Low-resistance ultra-clean generation-two cloth bag dust collector

A bag filter and filter component technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of affecting the purification effect of filter bags, cumbersome operation of replacing filter bags, labor and material costs, etc. Reduce the frequency of disassembly, maintenance or replacement, improve the cleaning effect, and reduce the effect of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

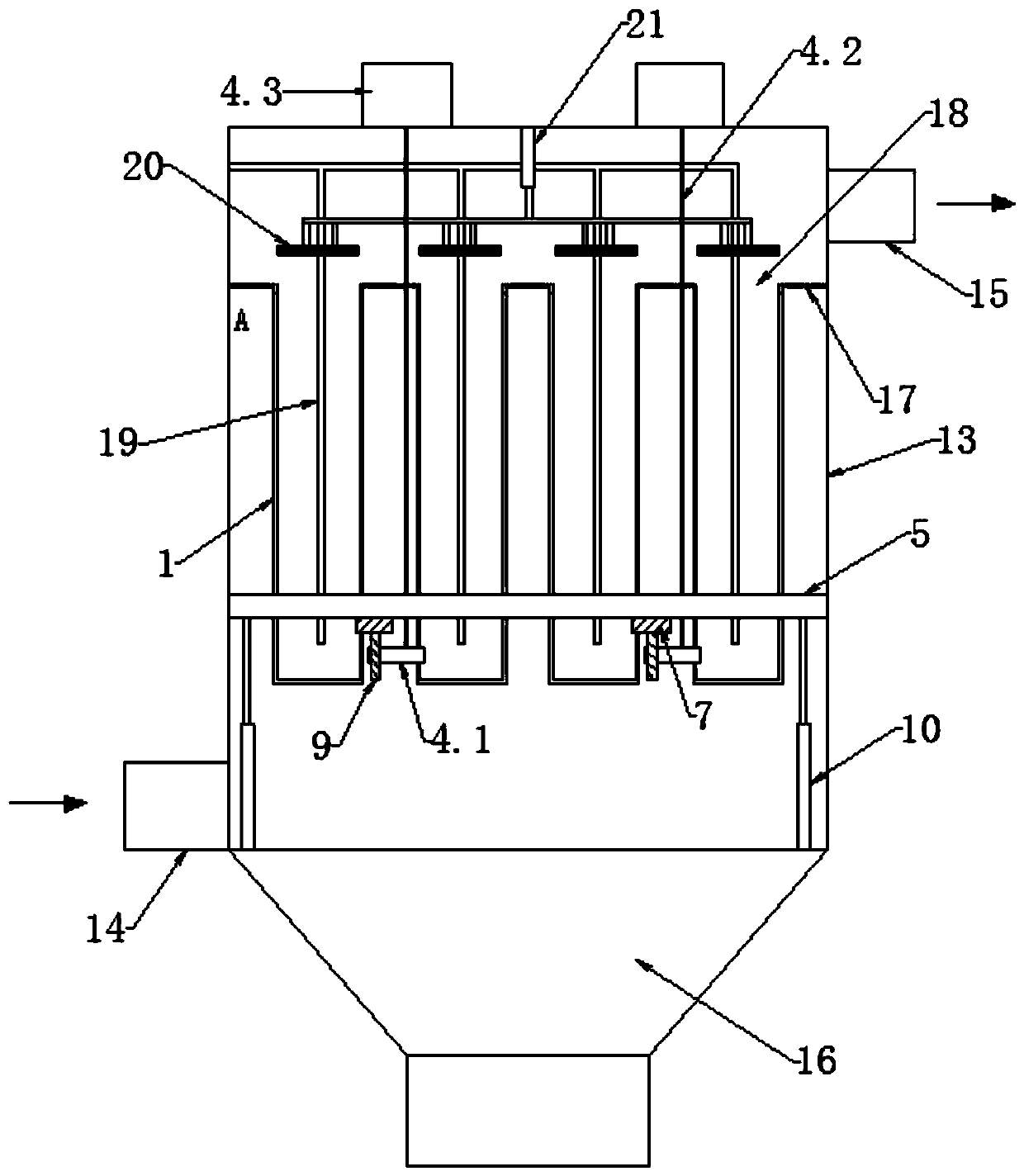

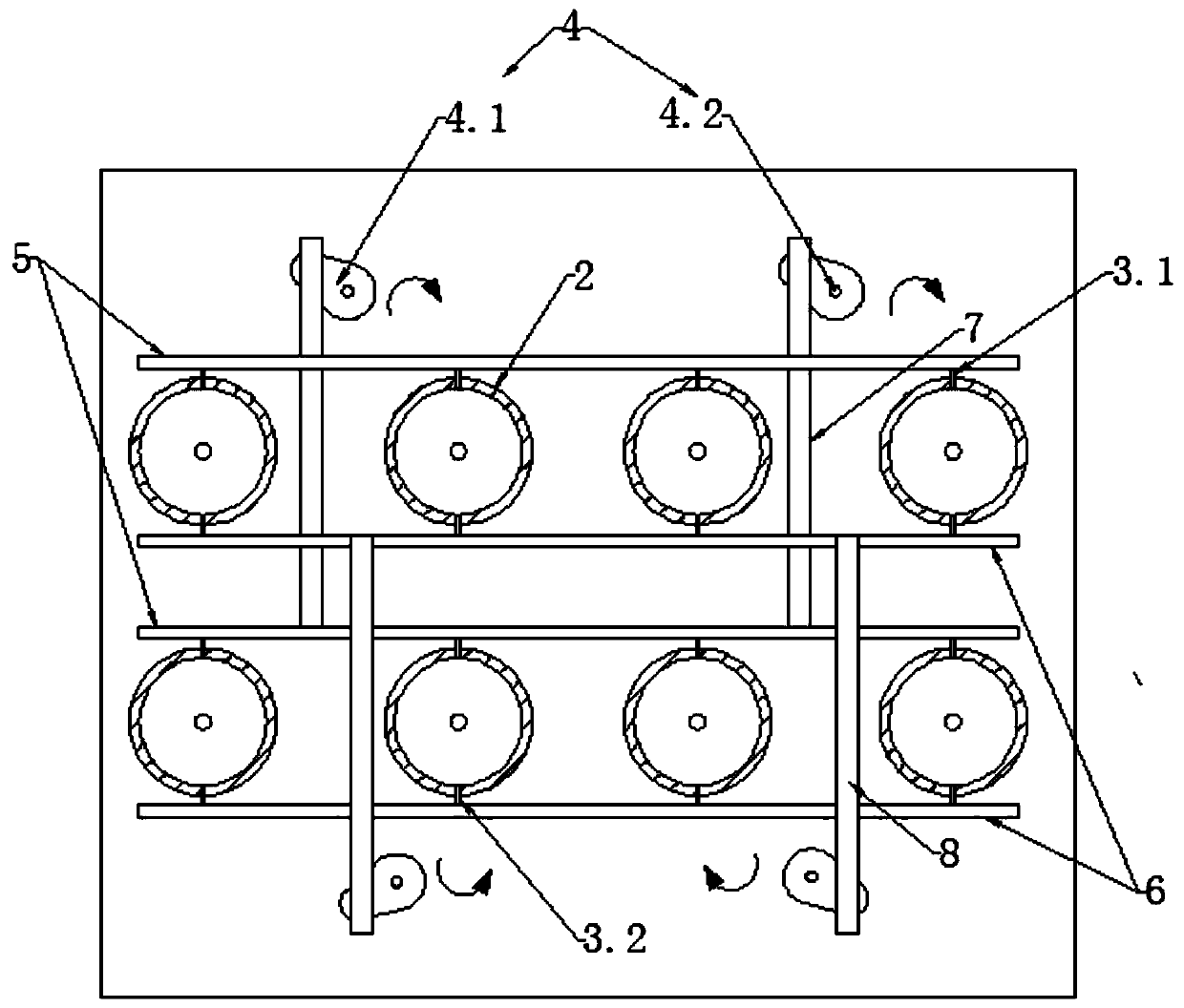

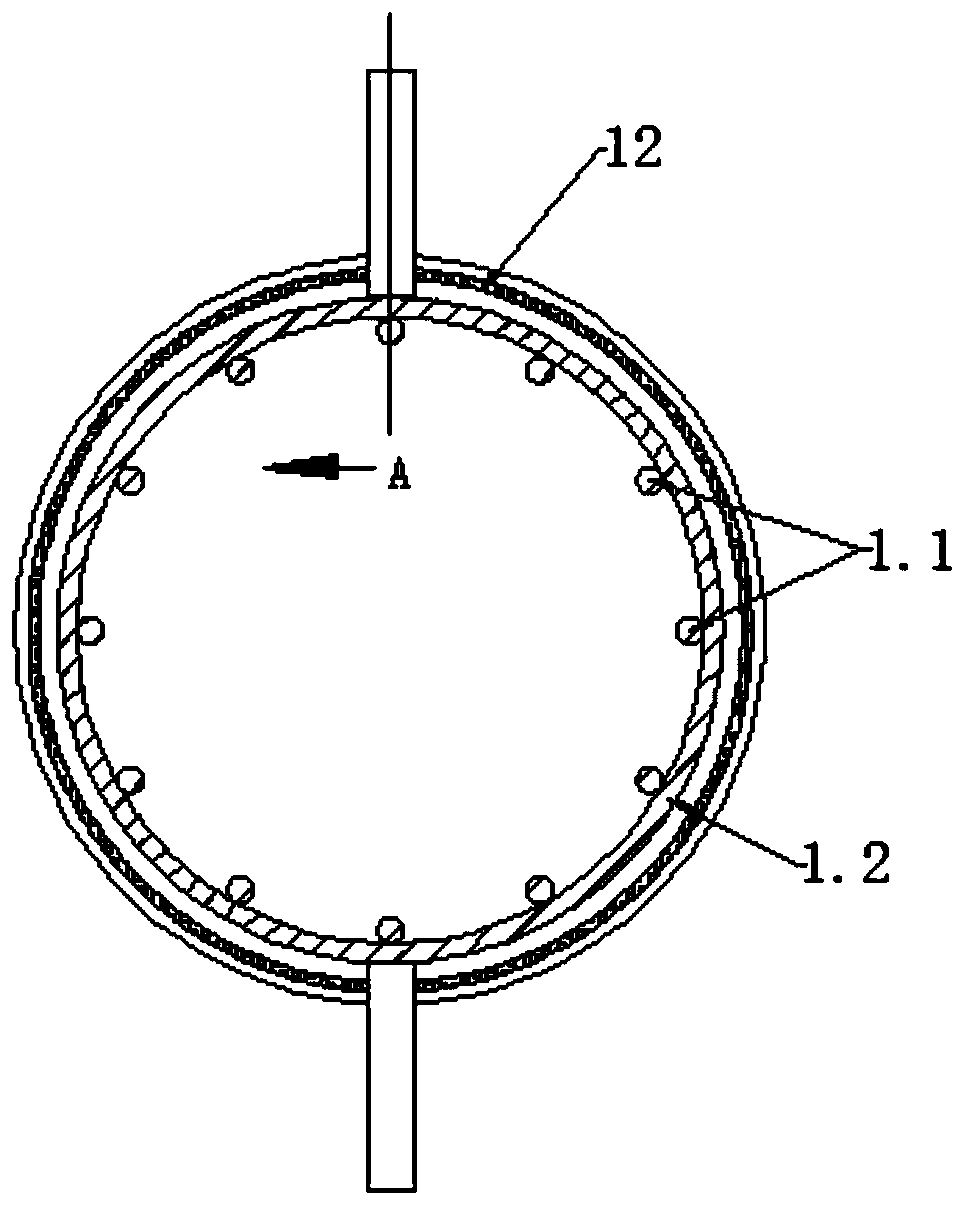

[0022] Such as Figure 1-4 As shown, the present invention is a low-resistance ultra-clean second-generation bag filter, including a filter assembly 1, and a dust removal structure is arranged on the filter assembly, and the dust removal structure includes an annular elastic member sleeved on the outside of the filter assembly 2. The ring-shaped elastic member is provided with a connecting piece 3, which is connected to the cam mechanism 4 connected to the bag filter, and the connecting piece pushes and pulls the elastic piece through the cam 4.1 in the cam mechanism to deform and make it leave the filter components. The cam can be an eccentric wheel or an elliptical wheel.

[0023] Both sides of the annular elastic member are respectively provided with a first connecting part 3.1 and a second connecting part 3.2, and the axes of the first connecting part and the second connecting part are collinear.

[0024] The bag filter includes eight filter assemblies, each of the first...

Embodiment 2

[0032] Such as Figure 5 As shown, the difference between Embodiment 2 and Embodiment 1 is that the annular elastic member 2 is provided with a connecting piece 3, and the connecting piece is connected to the windmill-shaped wheel mechanism connected to the bag filter. A driving rod 22 is arranged on the part, and the driving rod is parallel to the axis line of the annular elastic member, and the driving rod pushes the traction ring elastic member to move through the vanes of the runner 23 in the turning wheel mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com