Right-angle type HTHP (High Temperature High Pressure) pulse-jet valve

A high-temperature, high-pressure, pulse injection technology, applied in the direction of valve lift, valve details, valve devices, etc., can solve the problems of sealing technology that cannot be solved, and the structure of the injection valve has not yet appeared.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

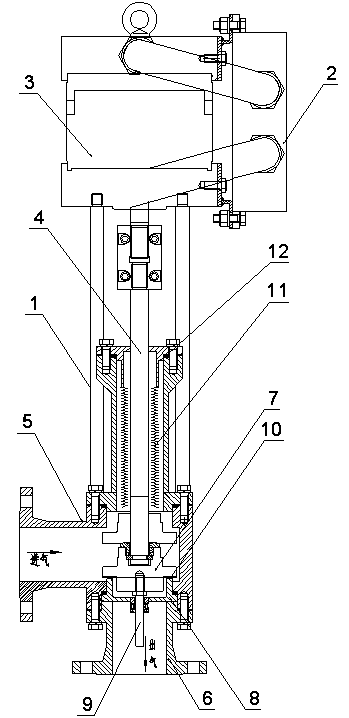

[0015] Such as figure 1 As shown, a right-angle high-temperature and high-pressure pulse injection valve includes a valve body 1, a solenoid valve 2, a two-way cylinder 3, a valve stem 4, a valve sealing assembly, an air inlet end 5 and an air outlet end 6, and the valve stem 4 and The gas outlet end 6 is coaxial, the tail end of the valve rod 4 is connected to the bidirectional cylinder 3, and the front end is connected to the valve sealing assembly, and the valve sealing assembly includes a sealing valve disc 7 and a sealing valve seat 8 used in conjunction with each other. The front end of the sealing valve disc 7 is provided with a guide 9 passing through the sealing valve seat 8 , and the size of the guide 9 protruding from the sealing valve seat 8 is slightly smaller than the design stroke of the sealing valve disc 7 .

[0016] The electromagnetic valve 2 adopts a two-position five-way solenoid valve, two positions refer to two working positions, five-way means five port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com