Prefabricated hollow reinforced concrete pouring formwork with cross holes inside and using method of pouring formwork

A technology of reinforced concrete and cross holes, applied in the direction of molds, manufacturing tools, mold auxiliary parts, etc., can solve the problems of low production efficiency and unstable quality, and achieve the effects of improving assembly efficiency, convenient installation of sealing structures, and convenient removal of molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

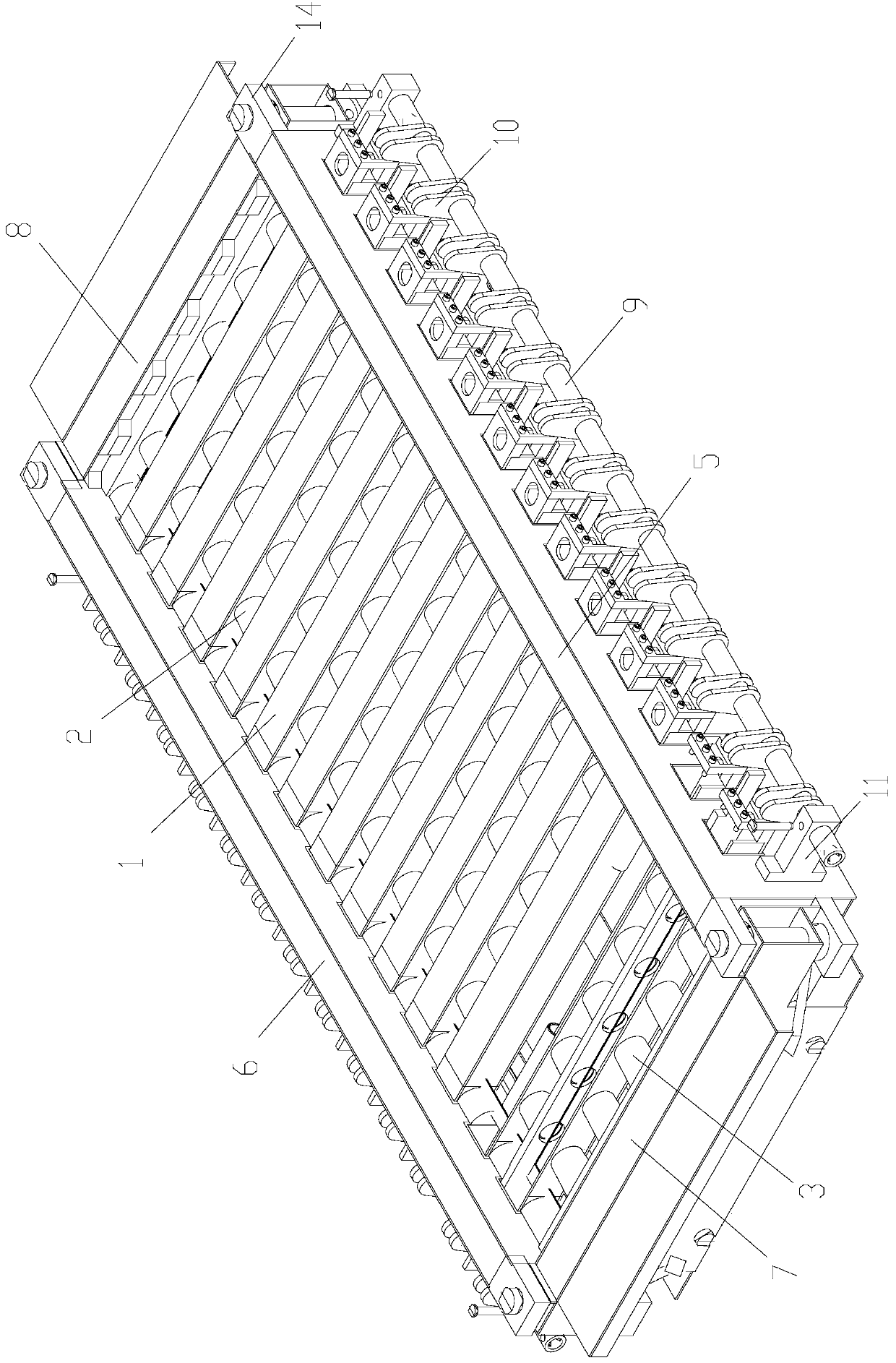

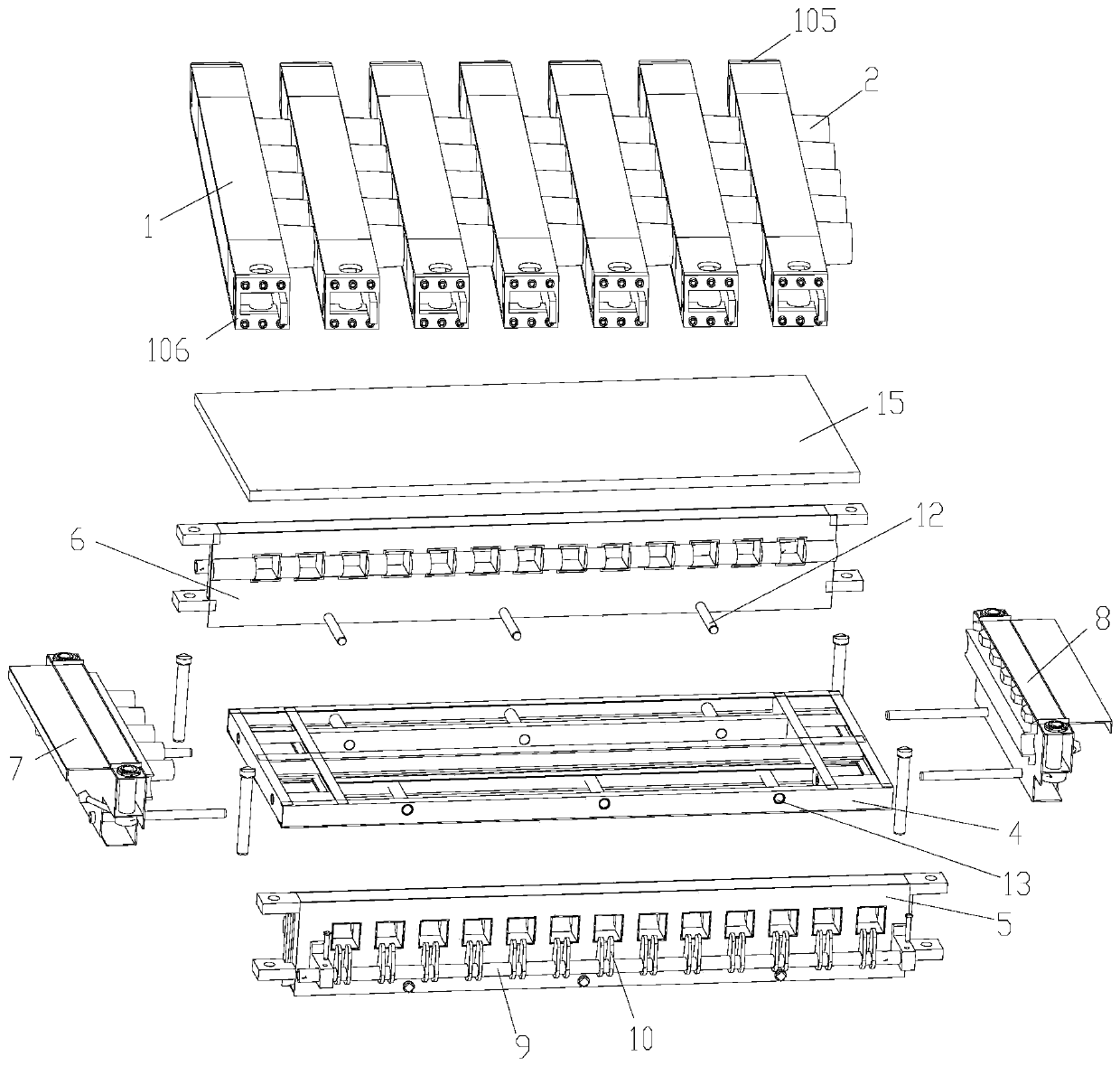

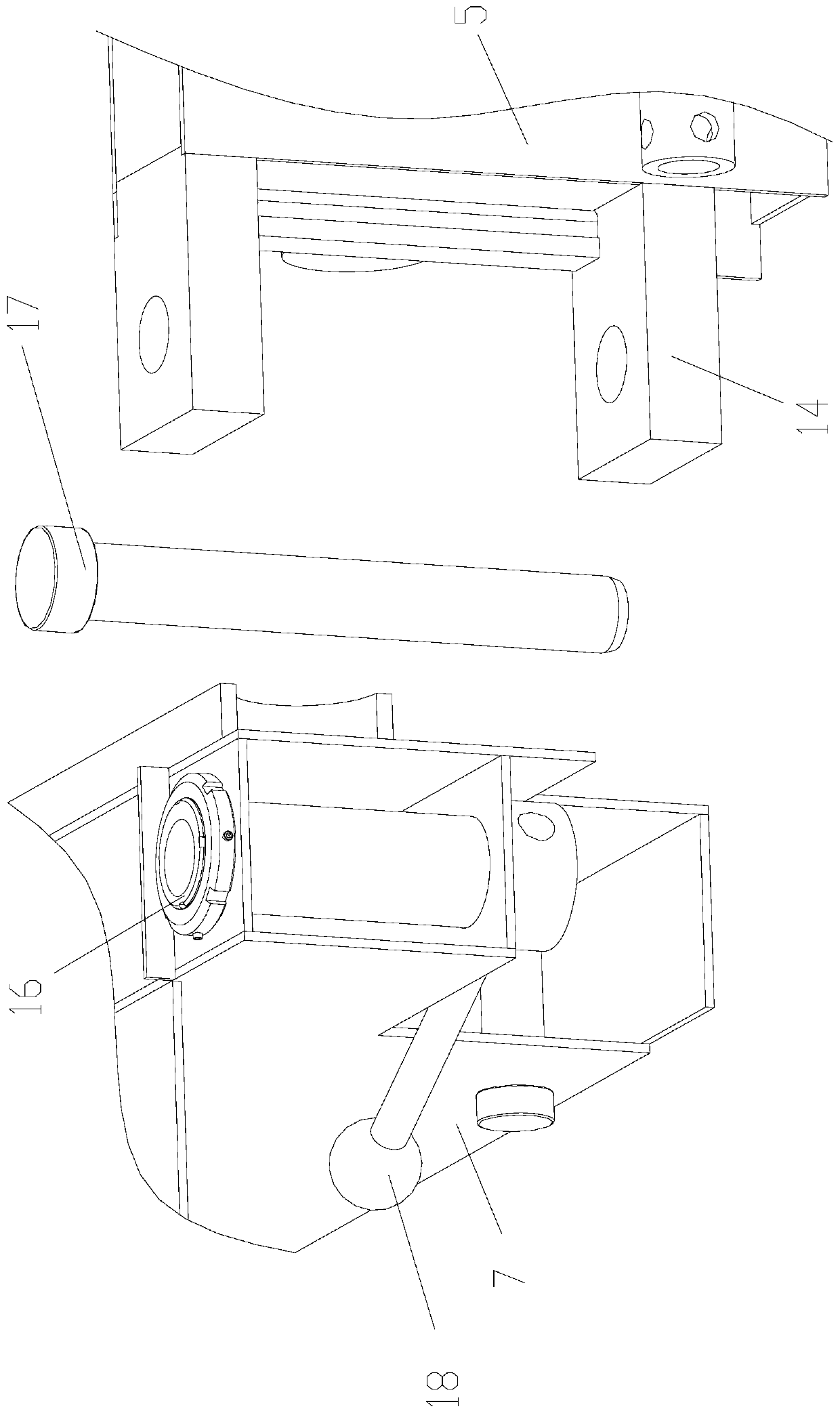

[0033] Specific embodiment 1: as Figure 1-5 As shown, this embodiment provides a pouring formwork for prefabricated hollow reinforced concrete with intersecting holes inside. The intersecting holes of reinforced concrete are formed by crossing several