Patents

Literature

74results about How to "No bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

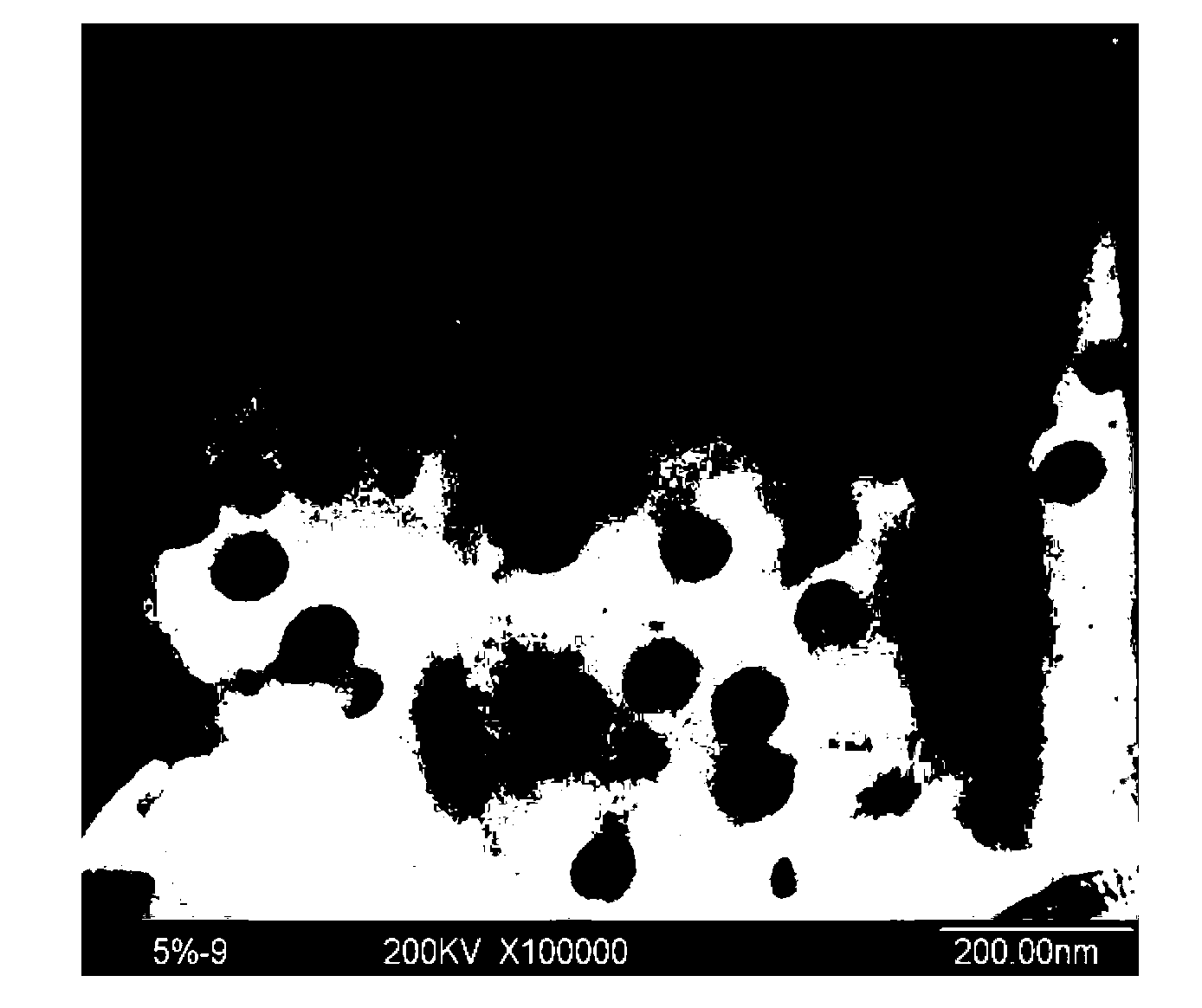

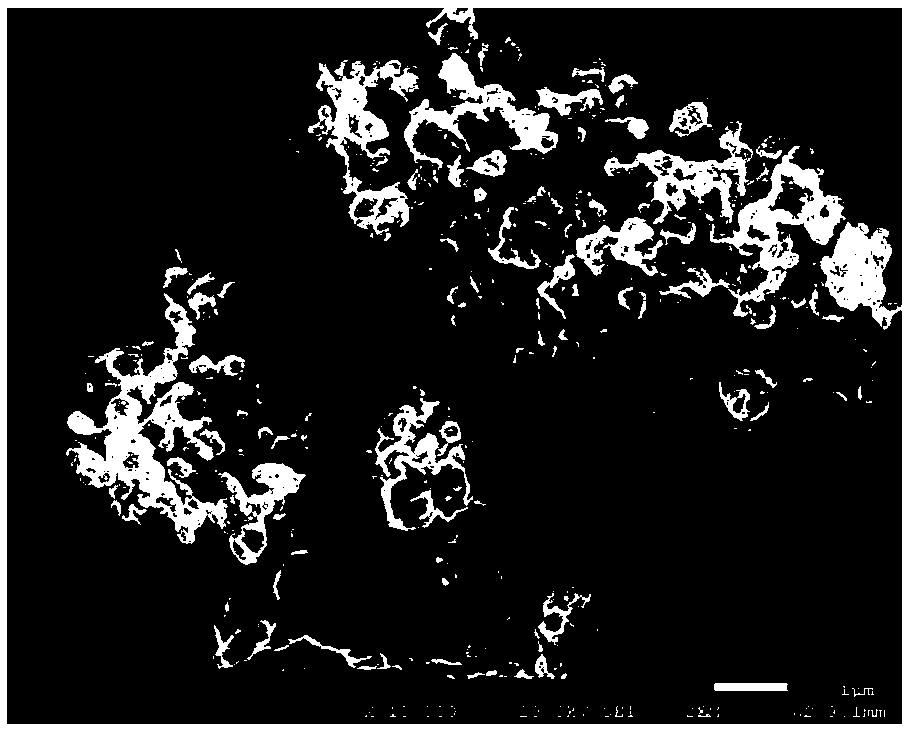

Method for preparing organic nanometer rubber particle enhanced epoxy resin self-repairing microcapsule

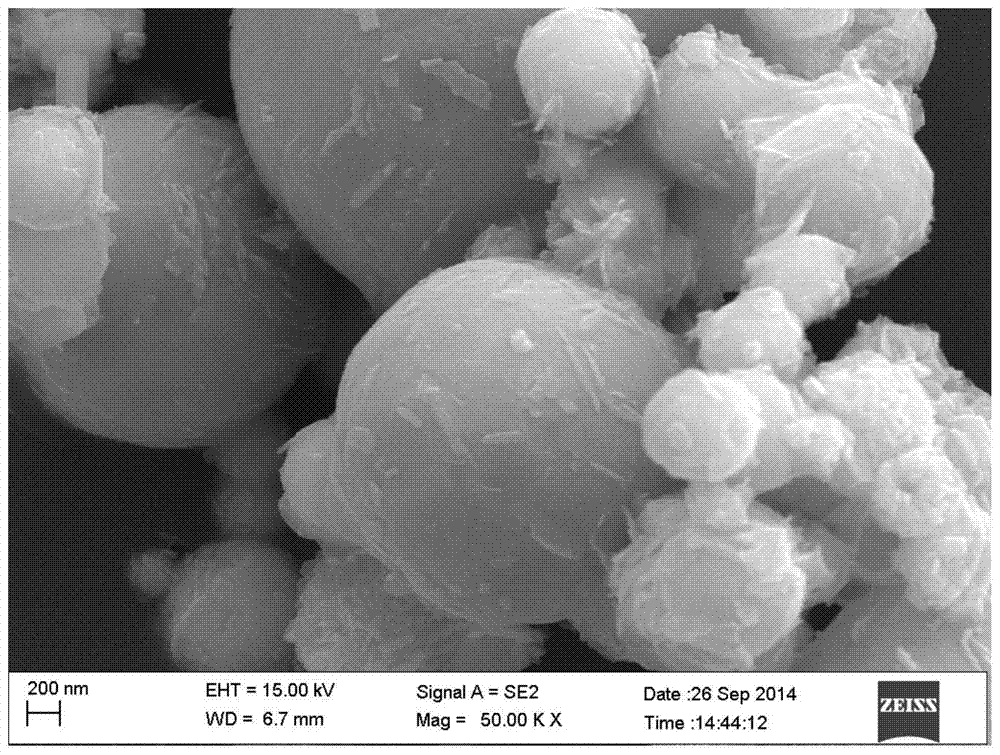

ActiveCN102698669AUniform particle size distributionGood dispersionMicroballoon preparationMicrocapsule preparationEpoxyMechanical property

A method for preparing organic nanometer rubber particle enhanced epoxy resin self-repairing microcapsule includes: (1) dispersing organic nanometer rubber particles into mixture of epoxy resin and diluent of the epoxy resin, evenly stirring, and performing grinding treating through a three-roller grinder to obtain stably dispersed nanophase enhaced epoxy resin; (2) dissolving emulsifier in deionized water to obtain aqueous solution of the emulsifier; and (3) mixing urea, ammonium chloride and resorcinol, adding the mixture into the aqueous solution of the emulsifier, stirring the mixture until the mixture is fully dissolved to obtain a mixed liquor, regulating the pH value of the mixed liquor to be 3.5, adding nanophase enhanced epoxy resins into the mixed liquor, performing emulsification, dropwise adding formaldehyde solution with the concentration of 37wt% into the emulsified liquid, heating the mixture to be 50 DEG C to 60 DEG C to react for 4 hours, filtering, cleaning a filter cake for several times through absolute ethyl alcohol or acetone, and drying to obtain powder. The microcapsule manufactured by the method can further improve solidification toughness of repairing agents and improve mechanical property of composite materials.

Owner:北京睿曼科技有限公司 +2

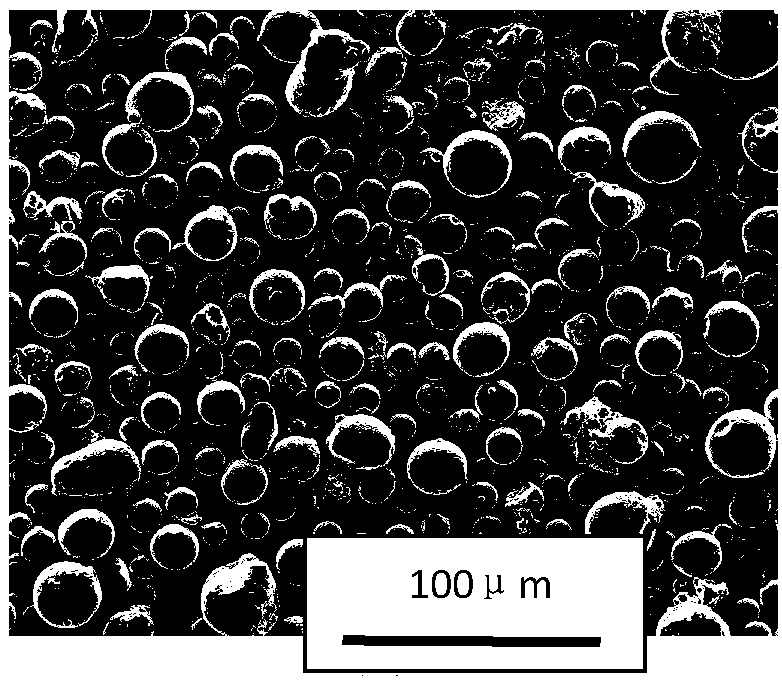

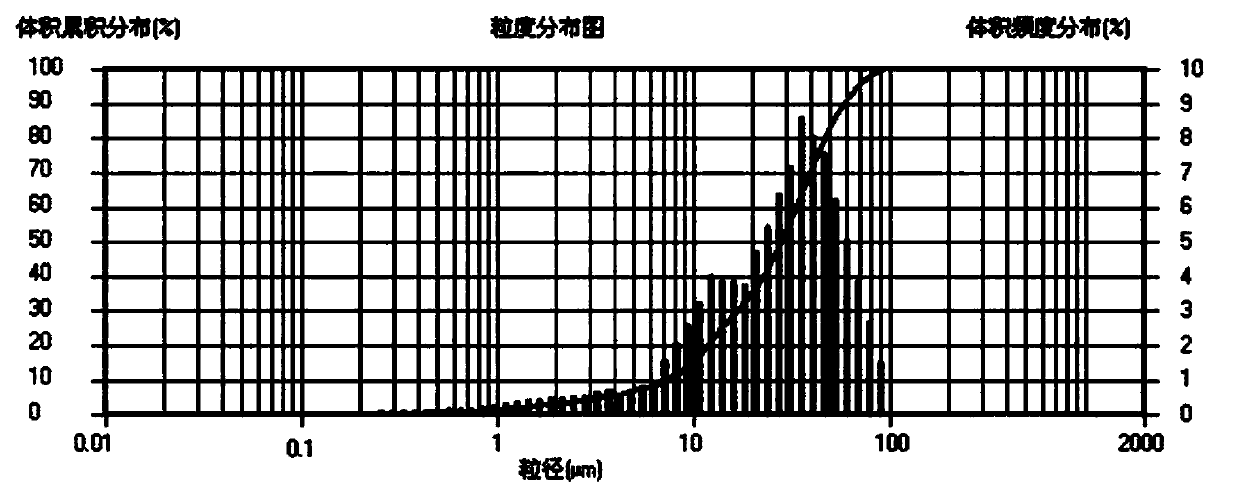

Ta-contained 3D printing cobalt chromium molybdenum alloy powder for dental department and preparation method thereof

ActiveCN107598151ASolve the broken porcelainSolve the problem of porcelain peelingAdditive manufacturing apparatusChemical compositionBond properties

The invention provides Ta-contained 3D printing cobalt chromium molybdenum alloy powder for the dental department and a preparation method thereof. The chemical components of the alloy power comprise,by weight, 26.0%-30.0% of Cr, 8.0%-10.0% of Mo, 0.5%-5.0% of Ta, 3.0%-8.0% of W and the balance Co. The preparation method of the Ta-contained 3D printing cobalt chromium molybdenum alloy powder comprises the three steps of mother alloy smelting, powder atomization, powder screening and drying treatment. According to the alloy powder, the particle size, the sphericility degree and the mechanicalproperty are ensured, and meanwhile, the gold-procelain bonding property, the thermal stability and the flowability are improved while the oxygen content is reduced, the problems of porcelain crackingand porcelain spalling of a cobalt chromium molybdenum alloy are effectively solved, and obtaining of dental rebuilt parts with the high quality is facilitated.

