Double-faced laser cleaning device for magnetic steel

A laser cleaning and laser cleaning technology, which is applied in the direction of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc., can solve the problems of low cleaning efficiency, toxicity and corrosion, time-consuming and labor-intensive, etc., and achieve air blowing Good effect, high cleaning efficiency and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

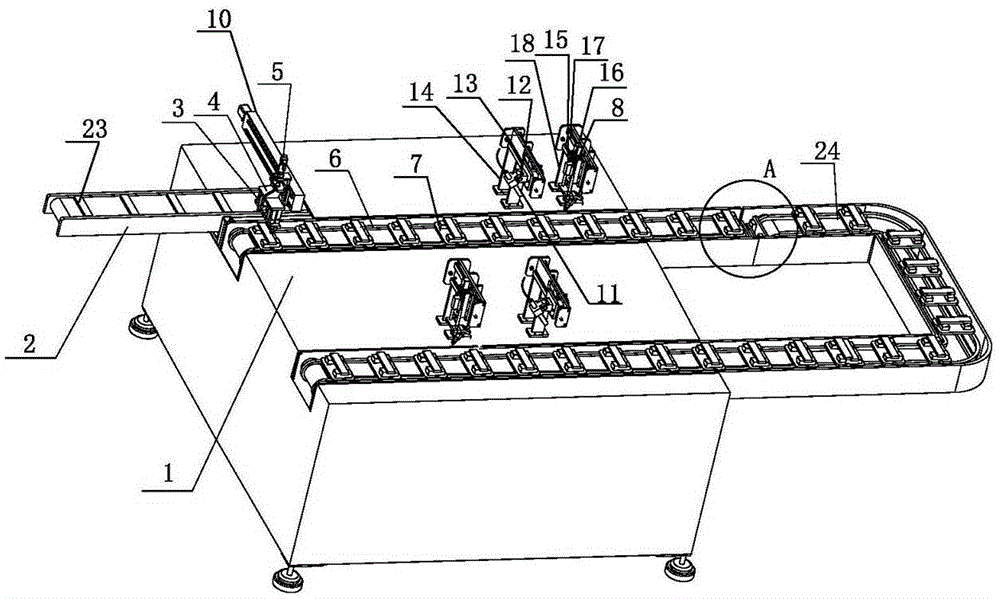

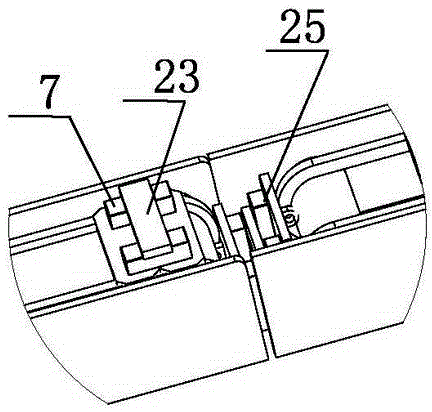

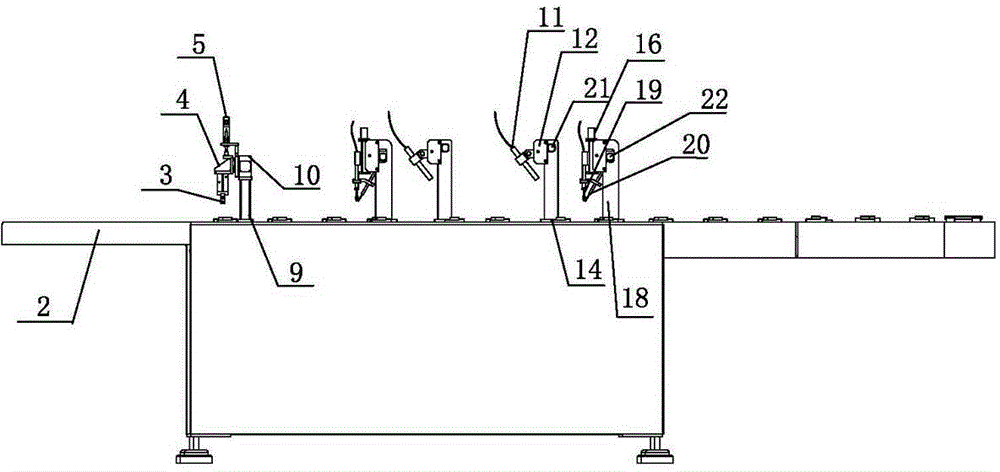

[0012] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] As shown in the accompanying drawings, a double-sided laser cleaning device for magnetic steel includes a control system, a workbench 1, a transmission mechanism controlled by the control system, a feeding manipulator assembly, and a machine that is sequentially arranged on one side of the workbench 1. The first blowing mechanism, the first laser cleaning mechanism, the second blowing mechanism and the second laser cleaning mechanism arranged on the other side of the workbench 1 in sequence, the first blowing mechanism and the second blowing mechanism both include The first support 14 installed on the workbench 1, the blowing nozzle 11 for blowing off the dust on the magnetic steel surface and the blowing nozzle translation mechanism installed on the first support 14 for driving the blowing nozzle 11 to translate left and right; The above-mentione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com