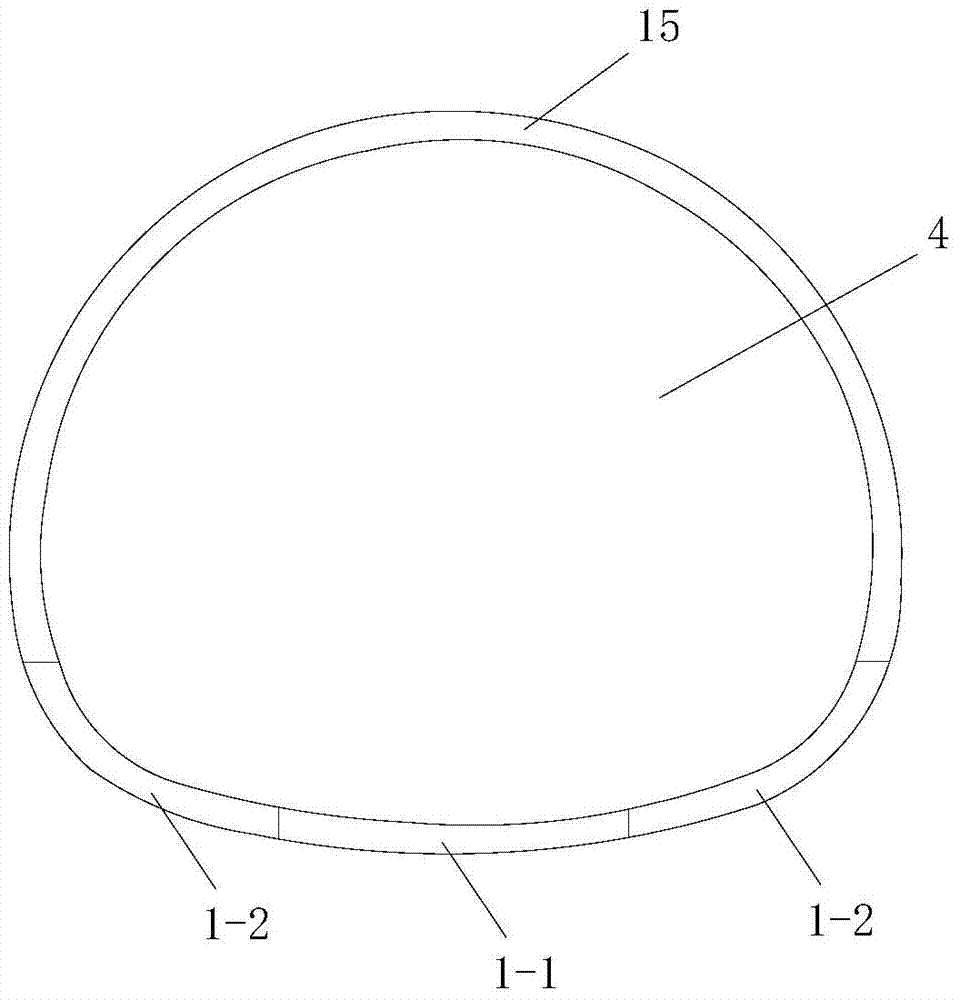

Tunnel inverted arch construction die carrier and tunnel inverted arch construction process

ActiveCN104500106ASimple structureReasonable designUnderground chambersTunnel liningBuilding constructionEngineering

The invention discloses a tunnel inverted arch construction die carrier and a tunnel inverted arch construction process. The die carrier comprises two side die carriers used for respectively constructing two side arch sections of a constructed inverted arch, wherein each side die carrier comprises an arc-shaped steel template for performing shaping construction on the upper surfaces of the side arch section, a template support which is positioned above the arc-shaped steel template and used for supporting the arc-shaped steel template and a front supporting and positioning mechanism positioned at the front side of the arc-shaped steel template. The adopted tunnel inverted arch construction process comprises the following steps of: 1, performing construction of a first inverted arch section, namely installing and positioning the side die carriers, casting inverted arch concrete and detaching a die; 2, performing construction of the other inverted arch section; 3, repeating the step 2 multiple times until the whole construction process of the constructed inverted arch is finished. The tunnel inverted arch construction die carrier is reasonable in design, convenient to realize, and simple and convenient in construction process; in the construction process, the templates are not deviated, the construction effect is god, not only can the tunnel inverted arch construction progress be quickened, but also the construction quality of the constructed and molded inverted arch is easily ensured.