Owner:CHENGDU KENINGDA MATERIALS

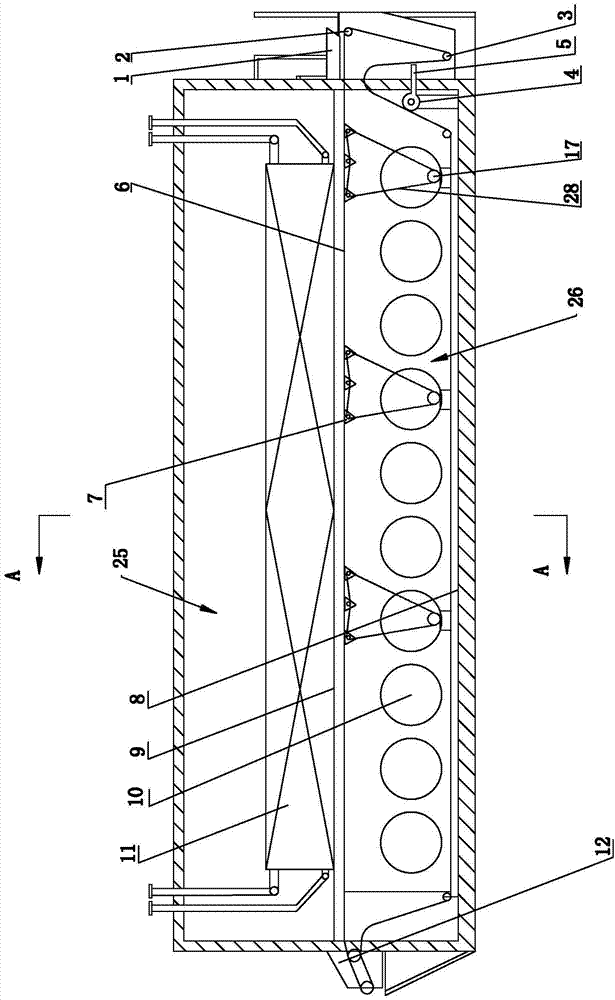

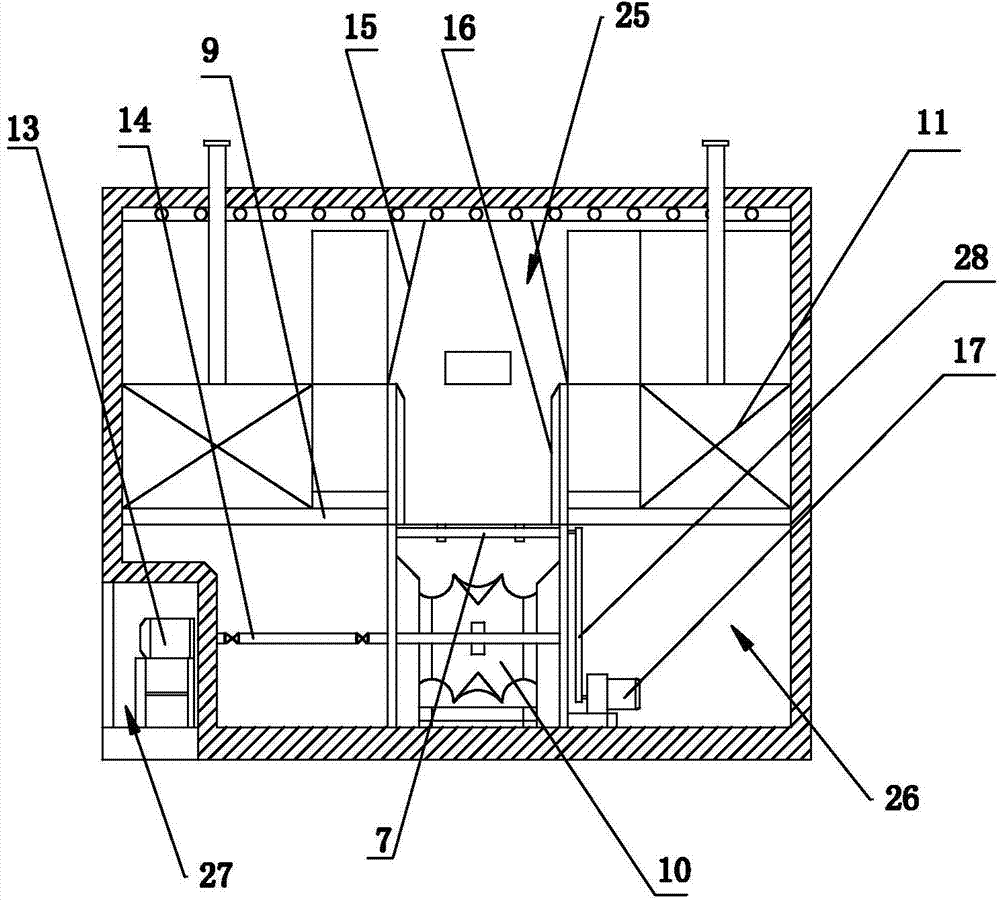

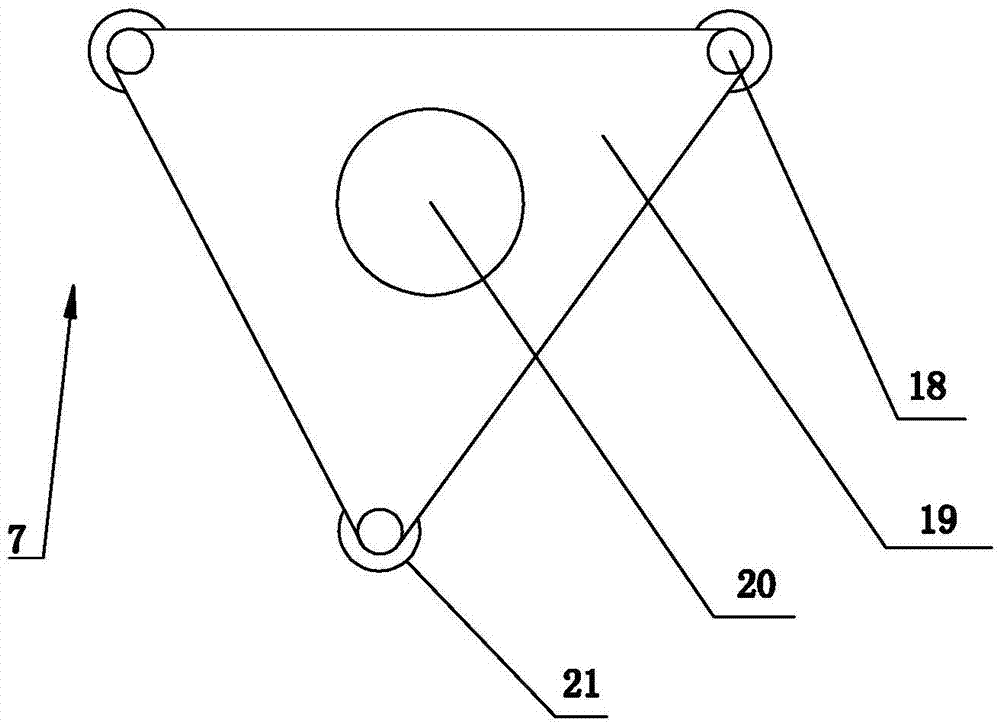

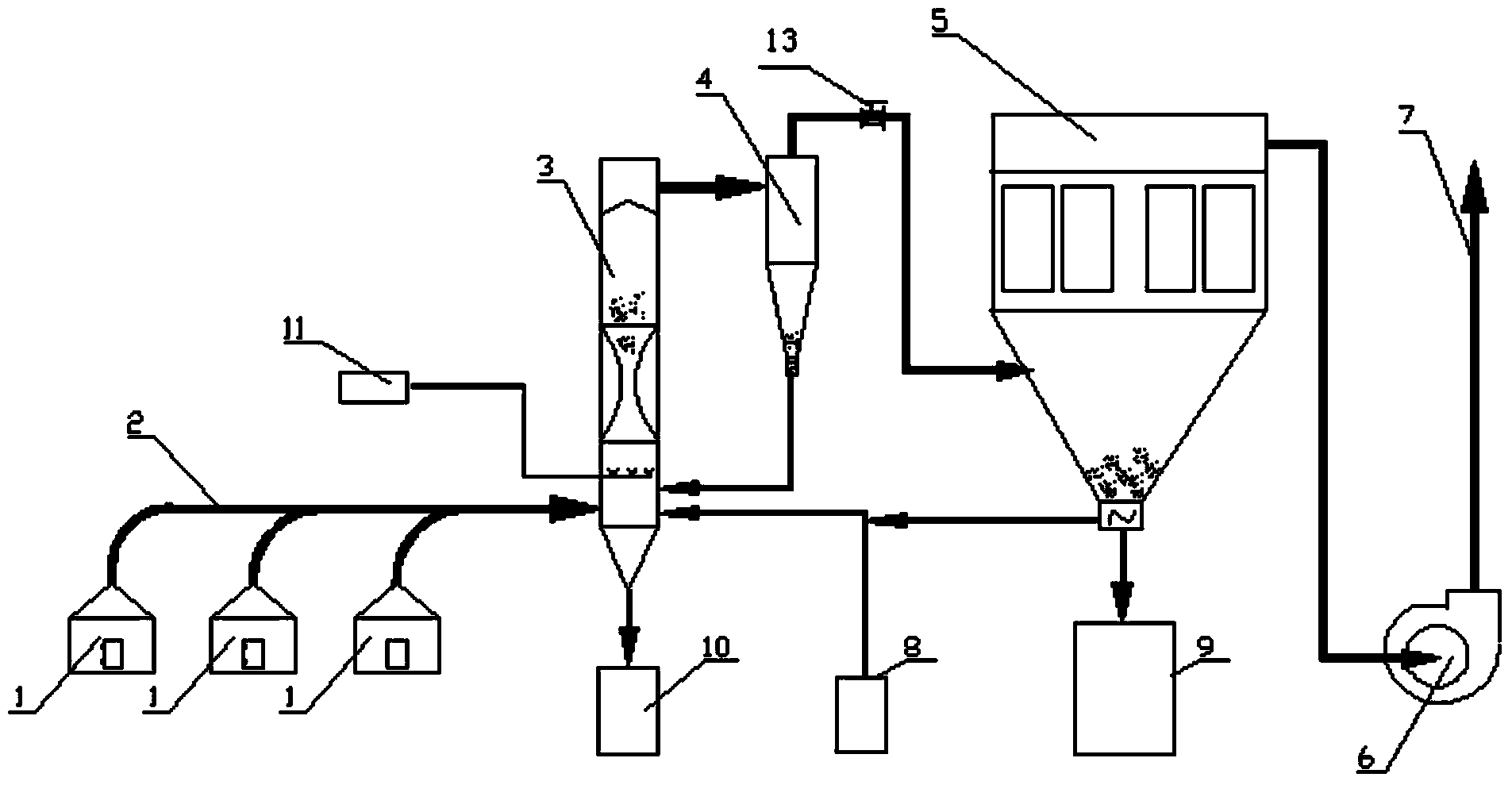

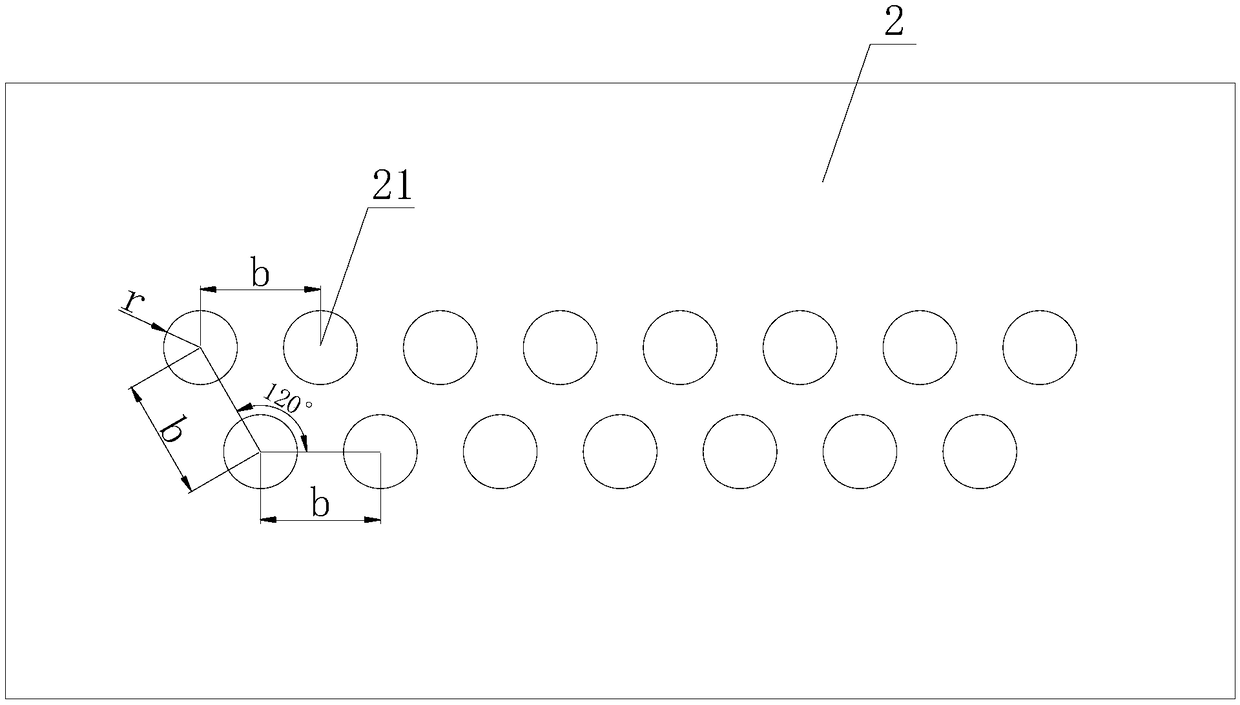

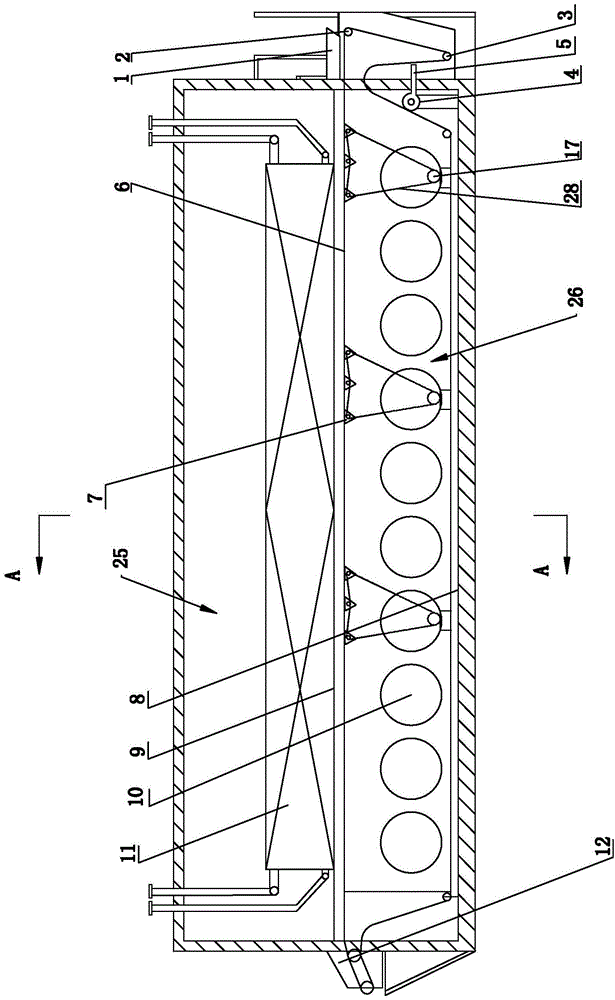

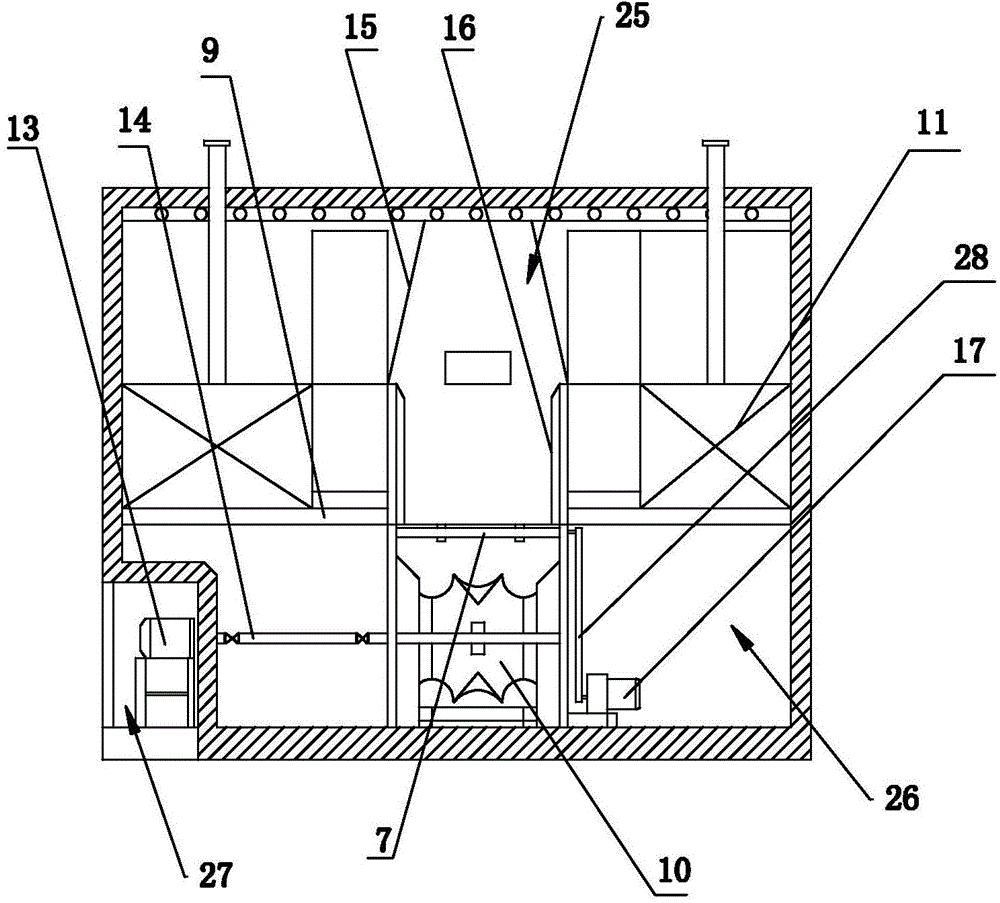

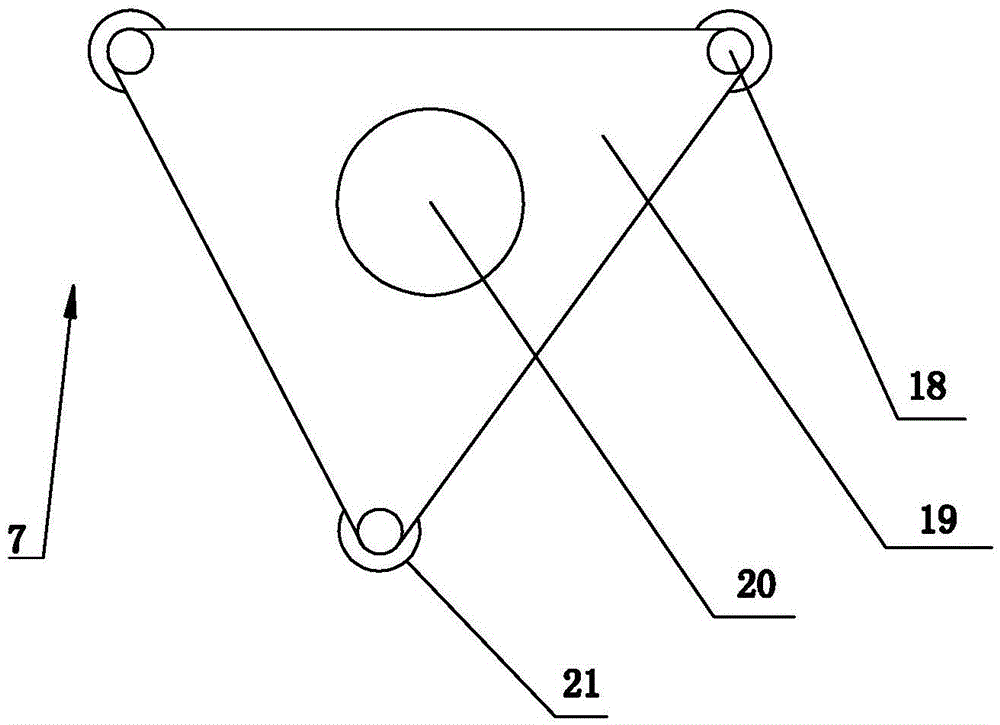

Instant freezer

ActiveCN103791671AReduce loadTake advantage ofLighting and heating apparatusStationary refrigeration devicesCold airEngineering

The invention discloses an instant freezer and belongs to the technical field of instant freezing equipment. The instant freezer comprises a freezer body, a freezing chamber and an air supply chamber provided with a cold air blowing device are arranged in the freezer body, a conveying belt is arranged in the position corresponding to the cold air blowing device around the air supply chamber, and a power chamber used for installation of a first power device is arranged outside the freezer body. The two ends of the conveying belt extend out of the inlet end and the outlet end of the freezer body, and a normal temperature heating device which is communicated with the power chamber and used for heating the conveying belt is arranged at the inlet end of the freezer body. Heat in the power chamber acts on the conveying belt through the normal temperature heating device, so that the temperature of the body of the conveying belt is raised, the function of the cold air blowing device is utilized in an auxiliary mode, fluidized instant freezing is achieved, the problem of adhering between goods and adhering between the goods and the conveying belt is avoided, the single rate of the goods and normal conveying of the conveying belt are guaranteed, and the production efficiency and the product quality are improved. Meanwhile, the first power device is externally arranged, the refrigerating capacity is fully utilized, the load of the freezer is reduced, and the purpose of energy conservation is achieved.

Owner:绿特国创(潍坊)节能科技有限公司

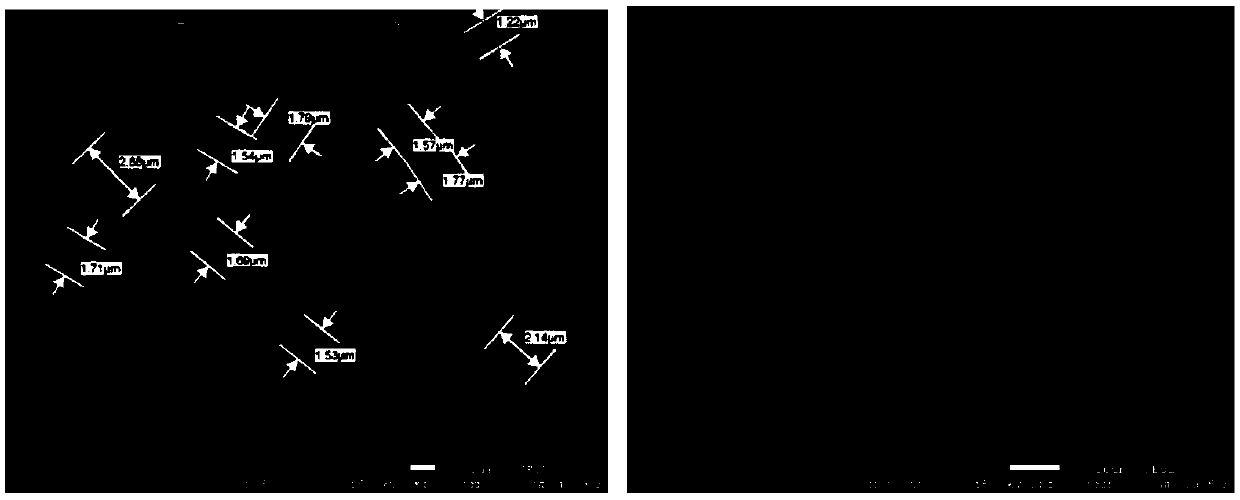

Preparation method of spherical silver powder for photovoltaic positive silver electrode

InactiveCN107931629AGood dispersionNo phenomenon of high agglomerationTransportation and packagingMetal-working apparatusDispersityWater baths

The invention relates to a preparation method of spherical silver powder for a photovoltaic positive silver electrode. The spherical silver powder prepared through the method is high in dispersity, high in sphericity and high in tap density; the particle size ranges from 1-3 microns, and the spherical silver powder is subjected to narrow particle size distribution. The method comprises the steps of adding a thickening agent and a dispersing agent to a prepared silver-ammonia solution; controlling system temperature and adding a weak reductant to an ultrasonic water bath kettle; and reducing toobtain the high-dispersity and high-density spherical silver powder. The silver powder is used for preparing photovoltaic positive silver electrode sizing, and uniform silver-silicon contact is realized after sintering; and meanwhile, the silver powder is high in photoelectric conversion efficiency and stable electricity performance.

Owner:GRIKIN ADVANCED MATERIALS

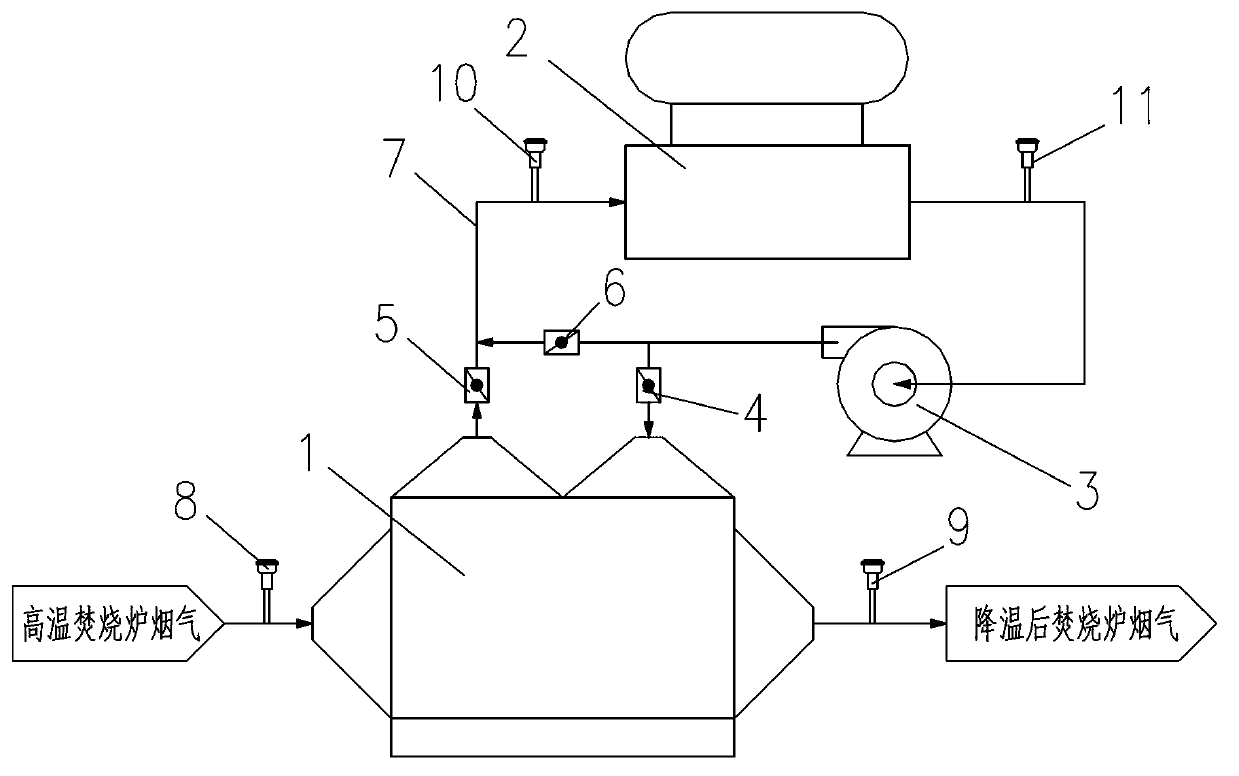

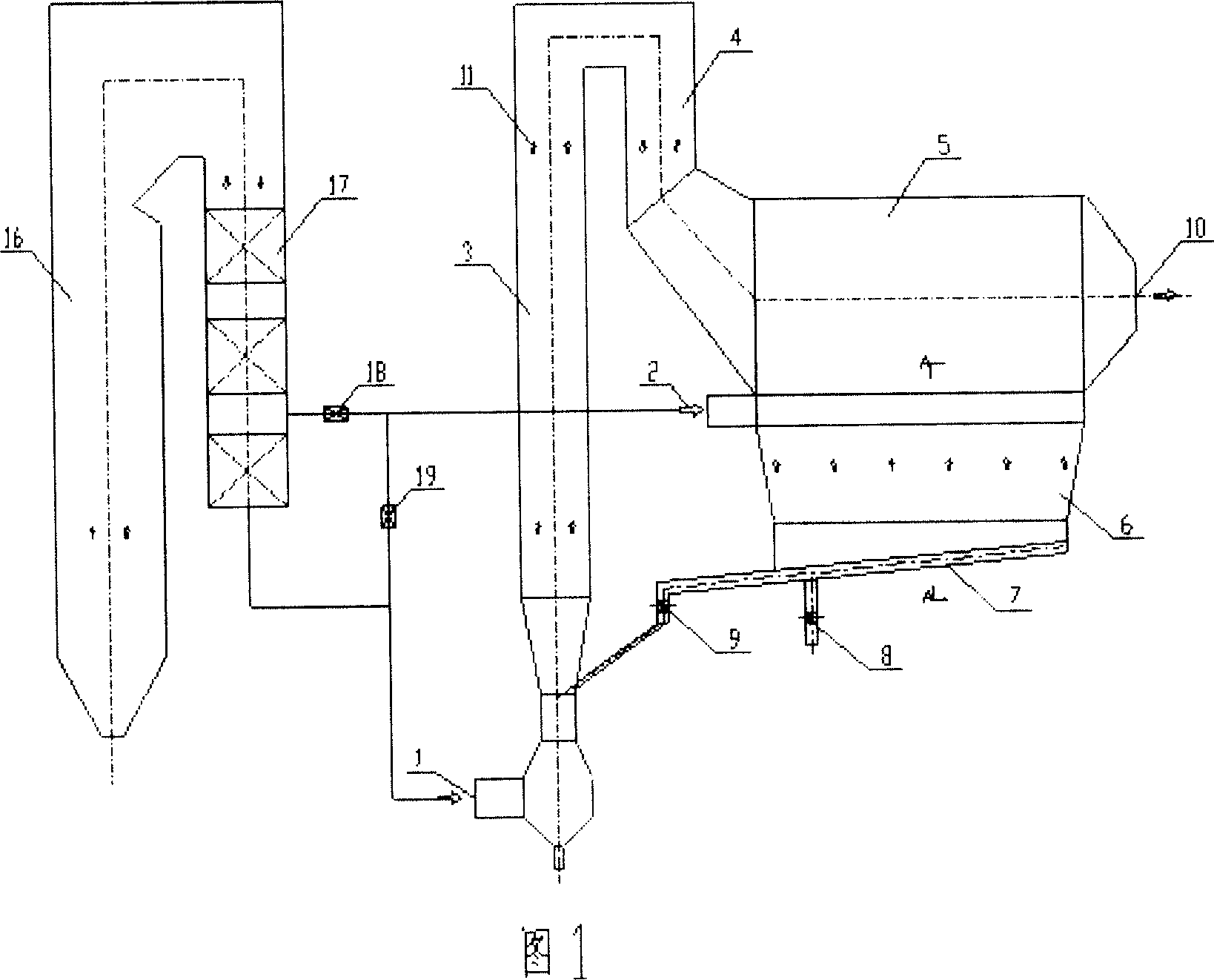

Waste incineration flue gas waste heat recovery device

ActiveCN103104922AImprove heat transfer efficiencyHigh hardnessEnergy industryIncinerator apparatusFlueProcess engineering

The invention discloses a waste incineration flue gas waste heat recovery device which comprises a ceramic heat exchanger and a waste heat boiler. The ceramic heat exchanger is provided with an air inlet and an air outlet. A ceramic heat exchange pipe is arranged between the air inlet and the air outlet. The air inlet is connected with an outlet flue of a garbage incineration boiler. Flue gas of the garbage incineration boiler after cooling is discharged by the air outlet. A pipeline is connected with the ceramic heat exchanger, the waste heat boiler and an air circulation fan. Clean air is filled in the pipeline. The air circulation fan drives the air to flow between the ceramic heat exchanger and the waste heat boiler in a circulating mode. The waste incineration flue gas waste heat recovery device is resistant to HC1 corrosion, highly-corrosive HC1 in the flue gas has no effect on operation of the ceramic heat exchanger basically, and the ceramic heat exchanger can operate stably for a long time. Moreover, the waste heat boiler is small in size and little in maintenance workload, and the amount of system heat exchange is convenient to control.

