Intelligent side forms mold device

A technology of molds and side molds, applied in the field of intelligent side mold mold devices, can solve the problems of unfavorable disassembly and removal of robots, heavy workload of cleaning work surfaces, inconvenient secondary use, etc., and achieve simple and light structure and improved production efficiency , The effect of convenient demolition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

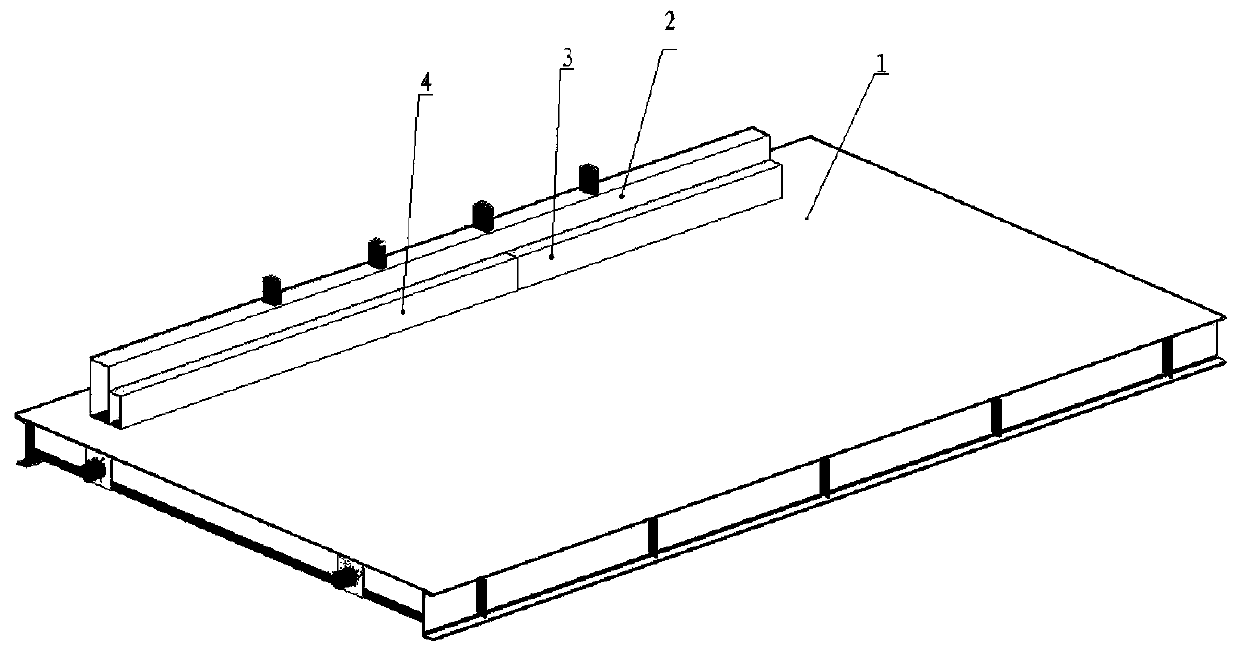

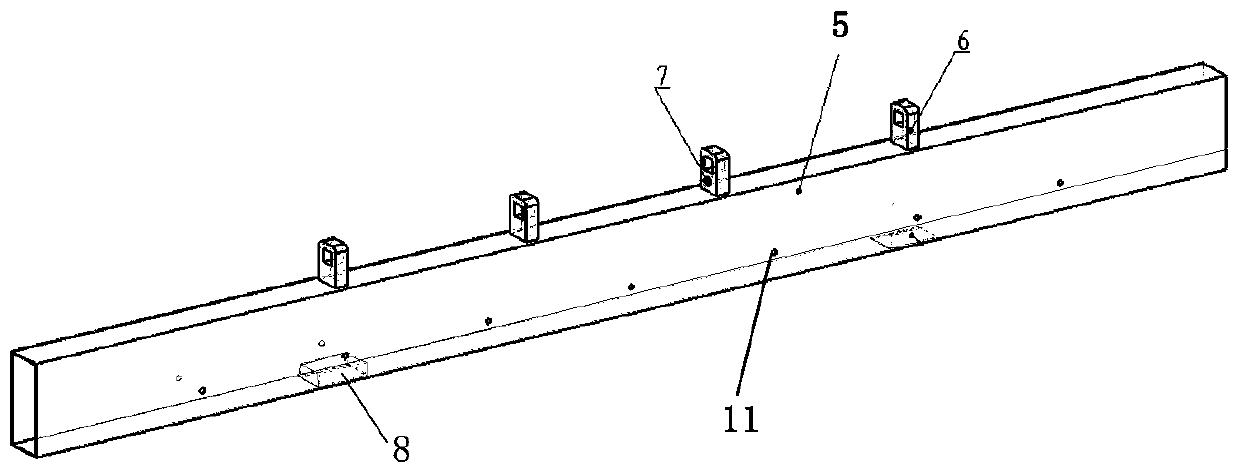

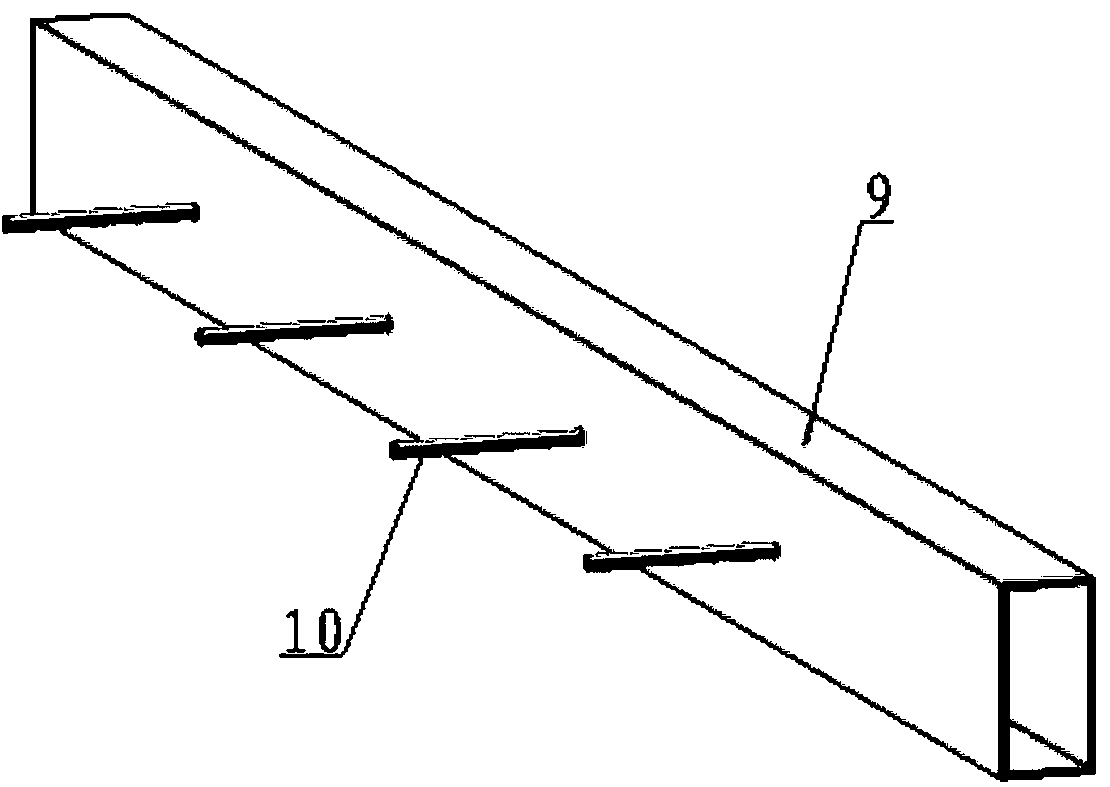

[0020] See attached Figure 1-3 It is an embodiment of the present invention, which discloses an intelligent side mold device, including a mold body, a robot and a control system. The mold body is placed on a working mold table 1, and the mold body includes a main mold 2. The first working mold 3 and the second working mold 4, the main mold 2 and the working mold are made of aluminum alloy profiles, with various standard sizes, and the matching mold bodies are spliced according to product specifications; the main mold The surface of the mold 2 is fixed with a plurality of hanging ears 6, and the inside of the hanging ears 6 are respectively equipped with two conductive probes 7, and the two conductive probes 7 are connected to the electro-permanent magnet 8 at the bottom of the main mold through lead wires. , the side wall near the electro-permanent magnet 8 is provided with a plurality of reserved holes, the main mold 2 adopts a rectangular profile with a cross-sectional di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com