Owner:CHINA RAILWAY 20 BUREAU GRP +1

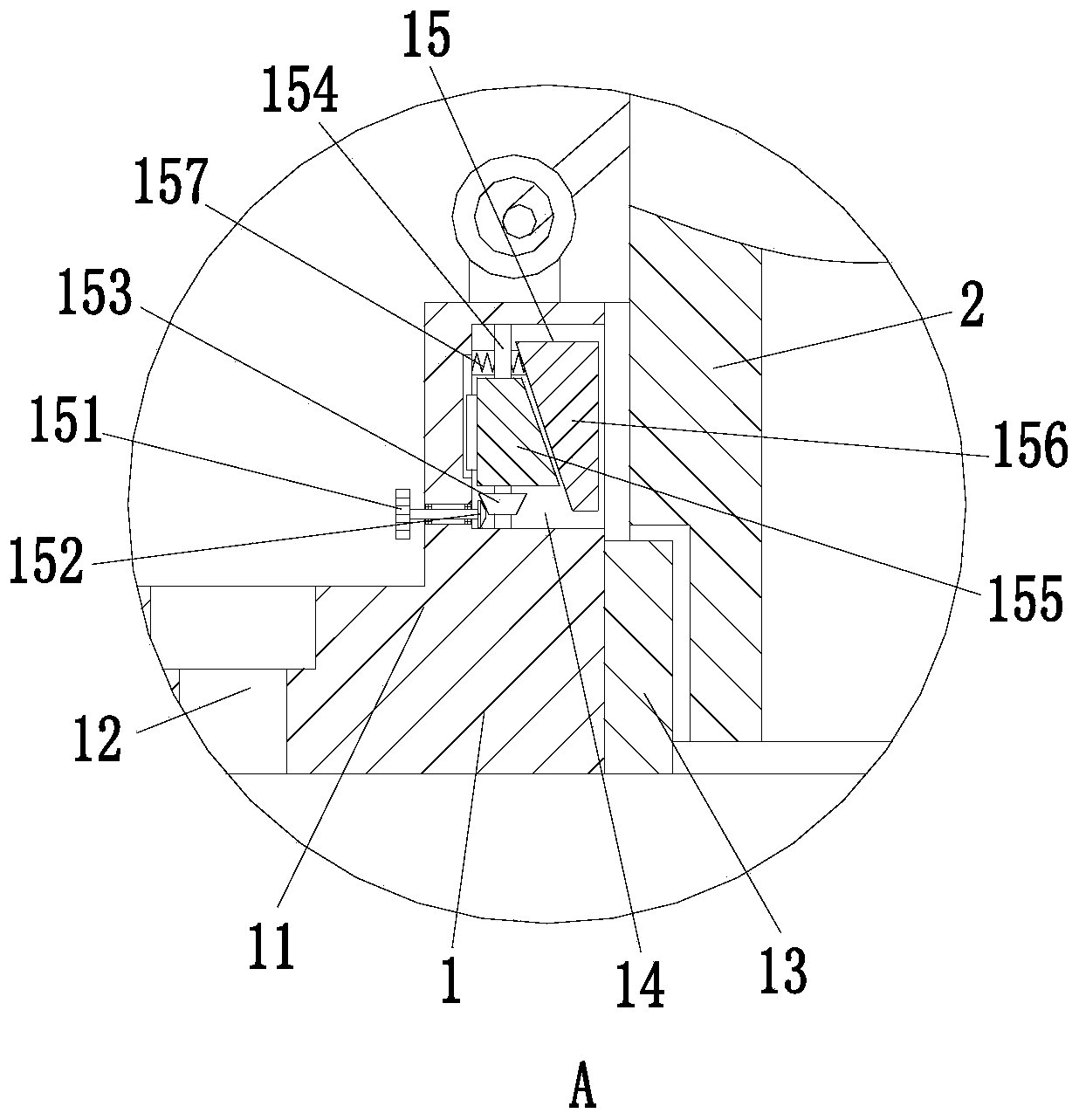

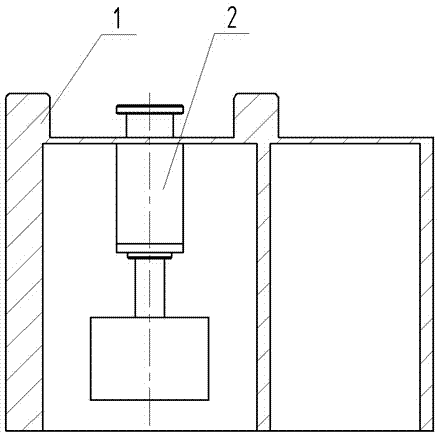

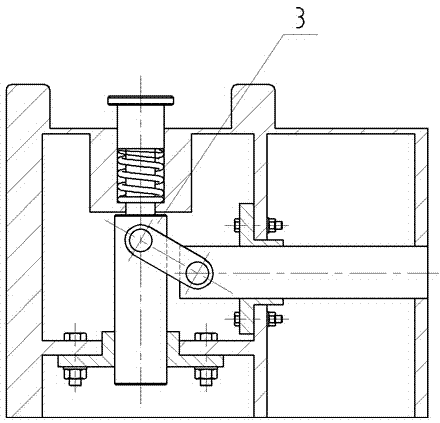

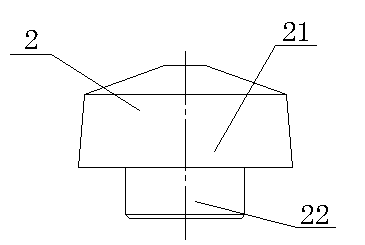

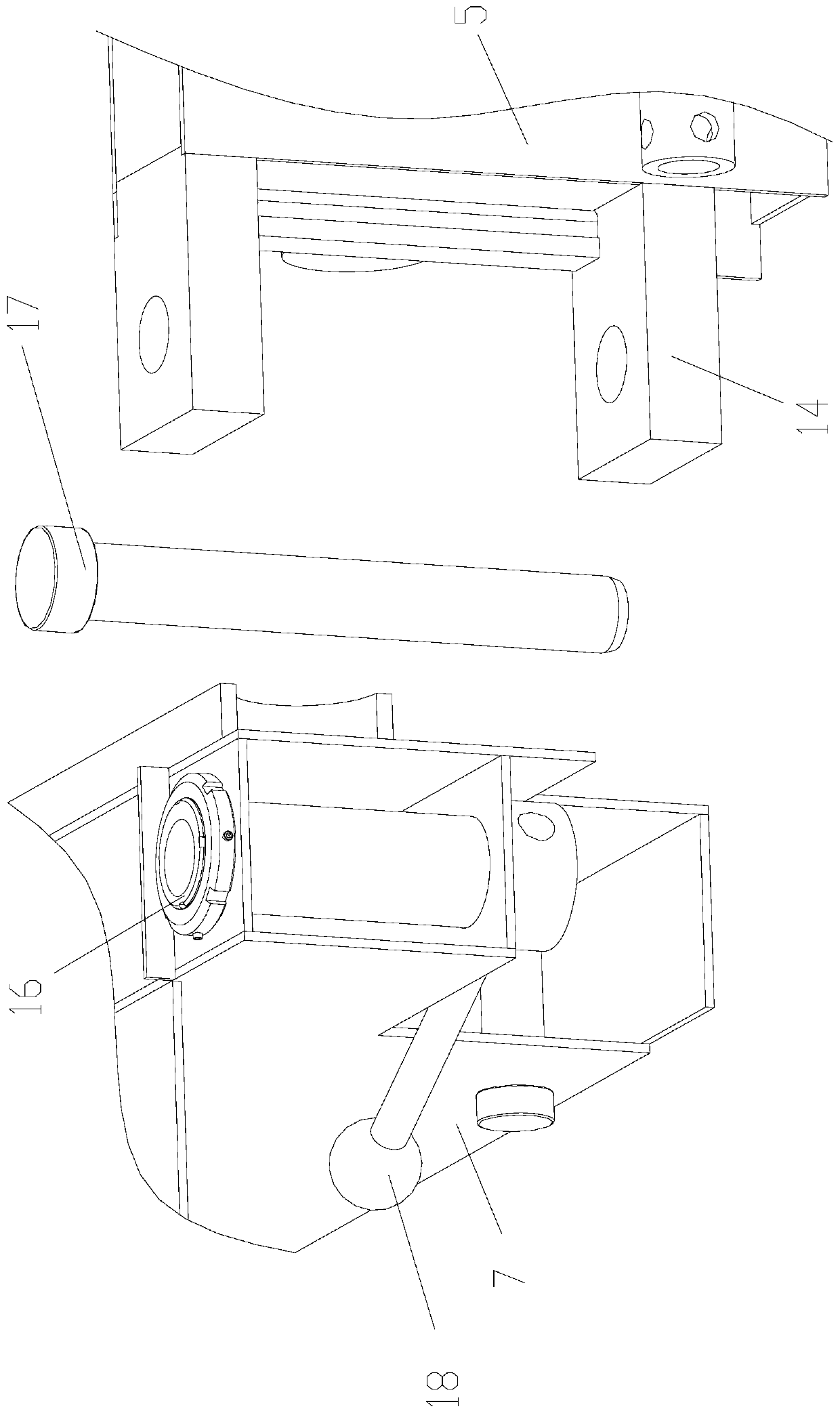

Concrete magnetic side form with form removal device

InactiveCN104328907AAvoid breakingImprove product qualityForming/stuttering elementsForm treatmentArchitectural engineeringPrecast concrete

The invention discloses a concrete magnetic side form with a form removal device, and the concrete magnetic side form is applied to the field of modern construction industry. The concrete magnetic side form consists of a side form body, a magnetic unit and the form removal device, wherein the magnetic unit and the form removal device are fixedly arranged in the side form body, the concrete magnetic side form can be fixedly arranged on a template tray, and the form removal device consists of a mandril cap, a spring, a vertical mandril, an intermediate connecting rod, a horizontal push rod, a push rod guide sleeve, a push rod pin shaft, a mandril pin shaft and a mandril guide sleeve. The horizontal push rod of the form removal device can be ejected out from the interior of the magnetic side form, and directly acts on a precast concrete component, the serious mold damage caused by form removal through dragging and beating is avoided, the precast concrete component damage caused by the form removal is avoided, the product quality of the precast concrete component is improved by virtue of the magnetic side form, meanwhile the form removal is convenient, automatic form removal of a manipulator is realized, the form removal time is effectively shortened, the labor efficiency of the form removal is improved, and the labor intensity of the form removal operation is lowered.