Owner:西安宇清环境工程科技有限责任公司

Twin tower circulating fluidized bed fume desulfurizing method and device

InactiveCN101053764AReduce electricity or steam consumptionReduce volumeDispersed particle separationCombustionFlue gas

The invention relates to a double-tower cycle fluidized bed flue gas desulfurization method and a device, which comprises a desulfurization reaction tower, a sprayer, a digestor, a revert unit, a gas-solid separator and a ash hopper thereof, and is characterized in that the dirty flue gas discharged by combustion equipment is divided into two parts: wherein one part enters into the king tower, and the other part enter into the tail tower formed by the ash hopper of the gas-solid separator. The advantage is that the flue gas can move is a lower temperature in the desulfurization reaction king tower, the efficiency of desulfurization is high, and volume of the king tower is small; the cycle ash can be heated effectively in the ash hopper, has a good fluidity without the defect of glue, fouling and corrosion, and the reliability of the device is well; and the invention can greatly reduce the electric heating power and energy consumption of desulfurization.

Owner:沙晓农

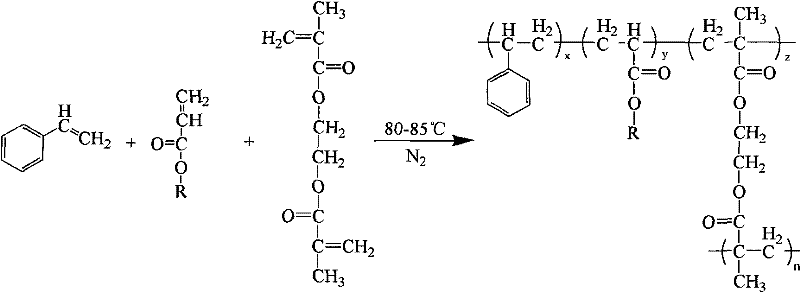

Preparation method of macroporous long alkyl side chain acrylic acid ester-styrene-ethylene dimethacrylate crosslinking copolymerization microballoon

The invention provides a preparation method of macroporous long alkyl side chain acrylic acid ester-styrene-ethylene dimethacrylate crosslinking copolymerization microballoon. The invention relates to macroporous long alkyl side chain acrylic acid ester-styrene-ethylene dimethacrylate crosslinking copolymerization microballoon and a preparation method thereof. In the preparation method, oil-soluble benzoyl peroxide is an initiator, long alkyl side chain acrylic acid ester, styrene and ethylene dimethacrylate are monomers, a suspension polymerization method is employed, an aqueous solution containing a dispersant and salt is water phase, and the monomers containing the initiator and a pore forming agent are mixed as stable oil phase. Under protection of nitrogen, the oil phase is stirred and subjected to a polymerization reaction at a certain temperature, and a resultant is subjected to filtering, washing, Soxhlet extraction, and vacuum drying treatments to obtain the macroporous crosslinking copolymerization microballoon. The above synthetic method has the advantages of safety, easy separation of products, low production cost, easy control of temperature, stable product quality the like, and is suitable for large scale industrial production. Since having porous and hydrophobic characteristics, the hydrophobic macroporous microballoon disclosed in the invention has a substantial advantage in removing enriched hydrophobic organic pollutants in water, which is a prospective environment friendly adsorption material and can be effectively used for processing relative organic waste water. The hydrophobic macroporous microballoon also has potential application value in fields of catalyst and drug carrier, bioseparation and the like.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Environment-friendly leather care agent

InactiveCN104561403AImprove permeabilityEasy accessLeather surface finishingLeather impregnationBenzeneSulfonate

The invention discloses an environment-friendly leather care agent which is prepared from the following raw materials in parts by weight: 20-45 parts of vegetable fat, 20-35 parts of polyether modified hydrophilic silicone oil, 6-15 parts of organic silicone oil, 30-55 parts of polyethylene glycol, 10-20 parts of sodium tetra(propylene benzene) sulfonate, 1-5 parts of twain 80, 0-3 parts of plant aromatic essential oil, and 0-2 parts of a brightener. The environment-friendly leather care agent disclosed by the invention can penetrate into leather for filling or lubricating gaps among fibers, so that the fibers regain the elasticity and are not bonded, therefore, the internal fiber structure of the leather is re-adjusted, and the softness of the leather is restored; in the process of preparing, by ultrasonic treatment, aliphatic long-chain molecules and fat in the vegetable fat are broken into small molecules, so that after being sprayed to the surface of leather, the leather care agent penetrates into the leather more easily; and leather treated by using the care agent disclosed by the invention has good air permeability, softness, rebound resilience and smooth feel.

Owner:GUANGDONG FION LEATHER CO LTD

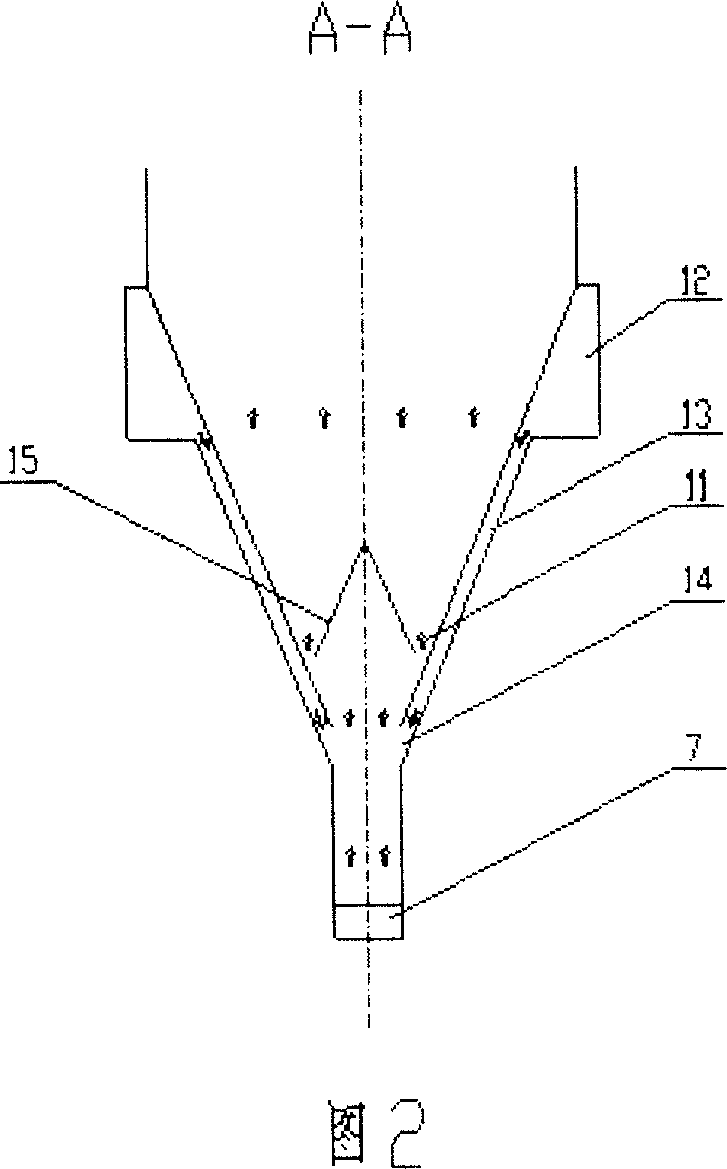

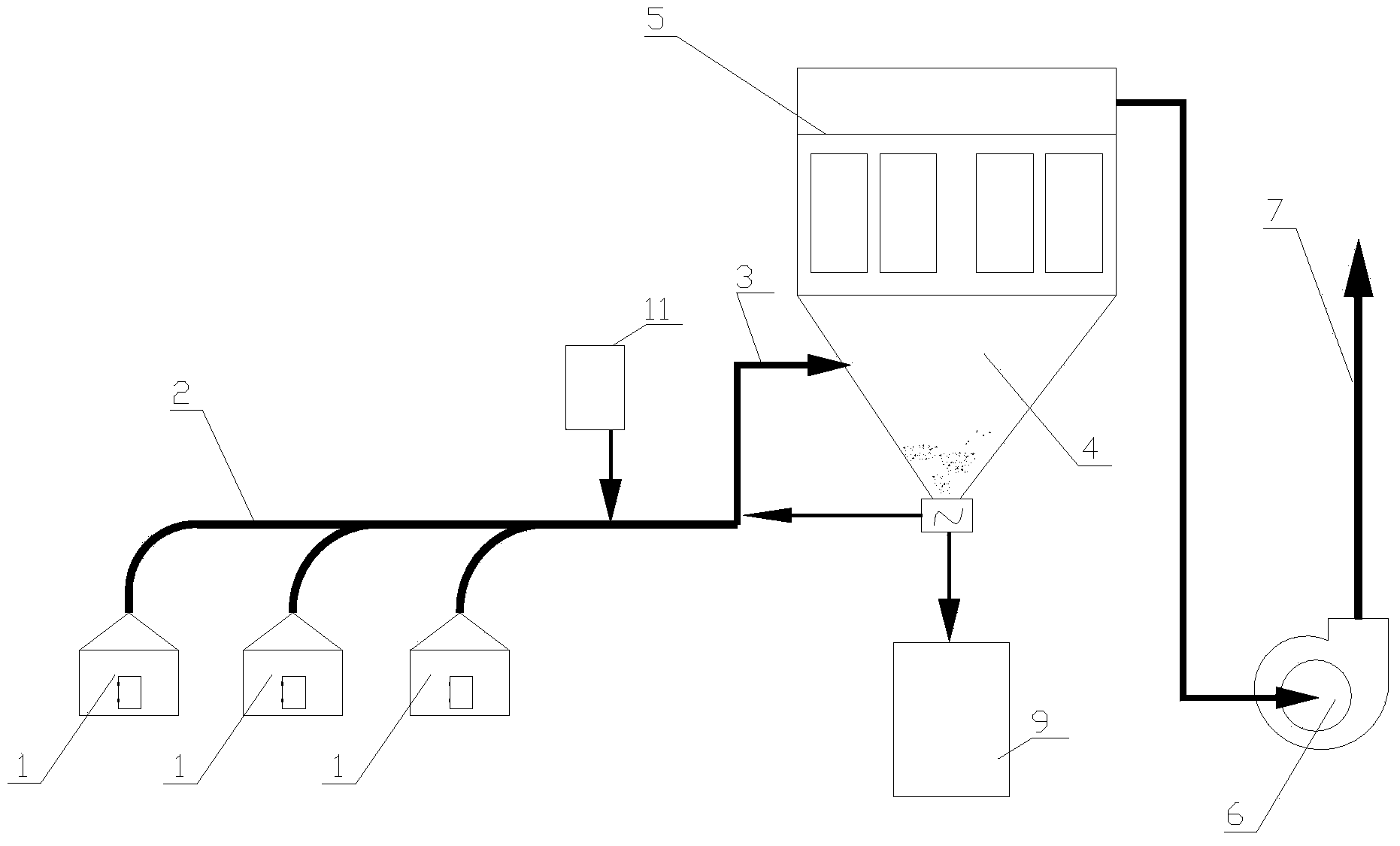

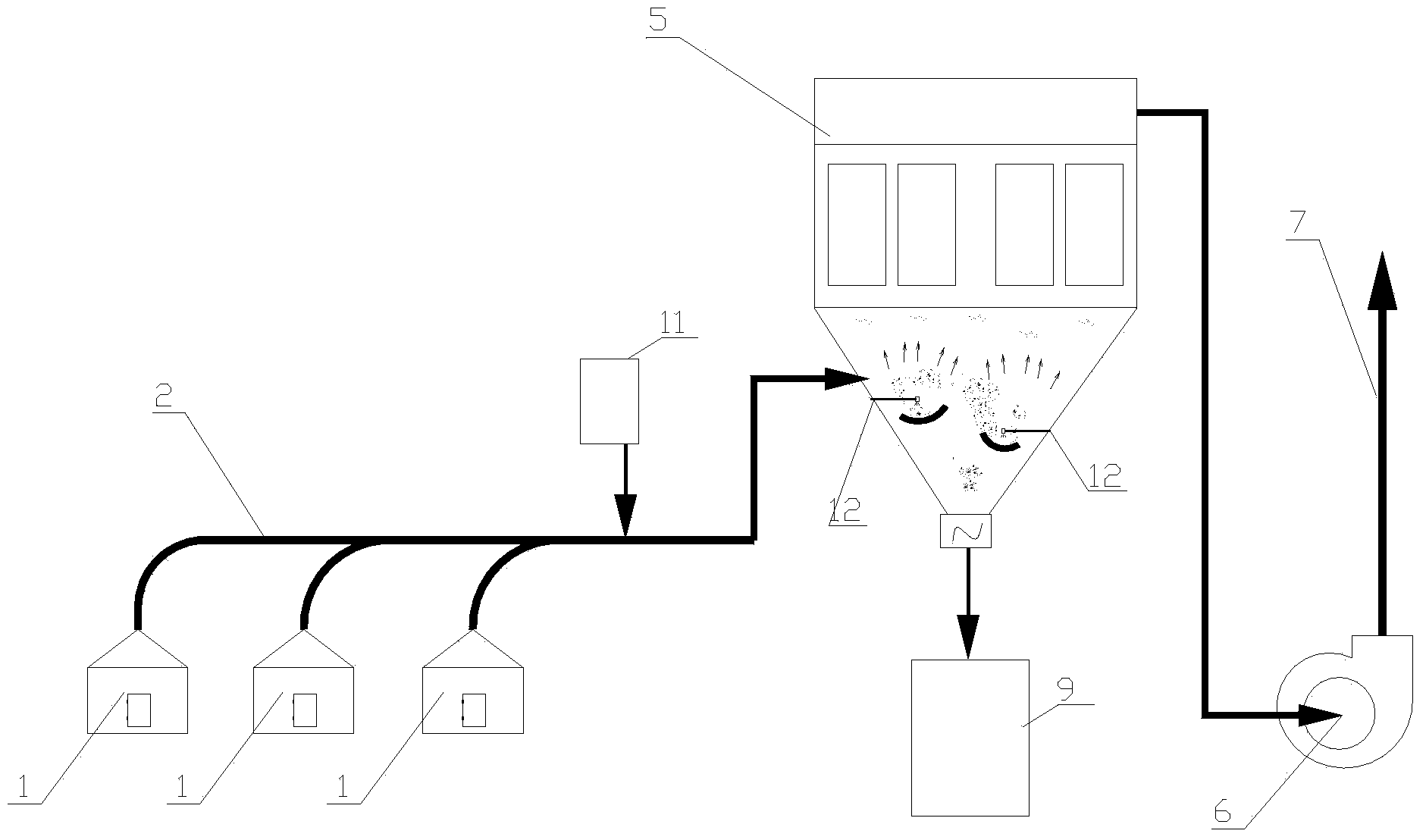

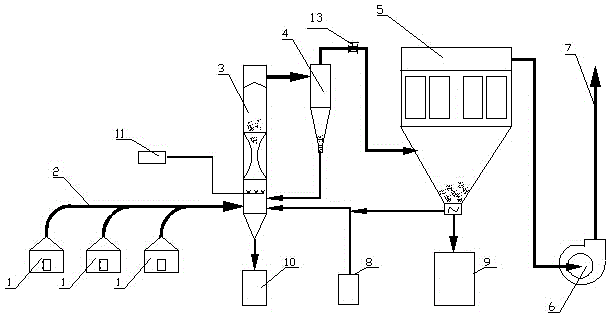

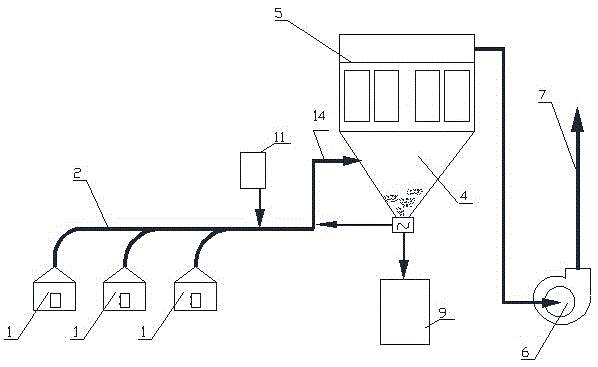

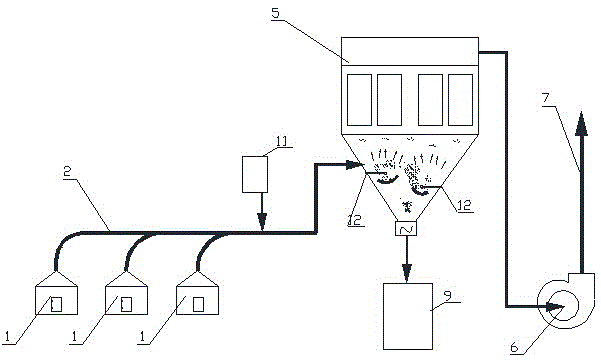

Process and device for purifying flue gas containing lead and cadmium by adopting sintered plate circulation adsorption method

ActiveCN103446876ASolve efficient, reasonable and economical governance technical problemsReduce concentrationDispersed particle separationHazardous substanceFiltration

The invention relates to a process and a device for purifying flue gas containing lead and cadmium by adopting a sintered plate circulation adsorption method, belonging to the technical field of environmental protection of the non-ferrous metal metallurgy industry. The process for purifying the flue gas containing lead and cadmium by adopting the sintered plate circulation adsorption method comprises the following steps of carrying out circulation fluidized adsorption by adopting powder, carrying out dust removal by filtration by virtue of a sintered plate, and combining with measures of mixing wind, dividing walls, humidifying and cooling, thus effectively removing and recycling harmful substances of lead, cadmium and the like in the smoke. By adopting the process for purifying the flue gas containing lead and cadmium by adopting the sintered plate circulation adsorption method, the effect that discharge of the harmful substances of lead, cadmium and the like is far below the national standard can be strictly guaranteed; meanwhile, the historic technical problems that a filter material is blocked, the efficiency is low and waste water treatment by a wet process technology is difficult in the traditional filtering type dust removal technology are solved, and no secondary pollution is produced in a treatment process, so that the process is suitable for development trends of environmental protection and circular economy and provides a new way for treating non-ferrous metal lead and cadmium smoke.

Owner:内蒙古森鼎环保节能股份有限公司

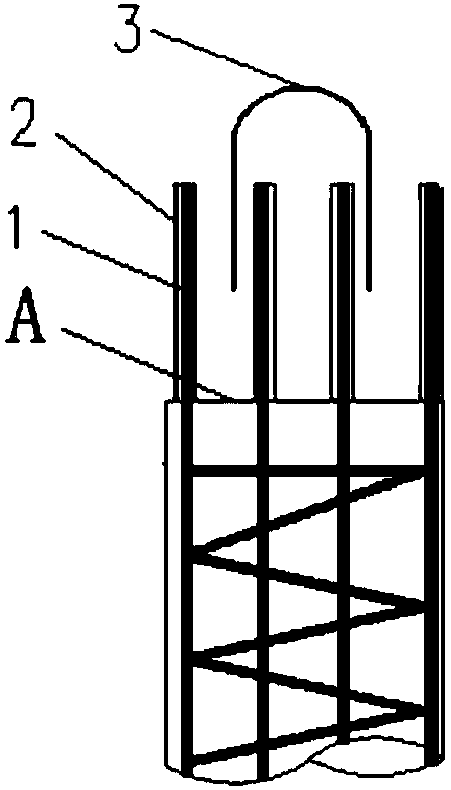

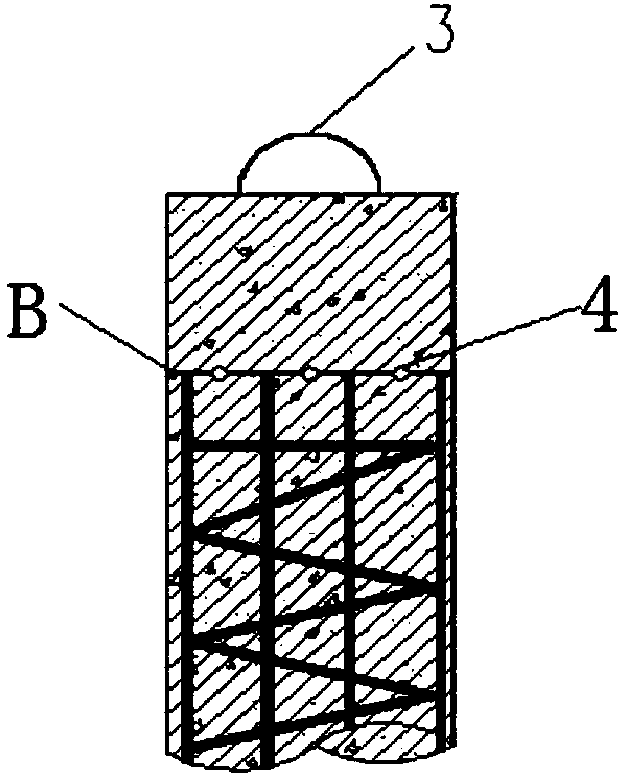

Construction method for fast breaking pile head of cast-in-place pile

A construction method for fast breaking a pile head of a cast-in-place pile includes the steps that the top end of each main steel bar of a steel bar cage is sleeved with a casing pipe, and an upper end port and a lower end port of each casing pipe are sealed; then pile foundation concrete grouting is performed till the designed elevation of the pile top is achieved; when grouting is performed atthe position of the elevation of the pile top, steel bar hoisting rings are pre-buried in pile head concrete above the elevation of the pile top; after the pile body concrete is solidified, earthworkaround the pile head is excavated; the portion needing pile cutting is measured and identified; after drilled holes are evenly distributed along the circumference of the identified position, the pilehead concrete is separated through a splitter; and the pile head concrete is hoisted out and carried away. The construction method effectively solves damage to the steel bars and a pile body in the construction process, improves the construction efficiency and guarantees the engineering quality.

