An anti-load anti-fatigue type TPE thermoplastic elastomer and a preparing method thereof

A thermoplastic elastomer and fatigue-resistant technology, applied in the field of polymer materials, can solve the problems of unresolved weather resistance and load resistance, insufficient bonding performance, etc., and achieve good load resistance and fatigue resistance, high molecular weight, and good plasticizing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

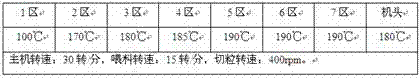

[0018] A load-resistant and fatigue-resistant TPE thermoplastic elastomer of the present invention and its preparation method will be further described below in conjunction with specific examples, wherein Example 1 is the best example.

[0019] The proportioning components of the examples of the load-resistant and fatigue-resistant TPE elastomer are shown in Table 1. Wherein embodiment 3 is the best implementation mode.

[0020]Table 1 Example 1~5 Anti-load and anti-fatigue type TPE elastomer formulation components (by weight)

[0021]

[0022] SEBS in Examples 1-3 is TAIROL3150 from Taiwan Rubber, SEBS in Example 4 is 502 from Yuehua, SEBS in Example 5 is 503 from Yuehua, the styrene content in SEBS is 29%~35%, and the Shore A hardness is 75 ~79, the tensile strength at break is 24 MPa ~27MPa; the octene content of the POE elastomer in Examples 1~3 is 18%~25%, and the Mooney viscosity ML at 120°C 1+4 is 5~8, and the weight part of POE elastomer is 9~10 parts. SP-179 mel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com