Owner:NORTHERN HEAVY IND GRP CO LTD

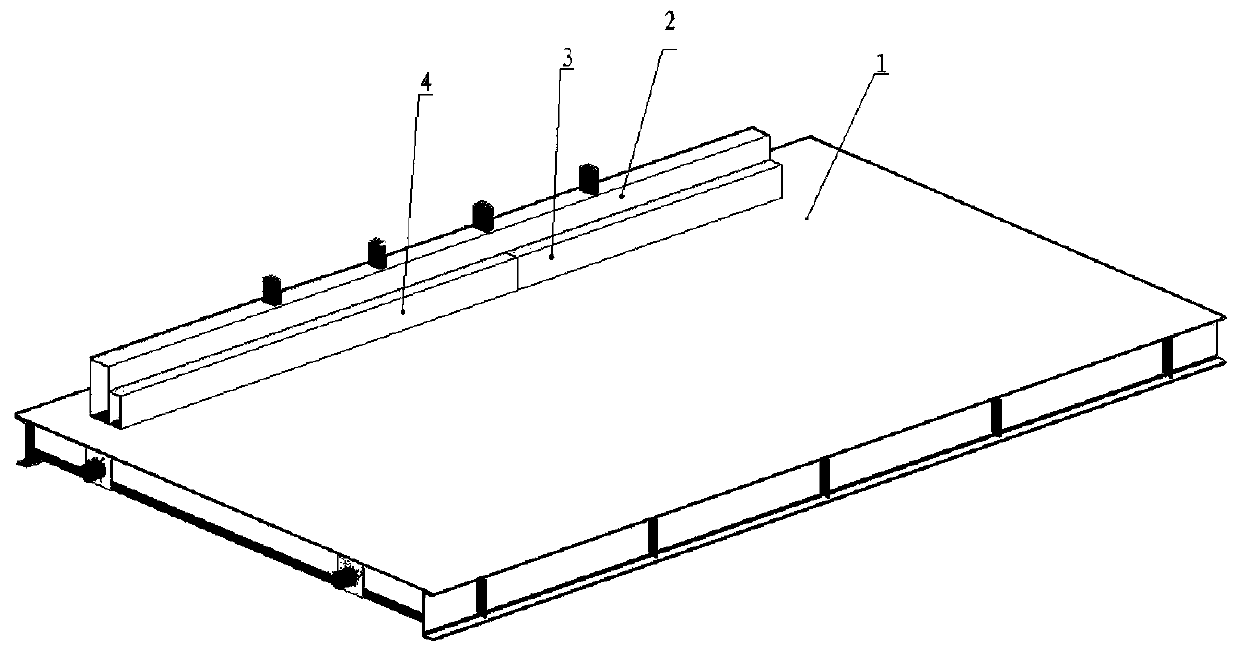

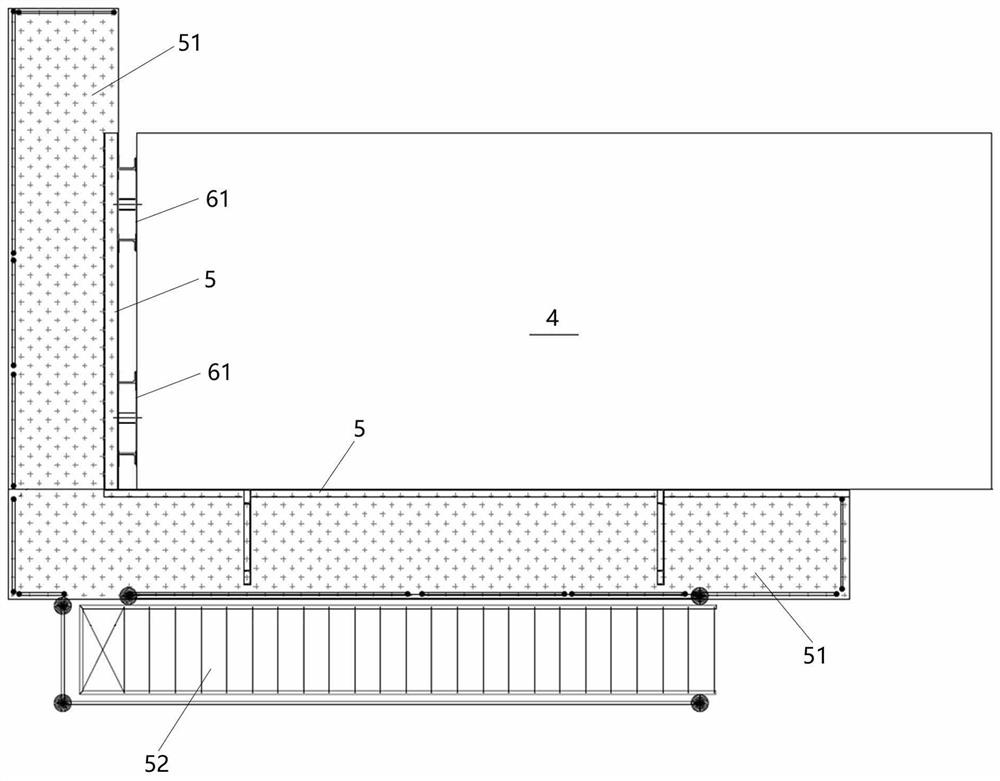

Template erecting method of floor post-cast strip and template used in method

InactiveCN109537881ASimple and fast operationEasy to remove formworkForms/shuttering/falseworksFloor slabEngineering

The invention discloses a template erecting method of a floor post-cast strip and a template used in the method. The template comprises a plate body of a rectangular-plate-shaped structure, wherein the middle of the plate body is provided with an opening extending to the bottom and penetrating through the front side and rear side of the plate body, the plate body is internally provided with a sliding groove, the sliding groove is communicated with the opening, the sliding groove is internally and slidably connected with two symmetrically arranged movable plates, each movable plate is providedwith an upper semicircular gap and a lower semicircular gap, and the semicircular gaps of the two movable plates cooperate to form a through hole allowing a reinforcing steel bar to pass through; oneside of the plate body is provided with elastic assemblies, each elastic assembly comprises a fixing part arranged on the plate body, a connecting part arranged on the corresponding movable plate anda tension spring connected between the corresponding fixing part and connecting part, the number of the elastic assemblies is two group, the movable plates are connected with the elastic assemblies respectively, the elastic force directions of the elastic assemblies connected with the two movable plates are opposite, and the tension springs are detachably connected with the connecting parts. The template erecting method of the floor post-cast strip and the template used in the method have the advantages that the template erecting and disassembling effects are achieved, and the template is noteasy to damage.

Owner:宁波市建筑设计研究院有限公司

Prefabricated ball, production device, production method and use method thereof

PendingCN110424414AGood for scrollingEasy to roll freelyCeramic shaping apparatusEmbankmentsEngineeringBuilding construction

The invention relates to the technical field of large filling, and discloses a prefabricated ball applied to large filling. The ball is a foam lightweight soil product, rapid backfill of a pit can berapidly achieved, the construction period can be greatly shortened, and a production device comprises a foam lightweight soil preparing machine, a casting machine and a ball mold, the structure is simple, the cost is low, the ball mold is easy and convenient to assemble, and mold dismounting and maintaining are facilitated. A production method is simple and easy to operate, commonly, after 24 hours, mold dismounting can be achieved, and after seven days of standing and maintaining, storage can be achieved. A use method is simple, the casting amount of site foam lightweight soil can be greatlyreduced, the filling efficiency is greatly improved, the construction period is shortened, the filling effect of the gap between prefabricated balls is good, the compactness is high, and the whole effect of solidification is good.

