UHPC (ultra-high performance concrete) poured orthotropic steel bridge deck combination structure and manufacturing method thereof

A combined structure and orthotropic technology, used in bridges, buildings, bridge parts, etc., can solve problems such as affecting bearing capacity, high price, easy aging, etc., to ensure driving safety, small bulk density, and ultra-high durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

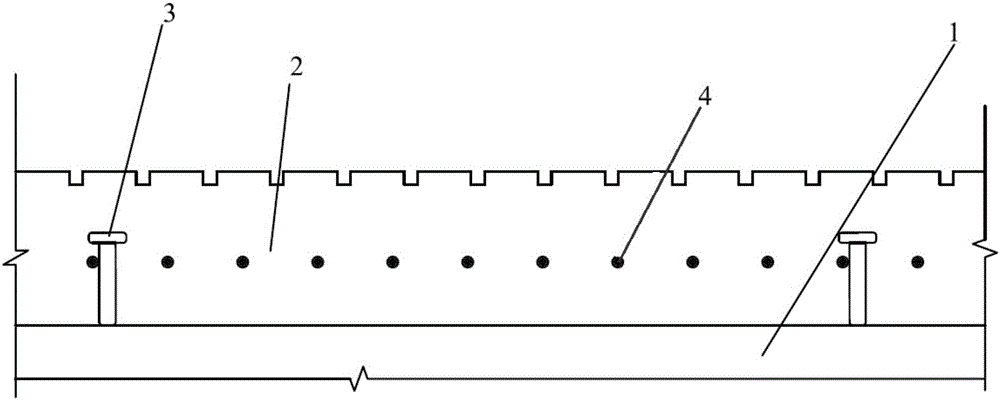

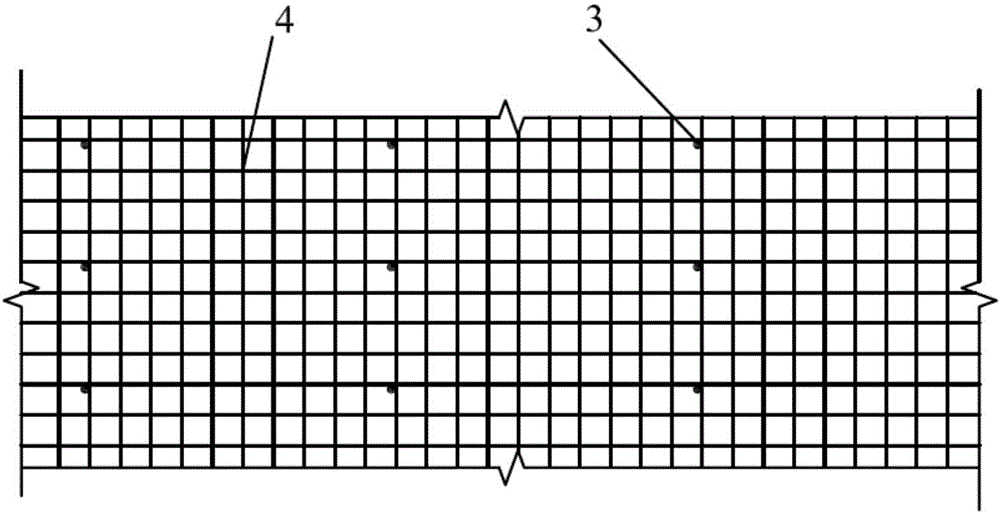

[0027] refer to Figure 1-6 , the implementation section is 36m long and 9.05m wide, totaling 325.8m 2 The pavement plan for the implementation section is to pour 8cm UHP2 and score it as a wear layer. Steel bridge deck 1 is derusted by hand and angle grinder, and the derusting standard reaches Sa2.5. Before rust removal, use a scraper or spatula to remove loose paint and rust layers, use mechanical wire brushes, grinding wheels or paper grinding wheels to polish the surface of the facility, and make the surface as rough as possible, and use angle grinding for the corners of the facility Machines, wire brushes or flat files and other tools for processing, and finally use rags, cotton yarn or compressed air to clean the derusted facilities to keep the surface clean.

[0028] The specification of the shear nails 3 is Φ16×45mm, and the interval is 400×400mm, and the setting-out positioning is carried out before construction. Special bolt welding equipment is used for welding. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com