Excavation construction method for underwater foundation pits of deep water foundation adjacent to existing line large-span continuous beam

A deep-water foundation and construction method technology, which is applied in the direction of foundation structure engineering, excavation, bridges, etc., can solve the problems of complex construction procedures, random construction operations, poor construction effects, etc., and achieve low construction costs, convenient processing and erection, The effect of easy processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

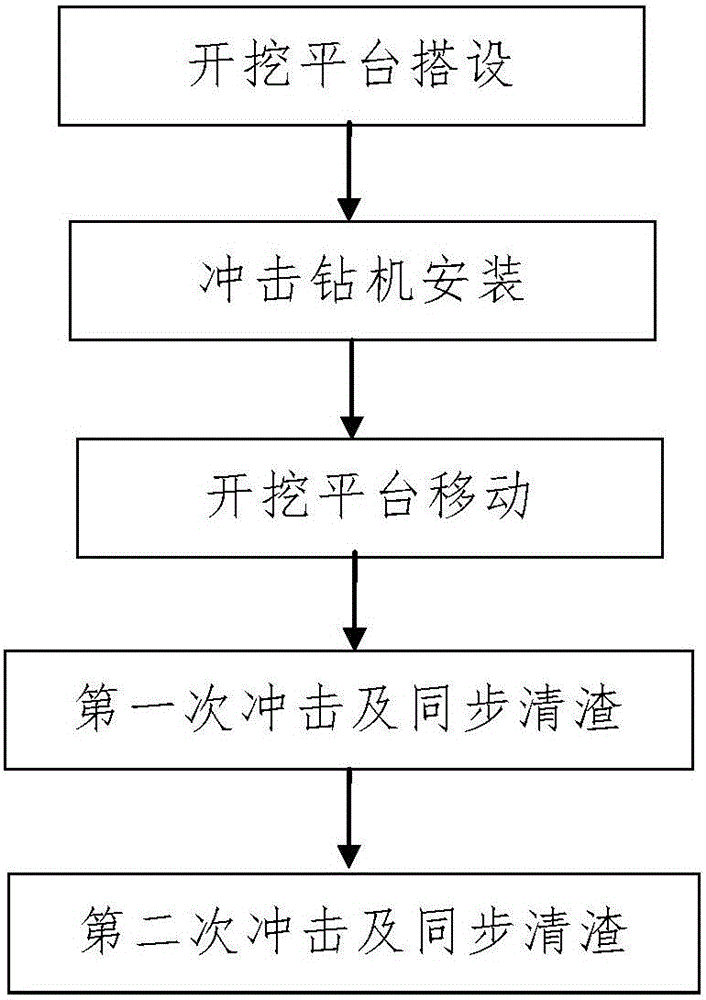

[0053] Such as figure 1 Shown is a construction method for excavating an underwater foundation pit of a large-span continuous beam deep-water foundation close to the existing line. Underwater bearing platform, described water bearing platform is the concrete bearing platform that adopts cofferdam 14 construction to form; When excavating the underwater foundation pit installed at the bottom of cofferdam 14, the process is as follows:

[0054] Step 1, setting up the excavation platform: setting up the excavation platform;

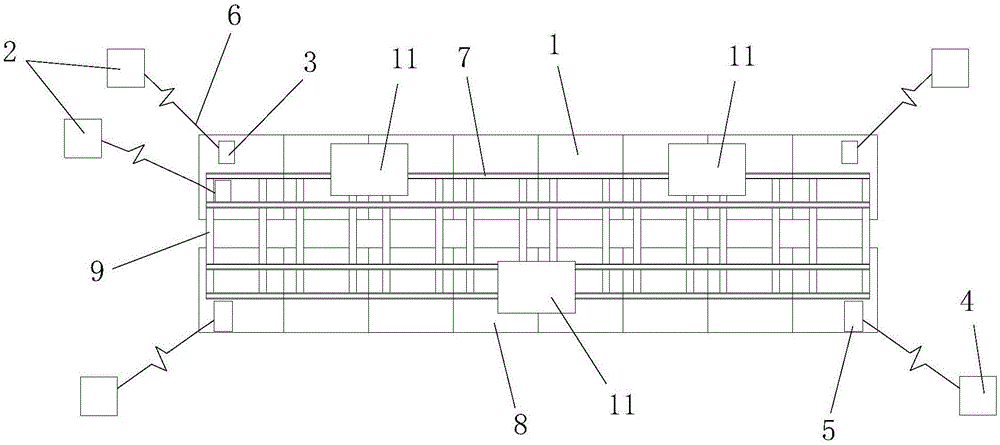

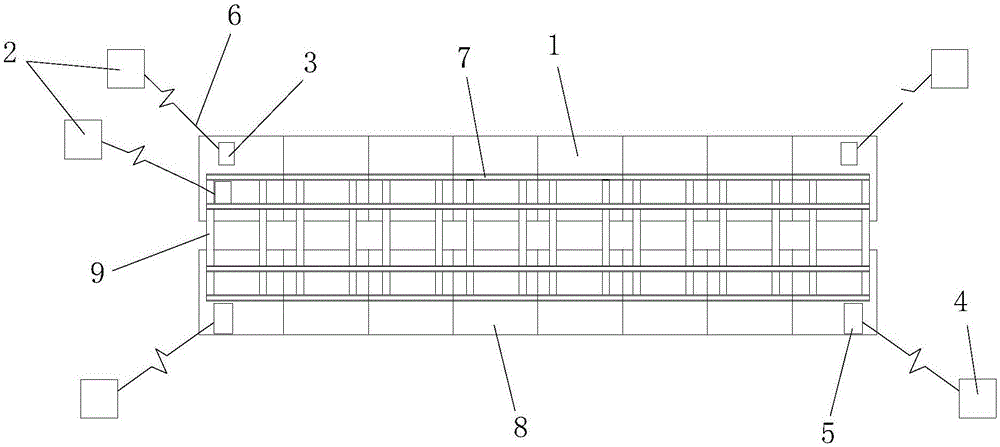

[0055] Such as image 3 As shown, the excavation platform includes an assembled floating body and a floating body position adjustment device for adjusting the position of the assembled floating body, the assembled floating body is rectangular, and the length of the assembled floating body is greater than that of the underwater platform The length and the width are greater than the width of the platform in the water; the assembled floating body includes two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com