Owner:YUNNAN NO 5 CONSTR ENG

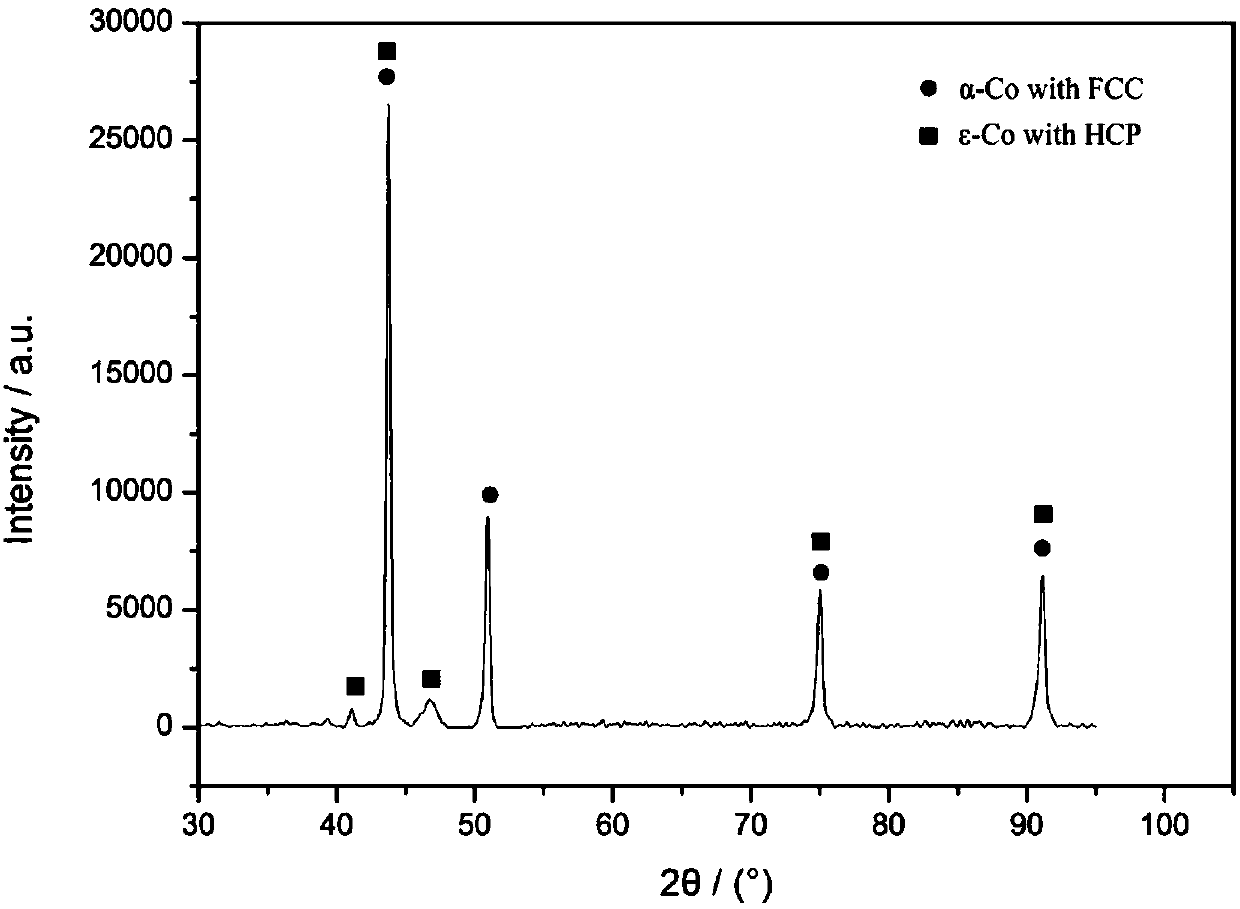

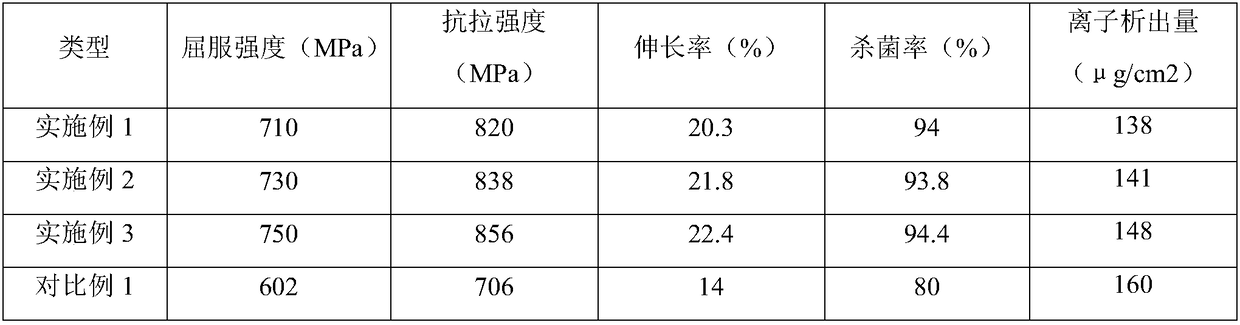

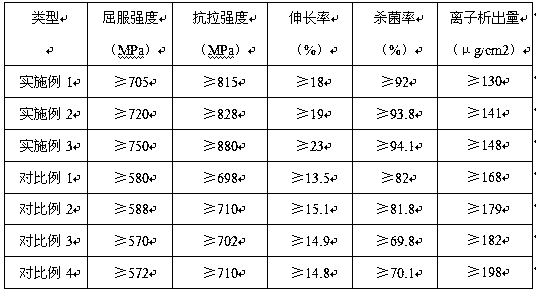

Cobalt base alloy for fixing human skeletons and preparation method thereof

The invention discloses a cobalt base alloy for fixing human skeletons. The cobalt base alloy is characterized by comprising the following chemical components in percentage by weight: 22.5-24.5% of Cr, 7-8% of Ni, 11-12% of W, 3-4% of Mo, 0.5-1.5% of Ta, 0.1-0.8% of Si, 0.1-0.5% of Mn, 0.1-0.5% of Nb, 1.0-2.0% of Cu, 0.1-0.2% of N, 0.01-0.08% of Sc+La+Ce, and the balance of Co and inevitable impurity elements. The yield strength of the cobalt base alloy is not less than 710 MPa, the tensile strength is not less than 820 MPa, the elongation is not less than 20%, and the sterilization rate is not less than 93.8%; and all the indexes are obviously higher than that of other products short of alloy elements, products not performing atomized pulverization and similar products not performing surface coating treatment.

Owner:王甲林

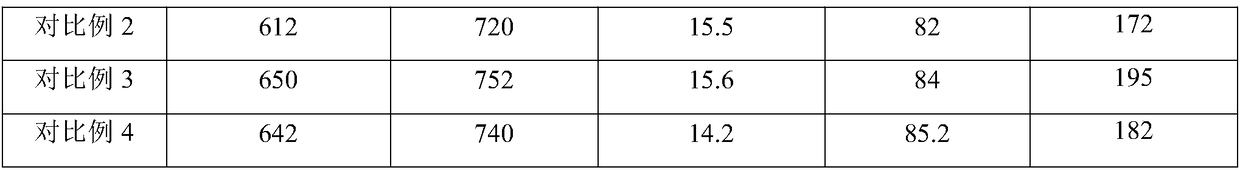

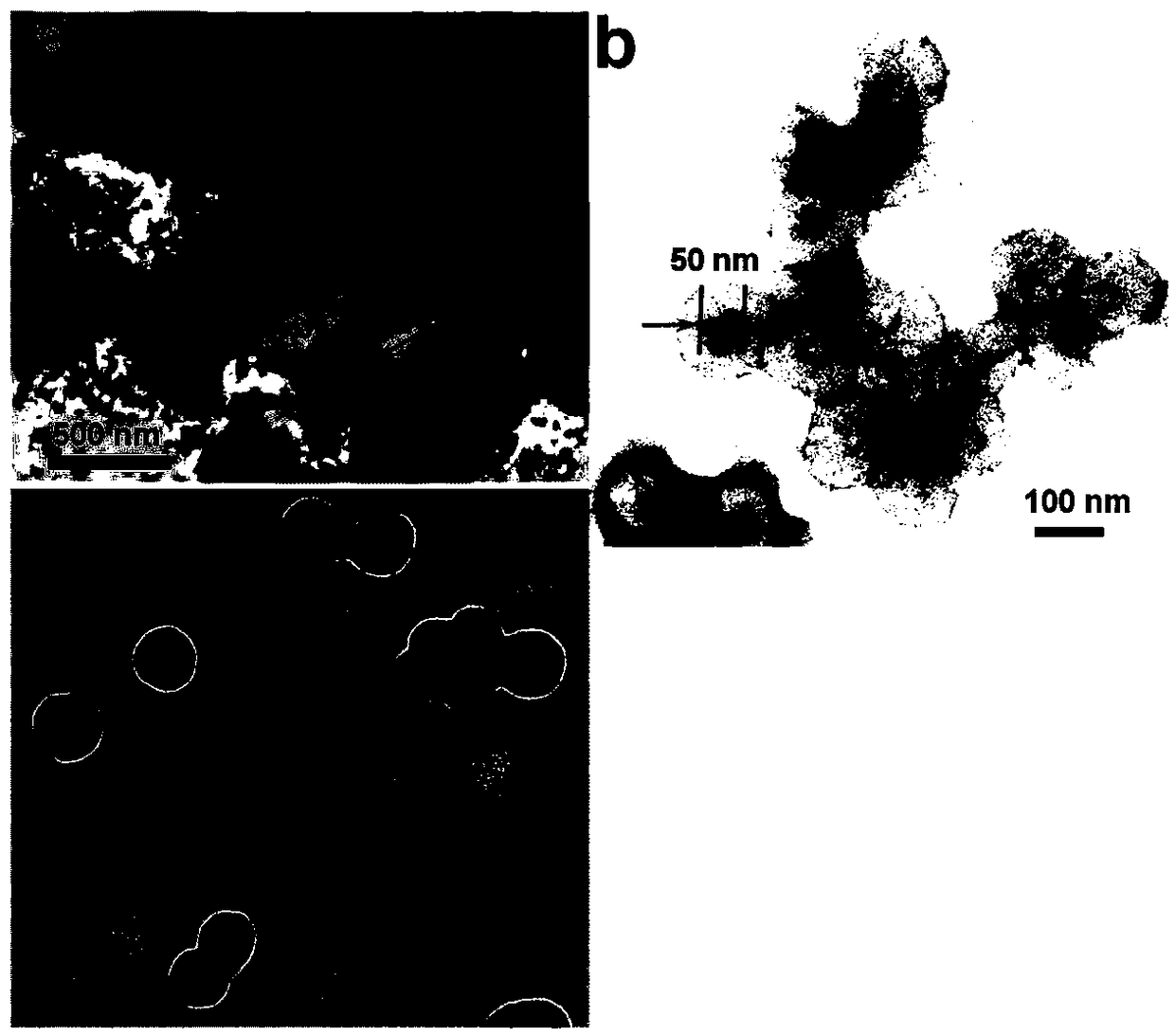

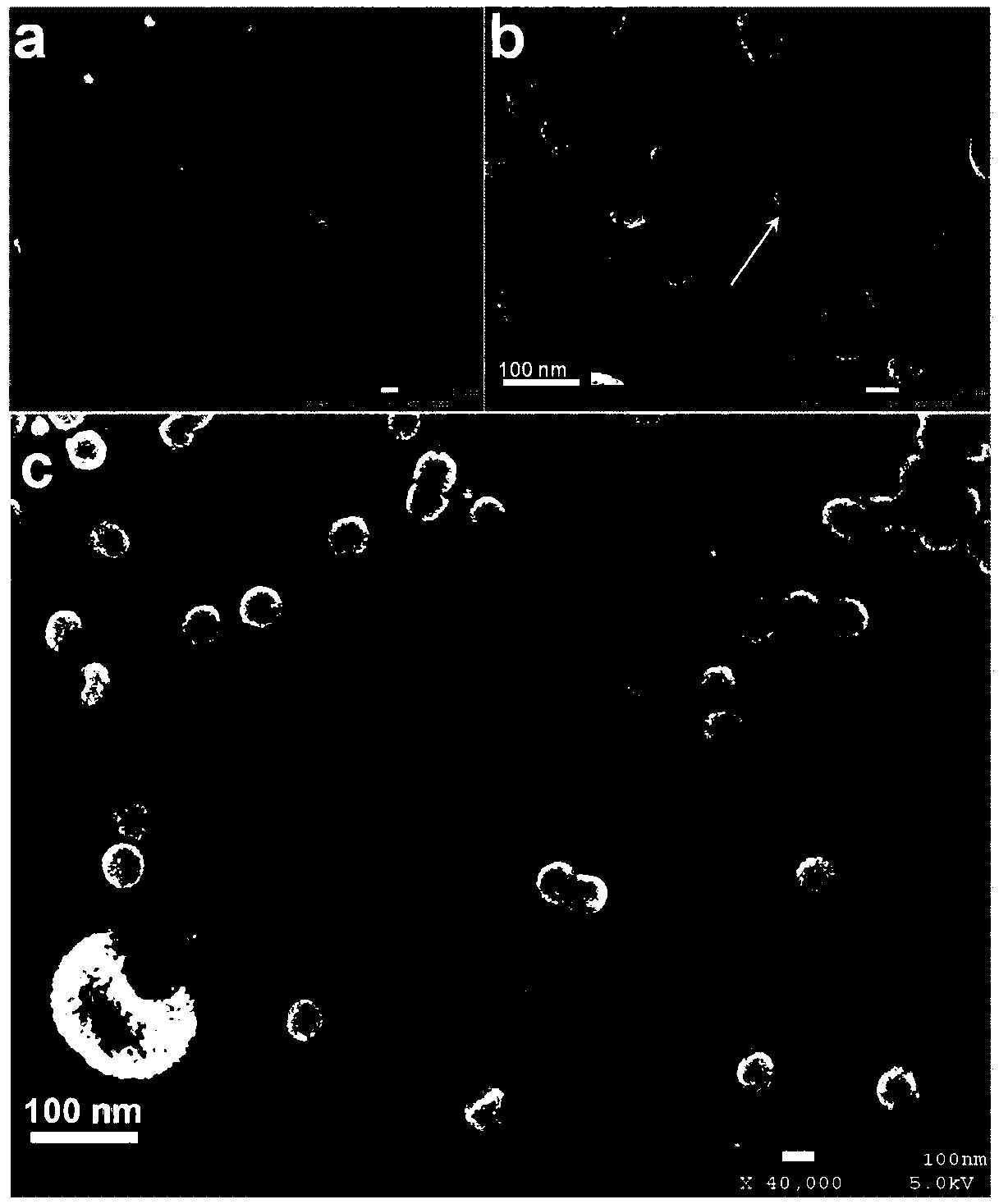

CO2 response polymer hollow microsphere and preparation method thereof

InactiveCN108659161AAchieve no irritating residueImplementing an Environmentally Friendly Response PatternMicroballoon preparationMicrocapsule preparationEtchingMicrosphere

The invention provides a preparation method of CO2 response polymer hollow microspheres. The preparation method comprises the following steps: firstly, enabling a monomer, namely styrene, methyl methacrylate, tert-butyl methacrylate, butyl acrylate or hydroxyl styrene, to react with an initiator and an emulsifier, so as to obtain a seed microsphere emulsion; secondly, simultaneously dropping a mixture of a compound A and a crosslinking agent, and the initiator into the seed microsphere emulsion, and carrying out a reaction so as to obtain a core-shell microsphere emulsion; mixing the core-shell microsphere emulsion with organic solvents, namely tetrahydrofuran (THF), chloroform, ethyl acetate, methylbenzene and the like, and carrying out selective etching. By adopting the preparation method, intelligent hollow microspheres of hollow structures with CO2 response are prepared, irritation residue-free and environmental-friendly response modes of a hollow microsphere material can be achieved, and in addition, the microspheres are controllable in morphology and CO2 irritation response.

Owner:SICHUAN UNIV

Method for regulating and controlling particle size of silicon dioxide microspheres

The invention provides a method for regulating and controlling the particle size of silicon dioxide microspheres. The method comprises the following steps that an ammonium chloride aqueous solution and a tetraethoxysilane ethanol solution with different concentrations are mixed, the pH value of the solution is regulated and controlled through triethylene tetramine, at the normal-temperature and normal-pressure conditions, a submicron-order and micron-sized silicon dioxide sphere precursor with adjustable particle size is successfully synthesized, an obtained drying sample is placed in a mufflefurnace, calcining is carried out for 2-6 hours at the temperature of 500-800 DEG C, and cooling is carried out to reach the room temperature so as to obtain silicon dioxide with different sphericaldiameters. The regulation and control method has the advantages that a required device is simple, the operation is simple and easy, the efficiency is high, and accurate control over the size of the product can be realized; and the particle size of the silicon dioxide microspheres prepared through the method ranges from 200 nm to 2 microns, the synthetic path is simple, the cost is low, the application is wide, and the like.

Owner:JIANGXI NORMAL UNIV

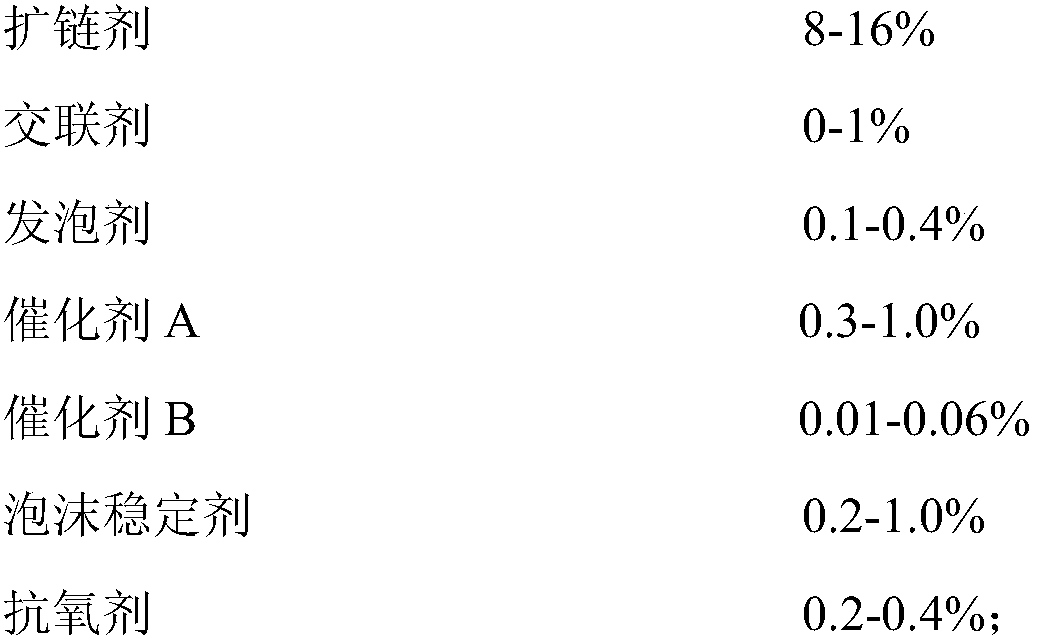

Composite material for polyurethane inflation-free inner tube and preparation method thereof

The invention relates to a composite material for a polyurethane inflation-free inner tube and a preparation method thereof, and belongs to the technical field of application of polyurethane. The composite material for the polyurethane inflation-free inner tube, provided by the invention, is prepared from a component A and a component B, wherein the weight percent ratio of the component A to the component B is 100 to (80 to 100); the component A is prepared from polyether polyol A, polymer polyol, a chain extender, a cross-linking agent, a foaming agent, a catalyst A, a catalyst B, a foam stabilizer and an antioxidant; the component B is prepared from modified isocyanate and a reaction inhibitor. The composite material for the polyurethane inflation-free inner tube, provided by the invention, is applied to bicycles, a flat tire problem is solved, and the service life is prolonged; the produced product has the advantages of good elasticity, good performance, good fatigue-resisting performance and the like. Meanwhile, the invention provides the preparation method which has the advantages of simplicity and feasibility, energy saving and consumption reduction.

Owner:SHANDONG INOV POLYURETHANE

Acid resistant ceramic materials, filter using the same, and preparation of them

InactiveCN101137597AStable structureIncrease contentFiltration separationThin material handlingHoneycombCordierite

Abstract The present invention provides porous ceramic materials having good resistance to heat, acid and base, comprising three or more oxides selected from an oxide of silicon (SiO ), an oxide of aluminum (Al O ), an oxide of a transition metal, MxOy, [wherein M represents a 4B, 5B or 6B-group transition metal which can be selected from Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, W or Ce, x represents an integer of 1 to 3, and y represents an integer of 1 to 3] and its preparation. By applying ceramic materials prepared according to the present invention that are structurally, thermally and chemically stable to a porous honeycomb support for the purification of exhaust gas or to a filter (DPF, Diesel Particulate Filter) for the purification of diesel engine exhaust gas, it is possible to prevent or remarkably reduce any structural destruction caused by corrosive gas, which results from employing a cordierite material as a structural support.

