Steel arch rib outer wrapped concrete construction method for steel trussed arch bridge

A technology of outsourcing concrete and construction method, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of difficult to control the quality of concrete construction, difficult construction of outsourced concrete, complicated supporting erection process, etc., so as to improve the overall construction Quality, overcoming narrow scope of application, strong applicability and economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0033] The invention provides a method for erecting a side-span steel truss girder of a cable-stayed bridge, comprising the following steps:

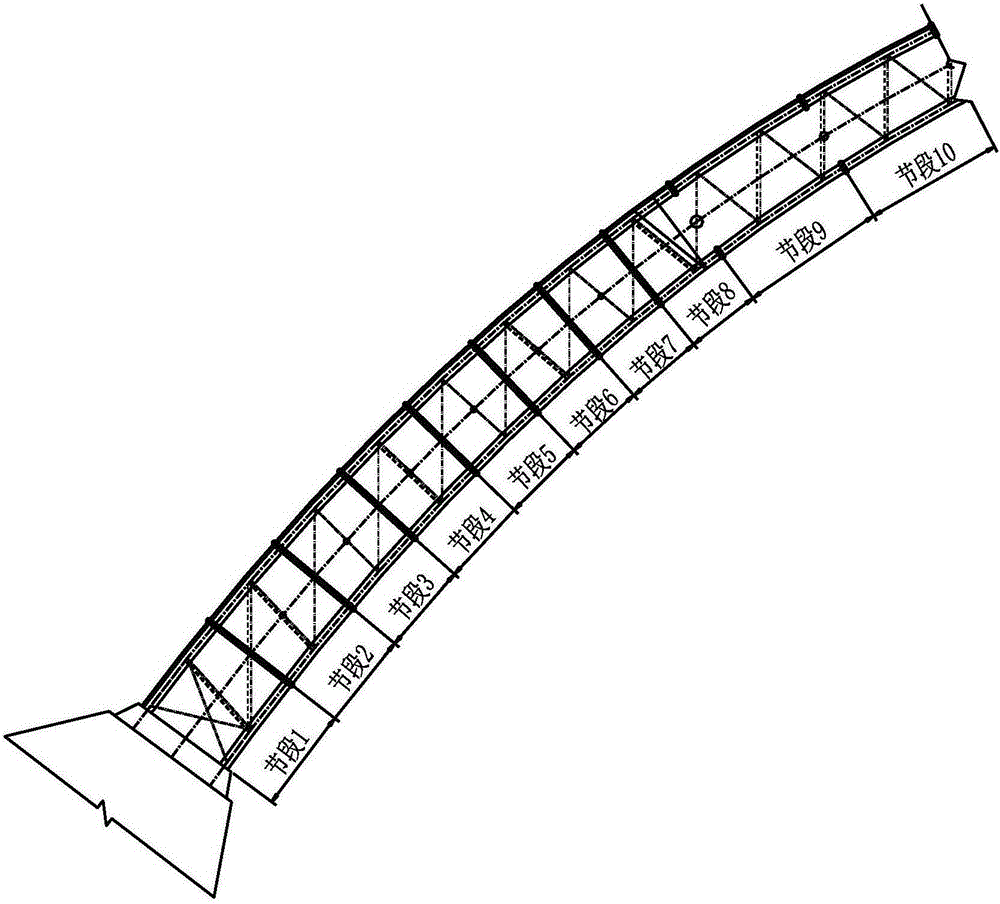

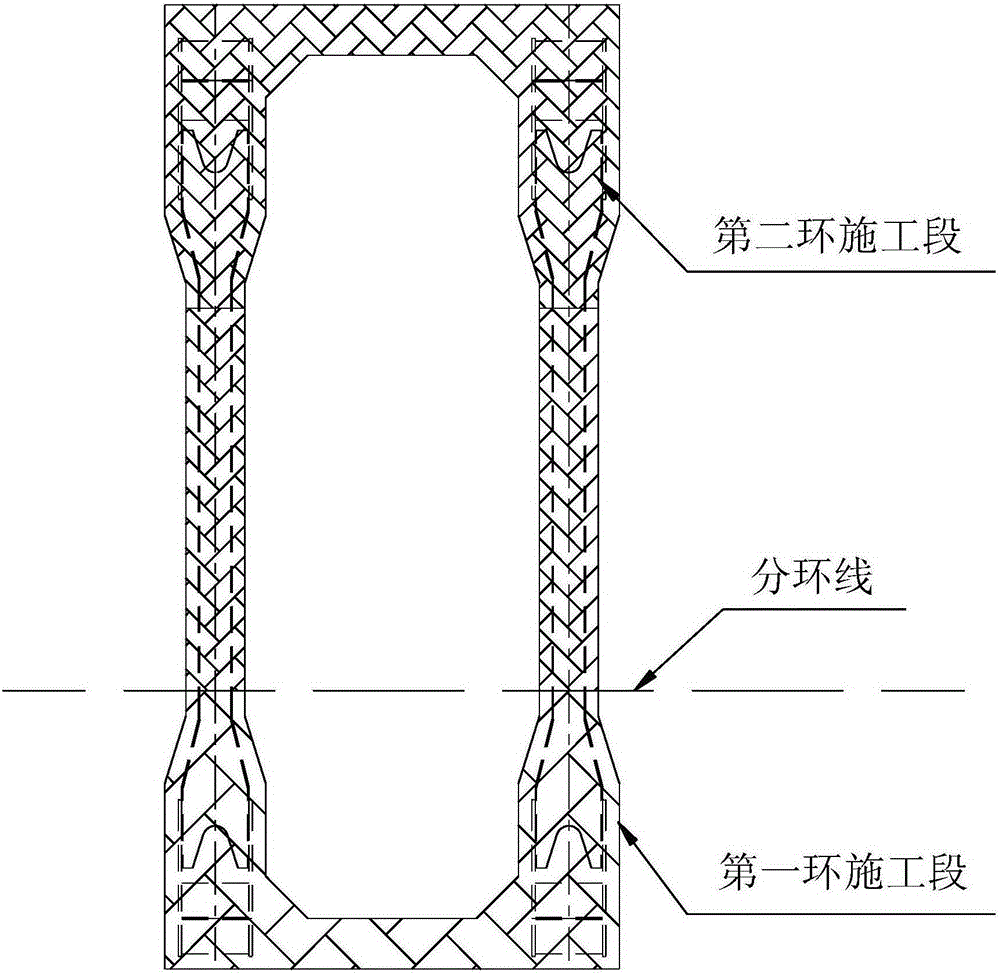