Owner:华泰恒生科技发展(北京)有限公司

Multi-hole vacuum casting mould component

The invention relates to a multi-hole vacuum casting mould component which is appropriate for a vacuum casting technique. The multi-hole vacuum casting mould component comprises a mould main body, a graphic cover and a graphic ring, wherein the mould main body consists of a cuboid inner mould and four cuboid outer moulds; the interfaces, adjacent to the outer moulds, of the inner mould are mould joints of a casting mould; multiple mould holes are symmetrically distributed on the peripheral mould joints; a center hole is formed in the inner mould; the handle part of the graphic cover is inserted into the center hole in the inner mould; the graphic ring is located on the mould main body; a graphic ring hole is formed in the center of the graphic ring; the head part of the graphic cover is arranged in the graphic ring; an interval exists between the head part of the graphic cover and the graphic ring. By the adoption of the multi-hole vacuum casting mould component, the casting of multiple castings can be simultaneously completed; the structure is simpler and more reasonable; the economical efficiency is good; as the shunting and the buffering of the graphic cover are adopted, the defects of a top pouring type casting way are overcome better.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

Adjustable double-T-plate moulding die

PendingCN109435024AFast demolition speedIncrease productivityDischarging arrangementMouldsEngineeringChassis

The invention discloses an adjustable double-T-plate moulding die, and mainly relates to the technical field of concrete building material production equipment. The adjustable double-T-plate mouldingdie comprises sliding side dies, a middle fixed die, supporting racks, a fixed bottom rack, end part die structures, barriers, foundation bolts and an operation table, and is characterized in that a width adjusting mechanism is arranged on the top end of each sliding side die; a rib height and rib width adjusting structure is arranged in each sliding side die; a side overturning mechanism is arranged on one side of each rib height and rib width adjusting structure; an ejection pin mechanism is arranged on one side of each side overturning mechanism; vibrators are arranged in the middle fixed die; and the sliding side dies are connected to a slide chute mechanism through the supporting racks.

Owner:DEZHOU HAITIAN ELECTROMECHANICAL TECH

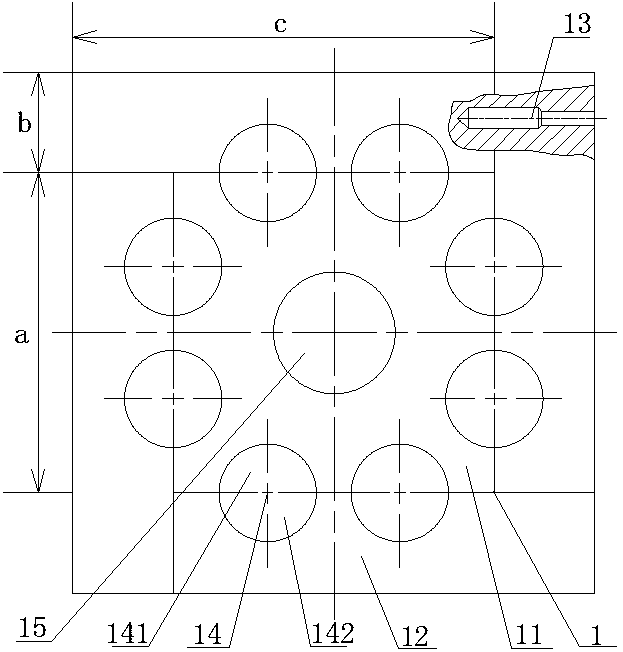

Prefabricated hollow reinforced concrete pouring formwork with cross holes inside and using method of pouring formwork

PendingCN111152340AEasy to installEasy to install and disassembleMouldsMould auxillary partsReinforced concreteArchitectural engineering

The invention provides a prefabricated hollow reinforced concrete pouring formwork with cross holes inside. The pouring formwork comprises a forming cavity used for forming reinforced concrete; a plurality of longitudinal core tubes used for forming longitudinal core holes are evenly distributed in the forming cavity longitudinally; a plurality of movable transverse core tubes used for forming transverse core holes are telescopically installed in each longitudinal core tube; the length of each movable transverse core tube is adapted to the distance between every two adjacent longitudinal coretubes, and the length direction of each movable transverse core tube is perpendicular to that of each longitudinal core tube; and the pouring formwork further comprises core tube retracting and protruding mechanisms used for driving the movable core tubes to move in a direction perpendicular to the length direction of the longitudinal core tubes. According to the pouring formwork, a hollow formwork is prefabricated in a factory, so that site construction efficiency is effectively increased; and moreover, the pouring formwork is simple in structure, convenient to operate and high in operation efficiency, and can greatly shorten factory prefabrication time.

Owner:FUJIAN QUNFENG MACHINERY

Construction method adopting aluminum formworks

InactiveCN107654062AOptimize the construction processImprove production efficiency and production effectAuxillary members of forms/shuttering/falseworksForming/stuttering elementsAluminiumEngineering

The invention relates to the construction field, in particular to aluminum formworks. A construction method adopting aluminum formworks comprises the following steps that firstly, the aluminum formworks are installed; secondly, back ribs are erected to support the aluminum formworks; thirdly, a K plate is arranged between the upper and lower layers of aluminum formworks, and the outer side of theK plate is provided with a first flange which is inclined from top to bottom; fourthly, back ribs are erected to support the K plate; and fifthly, nuts for fixing the K plate are installed. Through the construction method, the construction process applied when the aluminum formworks are adopted is optimized, and the production efficiency and product effect are improved. One side of the K plate isprovided with the first flange, falling concrete is prevented from adhering to the aluminum formworks, increase of the weight of the aluminum formworks is avoided, and the falling concrete is not solidified when just falling off, thereby being made to slide from the K plate when falling onto the K plate.