Owner:KH CHEM CO LTD

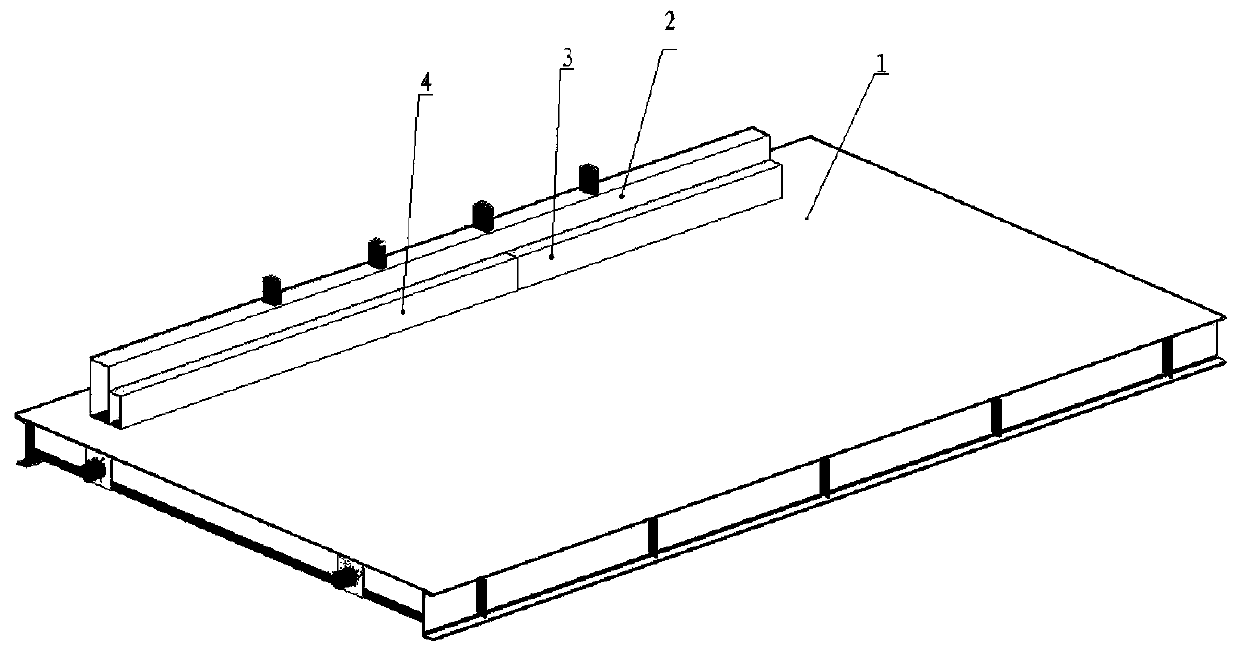

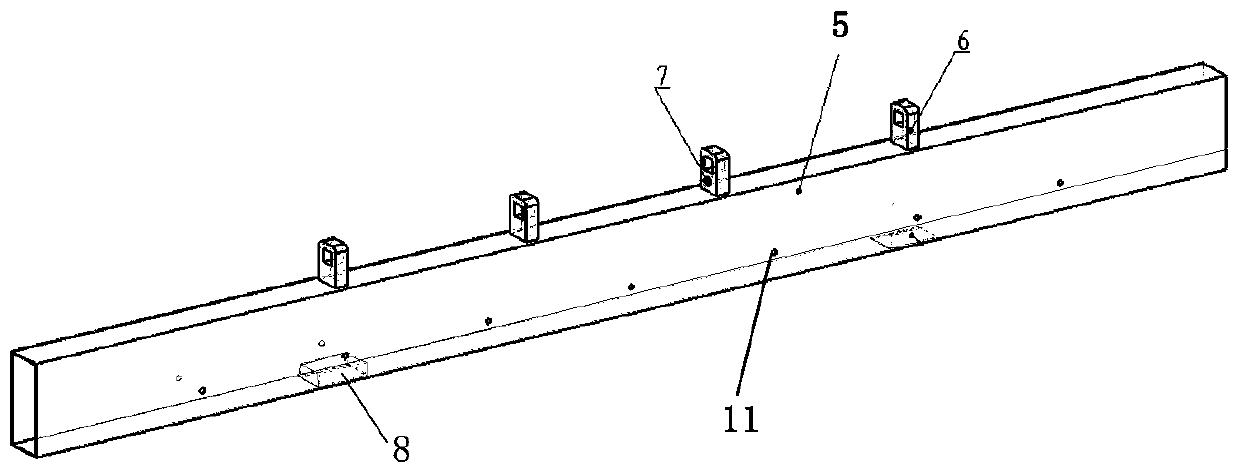

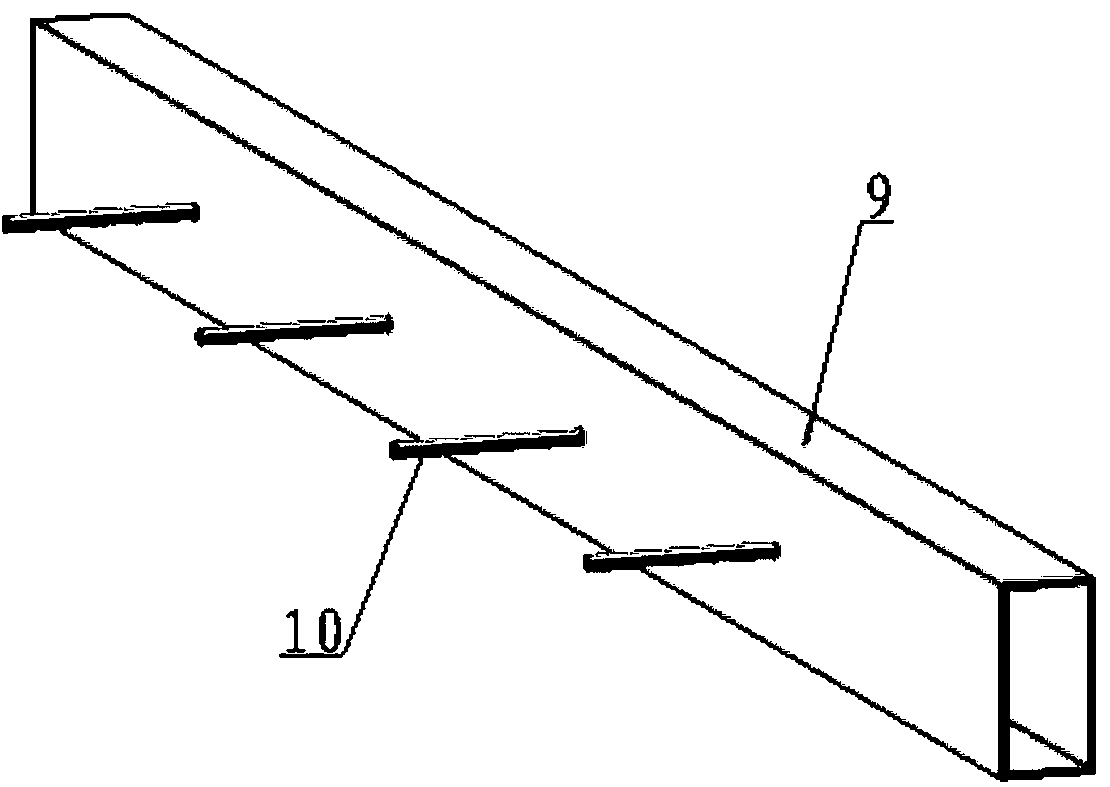

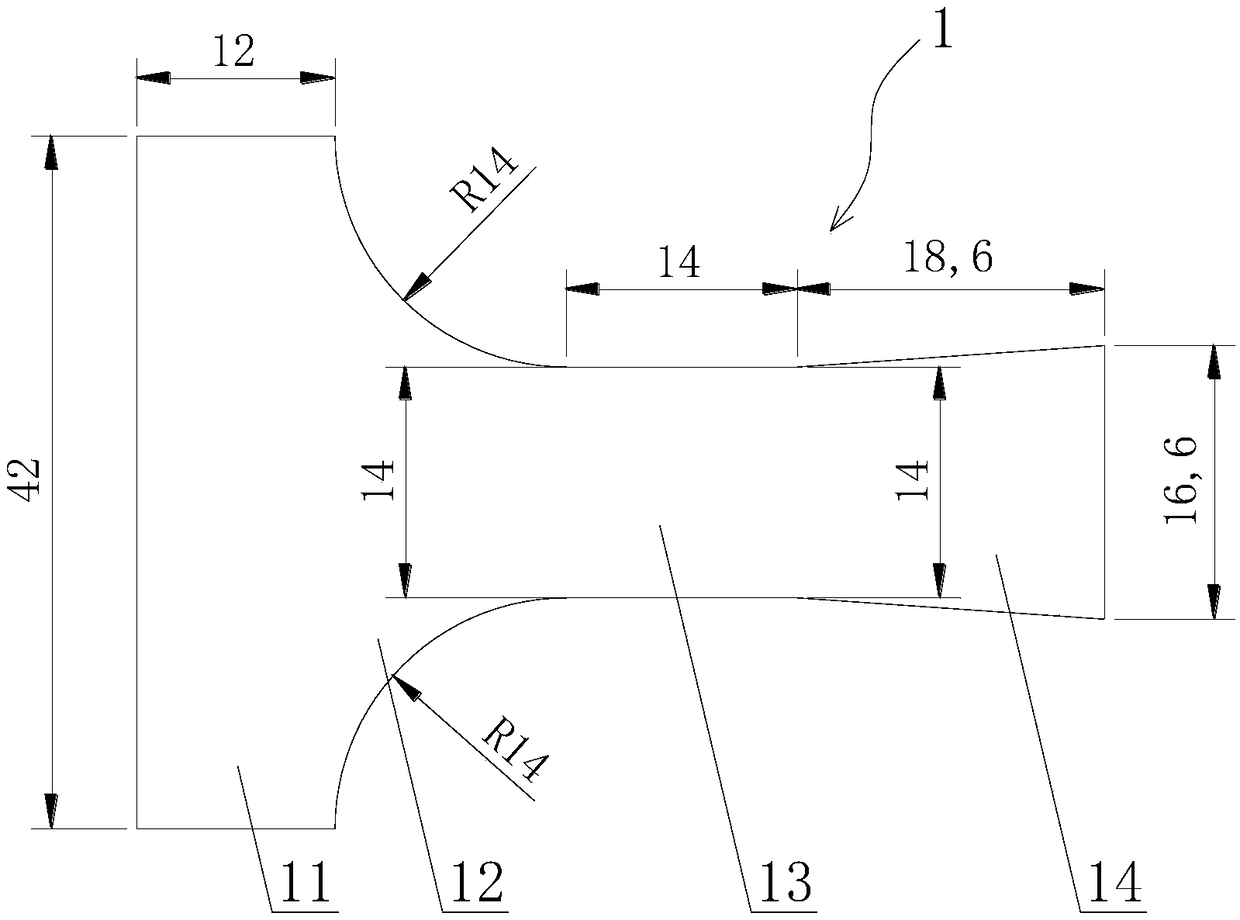

Intelligent side forms mold device

PendingCN109676757AGuaranteed not to shiftGuaranteed dimensional accuracyMould fastening meansControl systemAlloy

The invention discloses an intelligent side forms mold device. The mold device comprises a mold body, a robot and a control system, wherein the mold body comprises a working mold table and a pluralityof main molds and working molds arranged on the surface of the working mold table; the main molds and the working mold are all made of aluminum alloy profiles and are provided with various standard sizes; a plurality of mounting ears is fixedly arranged on the surface of the main molds;, the inner side of each mounting ear is provided with a conductive probe; the bottom of each main mold is alsoprovided with electric permanent magnet connected to the conductive probe; the side wall near to the electric permanent magnet is provided with a plurality of reserved holes; the robot is provided with a clamp; a working end of the clamp is provided with a female plug matching with the conductive probe; and a path is formed by the combination of the conductive probe and the female plug to controlthe charging and discharging of the electric permanent magnet. Compared with the prior art, the structure of the mold device is simple and light, the design is reasonable, the operation is convenient,the mold body of any size can be spliced according to actual needs, the electric permanent magnet ensures that the working mold table dose not shift during vibration, and the dimensional accuracy ofa PC component is ensured.

Owner:南阳精工匠人装配建筑科技有限公司

High-temperature liquid steel slag atomization laval spray pipe, atomization air box and atomization method

InactiveCN109338022AImprove blowing effectQuick shotRecycling and recovery technologiesSlagLiquid steel

The invention discloses a high-temperature liquid steel slag atomization laval spray pipe, an atomization air box and an atomization method, relates to the field of metallurgy industry, and aims at achieving the technical purpose of providing a laval spray pipe suitable for atomizing high-temperature liquid steel slag. According to the adopted technical scheme, according to the high-temperature liquid steel slag atomization laval spray pipe, a pipe cavity of the laval spray pipe is symmetric relative to the center axis, the pipe cavity is sequentially divided into an inlet section, a narrowingsection, a parallel section and an outlet section in the spraying direction, through the optimization design of various sections, airflow can be accelerated to the ideal speed, the high-temperature liquid steel slag is atomized, and a good blowing effect is achieved. The invention further provides the high-temperature liquid steel slag atomization air box, the problem that an existing air box isin poor in atomization effect on high-temperature liquid steel slag is solved, according to the adopted technical scheme, the high-temperature liquid steel slag atomization air box comprises a box body, a hole is formed in one side of the box body, and the laval spray pipe is arranged in the hole of the box body.

Owner:LIANGSHAN RUIJING ENVIRONMENTAL PROTECTION RESOURCE DEV

Freezer

ActiveCN103791671BReduce loadTake advantage ofLighting and heating apparatusStationary refrigeration devicesCold airQuick Freeze

The invention discloses an instant freezer and belongs to the technical field of instant freezing equipment. The instant freezer comprises a freezer body, a freezing chamber and an air supply chamber provided with a cold air blowing device are arranged in the freezer body, a conveying belt is arranged in the position corresponding to the cold air blowing device around the air supply chamber, and a power chamber used for installation of a first power device is arranged outside the freezer body. The two ends of the conveying belt extend out of the inlet end and the outlet end of the freezer body, and a normal temperature heating device which is communicated with the power chamber and used for heating the conveying belt is arranged at the inlet end of the freezer body. Heat in the power chamber acts on the conveying belt through the normal temperature heating device, so that the temperature of the body of the conveying belt is raised, the function of the cold air blowing device is utilized in an auxiliary mode, fluidized instant freezing is achieved, the problem of adhering between goods and adhering between the goods and the conveying belt is avoided, the single rate of the goods and normal conveying of the conveying belt are guaranteed, and the production efficiency and the product quality are improved. Meanwhile, the first power device is externally arranged, the refrigerating capacity is fully utilized, the load of the freezer is reduced, and the purpose of energy conservation is achieved.

Owner:绿特国创(潍坊)节能科技有限公司

Cobalt-base alloy for artificial tooth and preparation method of cobalt-base alloy

The invention discloses a cobalt-base alloy for an artificial tooth. The cobalt-base alloy is characterized by comprising the following chemical components in percentage by weight: 22.5-24.5% of Cr, 3-4% of Ni, 9-10% of W, 3-4% of Mo, 0.5-1.5% of Ta, 0.1-0.8% of Si, 0.1-0.5% of Mn, 0.1-0.5% of Ti, 1.0-2.0% of Cu, 0.1-0.2% of N, 0.01-0.08% of Sc+Y+La and the balance of Co and inevitable impurity elements. The yield strength of the cobalt-base alloy is greater than or equal to 700MPa, the tension strength of the cobalt-base alloy is greater than or equal to 800MPa, the elongation rate of the cobalt-base alloy is greater than or equal to 18%, the sterilization rate of the cobalt-base alloy is greater than or equal to 92%, and the indexes are remarkably higher than those of other products without alloy elements, remarkably higher than products without flow energy grinded powder, and remarkably higher than similar products without surface coating treatment.

Owner:温州市赢创新材料技术有限公司

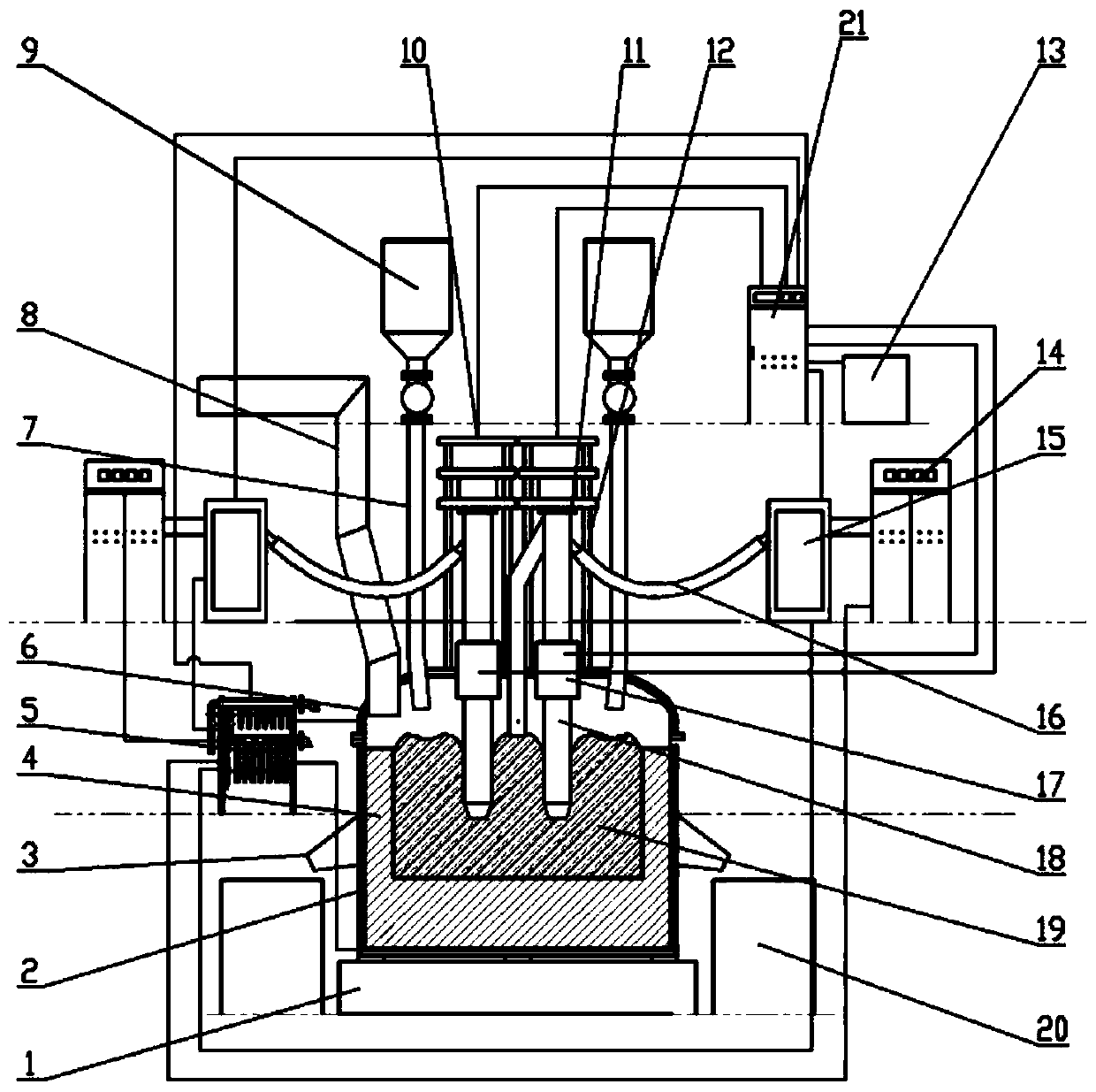

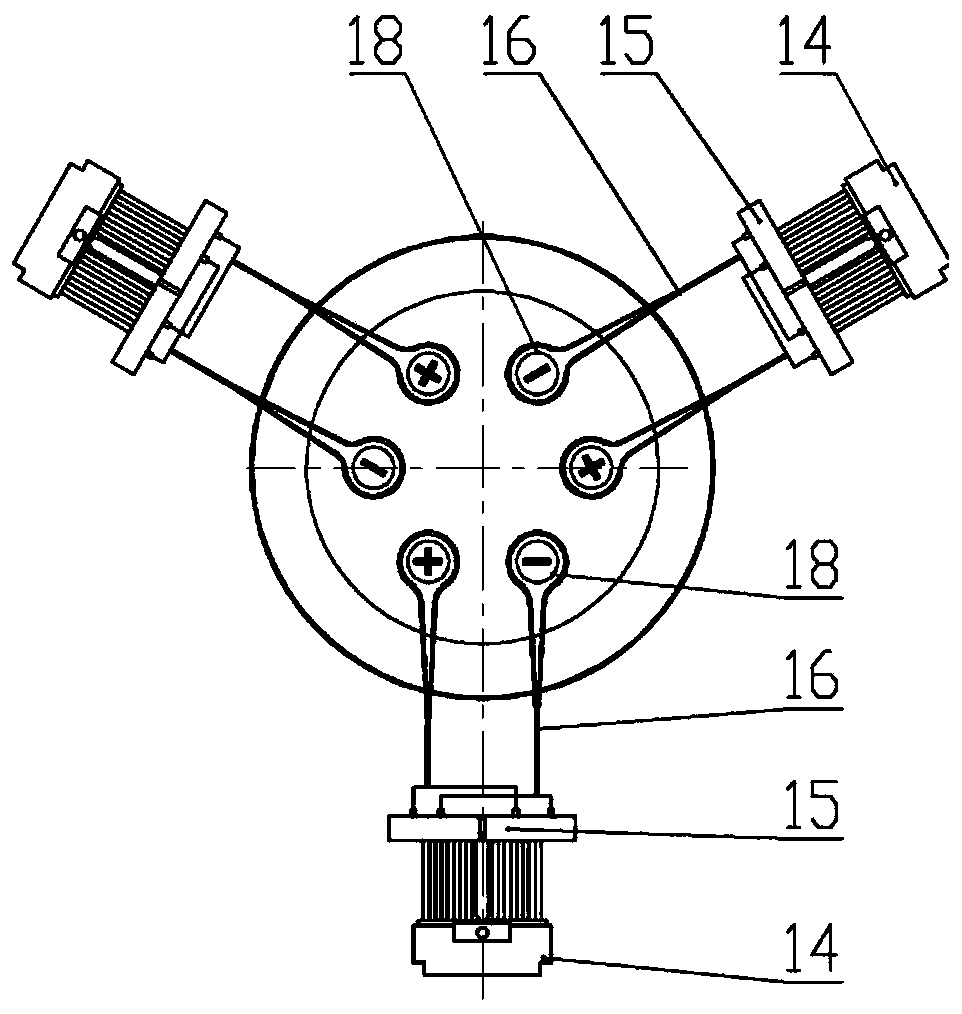

Direct-current aluminum-silicon alloy submerged arc furnace

PendingCN111187909ANo bondingNo riseCharge manipulationIncreasing energy efficiencySilicon alloyElectric control

The invention provides a direct-current aluminum-silicon alloy submerged arc furnace. The direct-current aluminum-silicon alloy submerged arc furnace comprises a furnace body foundation and a furnaceshell, a furnace outlet is formed in the bottom of the furnace shell, a furnace lining is arranged in the furnace shell, and a cooling water system is arranged outside the furnace shell; a furnace cover is arranged at the top of the furnace shell; a material falling pipe, a clean furnace gas flue and electrodes are arranged on the furnace cover; the material falling pipe is connected with a furnace top bin; an electrode lifting mechanism is connected with the electrodes through an electrode holder; an electrode guide mechanism is further arranged, and the electrodes are connected with an electrode bottom structure; the direct-current aluminum-silicon alloy submerged arc furnace further comprises an electric furnace transformer, the electric furnace transformer is connected with a rectifier, a short net and an electric control system, and the electric furnace transformer supplies direct current to the electrode bottom structure; the hydraulic system is connected with the electrode holder; and the electric control system is further connected with a temperature measuring system, a liquid aluminum-silicon alloy material level sensor in the furnace body, the electrode holder and an electrode lifting system. According to the direct-current aluminum-silicon alloy submerged arc furnace, the temperature in the furnace body is high, a hearth is integrally built without gaps, the depth and the diameter of the hearth are in geometric relation with the electrodes, the power density in unit volume is high, feeding and discharging are continuous, and the temperature can be adjusted.

