Multi-hole vacuum casting mould component

A vacuum casting and mold technology, which is applied in the field of casting molds, can solve problems such as unstable filling process, slag inclusion, and insufficient structure, and achieve the effects of uniform and stable filling process, reduced casting speed, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

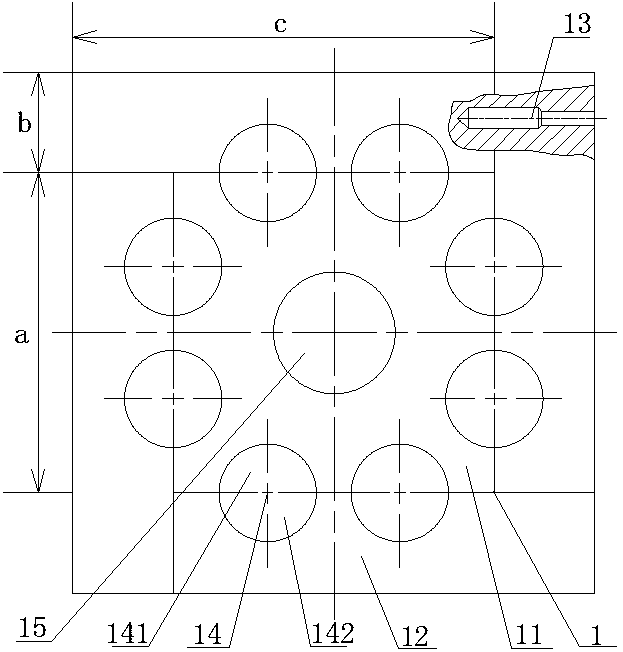

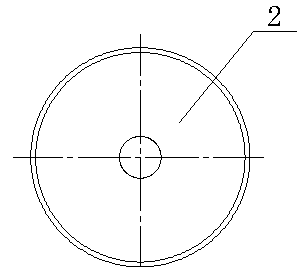

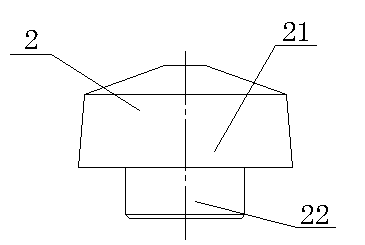

[0028] The present invention will be further described below in conjunction with the accompanying drawings and examples.

[0029] see Figure 1-Figure 7 , the present embodiment comprises: mold main body 1, graphite cover 2 and graphite ring 3, described mold main body 1 is made up of an inner mold 11 of a rectangular parallelepiped whose application surface is a square and four outer molds 12 of a rectangular parallelepiped whose application surface is a rectangle , the four outer molds 12 have the same shape and size, and the sum of the application surface side length a of the inner mold 11 and the short side length b of the application surface of the outer mold 12 is equal to the long side length c of the application surface of the outer mold 12, and the main body of the mold 1 The application surface is square; the four outer molds 12 are surrounded by the inner mold 11, and two adjacent outer molds 12 are connected by positioning pins 13; two inner mold holes are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com