Long-acting preserving and sealing protection method

A sealing protection, long-term anti-corrosion technology, used in pipeline anti-corrosion/anti-rust protection, damage protection, pipeline protection and other directions, can solve the problems of low heat resistance, poor elasticity, easy to crack and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

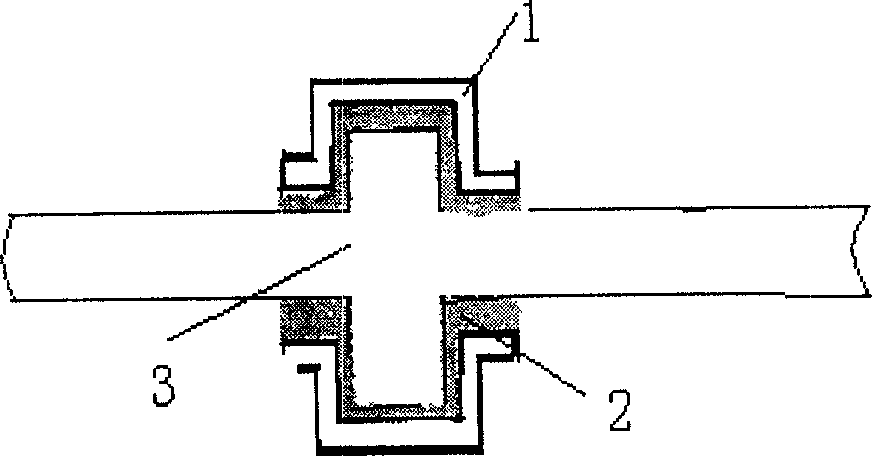

[0013] Example 1: Flange joint anti-corrosion sealing protection

[0014] figure 1 Schematic diagram of the anti-corrosion sealing double-layer protection structure of the flange joint. The outer neoprene jacket is prefabricated into a semicircular cavity structure with a thickness of 5mm. During construction, it is only necessary to fill the cavity with polysulfide sealant, close the two semicircles and lock them with a throat hoop, scrape off the excess sealant, and wait until completely After curing, remove the hose clamp. The sealing structure has double protection inside and outside, and the anti-corrosion effect is very effective. When repairing and disassembling, it is only necessary to cut the outer layer of rubber along the closing seam, scrape off the sealant in the cavity, and the neoprene jacket can be reused.

[0015] After the practical application of this long-term anti-corrosion sealing protection method, the appearance is beautiful and smooth, the construct...

example 2

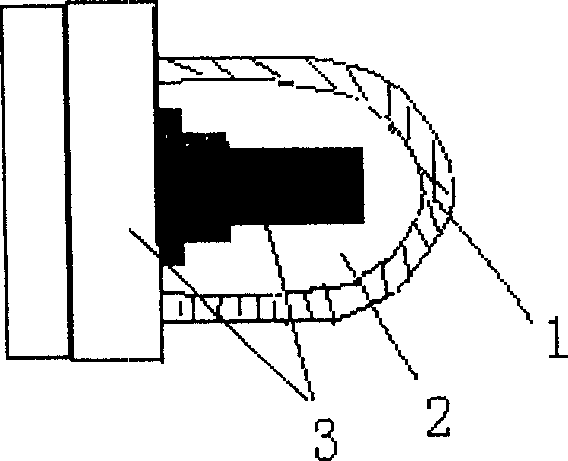

[0016] Example 2: Bolt oil-resistant anti-corrosion seal application

[0017] figure 2 Schematic diagram of the anti-corrosion sealing double-layer protection structure of the bolt. The nitrile rubber jacket is designed as a cylindrical cavity structure with one end sealed, with a thickness of 3mm. The inner layer material is polyurethane sealant with excellent oil resistance and strong bonding performance. After the polyurethane sealant is injected into the cavity during construction, it is set on the bolt, scraped off the excess polyurethane, and pressed with tape. After it is completely cured, remove it. adhesive tape.

