High-temperature liquid steel slag atomization laval spray pipe, atomization air box and atomization method

A Laval nozzle and liquid steel slag technology, applied in the field of metallurgical industry, can solve the problems of insufficient injection distance and insufficient air cooling time, and achieve excellent injection effect, good atomization effect and good molding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

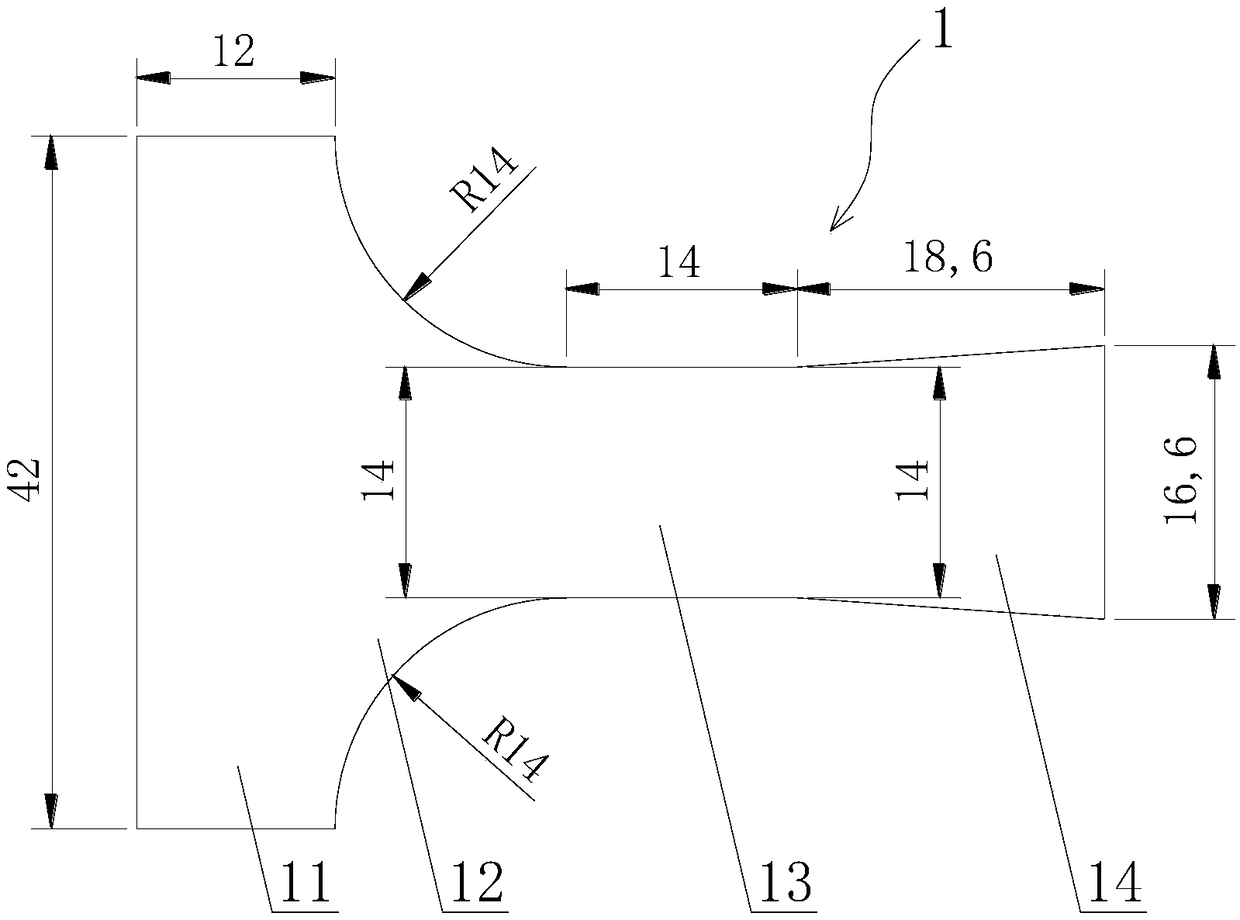

[0022] Such as figure 1 As shown, the high-temperature liquid steel slag atomizing Laval nozzle of the present invention, the lumen of the Laval nozzle 1 is axisymmetric about the center line, and the lumen of the Laval nozzle 1 is an inlet section 11 and a narrowing section 12 in sequence along the injection direction. , parallel section 13 and outlet section 14, according to figure 1 In the direction shown, from left to right is the spraying direction. Wherein, the diameter of the inner tube wall of the inlet section 11 is 42 mm, and the length of the inlet section 11 is set according to actual needs, for example, the tube length of the inlet section 11 is 12 mm. The length of the inner pipe wall of the narrowing section 12 is 14 mm, and the inner pipe wall of the narrowing section 12 is a quarter arc with a radius of 14 mm. The connection between the inner tube wall o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com