Cut-off mechanism including a strip actuated by an electromagnet comprising two air-gaps

An electromagnet and air gap technology, which is applied in the field of motor vehicle headlights and lighting headlights, can solve the problems of large electromagnets, expensive, undesired price and size, and achieve the effect of size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In the following description, references to the optical axis of the mirror include longitudinal or lateral references, and the terms front or rear refer to the direction of beam propagation.

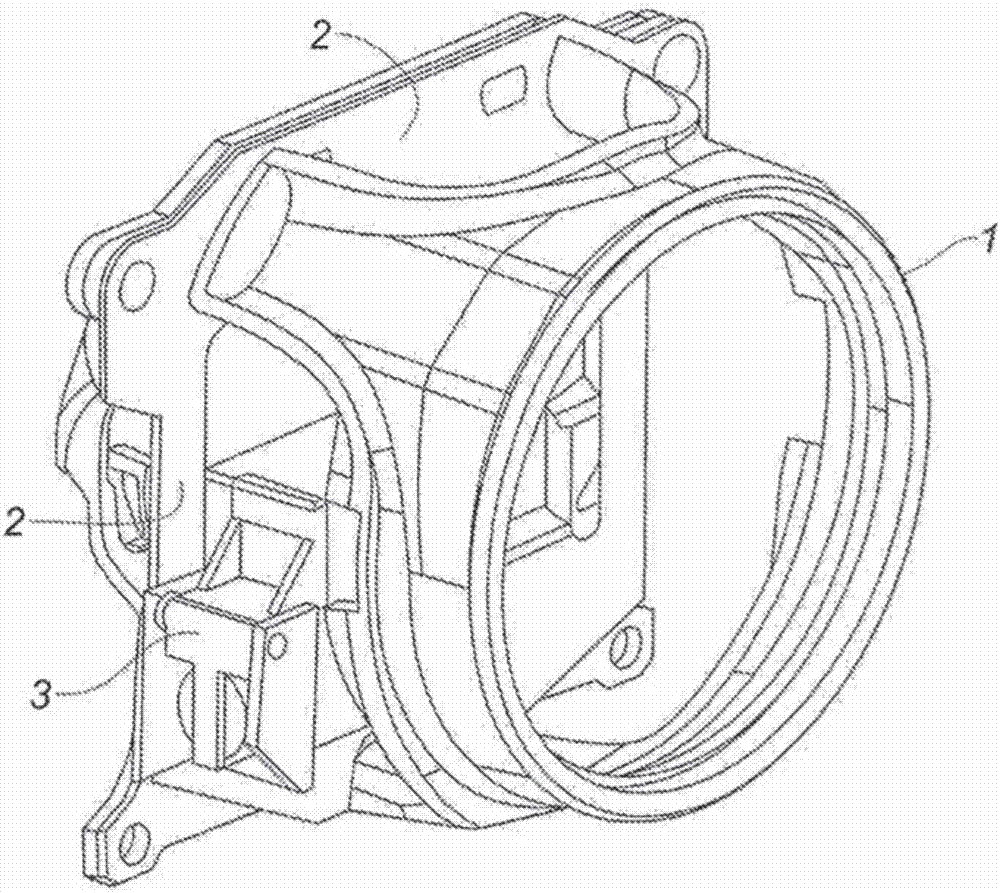

[0028] refer to figure 1 , the front part of a motor vehicle headlamp can be seen, which comprises a cylindrical lens holder 1 extending from a rectangular frame 2 towards the front. A rectangular frame extends into a plane perpendicular to the optical axis of the beam and is cut in its center to pass said beam. A cut-off mechanism is fixed on the frame, and the function of the cut-off mechanism is to block the light beam more or less according to the driving conditions of the vehicle. Invisibly, the light source generating the light beam and the mirrors directing the light beam towards the front and towards the lens (not shown) are positioned behind the frame mounted on the front edge of the lens holder 1 .

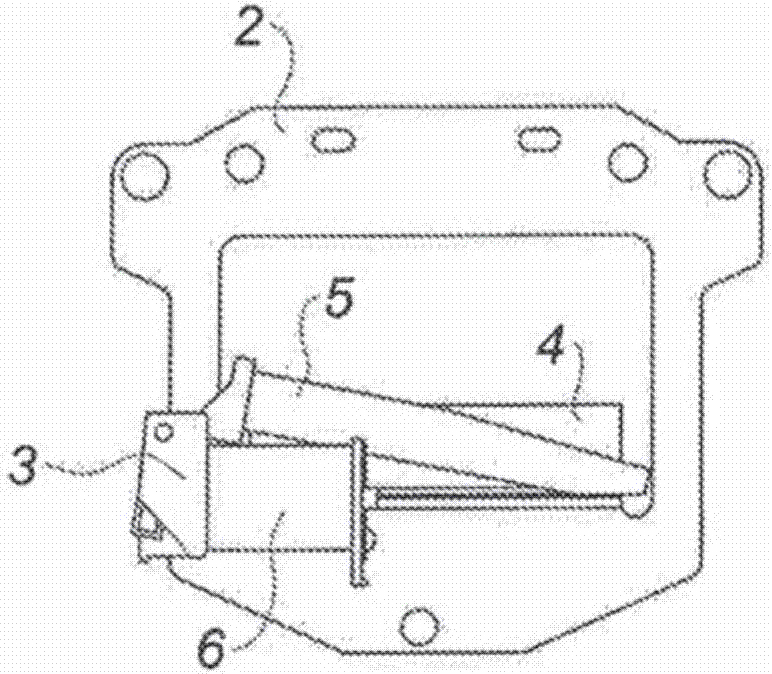

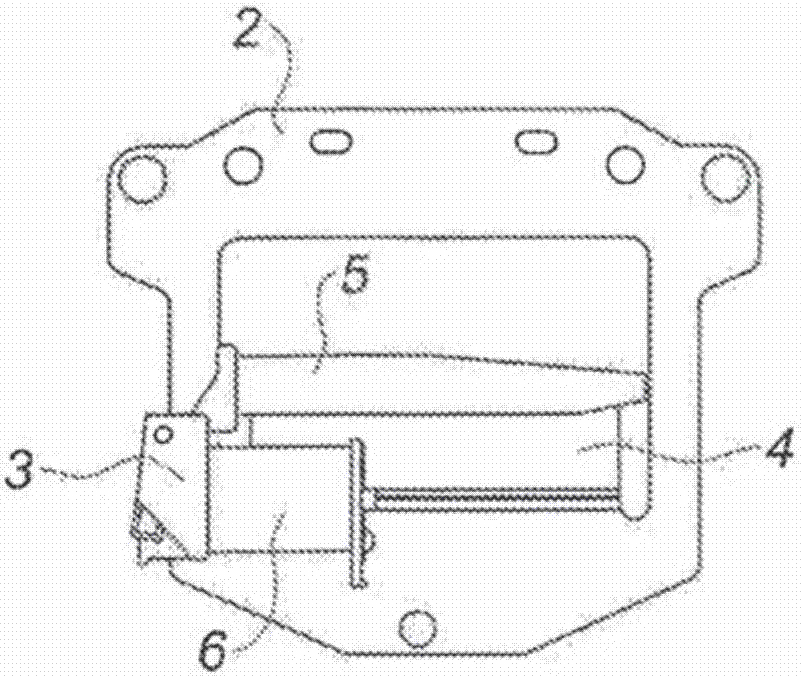

[0029] refer to figure 2 and image 3 , the front view of the shut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com