Owner:BEIJING OUFEI JINTAI TECH CO LTD

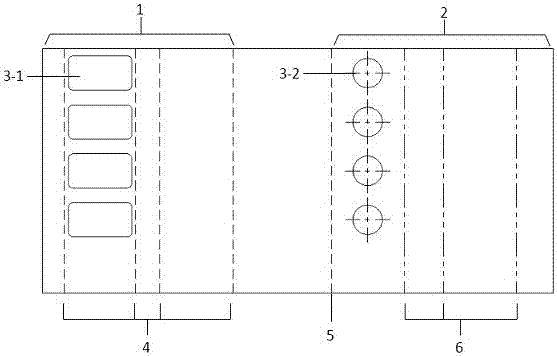

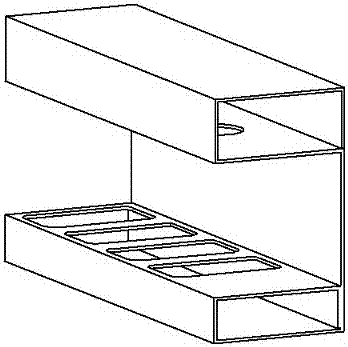

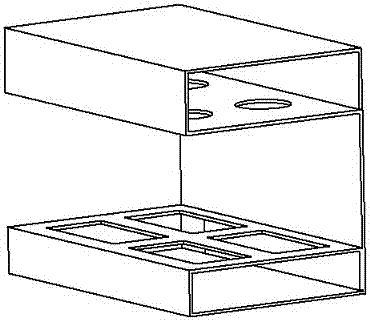

Cushion pad for multi-combination bottled product electronic commerce packing

PendingCN107264943AIntegral formabilityNo bondingContainers to prevent mechanical damageRigid containersBottle capBottle fed

The invention discloses a cushion pad for multi-combination bottled product electronic commerce packing. The cushion pad comprises an upper folded plate, a lower folded plate and notches, wherein the upper folded plate and the lower folded plate are provided with the notches which are suitable for shapes and sizes of bottle caps and bottle bodies of products; the upper folded plate is folded along an outer folding line, forming an upper cavity which is used for protecting the bottle caps of the products and plays leakage prevention and fixation effects; the lower folded plate is folded along an inner folding line, forming a lower cavity which is used for fixing the bottle bodies and bottle bottoms, and the lower cavity is combined with the upper cavity to act and play a role of fixing the products. The cushion pad can be formed integrally and is convenient to process; there is no need for pasting or preassembly, operation is easy and convenient, rapid molding can be realized, and the cushion pad is applied to fast assembly scenes of electronic commerce packing; the cushion pad is formed by folding corrugated boards and can be recycled; the cushion pad is appropriate for bottled products of various combination types and wide in applicability.

Owner:无锡新祥恒包装科技有限公司

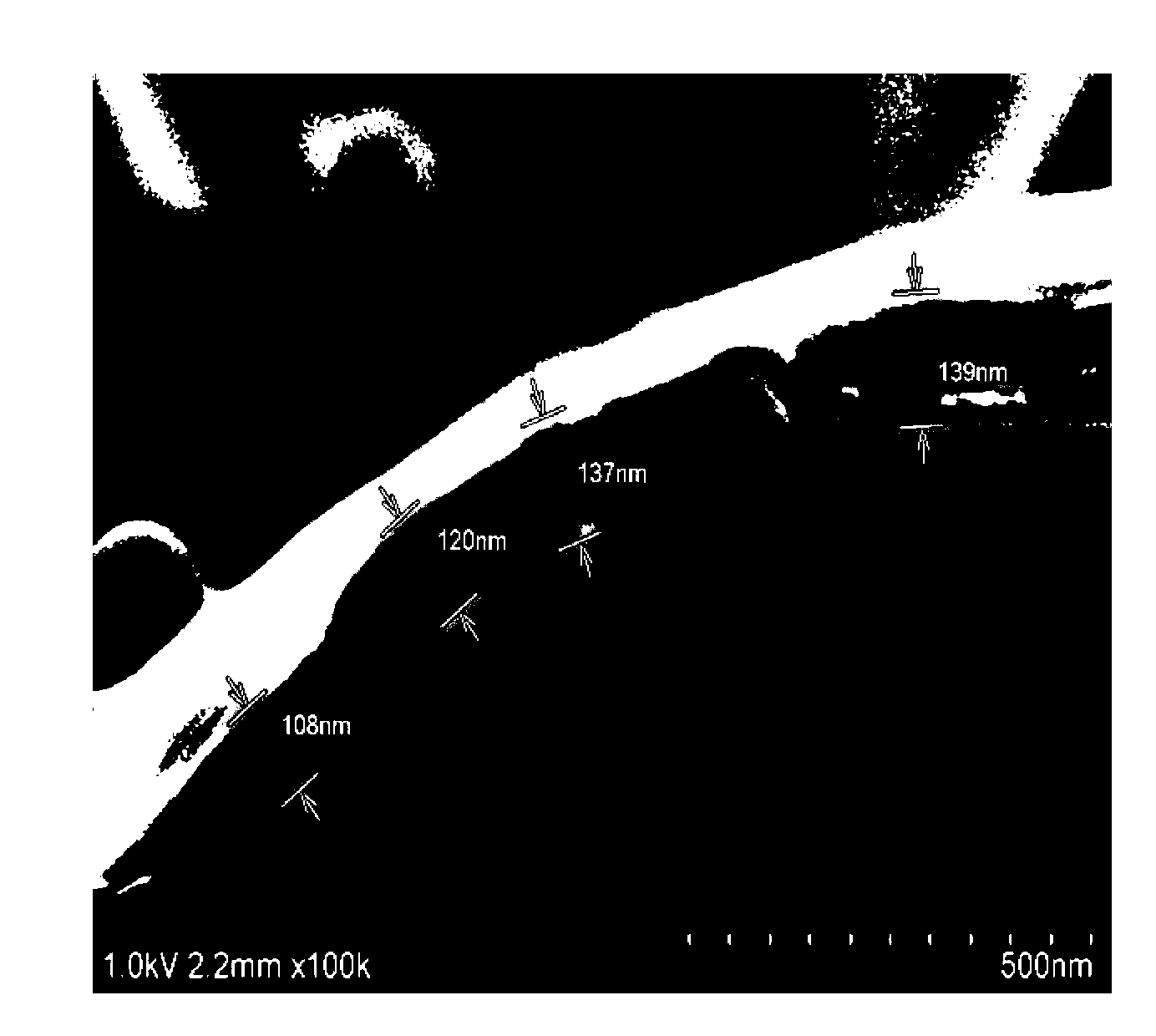

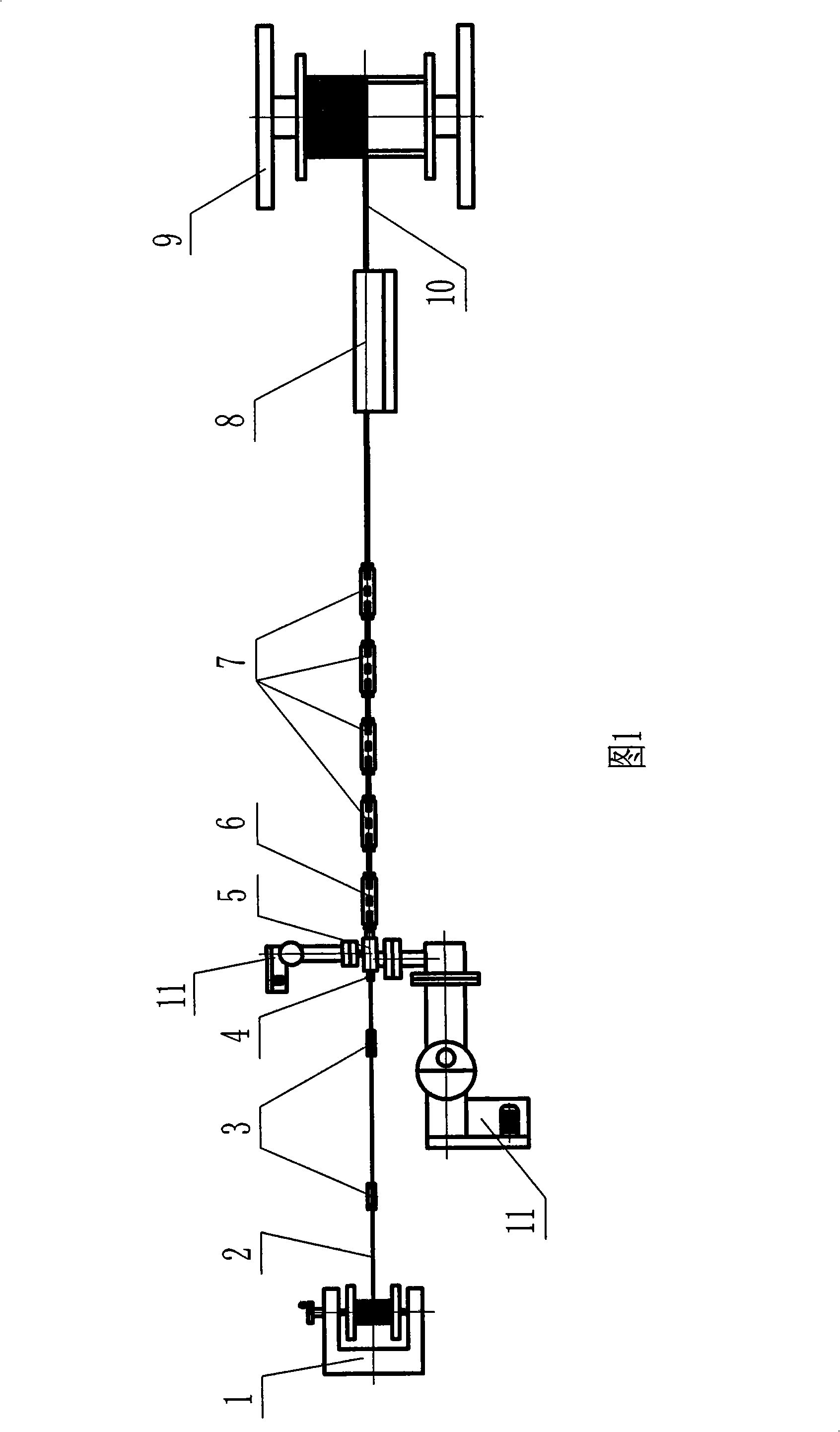

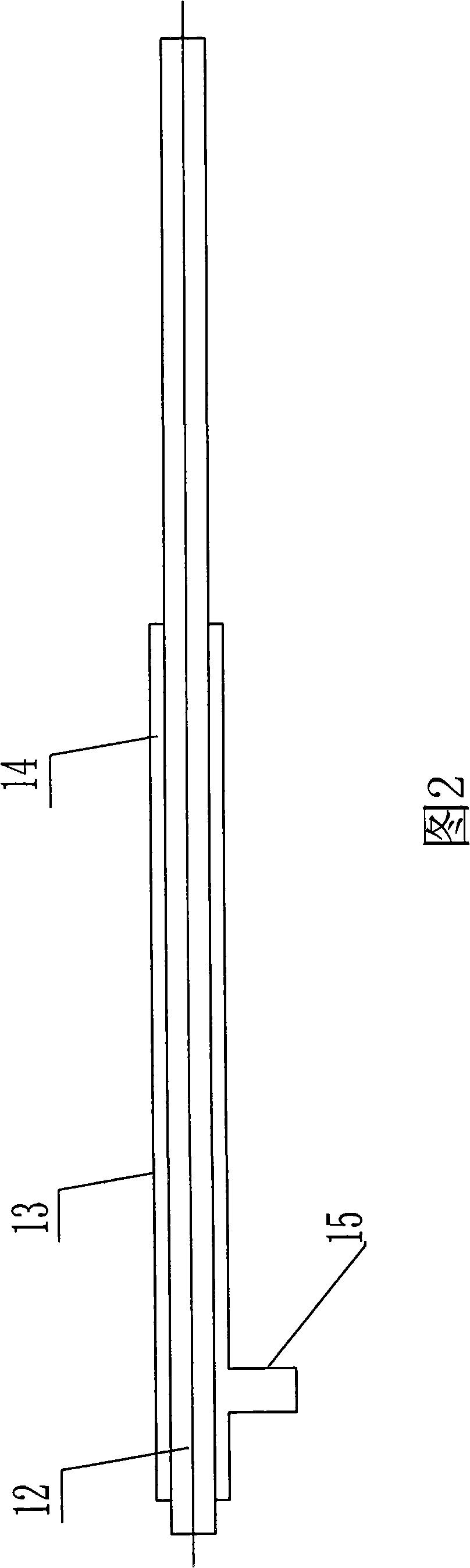

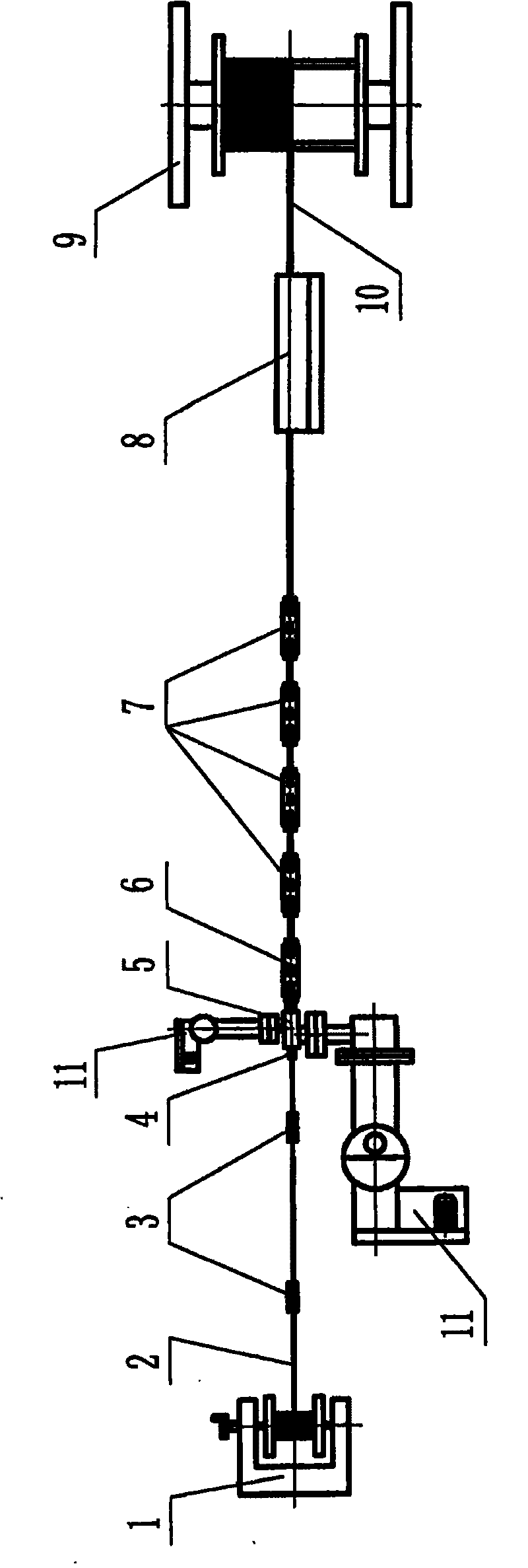

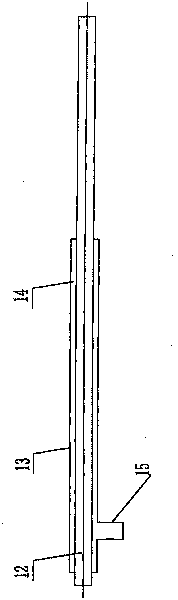

Pipe compound optical fiber cable processing technique

ActiveCN101295060AMeet needsExpand coverageFibre mechanical structuresEngineeringOptical fiber cable

The invention relates to a processing technique of a pipeline compound optical cable used for transmitting information in an optical communication network, which belongs to the technical field of optical cable processing. The invention is characterized in that: the optical cable is synchronously combined into the pipeline when the pipeline is produced to form the pipeline compound optical cable. Loose state is kept between the optical cable in the pipeline and the pipeline without bonding phenomenon, thus ensuring the repeated extraction and use of the pipeline and the optical cable; the product length can be cut at will according to needs of users and different situation of transport means; above 4 kilometers for each pallet can be achieved, and the processing efficiency is high, the equipment structure is simple, the working processes are less, and the appearance is beautiful. The processing technique of the pipeline compound optical cable overcomes the shortcomings of large investment for equipment, numerous constructors, big organization difficulty, low working efficiency and comparatively short unit product length, etc. in the existing pipeline optical compound production which mainly adopts an air blow method and completes the pipeline production and the optical cable compound by two times; therefore, the processing technology is suitable for the processing of various pipeline compound optical cables.

Owner:HUBEI KAILE SCI & TECH

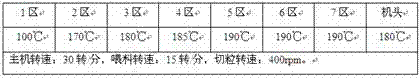

An anti-load anti-fatigue type TPE thermoplastic elastomer and a preparing method thereof

An anti-load anti-fatigue type TPE thermoplastic elastomer and a preparing method thereof are disclosed and belong to the technical field of polymer materials. The elastomer is characterized by comprising, by weight, 46-50 parts of SEBS, 8-12 parts of a POE elastomer, 16-20 parts of copolymerized PP, 28-32 parts of liquid polybutylene (PB), 0.4-0.8 part of an antioxidant, 11-15 parts of calcium carbonate and 0.6-0.8 part of a processing lubricant. The method includes weighing most of the materials, adding the weighed materials into a high-speed mixer, mixing the materials, heating the mixtureto 65-75 DEG C, then adding the liquid polybutylene into the mixture, performing high-speed mixing until the liquid component is completely absorbed by the material mixture, cooling the mixture, and granulating the mixture. Compared with TPE materials in the prior art, the TPE thermoplastic elastomer has good anti-load and anti-fatigue properties, and when the TPE thermoplastic elastomer is used as a hub covering material, the TPE thermoplastic elastomer has good resilience and high adhesive force, and the service lifetime of the TPE thermoplastic elastomer is far longer than that of the TPE materials in the prior art.

Owner:CHINA PETROLEUM & CHEM CORP

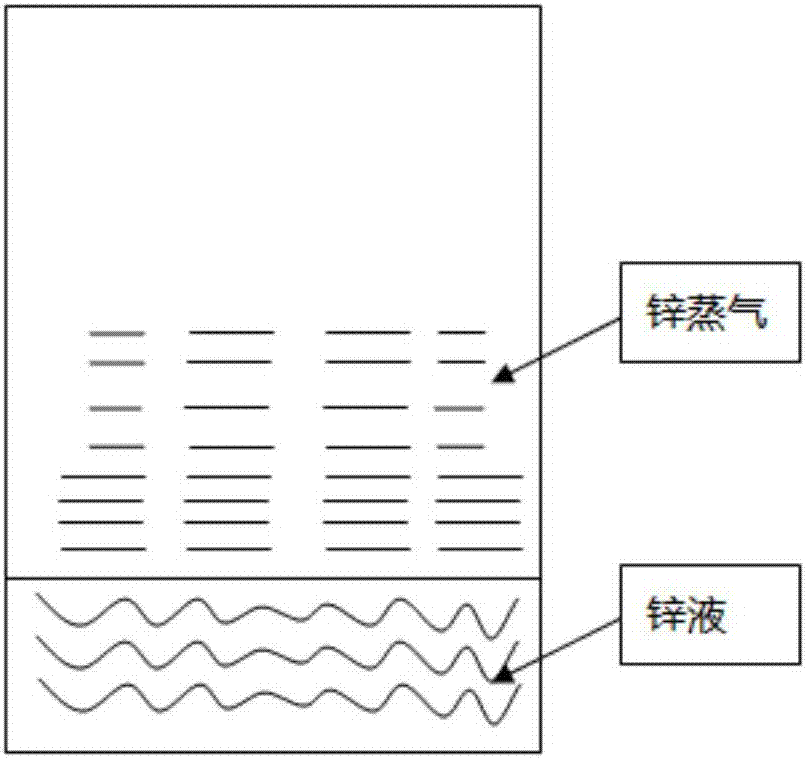

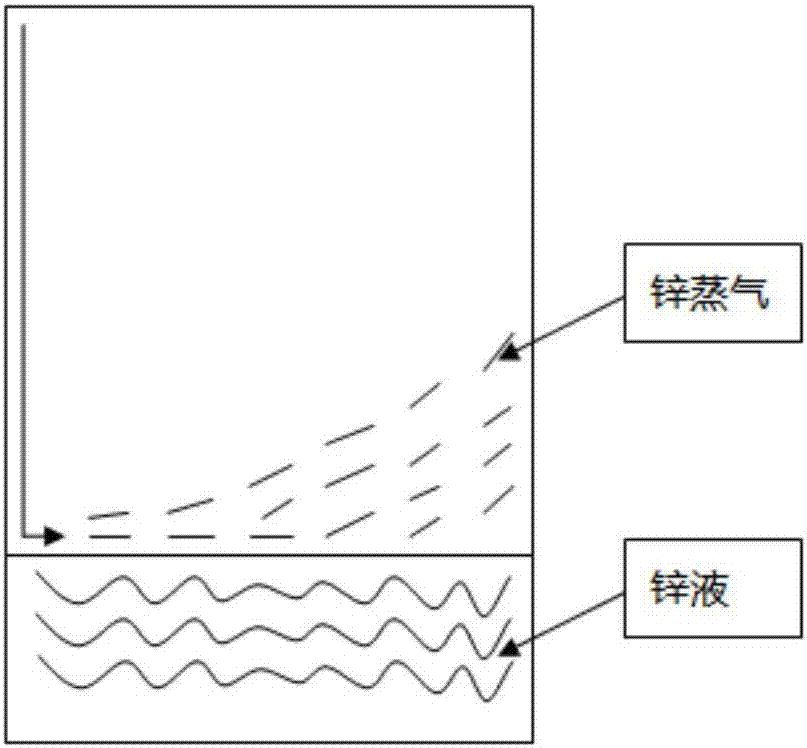

A method for producing spherical zinc powder using hot-dip galvanizing slag

ActiveCN105499592BEliminate the process of smelting and impurity removalShort processTransportation and packagingMetal-working apparatusSlagEvaporation

Owner:NORTHEASTERN UNIV LIAONING

Process and device for purifying flue gas containing lead and cadmium by sintered plate circular adsorption method

The invention relates to a process and a device for purifying flue gas containing lead and cadmium by adopting a sintered plate circulation adsorption method, belonging to the technical field of environmental protection of the non-ferrous metal metallurgy industry. The process for purifying the flue gas containing lead and cadmium by adopting the sintered plate circulation adsorption method comprises the following steps of carrying out circulation fluidized adsorption by adopting powder, carrying out dust removal by filtration by virtue of a sintered plate, and combining with measures of mixing wind, dividing walls, humidifying and cooling, thus effectively removing and recycling harmful substances of lead, cadmium and the like in the smoke. By adopting the process for purifying the flue gas containing lead and cadmium by adopting the sintered plate circulation adsorption method, the effect that discharge of the harmful substances of lead, cadmium and the like is far below the national standard can be strictly guaranteed; meanwhile, the historic technical problems that a filter material is blocked, the efficiency is low and waste water treatment by a wet process technology is difficult in the traditional filtering type dust removal technology are solved, and no secondary pollution is produced in a treatment process, so that the process is suitable for development trends of environmental protection and circular economy and provides a new way for treating non-ferrous metal lead and cadmium smoke.