transverse core holes and several longitudinal core holes, including forming cavities for forming reinforced concrete , there are several longitudinal core tubes 1 uniformly distributed longitudinally in the molding cavity for forming longitudinal core holes, and several movable transverse core tubes 2 are telescopically installed in each longitudinal core tube 1, and the movable transverse core tubes 2 The length direction of the longitudinal core tube 1 is perpendicular to the length direction of the longitudinal core tube 1, and the movable transverse core tubes 2 on each longitudinal core tube 1 are arranged in one-to-one correspondence and the length of the movable transverse core tube 2 is the same as the distance between t...

specific Embodiment 2

[0042] Specific embodiment 2: the present embodiment provides a kind of using method of pouring formwork, comprises the following steps:

[0043] (1) Insert the positioning posts 12 on the front side plate 5, rear side plate 6, left side plate 7 and right side plate 8 into the positioning holes 13 of the bottom frame 4, and at the same time, the left side plate 7 and the right side plate 8 snap Insert the pin into the I-shaped connector 14 of the front side plate 5 and the rear side plate 6, then insert the latch into the eccentric sleeve 16 of the left side plate 7 and the right side plate 8, turn the handle to lock it quickly, and then place the supporting plate 15 On the bottom frame 4, a molding cavity is formed;

[0044] (2) Laying steel bars in the forming cavity, after laying, the longitudinal core tube 1 is inserted into the forming cavity from the core hole, and the plectrums 104 at both ends of the longitudinal core tube 1 expose the core tube cavity 103;

[0045] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com