Fixing fixture

A technology for fixing jigs and positioning columns, which is applied to electrical components, electrical components, etc., can solve problems such as high defect rate, easy assembly deviation, and difficulty in ensuring assembly effect, so as to improve production yield, improve assembly accuracy, and improve The effect of positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

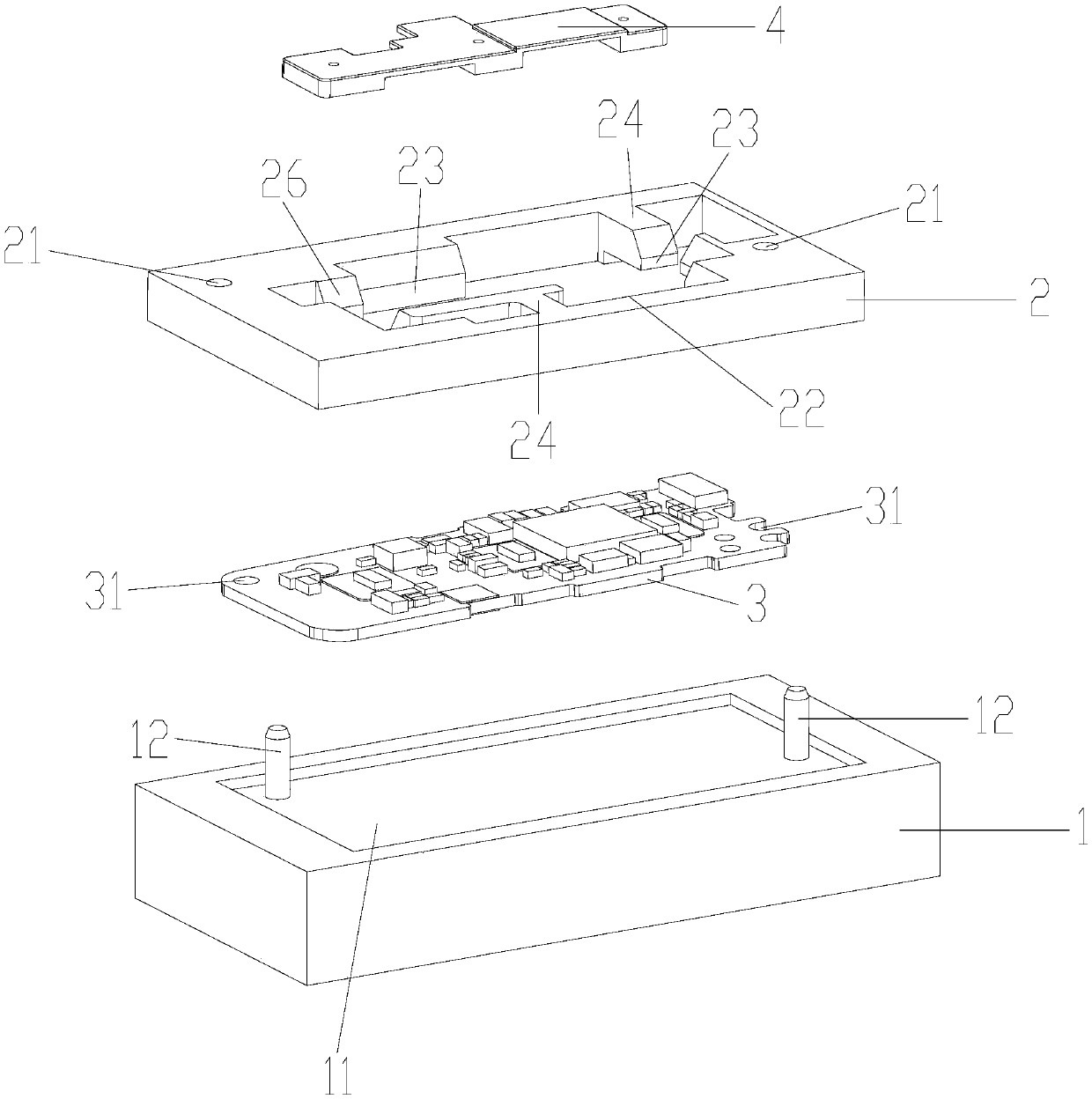

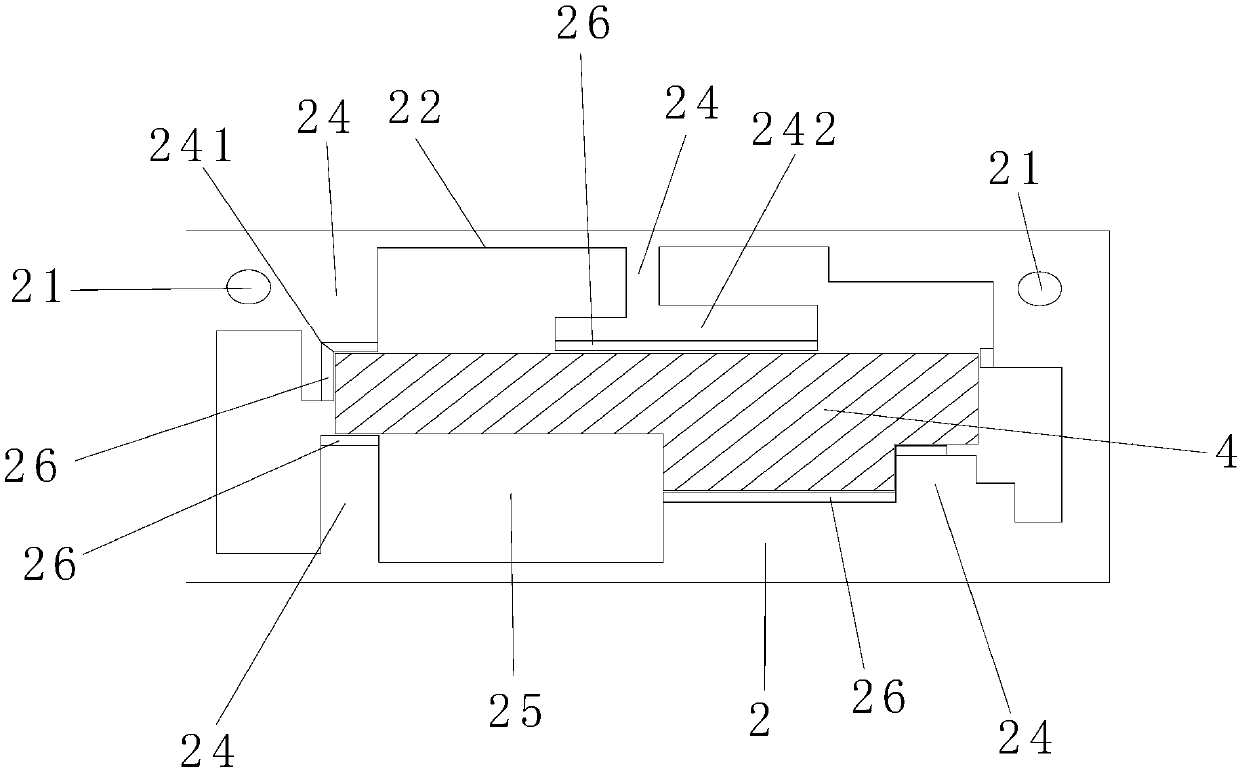

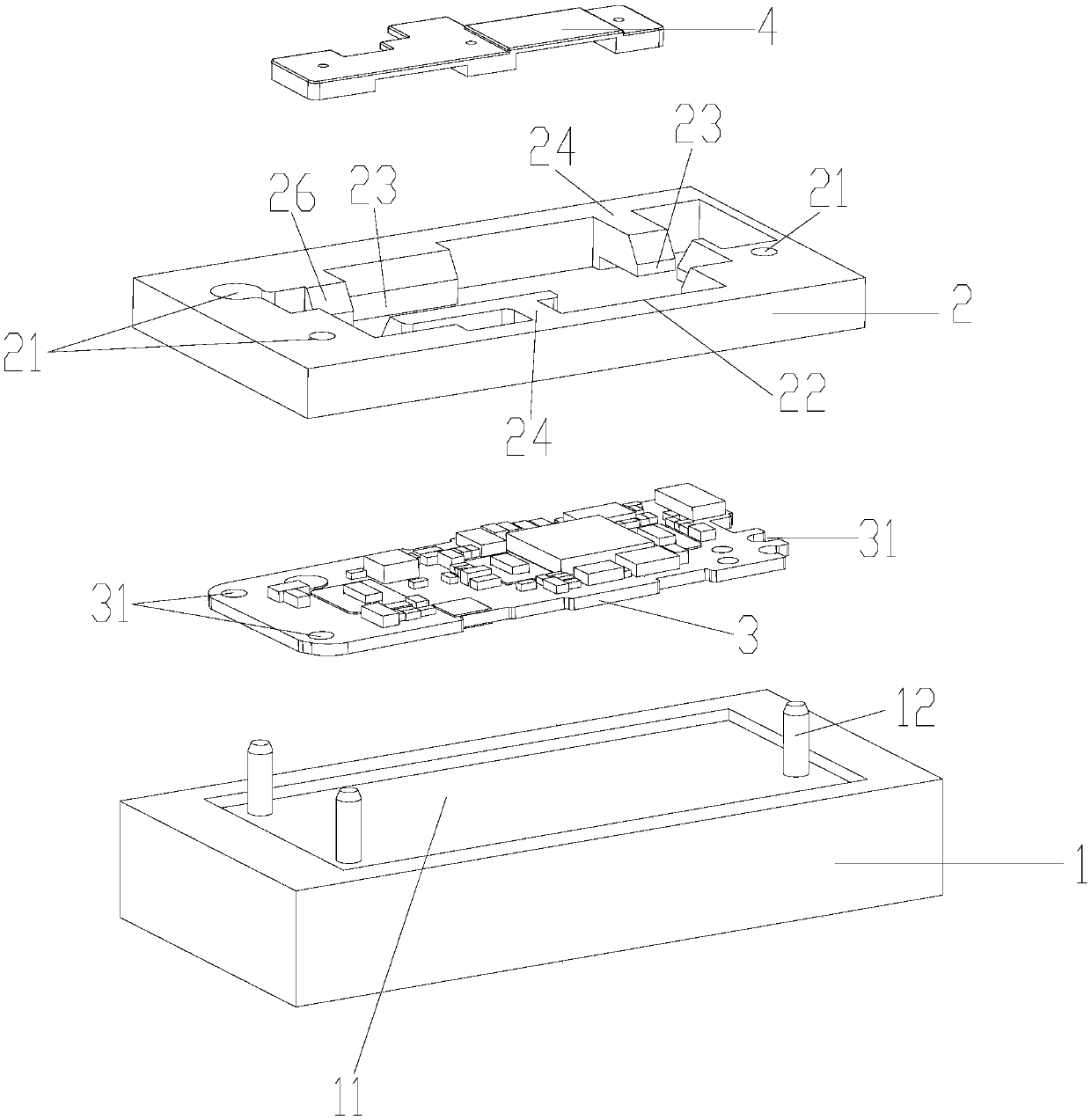

[0021] The following combination figure 1 and figure 2 To illustrate Embodiment 1 of the present invention, in this embodiment, a groove 11 is provided on the surface of the base 1 facing the upper cover 2, the groove 11 is used to carry the PCB board 3, and two positioning holes are arranged in the groove 11. Column 12, the setting position of the positioning column 12 corresponds to the two first positioning holes 31 of the carried PCB board 3, so as to position and fix the PCB board 3; wherein, the shape of the groove 11 is consistent with the outer surface of the PCB board 3 The shapes are interlinked and matched with each other, so that the PCB board 3 can be fixed more stably; the upper cover 2 includes two second positioning holes 21, and the setting positions of the second positioning holes 21 correspond to the positioning columns 12, and at the same time Corresponding to the first positioning hole 31 on the PCB board 3, the upper cover 2 also includes a processing s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com