Owner:内蒙古森鼎环保节能股份有限公司

Pipe compound optical fiber cable processing technique

ActiveCN101295060BMeet needsExpand coverageFibre mechanical structuresEngineeringOptical fiber cable

The invention relates to a processing technique of a pipeline compound optical cable used for transmitting information in an optical communication network, which belongs to the technical field of optical cable processing. The invention is characterized in that: the optical cable is synchronously combined into the pipeline when the pipeline is produced to form the pipeline compound optical cable. Loose state is kept between the optical cable in the pipeline and the pipeline without bonding phenomenon, thus ensuring the repeated extraction and use of the pipeline and the optical cable; the product length can be cut at will according to needs of users and different situation of transport means; above 4 kilometers for each pallet can be achieved, and the processing efficiency is high, the equipment structure is simple, the working processes are less, and the appearance is beautiful. The processing technique of the pipeline compound optical cable overcomes the shortcomings of large investment for equipment, numerous constructors, big organization difficulty, low working efficiency and comparatively short unit product length, etc. in the existing pipeline optical compound production which mainly adopts an air blow method and completes the pipeline production and the optical cable compound by two times; therefore, the processing technology is suitable for the processing of various pipeline compound optical cables.

Owner:HUBEI KAILE SCI & TECH

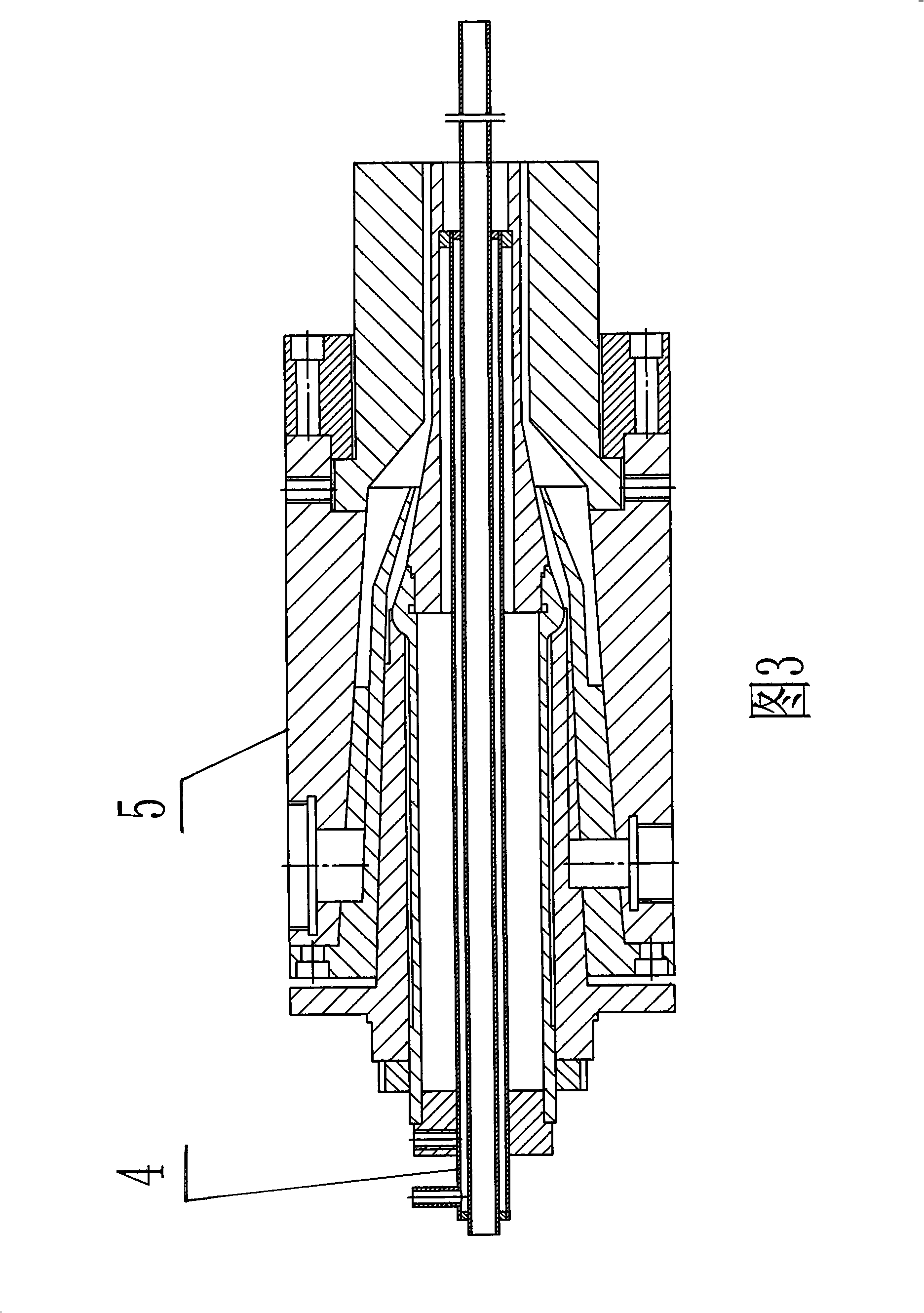

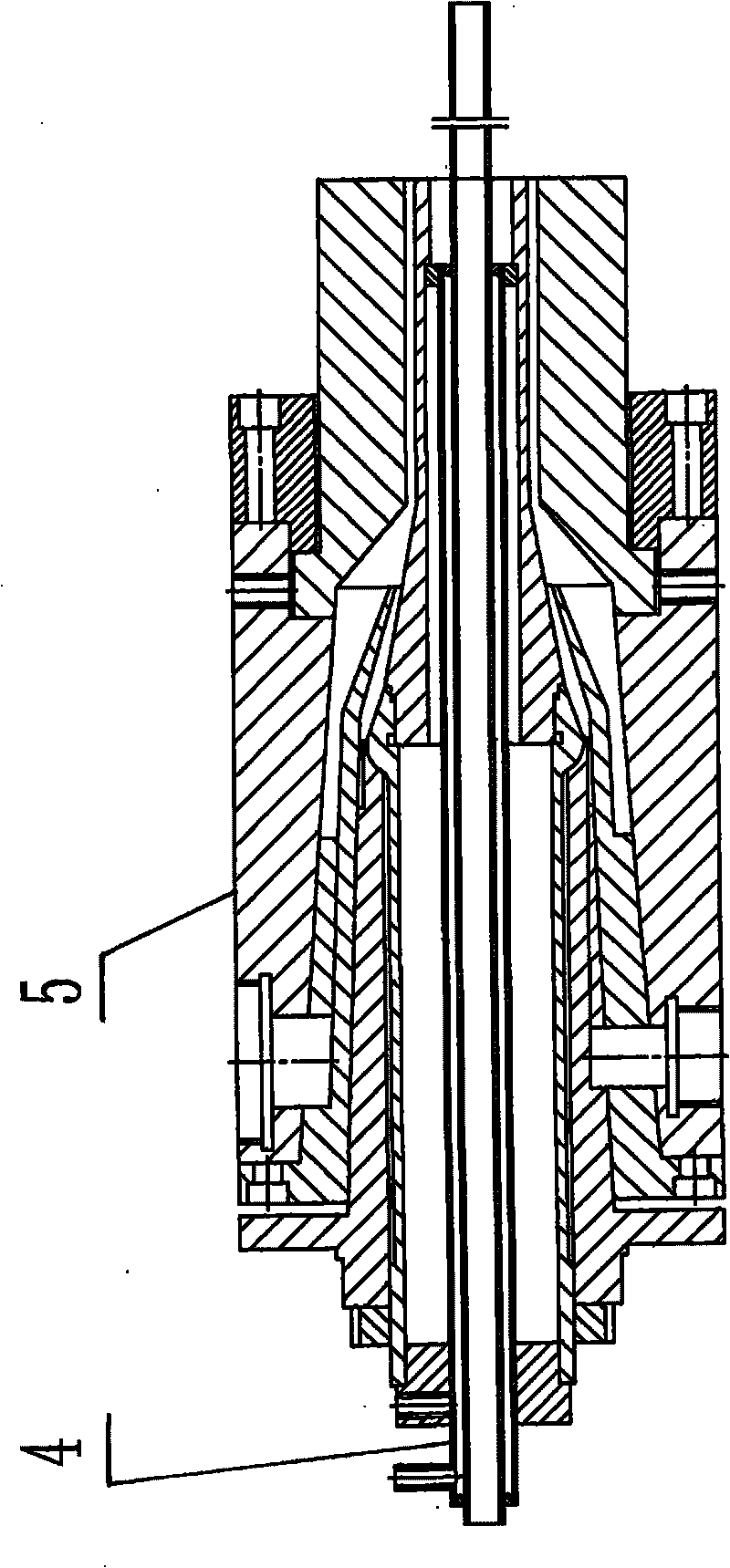

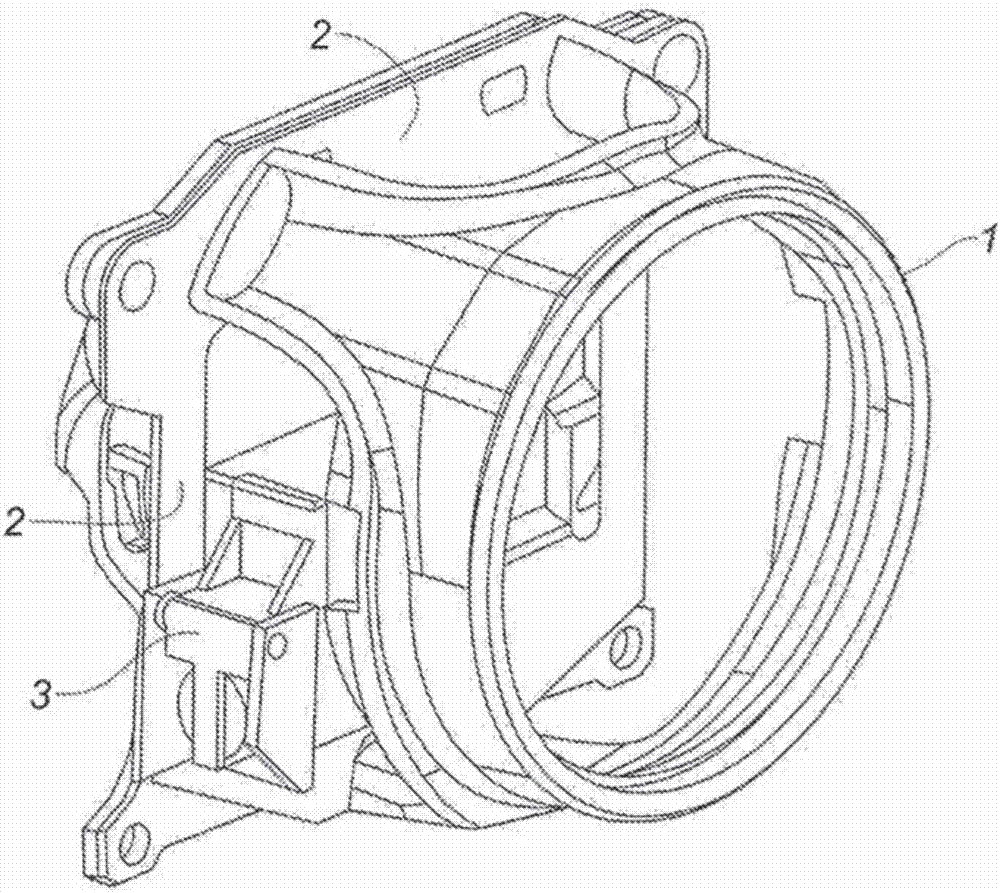

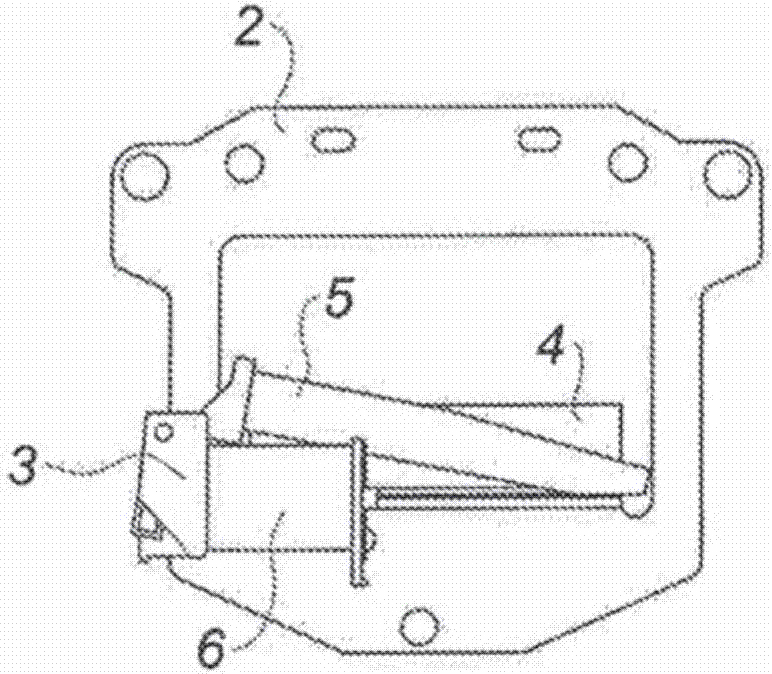

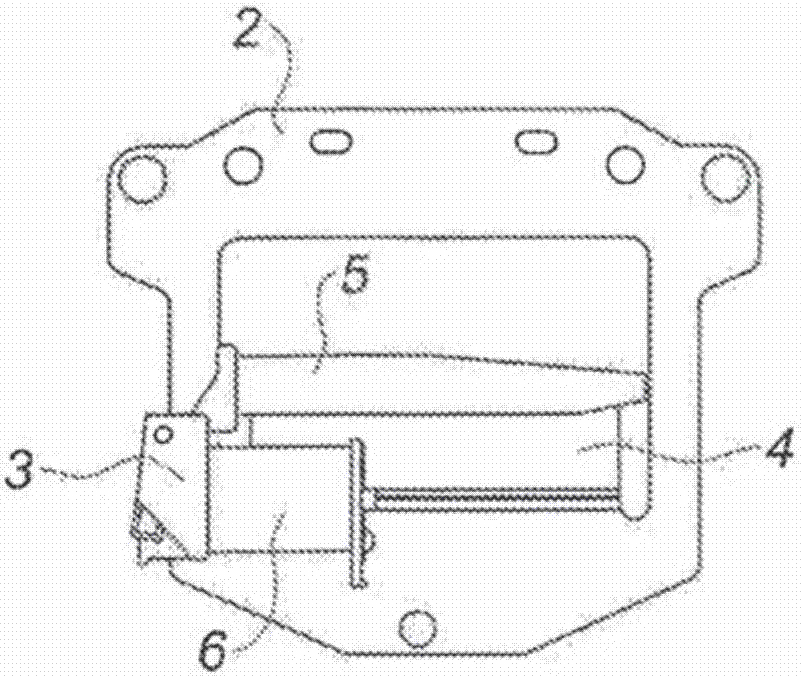

Cut-off mechanism including a strip actuated by an electromagnet comprising two air-gaps

Cut-off mechanism for an automotive vehicle headlamp comprising a strip (5) borne by a movable assembly (40) and shaped to block to a greater or lesser extent a light beam so as to change the optical operating mode of said headlamp, said mechanism furthermore comprising a motor (6) for actuating said movable assembly using an electromagnet including an inductive coil (61) associated with a fixed ferromagnetic core (62) positioned in its centre and with a metal carcass (64) surrounding said coil, said movable assembly being movable under the action of said electromagnet, against the action of a return spring, between a contact position and a distant position, via a first air-gap (h1) of said ferromagnetic core (62). Said movable assembly (40) is shaped to create a rupture in the continuity of the magnetic circuit formed by said ferromagnetic core (62), said metal carcass (64) and said movable assembly (40), when it makes contact with said ferromagnetic core (62).

