Electric fan

a technology of electric fans and fan blades, applied in the direction of machines/engines, stators, liquid fuel engines, etc., can solve the problems of screw loosening, falling down, and losing its function, and achieve the effect of better blowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

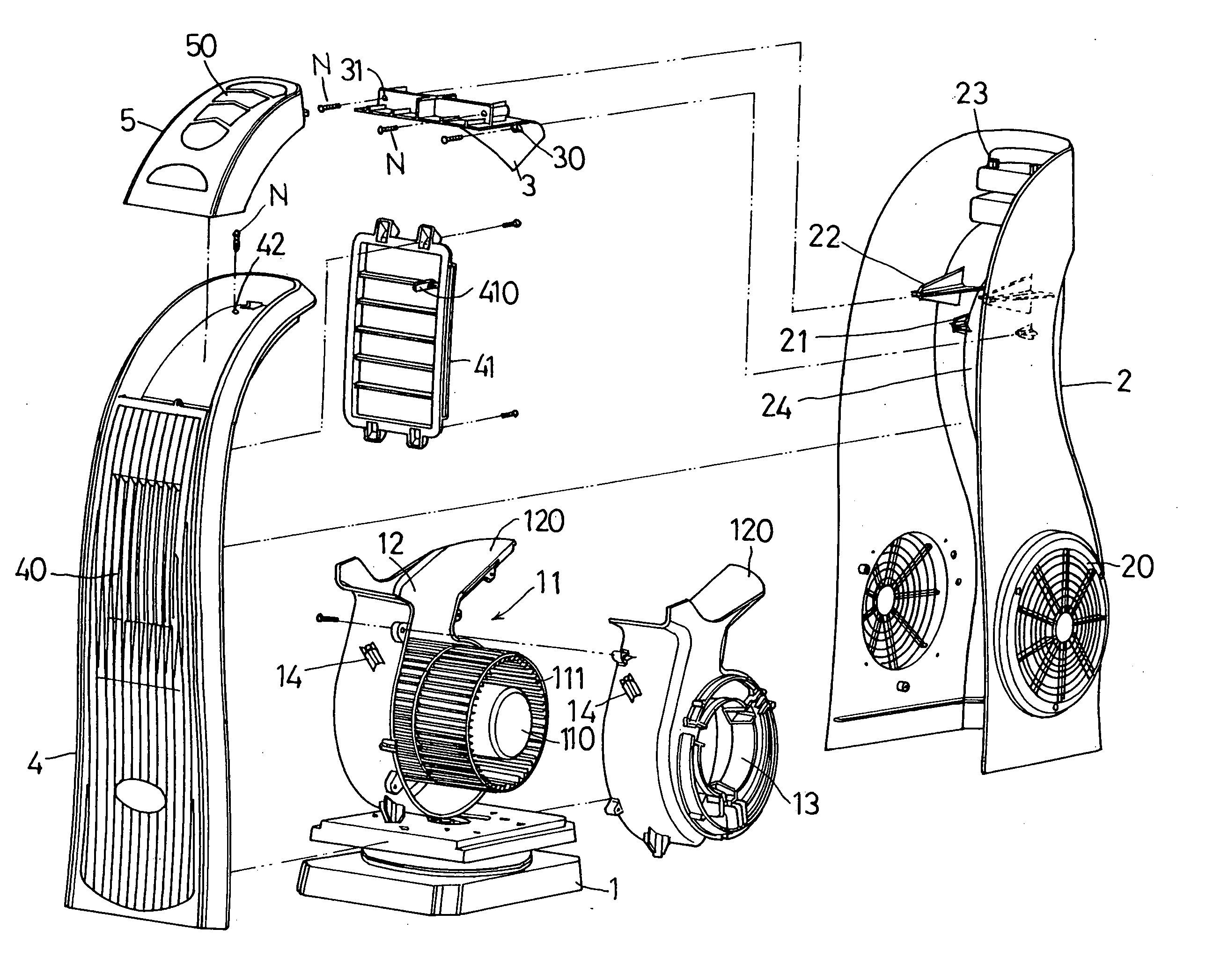

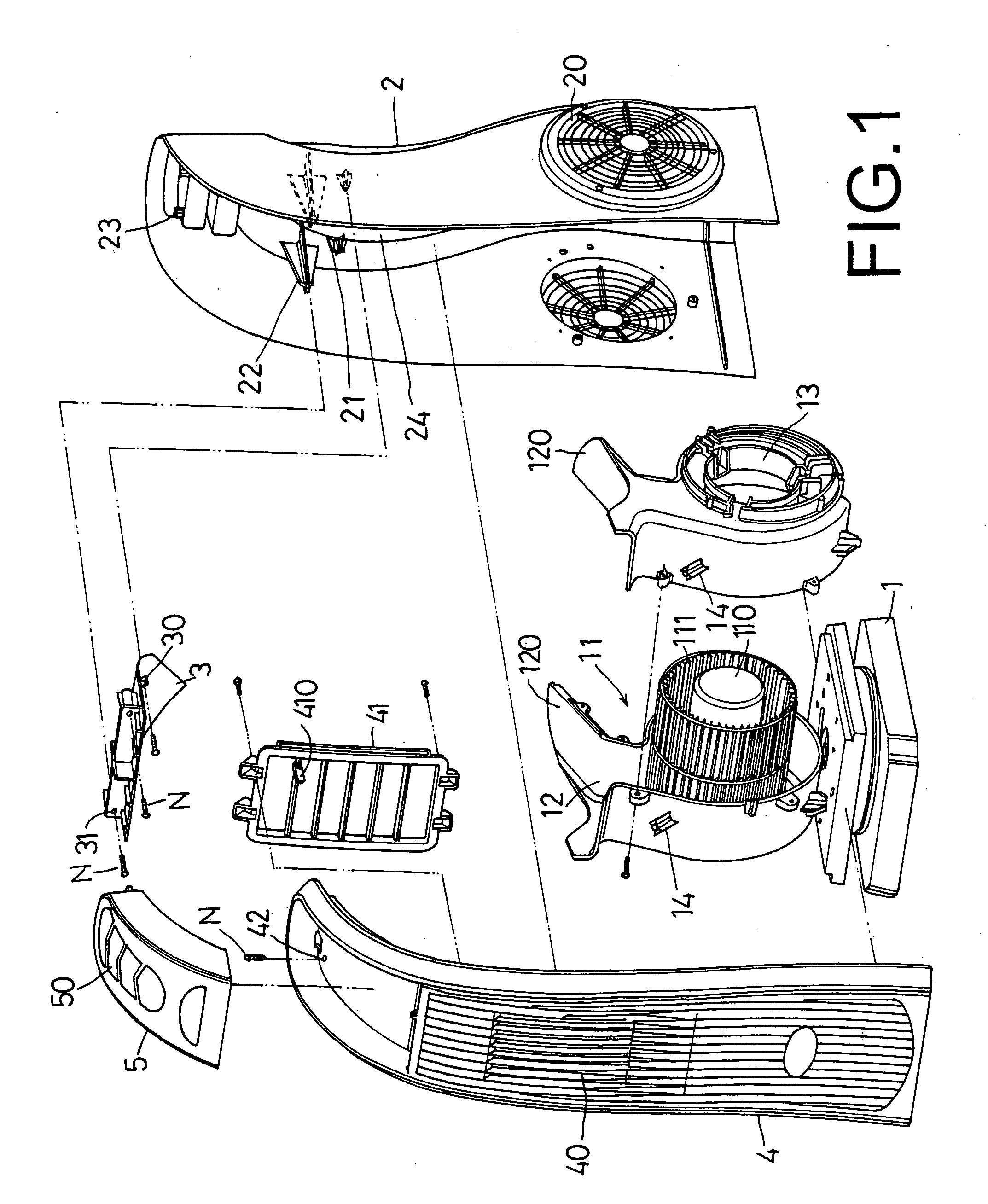

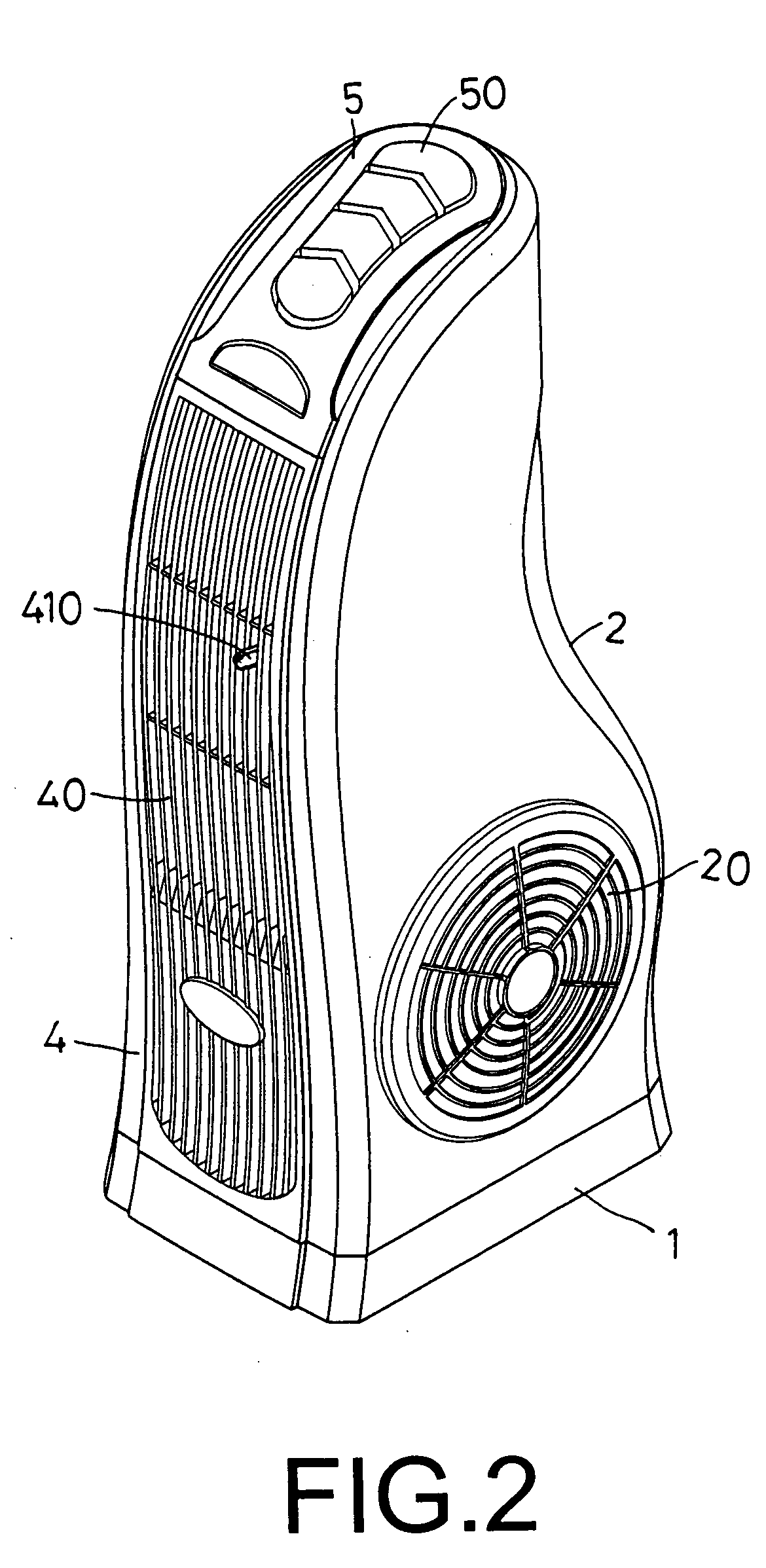

[0013] A preferred embodiment of an electric fan in the present invention, as shown in FIGS. 1, 2, 3 and 4, includes a base 1, a turbine fan 11, a housing 2, a guide plate 3, a front cover 4, an upper cap 5, as main components combined together.

[0014] The turbine fan 11 has a motor 110 installed on the base 11 and possible to change its directions, a set of leaves 11, a wind passageway 12 formed in an upper portion, a sloped guide surface 120 extending sloping upward from the wind passage 12, a wind inlet 13 respectively formed in the two sides, and a combine post 14 formed on a front side surface.

[0015] The housing 2 is combined on the base 1, shaped nearly as U, surrounding the two sides and a rear side of the turbine fan 11, having plural grid inlets 20 formed in the two sides and facing the wind inlet 13 of the turbine fan 11, and plural combine posts 21, 22 and 23 formed on an upper inner surface and a curved surface 24 on the rear side.

[0016] The guide plate 3 is fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com