Process and device for purifying flue gas containing lead and cadmium by sintered plate circular adsorption method

A technology of sintered plate and adsorption method, which is applied in the direction of separation methods, chemical instruments and methods, and separation of dispersed particles, to achieve the effects of increasing adsorption and coagulation, reliable and efficient technology, and realizing recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

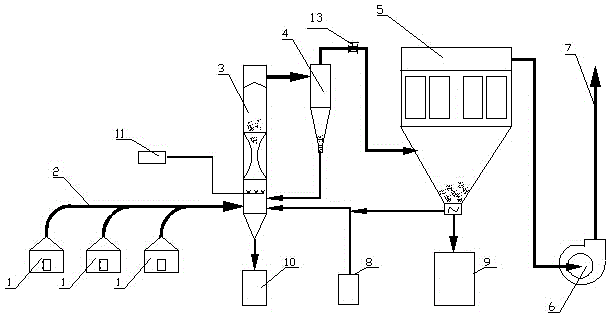

[0030] see figure 1 , the equipment outer loop

[0031] 1) Select 150-mesh lead-zinc ore powder 5% fly ash 75%, diatomaceous earth 5%, talcum powder 15% mixture according to the percentage and put it into the powder material system 8 for storage;

[0032] 2) Turn on the fan in the powder system 8 to fluidize the solid powder adsorption powder through the conveying system and send it into the fluidized adsorber 3 according to the metering: 80Kg / h for pre-circulation. This cycle lasts for 5-10 minutes Afterwards, the induced draft fan 6 is turned on so that the flue gas enters the flue gas pipe 2 through the fume collecting hood 1, and enters the fluidized adsorber 3 from the outlet of the flue gas pipe 2, and the flue gas is adsorbed and condensed with the mixed adsorption powder in the fluidized adsorber 3 , collision reaction; the powder after the reaction is discharged into the emptying bin 10 through the air lock and ash discharge device at the feed port of the fluidized a...

Embodiment 2

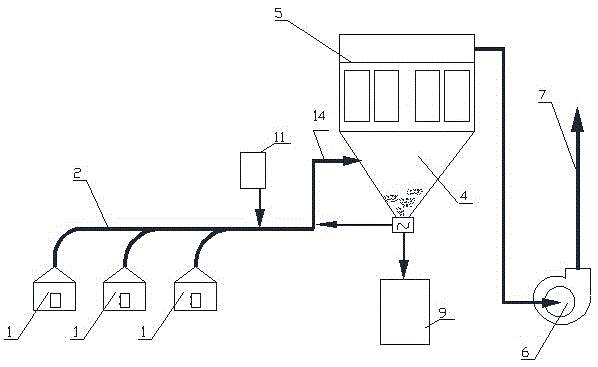

[0035] see figure 2 , pipe outer circulation

[0036] 1) Select 300-mesh lead-zinc ore powder 5% fly ash 75%, diatomaceous earth 5% and talcum powder 15% according to the percentage and put it into the powder material system 8 for storage.

[0037] 2) Start the induced draft fan 6 of the system, so that the flue gas passes through the fume collecting hood 1, the flue 2, the reaction pipe 14, and the sintered plate dust collector 5, and is discharged by the fan 6 through the chimney 7.

[0038]3) The adsorption powder is metered into the reaction tube 14 through the delivery system according to the ratio of 7:1 to the pollutants, and the powder completes the mixing and adsorption process with various pollutants in the flue gas in the reaction tube 14, Then the flue gas enters the sintered plate dust collector 5 .

[0039] 4) The flue gas is deeply and efficiently purified in the sintered plate dust collector 5, and part of the collected dust can be returned to the reaction t...

Embodiment 3

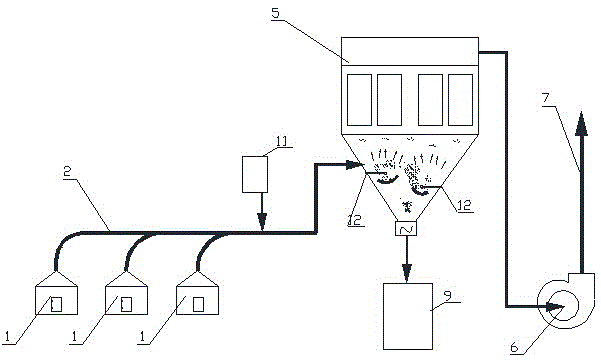

[0043] see image 3 Circulation within the equipment

[0044] 1) Select 260-mesh lead-zinc ore powder 1% fly ash 85%, diatomaceous earth 10%, talcum powder 4% mixture according to the percentage and put it into the powder material system 8 for storage.

[0045] 2) Start the induced draft fan 6 of the system, so that the flue gas passes through the smoke collecting hood 1, the flue 2, and the sintered plate dust collector 5 respectively, and is discharged by the fan 6 through the chimney 7.

[0046] 3) According to the ratio of 10:1 to the pollutants, the adsorption powder is metered into the pipeline 2 through the conveying system. The powder completes the mixing and adsorption process with various pollutants in the flue gas in the pipeline 2, and then the flue gas The gas enters the sintered plate dust collector 5.

[0047] 4) The flue gas is deeply and efficiently purified in the sintered plate dust collector 5, and a small part of the collected dust falls on the return de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com