Test mold device for pouring hollow cylindrical mortar test piece

A hollow cylinder and mold test technology, applied in the field of construction, can solve the problems of discount of theoretical research, difficult to realize test, loss of test data, etc., to ensure the quality of pouring, reduce impact, and save costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

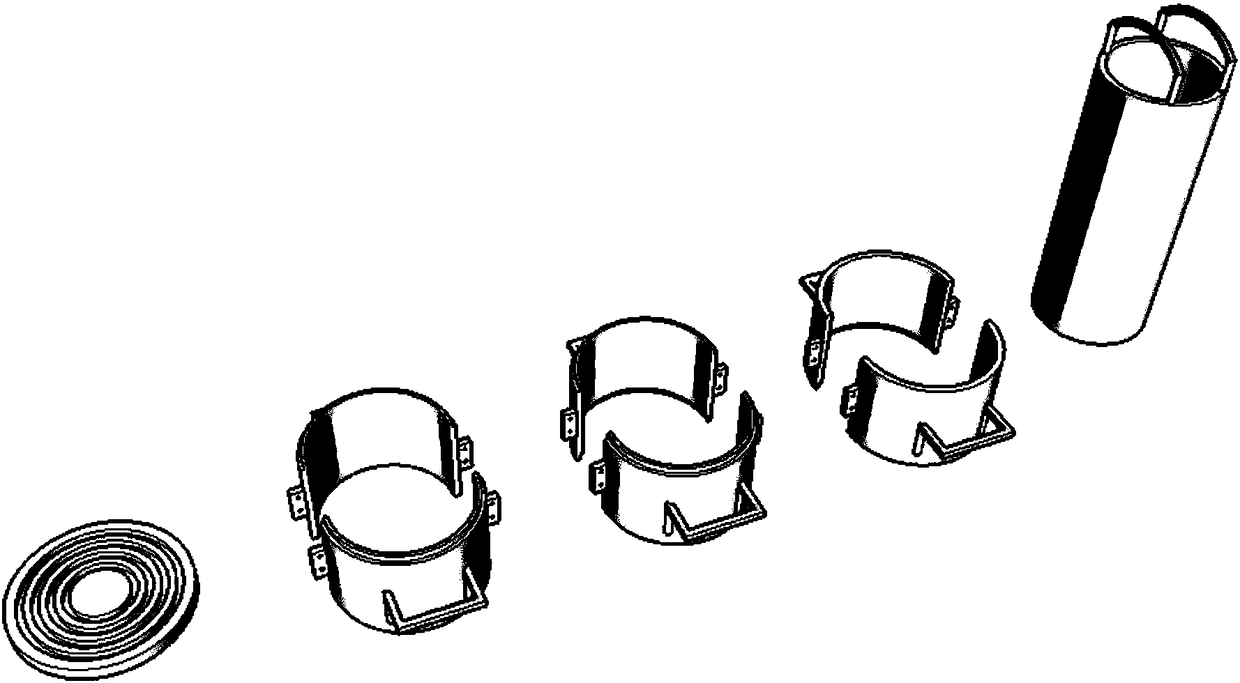

[0022] Such as figure 1 As shown, the present embodiment provides a mold trial device for pouring hollow cylindrical mortar specimens, which includes three parts: a trial mold base 1 , a trial mold outer cover and a trial mold liner.