Owner:梁瑞武

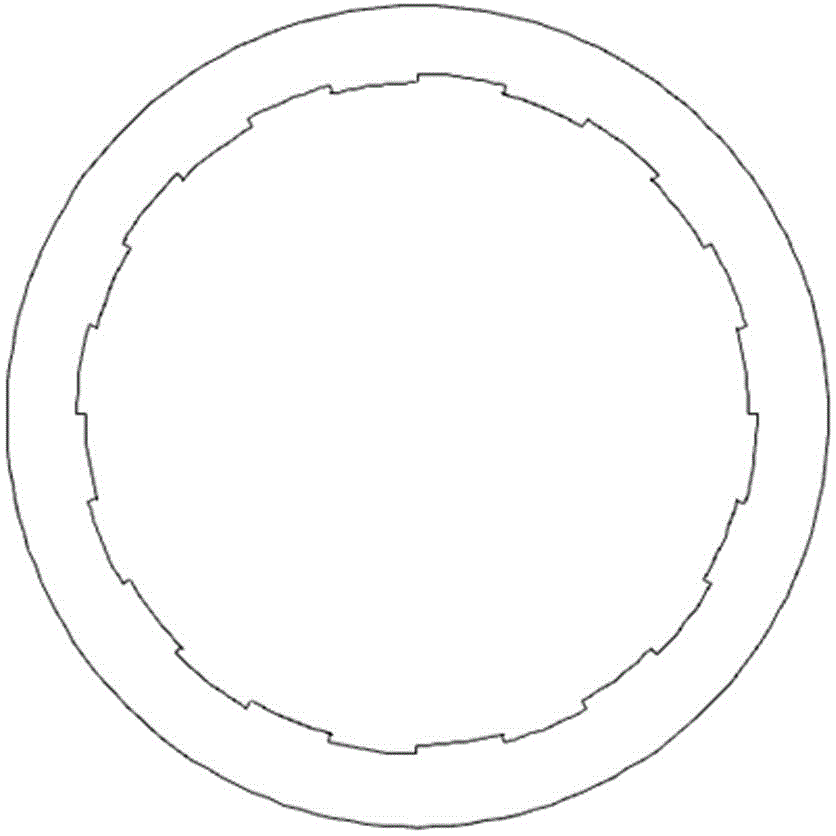

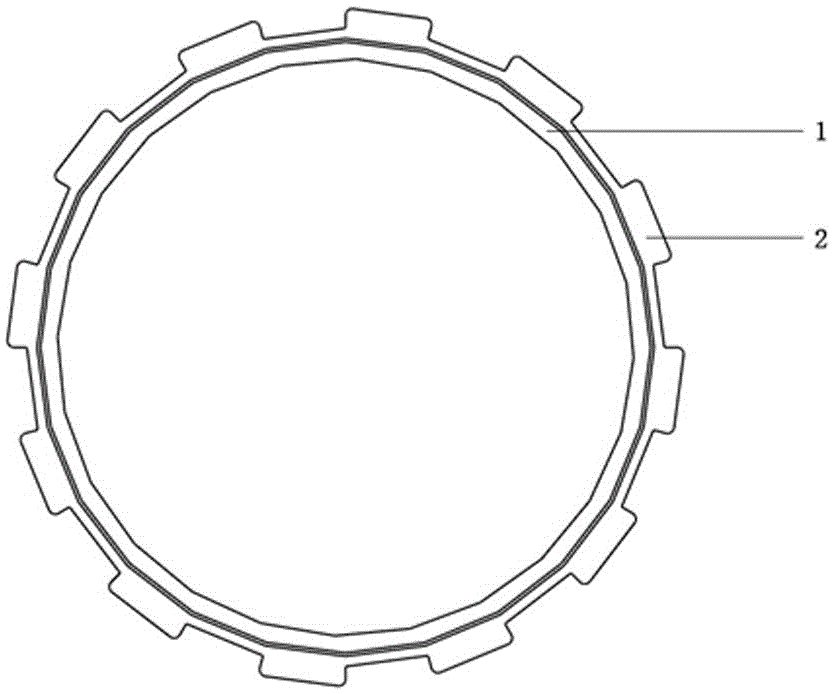

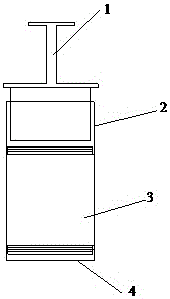

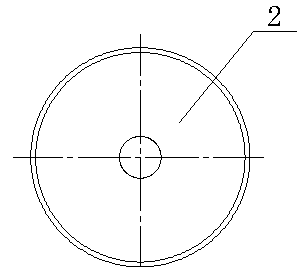

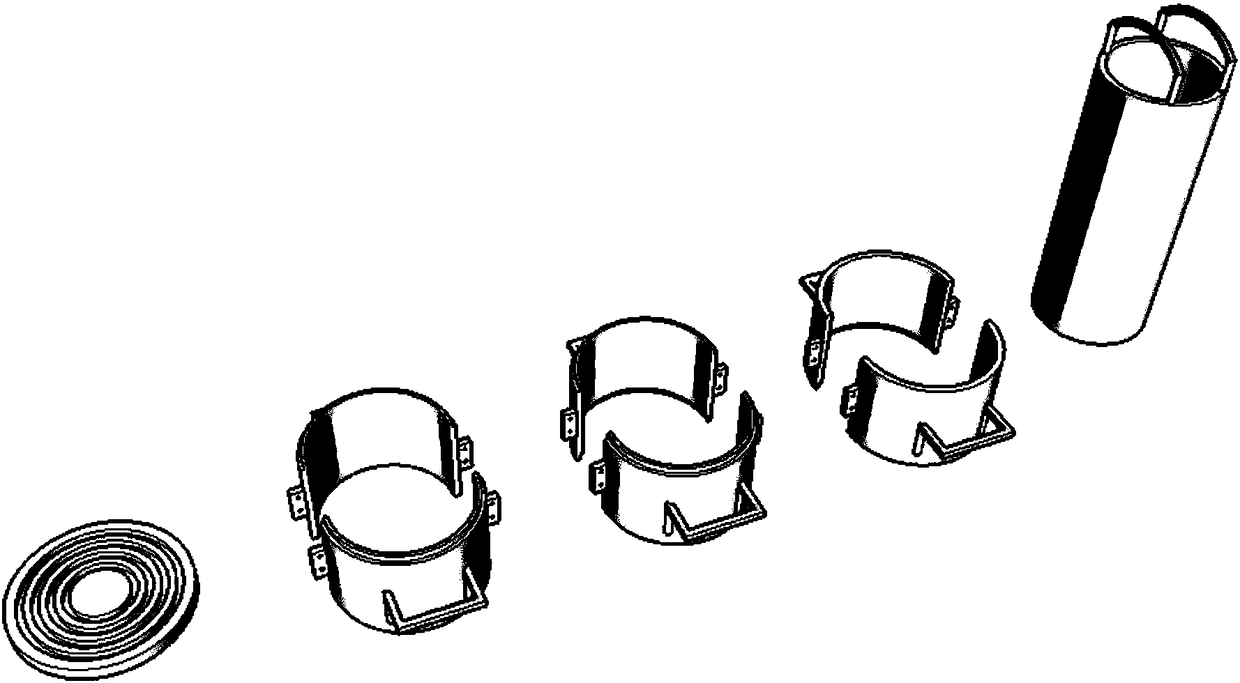

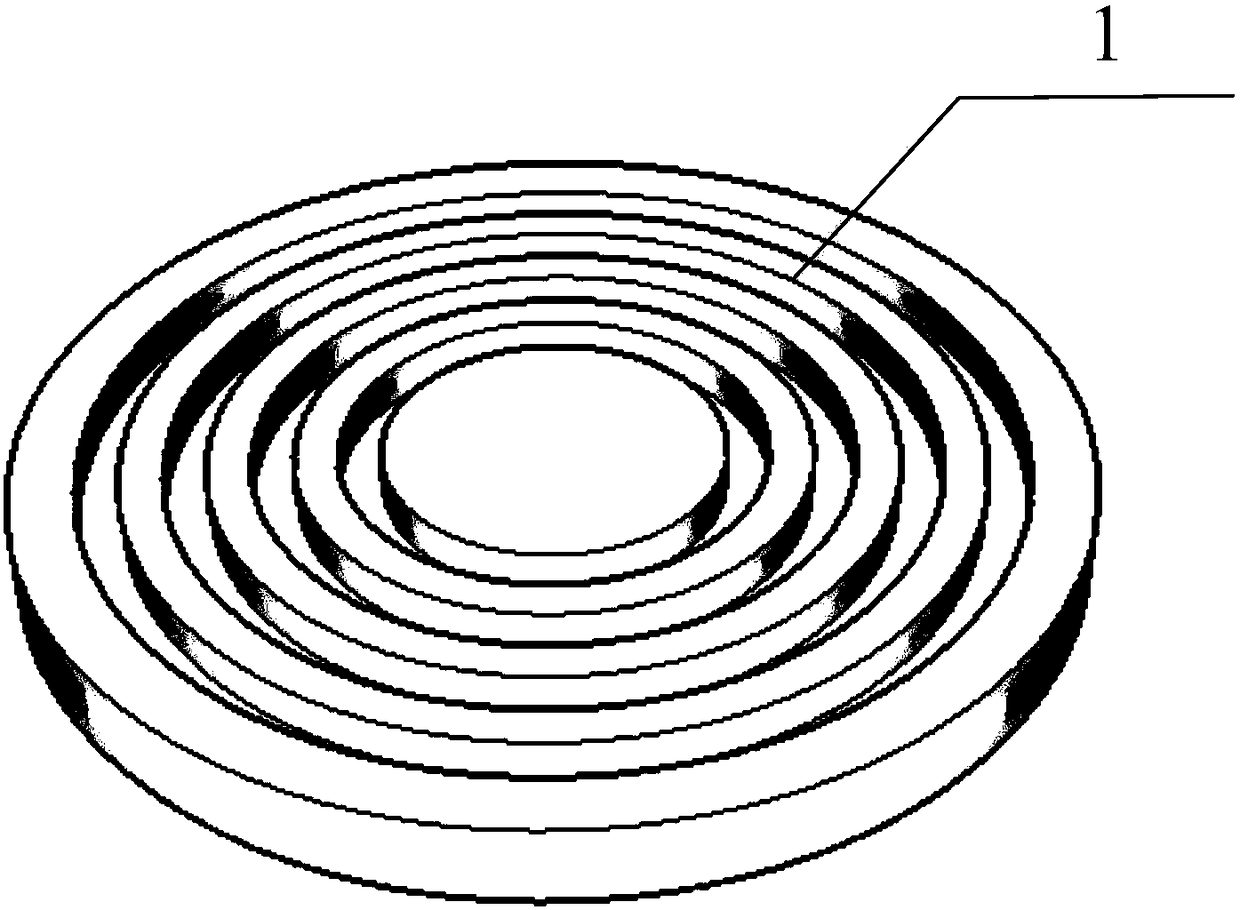

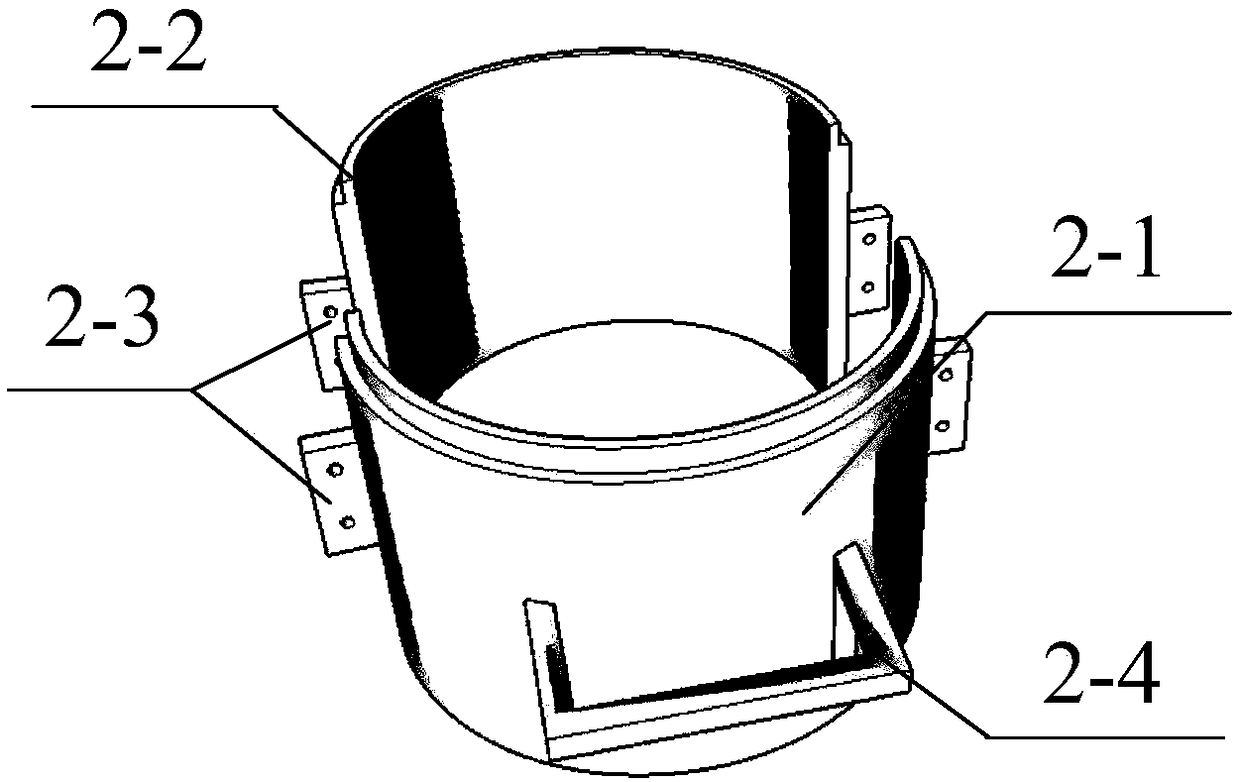

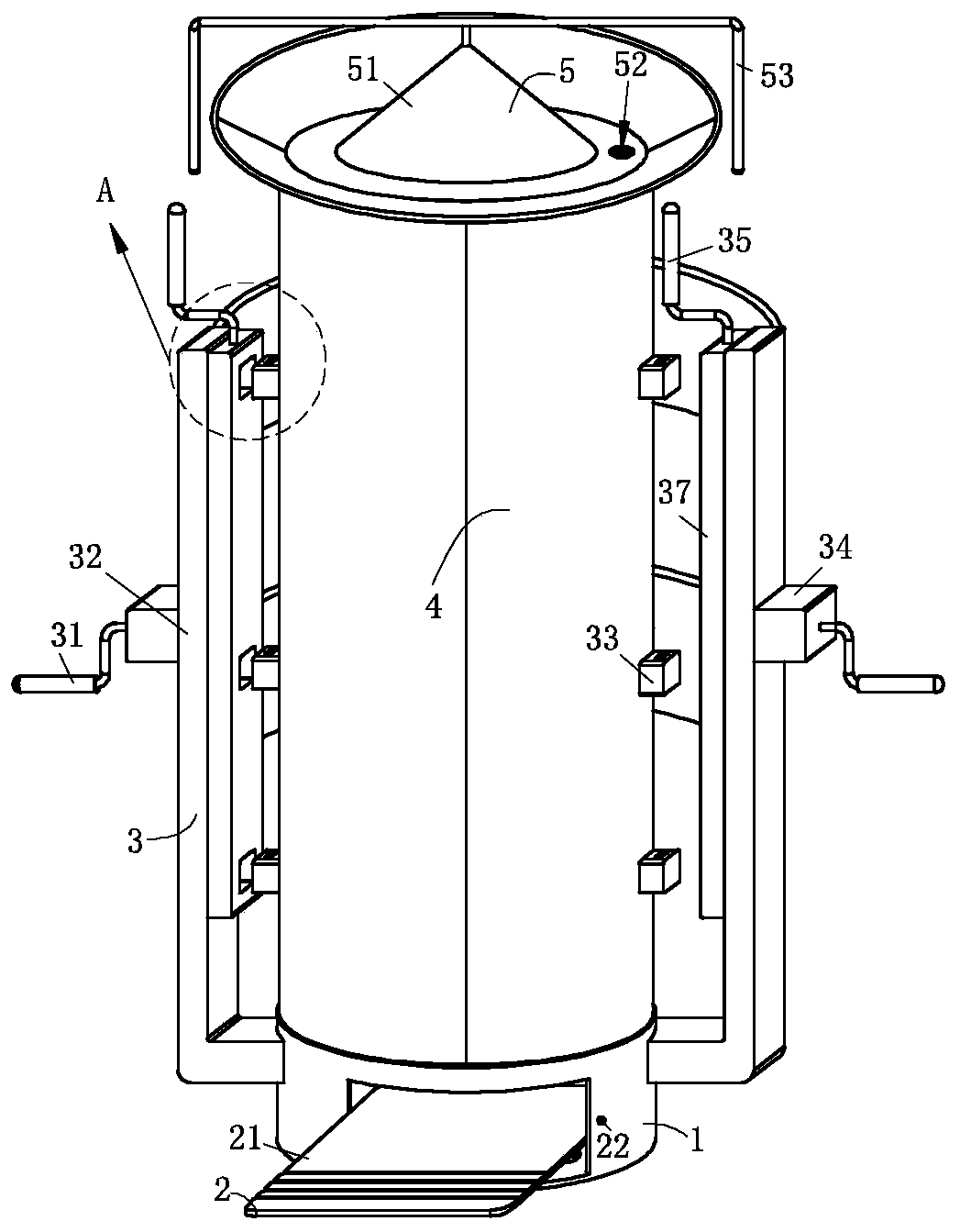

Test mold device for pouring hollow cylindrical mortar test piece

PendingCN108257498AGuarantee the pouring qualityLow costPreparing sample for investigationEducational modelsHollow cylinderMaterials science

The invention discloses a test mold device for pouring a hollow cylindrical mortar test piece. The test mode device comprises a test mold base, an outer test mold cover and an inner test mold liner. The test mode base is a circular iron plate engraved with a plurality of concentric circular-ring-shaped grooves. The outer test mold cover consists of a bottom outer cover, a standard layer outer cover, and a top outer cover. The inner test mold liner is a long hollow cylinder. The outer test mold cover is assembled; the assembled outer test mold cover and the inner test mold liner are arranged onthe test mold base to form hollow cylindrical pouring space. According to the invention, hollow cylindrical mortar test pieces with different specifications are poured by adjusting the dimensions ofthe outer test mold cover and the inner test mold liner. An effective test data support can be provided for water and earth pressure study of the underwater tunnel and the assistance is provided for the theoretical analysis.