[0034] S1: see figure 1 As shown in , the steel arch rib is divided into several steel arch rib segments along the direction of the bridge; see figure 2 As shown, each steel arch rib segment is divided into the first ring construction section and the second ring construction section from bottom to top, go to S2.

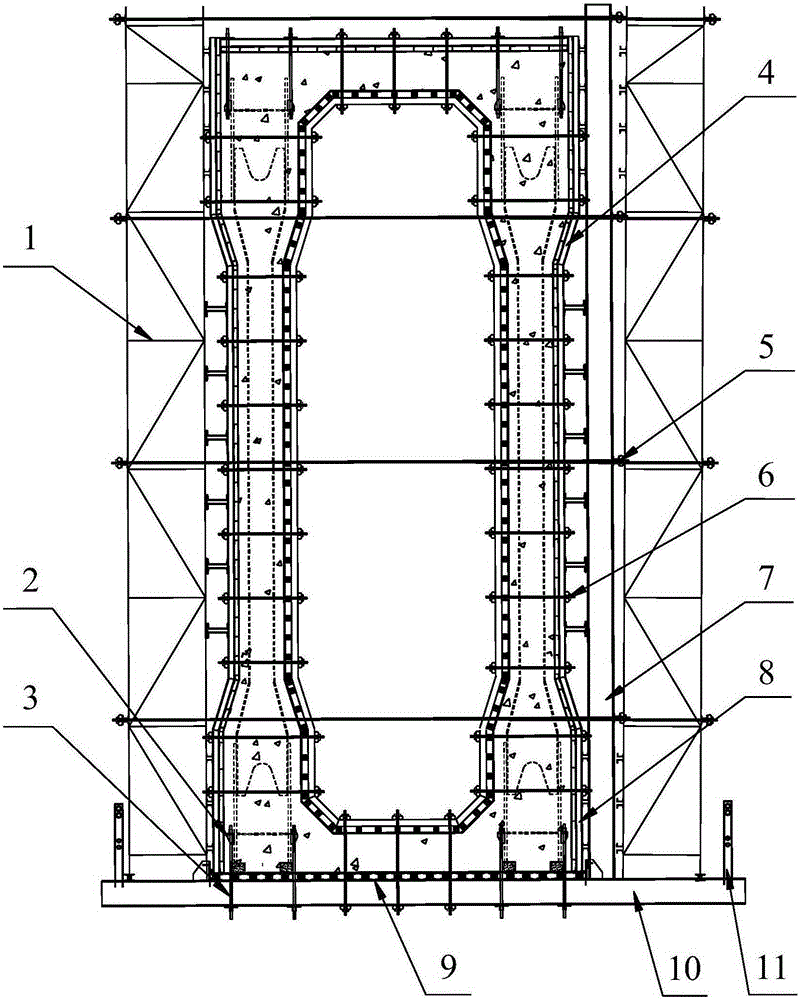

[0035] S2: see image 3 As shown, the bottom formwork 9 is laid at the bottom of the steel arch rib section to be poured, and the reaction force seat 2 and the boom 3 are welded on the lower chord of the steel arch rib section to be poured, and the reaction force seat 2 and the suspension rod are used to The hanger system is installed on the pole 3. The hanger system includes a beam 10, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com