example 3

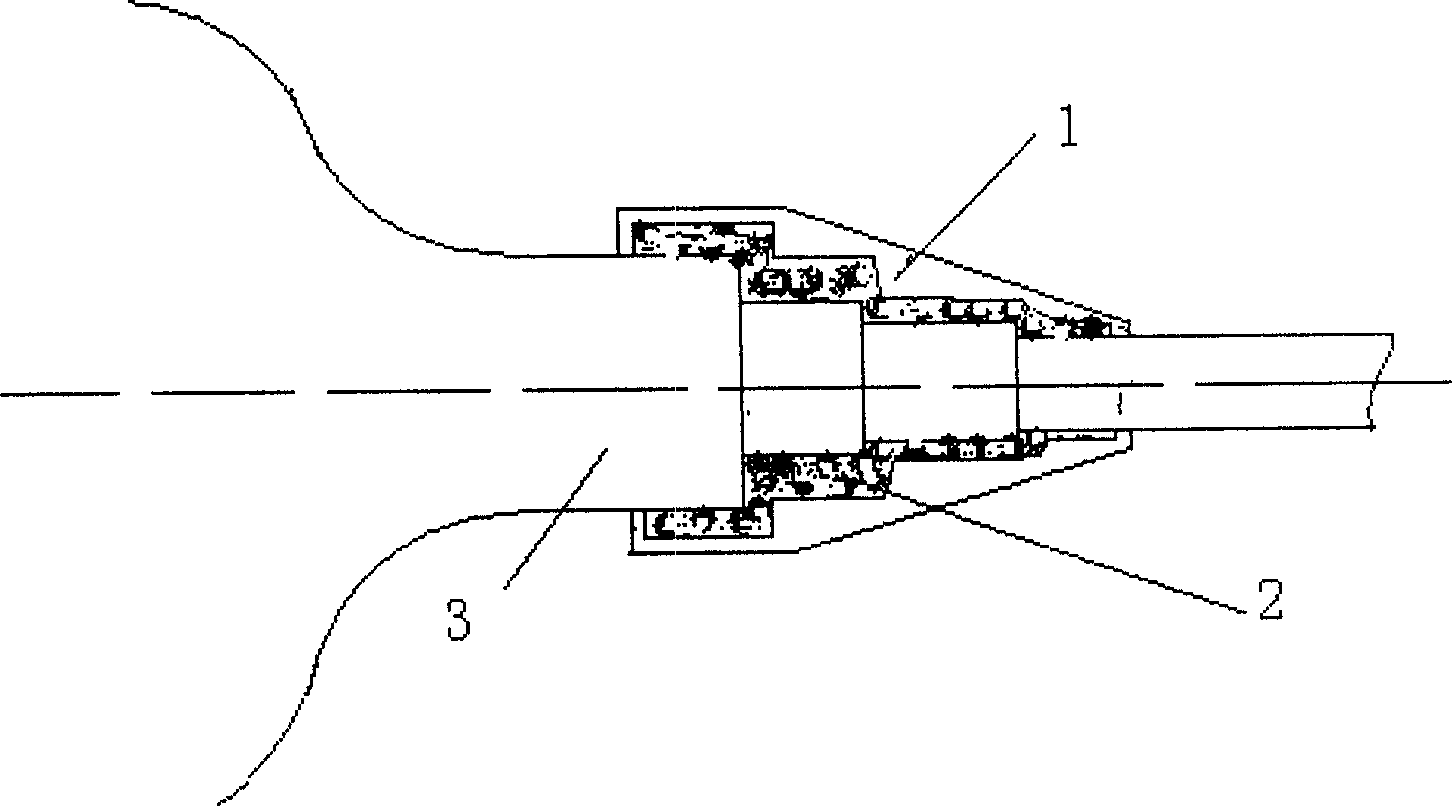

[0018] Example 3: Gas cylinder anti-corrosion sealing protection

[0019] image 3 Schematic diagram of the double-layer protective structure of the gas cylinder joint. The average thickness of the outer styrene-butadiene rubber jacket is 5mm-10mm. The semicircular cavity structure has a smooth outer surface. The diameter is 8-10mm. After filling the cavity with silicone sealant during construction, close the two semi-circular cavities and lock them with throat clamps. Scrape off the excess sealant. After it is completely cured, remove the throat clamps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com