Owner:AML SYST

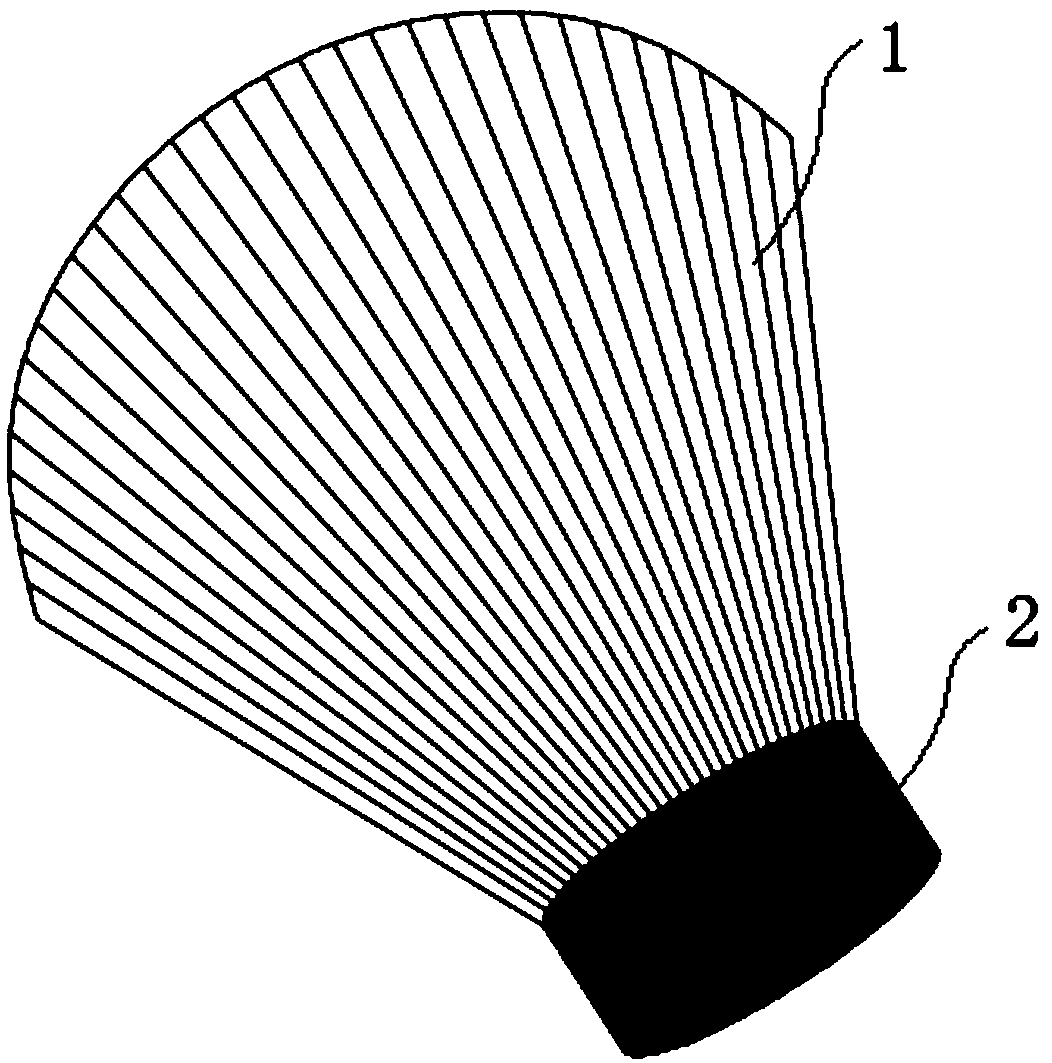

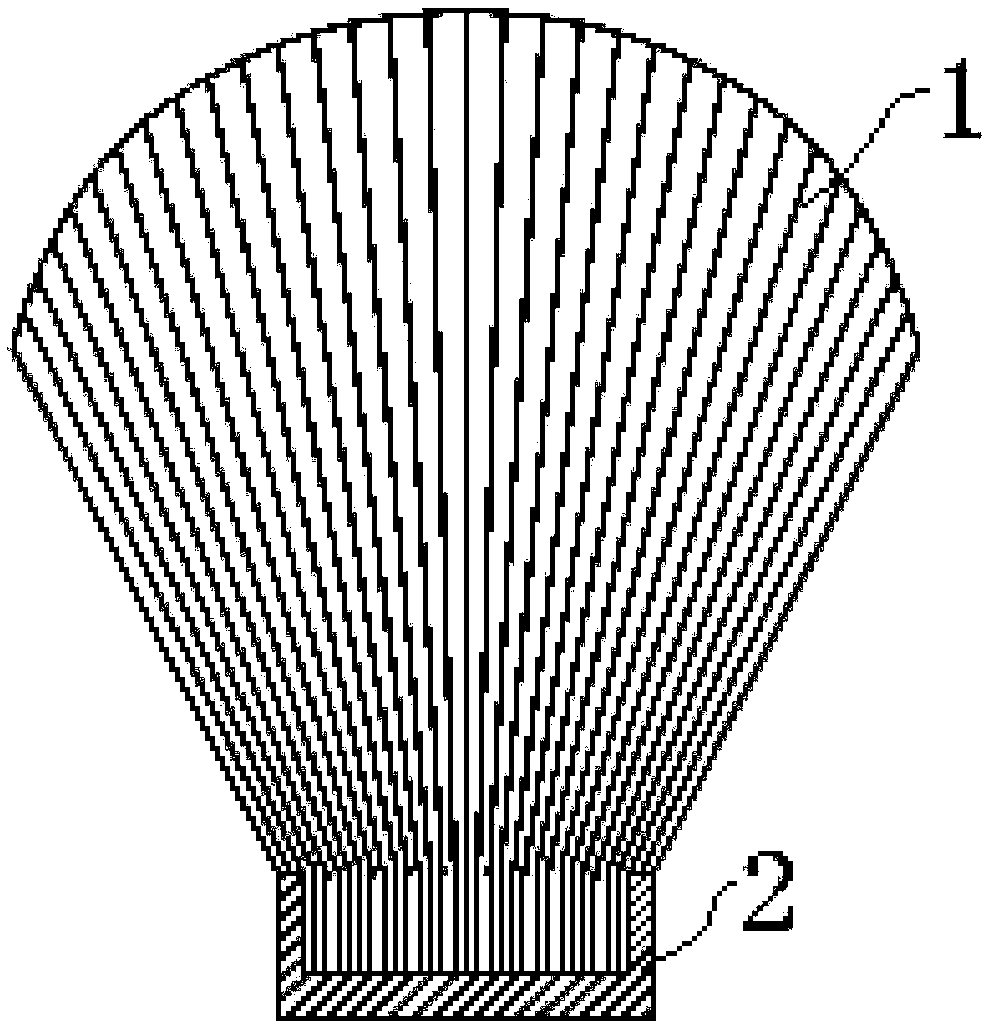

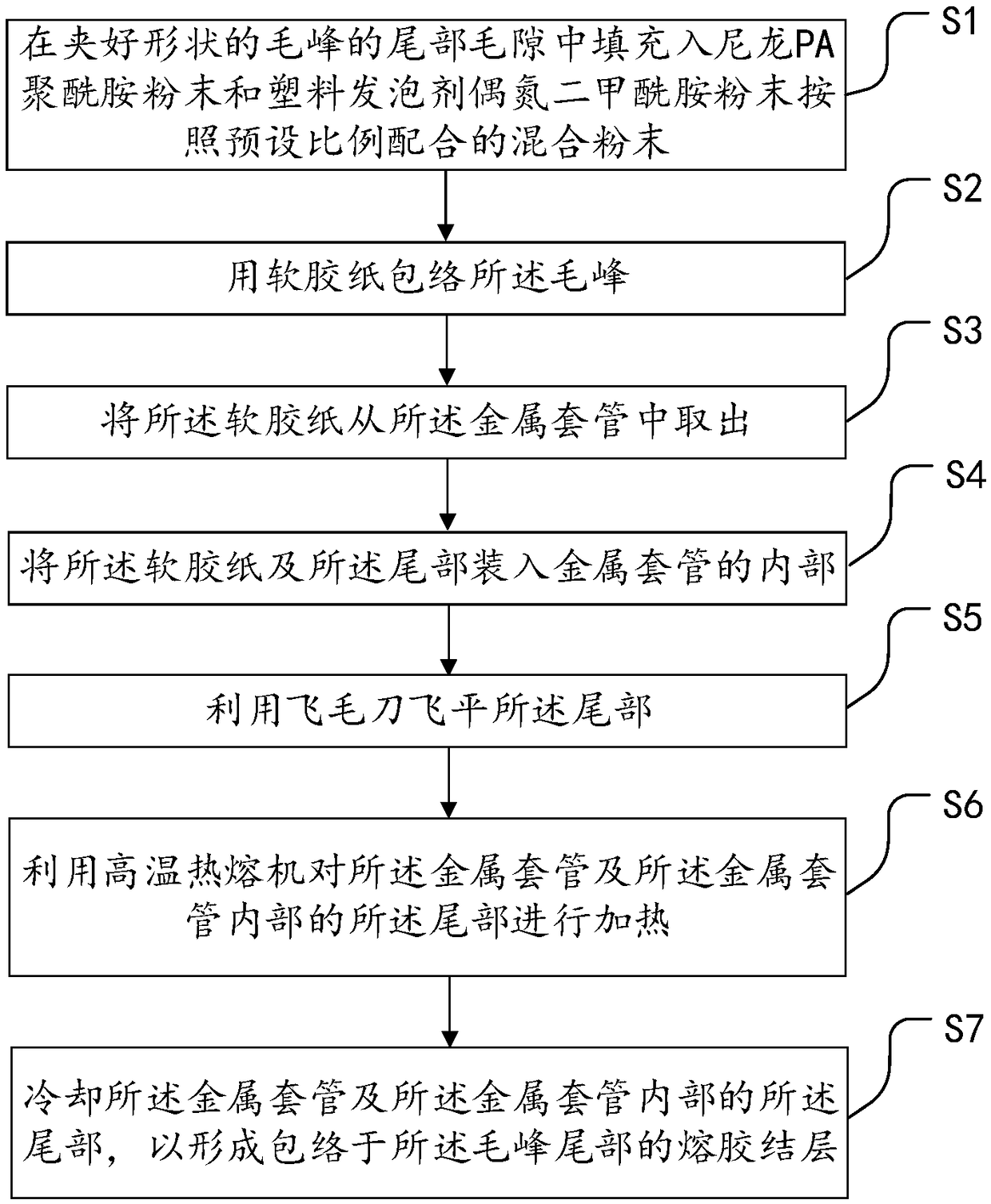

Bristle head of cosmetic brush and method for manufacturing bristle head of cosmetic brush

The invention provides a bristle head of a cosmetic brush. The bristle head comprises a bristle peak part, the bristle peak part is composed of nylon PA polyamide. The bristle head further comprises amelt adhesive bonding layer wrapping the tail of the bristle peak part at 360 degrees, and the melt adhesive bonding layer is formed by carrying out heating on nylon PA polyamide powder and a plasticfoaming agent, namely, azodicarbonamide powder at the temperature of 290-300 DEG C. For the bristle head of the cosmetic brush provided by the invention, a metal sleeve part is saved, so that the structure of the bristle head of the cosmetic brush is simplified, the firm fixing for the bristle peak part is also realized, therefore, the phenomenon of bristle separating and falling of the bristle peak part is obviously improved, and further, the service life of the bristle head of the cosmetic brush is prolonged. The invention further provides a method for manufacturing the bristle head of thecosmetic brush. The processing technology is simple and is easy to implement, the production efficiency is high, the production cost is low, and the manufactured bristle head of the cosmetic brush ismild and free of stimulation, and has the good environmental protection property.

Owner:雅香丽化妆用品(深圳)有限公司

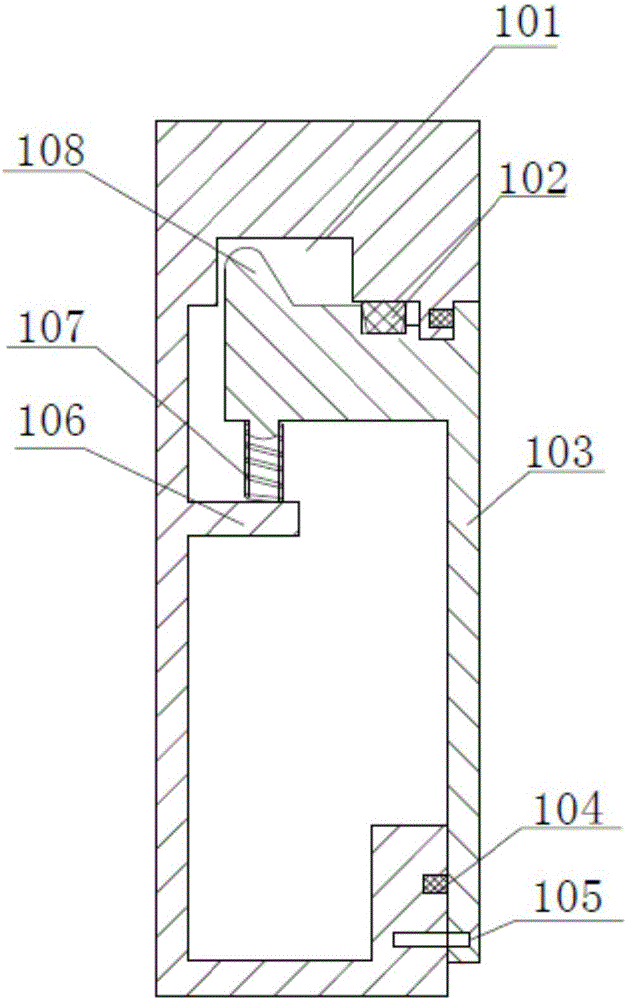

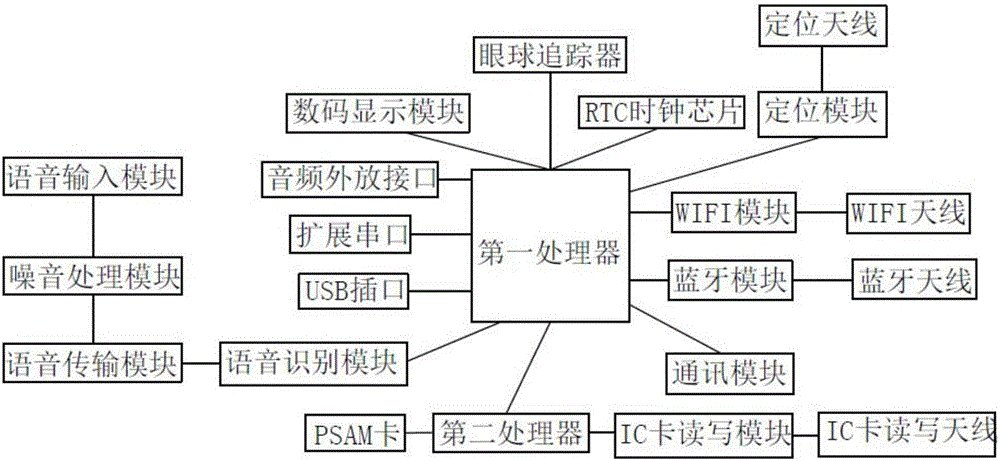

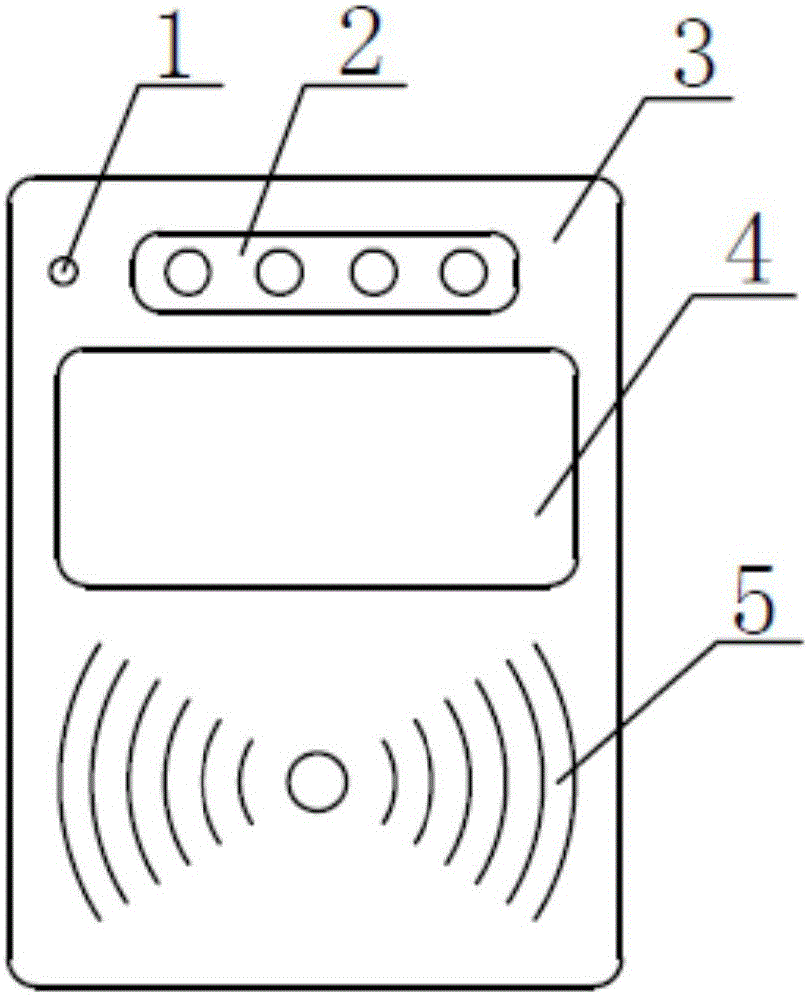

Waterproof PSAM (purchase secure access module) card slot and waterproof bus card machine

InactiveCN106780997AWith voice recognitionWith waterproof functionCoded identity card or credit card actuationAdhesion processComputer module

The invention provides a waterproof PSAM card slot and a waterproof bus card machine. The waterproof bus card machine comprises a card machine housing, and the front panel of the card machine housing is provided with a liquid crystal screen; a card wiping area is arranged under the liquid crystal screen, a power indicator lamp and function buttons are arranged above the liquid crystal screen; the rear panel of the waterproof bus card machine is provided with a digital display module, a reset button, a switch button, a loudspeaker and the PSAM card slot; the side surface of the waterproof bus card machine is provided with an expansion serial interface, a power socket, a USB (universal serial bus) socket and an audio playing socket; a PSAM card is mounted inside the PSAM slot. The waterproof PSAM card slot and the waterproof bus card machine achieve a waterproof function, and through sealing by a sealing ring and a sealing stripe, save adhesion processes and are high in sealing performance, convenient to mount and less prone to falling off; by speaking out a designated voice instruction, a user enables the waterproof bus card machine to enter a corresponding state.

Owner:联合华通(天津)科技有限公司

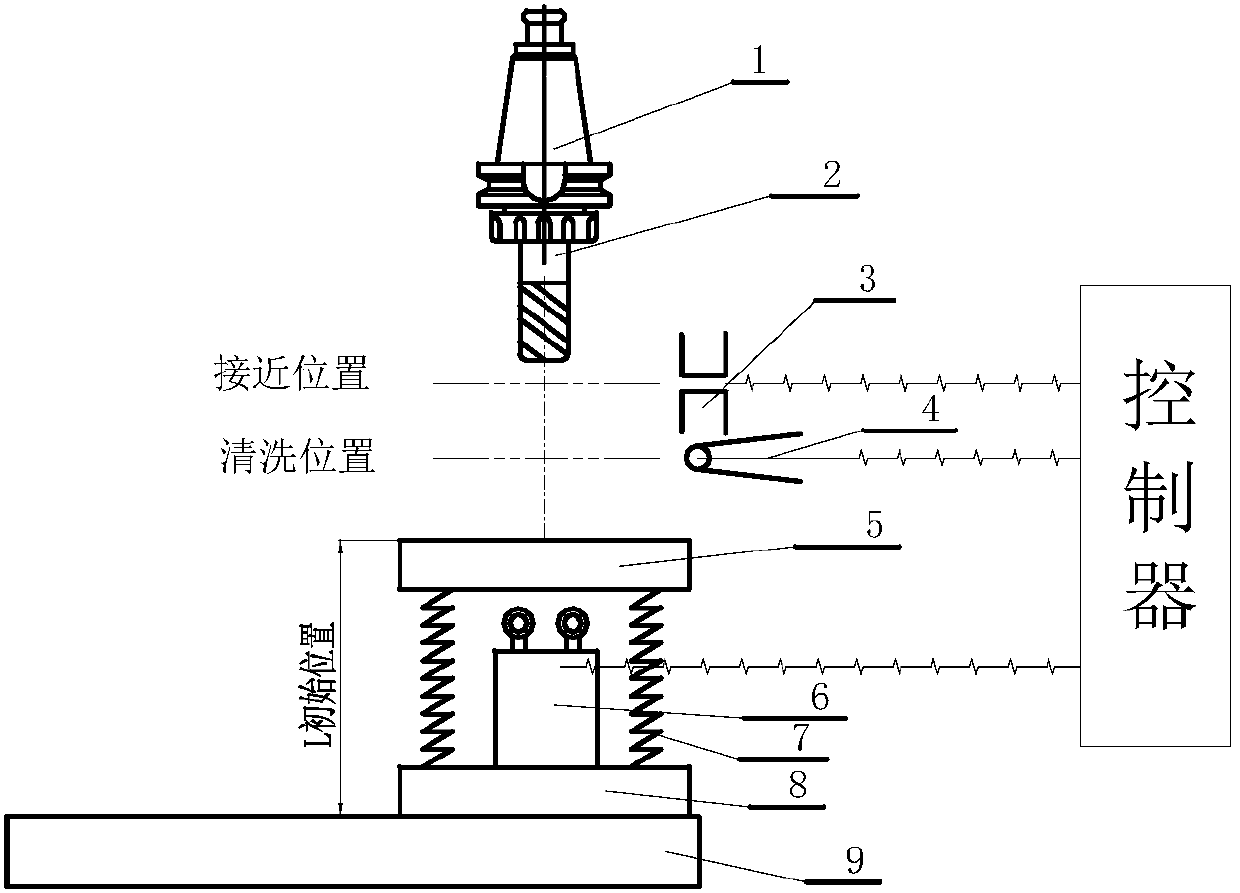

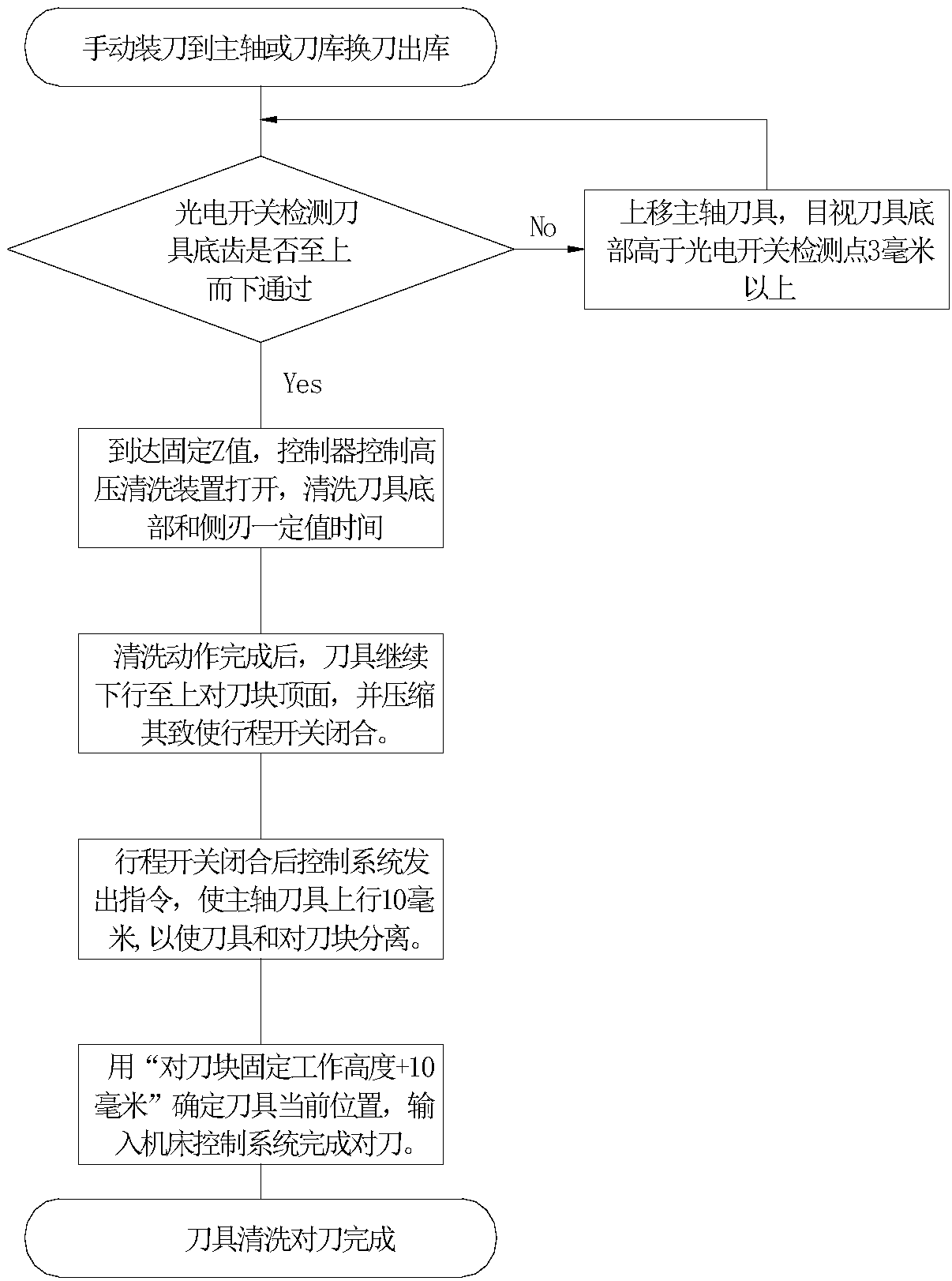

Method for automatically cleaning tools and measuring lengths of tools on line

The invention discloses a method for automatically cleaning tools and measuring lengths of the tools on line, and belongs to the technical field of machine tool clamps. A device is additionally arranged on a numerical-control machine tool, so that in a using process, the numerical-control machine tool can be matched with existing tools of a tool magazine to be equipped with all tools to start processing a part after programming is completed once workpieces are clamped; and a tool setting long instruction is added during primary processing. All the tools are cleaned under high pressure to ensure the effect that scrap iron bonding is avoided, so that built-up edge production probability is also reduced. Tool data measurement is accurate, and interferences of artificial factors are avoided. The method is suitable for high-quality efficient production.

Owner:SHAANXI AVIATION ELECTRICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com