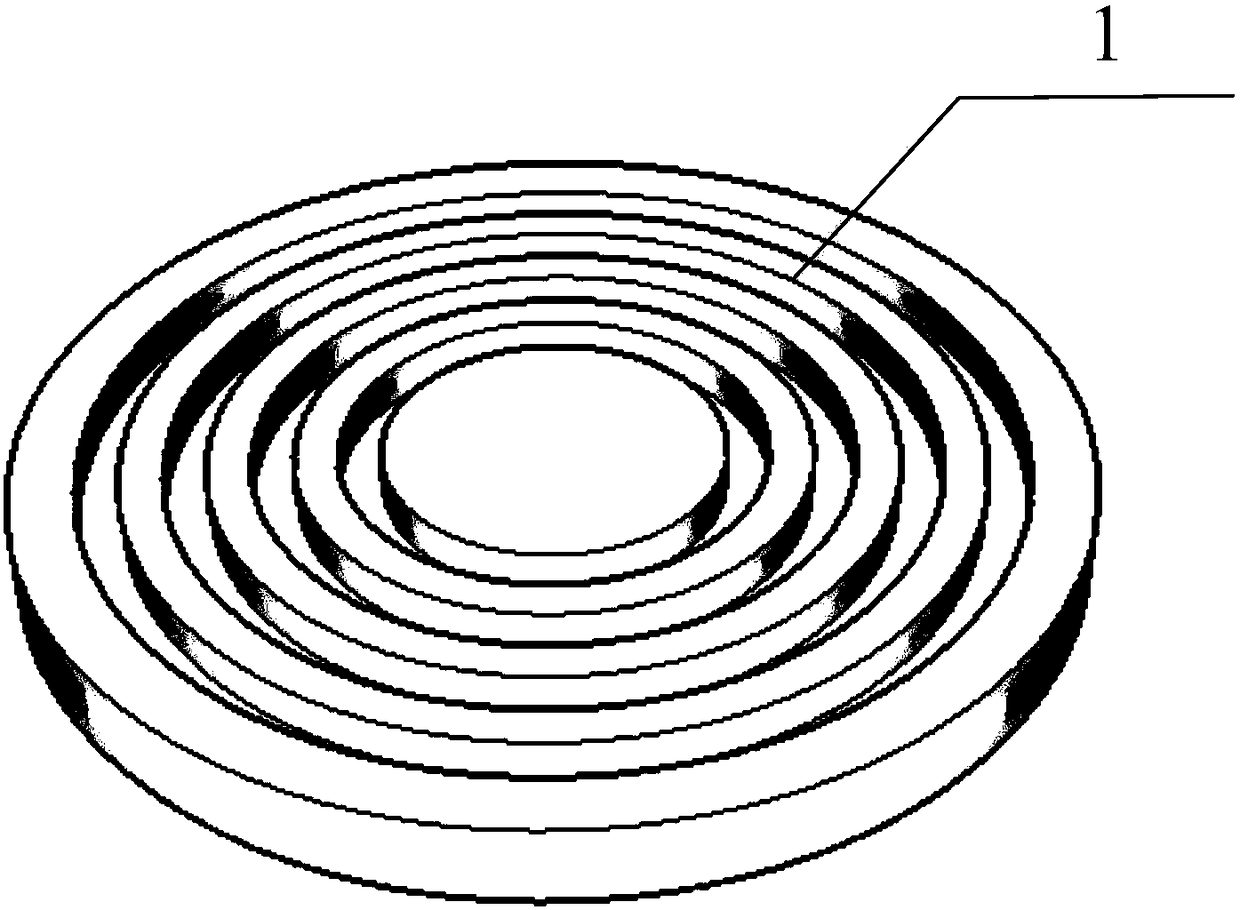

[0023] Such as figure 2 As shown, the test mold base 1 is a circular iron plate with 4 concentric circular grooves. In this example, the diameter of the circular steel plate is 250mm, and the thickness is 20mm. The inner and outer diameters of the first groove are respectively 200mm, 220mm, the second groove is 160m, 180mm, the third groove is 120mm, 140mm, the fourth groove is 80mm, 100mm.

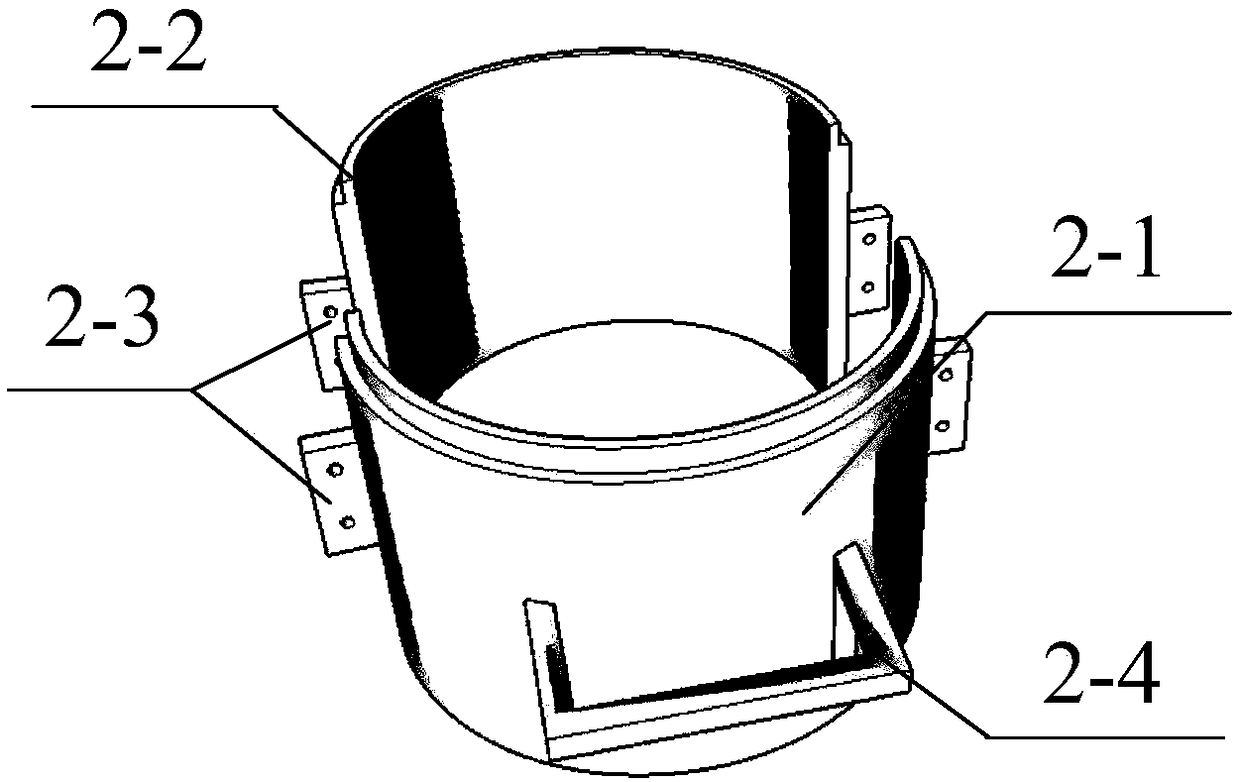

[0024] The tryout cover includes a bottom cover, a standard cover and a top cover.

[0025] Such as image 3 As shown, the bottom cover is two consistent 180° curved steel plates A2-1, the inner and outer diameters of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com