Owner:ZHEJIANG UNIV

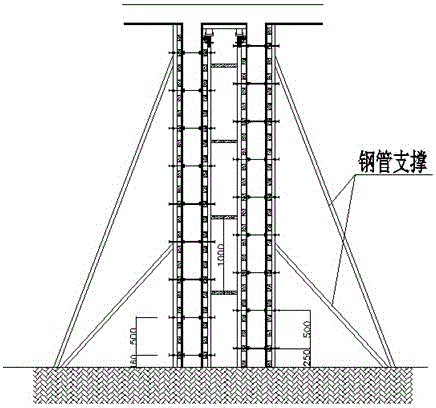

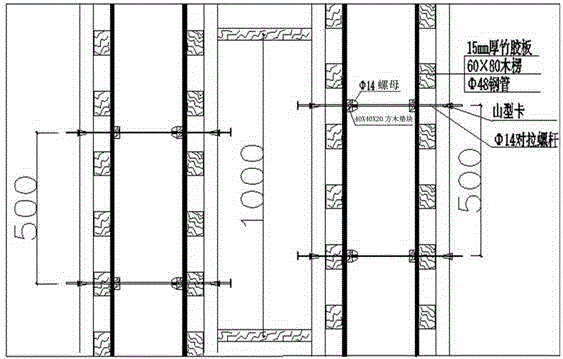

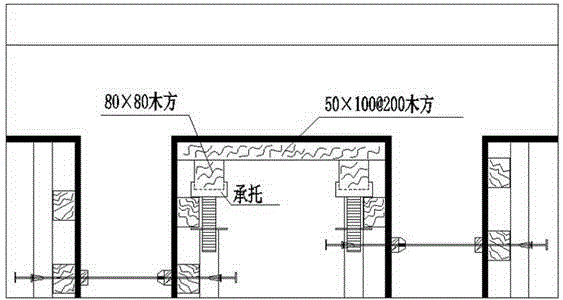

Vault shear wall anti-explosion and drilling-resistant formwork erecting construction method

InactiveCN106437140AReduce supportReduce the difficulty of dismantlingForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksShear wallBuilding construction

The invention relates to a vault shear wall anti-explosion and drilling-resistant formwork erecting construction method. The construction method comprises the following steps that (1) materials are selected; (2) ambulatory wall formworks are erected; (3) ambulatory cast-in-place slab formworks are erected; and (4) the formworks are dismounted. During formwork design, fixing inner nuts are used on the inner sides, and left split bolts and right split bolts are staggered up and down. The method has the advantages that through the vault shear wall anti-explosion and drilling-resistant formwork erecting construction method, the formwork erecting and dismounting difficulty is lowered, and thus the construction quality is well ensured.

Owner:JIANGSU JIANGZHONG GROUP

Intelligent side forms mold device

PendingCN109676757AGuaranteed not to shiftGuaranteed dimensional accuracyMould fastening meansControl systemAlloy

The invention discloses an intelligent side forms mold device. The mold device comprises a mold body, a robot and a control system, wherein the mold body comprises a working mold table and a pluralityof main molds and working molds arranged on the surface of the working mold table; the main molds and the working mold are all made of aluminum alloy profiles and are provided with various standard sizes; a plurality of mounting ears is fixedly arranged on the surface of the main molds;, the inner side of each mounting ear is provided with a conductive probe; the bottom of each main mold is alsoprovided with electric permanent magnet connected to the conductive probe; the side wall near to the electric permanent magnet is provided with a plurality of reserved holes; the robot is provided with a clamp; a working end of the clamp is provided with a female plug matching with the conductive probe; and a path is formed by the combination of the conductive probe and the female plug to controlthe charging and discharging of the electric permanent magnet. Compared with the prior art, the structure of the mold device is simple and light, the design is reasonable, the operation is convenient,the mold body of any size can be spliced according to actual needs, the electric permanent magnet ensures that the working mold table dose not shift during vibration, and the dimensional accuracy ofa PC component is ensured.

