Stainless steel pipe cutting device

A technology for cutting devices and stainless steel pipes, applied in the direction of pipe shearing devices, shearing devices, shearing machines, etc., can solve the problems of low work efficiency, steel pipe transportation deviation, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

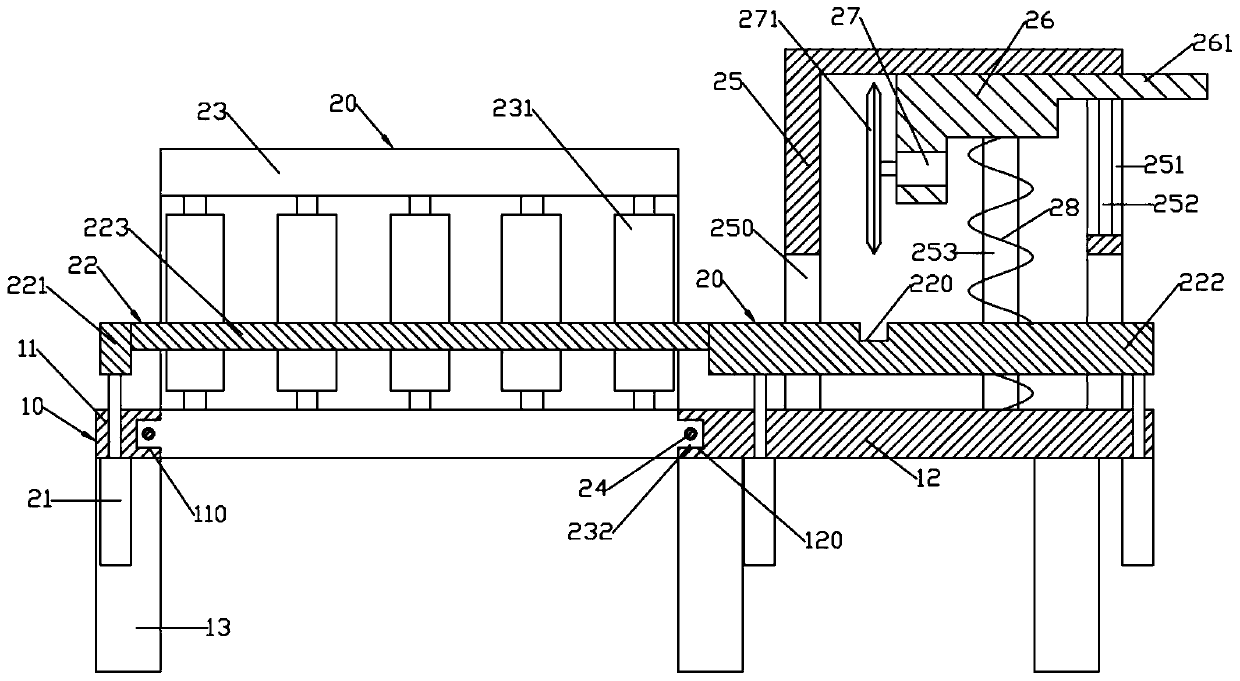

[0014] Such as figure 1 As shown, a stainless steel pipe cutting device includes a supporting workbench 10 and a delivery cutting device 20; the supporting workbench 10 includes a left support plate 11 and a right support plate 12; the bottom surfaces of the left support plate 11 and the right support plate 12 are all installed There are a number of evenly distributed support feet 13; the conveying and cutting device 20 includes a conveying device; the conveying device includes a pair of "凵"-shaped conveying support seats 23 and a lifting support plate 22; a pair of conveying support seats 23 have openings opposite to each other; The support base 23 is moved back and forth between the left support plate 11 and the right support plate 12 and is moved away from or close to each other synchronously; between a pair of vertically symmetrical horizontal parts of the transport support base 23, a number of uniformly distributed transport rollers 231 are arranged in rotation; Lifting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com