Owner:南阳精工匠人装配建筑科技有限公司

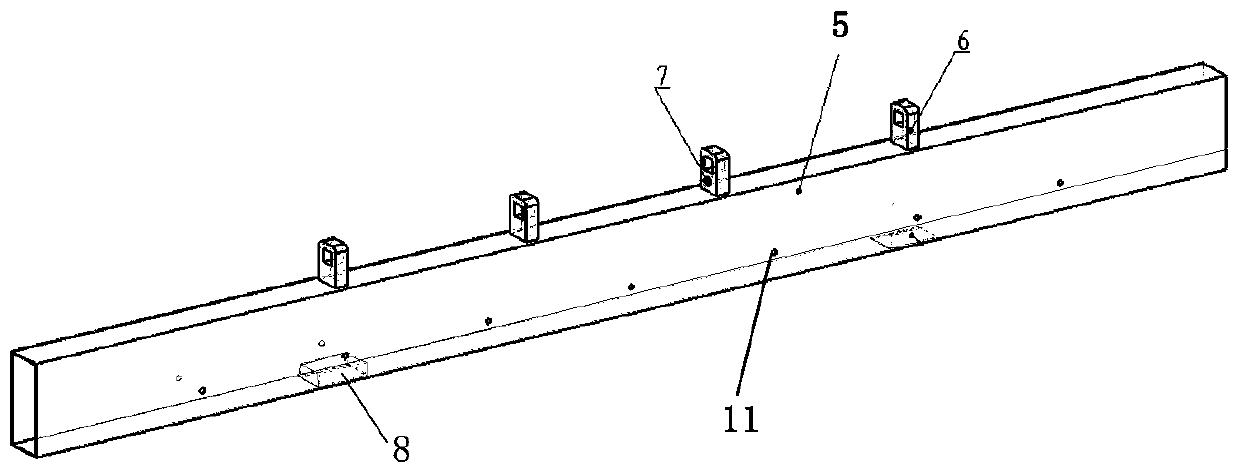

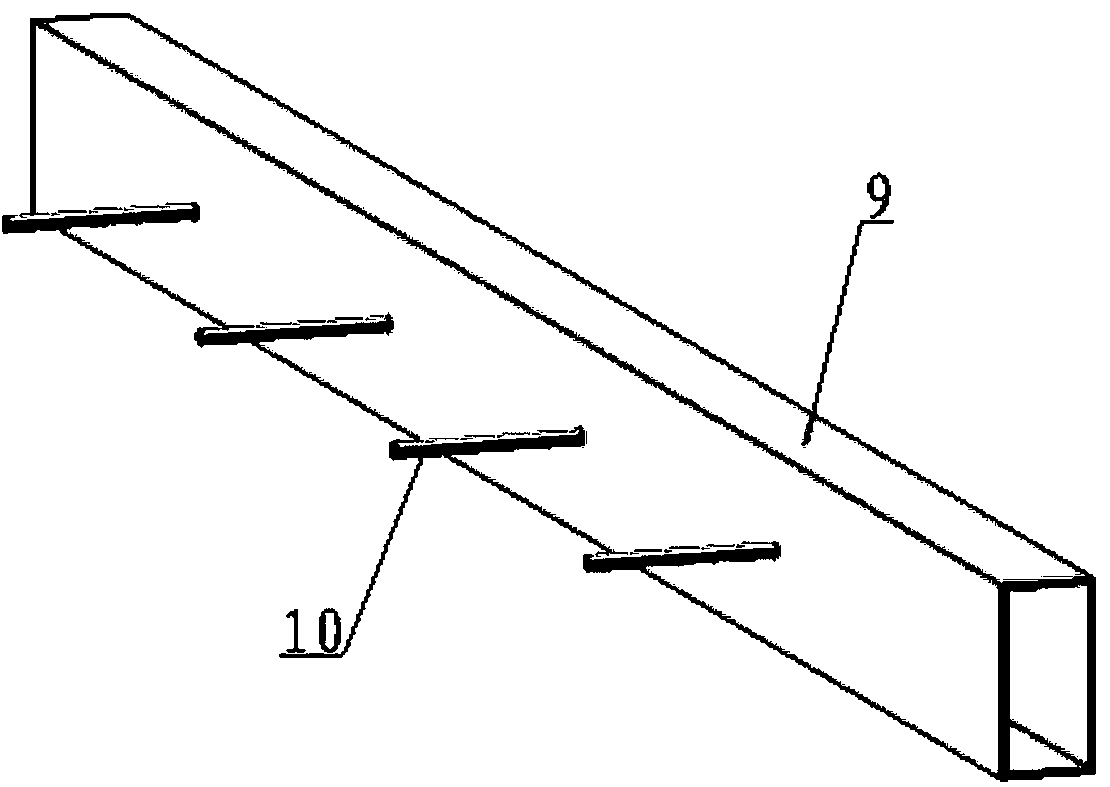

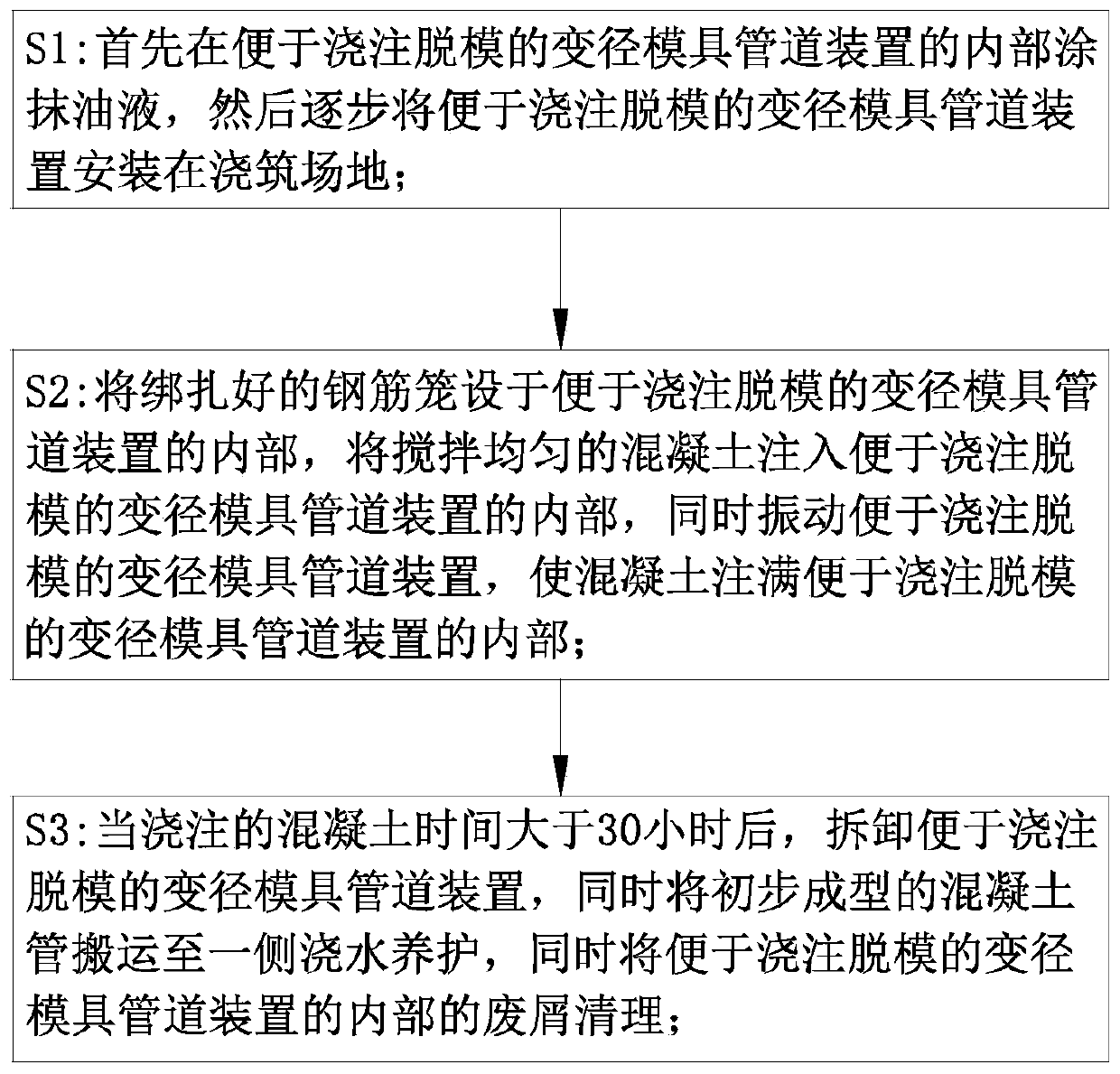

Variable-diameter mold pipeline device facilitating pouring and stripping and variable-diameter method

ActiveCN110370450AEven by forceImprove the forceShaping reinforcementsMaterials scienceStructure control

The invention relates to the field of molds, in particular to a variable-diameter mold pipeline device facilitating pouring and stripping and a variable-diameter method. The variable-diameter mold pipeline device convenient facilitating pouring and stripping in the method comprises a base, a vibrating structure, a limiting structure, first mold plates, a flow guide structure and a mold stripping structure, wherein the limiting structure is connected to the base, so that the two first mold plates which are of semi-annular structures and are used for pouring a concrete pipe can be convenientlycontrolled to move north or relative to each other through the limiting structure, so that the stress between the two first mold plates is more uniform, repositioning in the process of the first moldplates is avoided, the mold stripping structure is arranged inside a cylinder cavity defined by the two first mold plates, the mold stripping structure is fixed on the base, so that the stress of an inner mold is more uniform, mold stripping after the concrete pipe is formed is more convenient and rapid, the concrete pipe is effectively prevented from rotating in the mold stripping process, so that the mold stripping efficiency and quality of the concrete pipe is greatly improved.

Owner:芜湖新芜新型建材有限公司

Method for manufacturing rapidly-detachable rebuilt and reassembled composite building unit

InactiveCN112359962AQuality improvementReduce weightForms/shuttering/falseworksConstruction engineeringBuilding unit

The invention discloses a method for manufacturing a rapidly-detachable rebuilt and reassembled composite building unit. The method includes the steps of firstly, respectively and independently prefabricating plates such as a top plate, wallboards and the like of the building unit, reserving post-cast strips and exposed reinforcing steel bars between the adjacent plates, and fixing the prefabricated wallboards on a bottom table and a formwork fixed at the outer side of the bottom table; fixing the top plate on a top plate support frame mounted on the bottom table, binding the reinforcing steelbars at the post-cast strips of the wallboards and the top plate, and mounting wallboard inner and outer molds and a top plate bottom mold; and then pouring concrete at the post-cast strips of the wallboards and the top plate to form the top plate and the wallboards which are integrally connected, and finally combining the wallboards with a bottom plate are to form the complete building unit. According to the method for manufacturing the rapidly-detachable rebuilt and reassembled composite building unit, a mold inner container does not need to be manufactured, and building units with the length and the width smaller than or equal to the length and the width of the bottom table can share one set of the molds, so that the use amount of the formworks can be greatly reduced, the mold manufacturing cost can be reduced, and mold mounting and mold dismounting are very rapid and easy.

Owner:YOULIHUA BUILDING MATERIALS HUIZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com